check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 646 of 3066

ATC-68

TROUBLE DIAGNOSIS

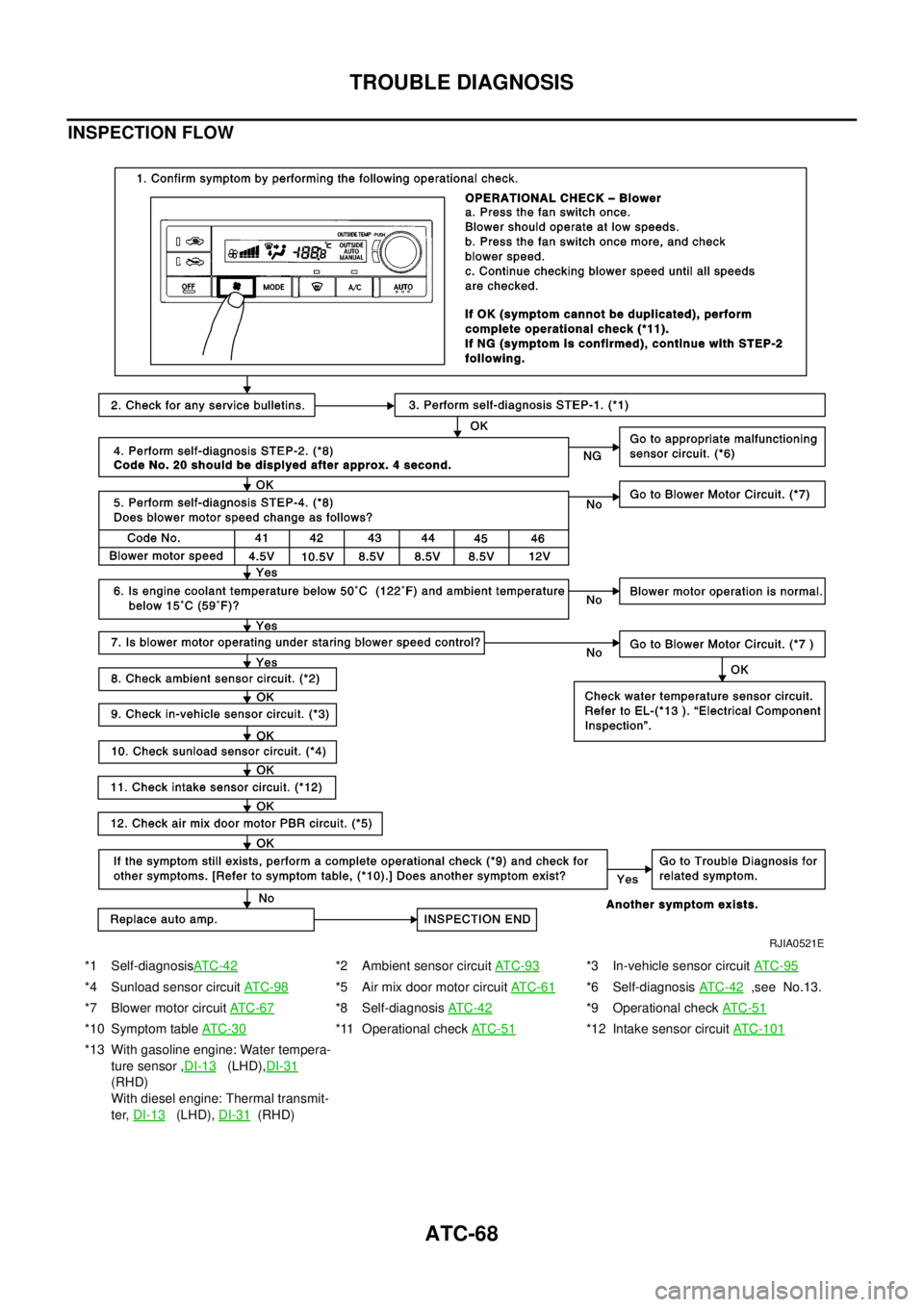

INSPECTION FLOW

*1 Self-diagnosisAT C -4 2*2 Ambient sensor circuitAT C - 9 3*3 In-vehicle sensor circuitAT C - 9 5

*4 Sunload sensor circuitAT C - 9 8*5 Air mix door motor circuitAT C - 6 1*6 Self-diagnosisAT C - 4 2,see No.13.

*7 Blower motor circuitAT C -6 7

*8 Self-diagnosisAT C -4 2*9 Operational checkAT C -5 1

*10 Symptom tableAT C -3 0*11 Operational checkAT C - 5 1*12 Intake sensor circuitATC-101

*13 With gasoline engine: Water tempera-

ture sensor ,DI-13

(LHD),DI-31

(RHD)

With diesel engine: Thermal transmit-

ter,DI-13

(LHD),DI-31(RHD)

RJIA0521E

Page 655 of 3066

TROUBLE DIAGNOSIS

ATC-77

C

D

E

F

G

H

I

K

L

MA

B

AT C

4.CHECK A/C RELAY AFTER DISCONNECTING IT

Refer toAT C - 8 0 , "

A/C Relay".

OK or NG

OK >>ReconnectA/Crelay.AndGOTO5.

NG >> 1. replace A/C relay.

2. Go to self-diagnosis step-by-step procedure:ATC-43, "

PROCEDURE"and perform self-diag-

nosis STEP-4.Confirm that magnet clutch operation is normal.

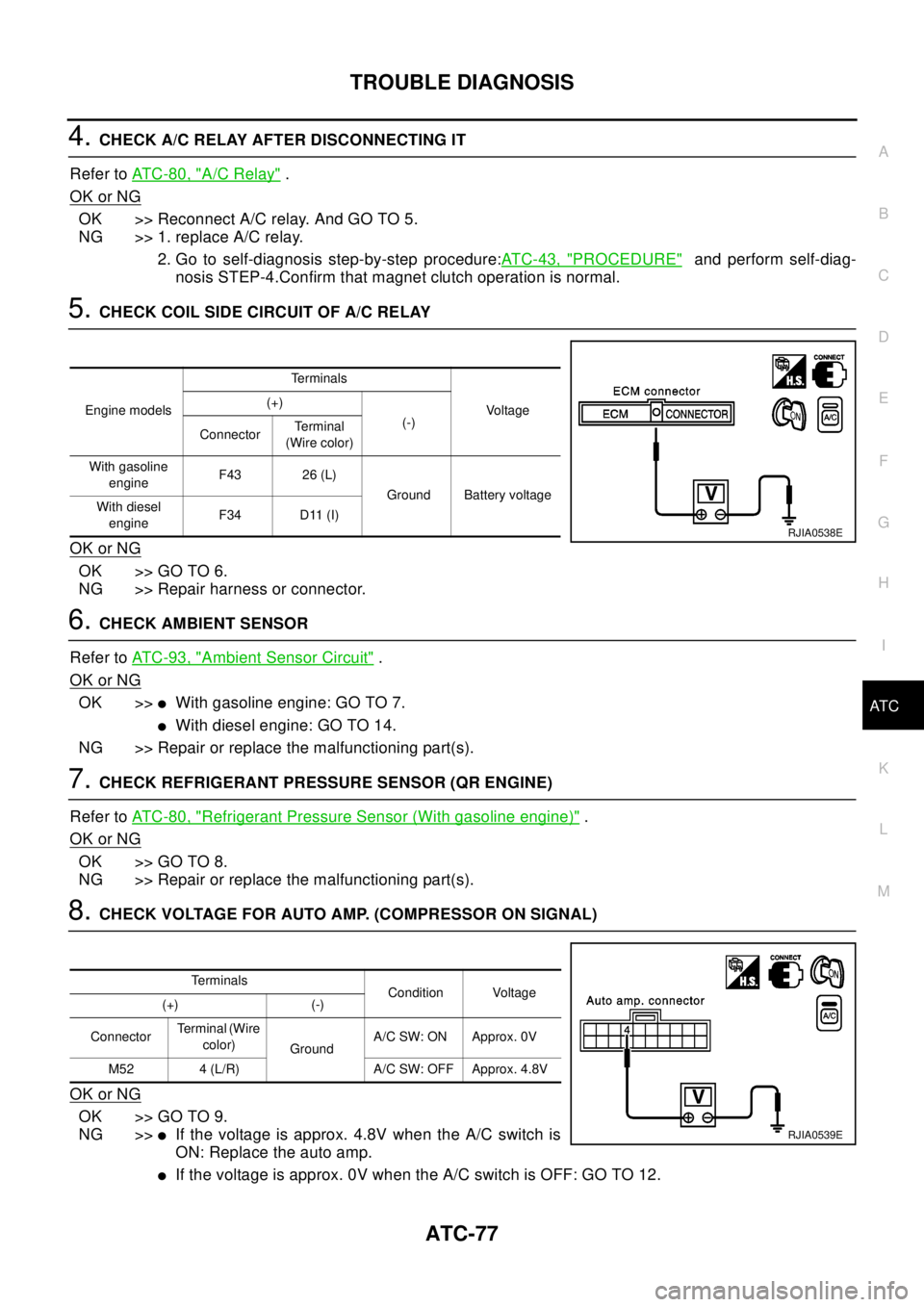

5.CHECK COIL SIDE CIRCUIT OF A/C RELAY

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK AMBIENT SENSOR

Refer toAT C - 9 3 , "

Ambient Sensor Circuit".

OK or NG

OK >>lWith gasoline engine: GO TO 7.

lWith diesel engine: GO TO 14.

NG >> Repair or replace the malfunctioning part(s).

7.CHECK REFRIGERANT PRESSURE SENSOR (QR ENGINE)

Refer toAT C - 8 0 , "

Refrigerant Pressure Sensor (With gasoline engine)".

OK or NG

OK >> GO TO 8.

NG >> Repair or replace the malfunctioning part(s).

8.CHECK VOLTAGE FOR AUTO AMP. (COMPRESSOR ON SIGNAL)

OK or NG

OK >> GO TO 9.

NG >>

lIf the voltage is approx. 4.8V when the A/C switch is

ON: Replace the auto amp.

lIf the voltage is approx. 0V when the A/C switch is OFF: GO TO 12.

Engine modelsTe r m i n a l s

Vo l ta g e (+)

(-)

ConnectorTe r m i n a l

(Wire color)

With gasoline

engineF43 26 (L)

Ground Battery voltage

With diesel

engineF34 D11 (I)

RJIA0538E

Te r m i n a l s

Condition Voltage

(+) (-)

ConnectorTerminal (Wire

color)

GroundA/C SW: ON Approx. 0V

M52 4 (L/R) A/C SW: OFF Approx. 4.8V

RJIA0539E

Page 657 of 3066

TROUBLE DIAGNOSIS

ATC-79

C

D

E

F

G

H

I

K

L

MA

B

AT C

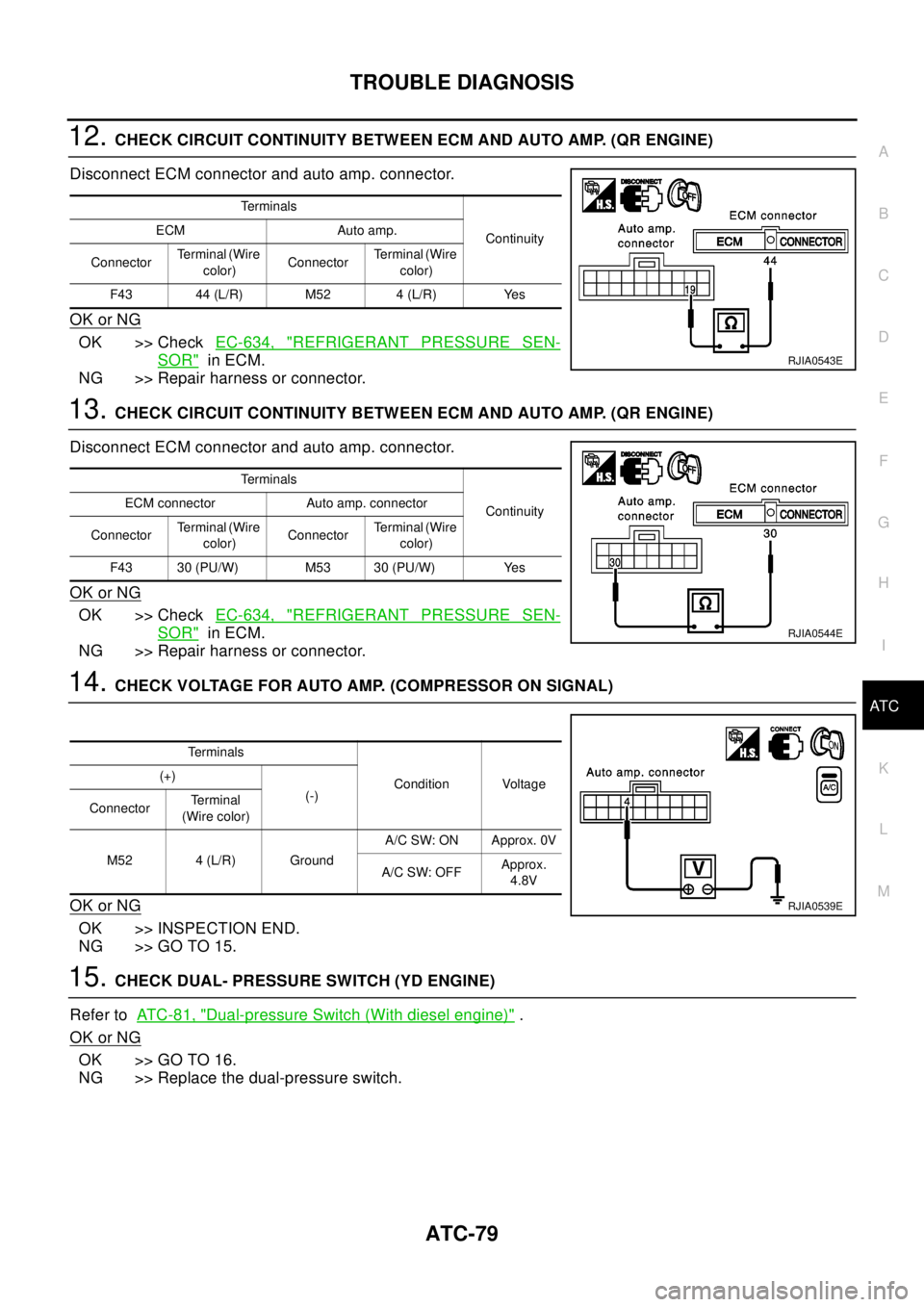

12.CHECK CIRCUIT CONTINUITY BETWEEN ECM AND AUTO AMP. (QR ENGINE)

Disconnect ECM connector and auto amp. connector.

OK or NG

OK >> CheckEC-634, "REFRIGERANT PRESSURE SEN-

SOR"in ECM.

NG >> Repair harness or connector.

13.CHECK CIRCUIT CONTINUITY BETWEEN ECM AND AUTO AMP. (QR ENGINE)

Disconnect ECM connector and auto amp. connector.

OK or NG

OK >> CheckEC-634, "REFRIGERANT PRESSURE SEN-

SOR"in ECM.

NG >> Repair harness or connector.

14.CHECK VOLTAGE FOR AUTO AMP. (COMPRESSOR ON SIGNAL)

OK or NG

OK >> INSPECTION END.

NG >> GO TO 15.

15.CHECK DUAL- PRESSURE SWITCH (YD ENGINE)

Refer toAT C - 8 1 , "

Dual-pressure Switch (With diesel engine)".

OK or NG

OK >> GO TO 16.

NG >> Replace the dual-pressure switch.

Te r m i n a l s

Continuity ECM Auto amp.

ConnectorTerminal (Wire

color)ConnectorTerminal (Wire

color)

F43 44 (L/R) M52 4 (L/R) Yes

RJIA0543E

Te r m i n a l s

Continuity ECM connector Auto amp. connector

ConnectorTerminal (Wire

color)ConnectorTerminal (Wire

color)

F43 30 (PU/W) M53 30 (PU/W) Yes

RJIA0544E

Te r m i n a l s

Condition Voltage (+)

(-)

ConnectorTe r m i n a l

(Wire color)

M52 4 (L/R) GroundA/C SW: ON Approx. 0V

A/C SW: OFFApprox.

4.8V

RJIA0539E

Page 658 of 3066

ATC-80

TROUBLE DIAGNOSIS

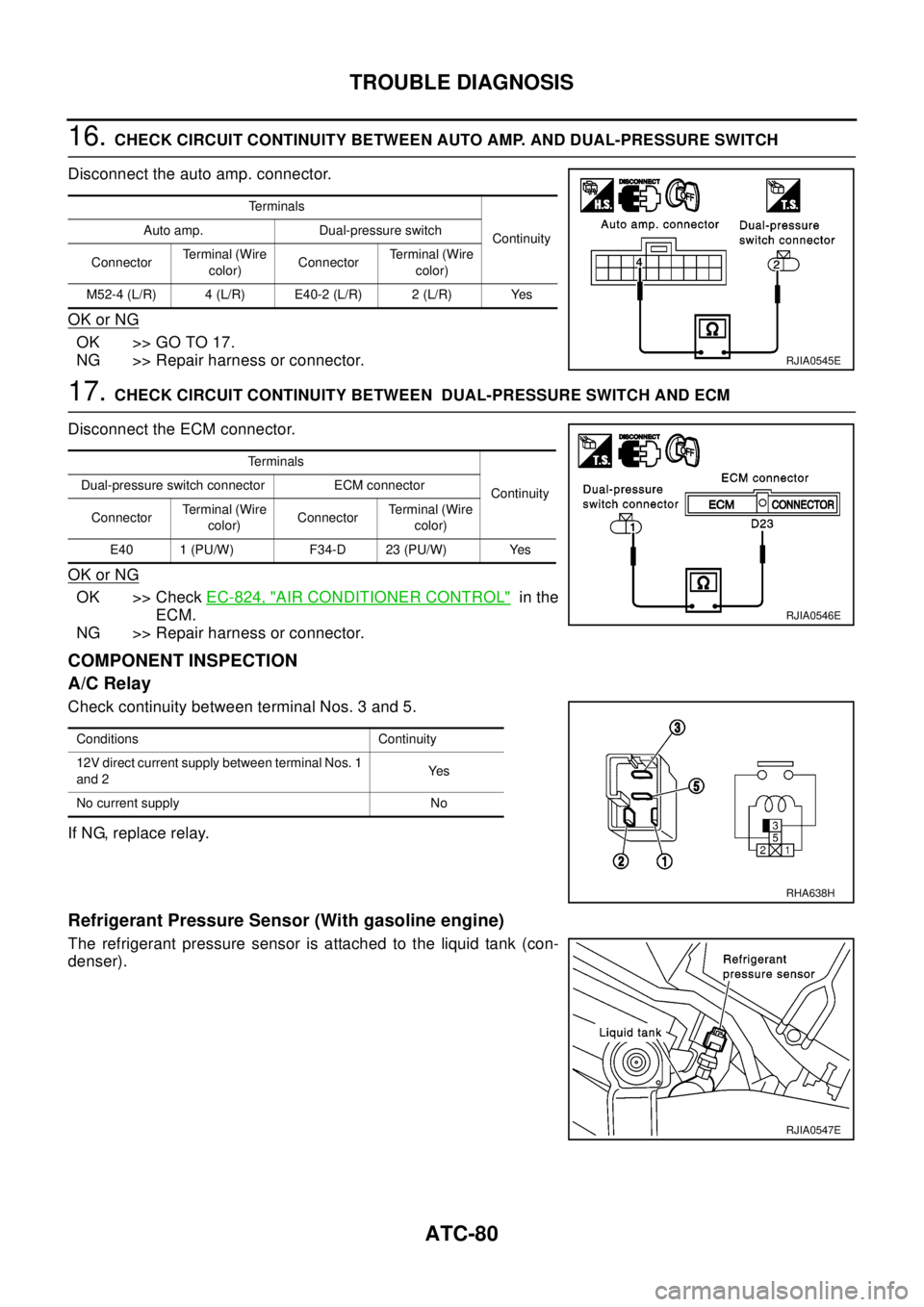

16.CHECK CIRCUIT CONTINUITY BETWEEN AUTO AMP. AND DUAL-PRESSURE SWITCH

Disconnect the auto amp. connector.

OK or NG

OK >> GO TO 17.

NG >> Repair harness or connector.

17.CHECK CIRCUIT CONTINUITY BETWEEN DUAL-PRESSURE SWITCH AND ECM

Disconnect the ECM connector.

OK or NG

OK >> CheckEC-824, "AIR CONDITIONER CONTROL"in the

ECM.

NG >> Repair harness or connector.

COMPONENT INSPECTION

A/C Relay

Check continuity between terminal Nos. 3 and 5.

If NG, replace relay.

Refrigerant Pressure Sensor (With gasoline engine)

The refrigerant pressure sensor is attached to the liquid tank (con-

denser).

Te r m i n a l s

Continuity Auto amp. Dual-pressure switch

ConnectorTerminal (Wire

color)ConnectorTerminal (Wire

color)

M52-4 (L/R) 4 (L/R) E40-2 (L/R) 2 (L/R) Yes

RJIA0545E

Te r m i n a l s

Continuity Dual-pressure switch connector ECM connector

ConnectorTerminal (Wire

color)ConnectorTerminal (Wire

color)

E40 1 (PU/W) F34-D 23 (PU/W) Yes

RJIA0546E

Conditions Continuity

12V direct current supply between terminal Nos. 1

and 2Ye s

No current supply No

RHA638H

RJIA0547E

Page 659 of 3066

TROUBLE DIAGNOSIS

ATC-81

C

D

E

F

G

H

I

K

L

MA

B

AT C

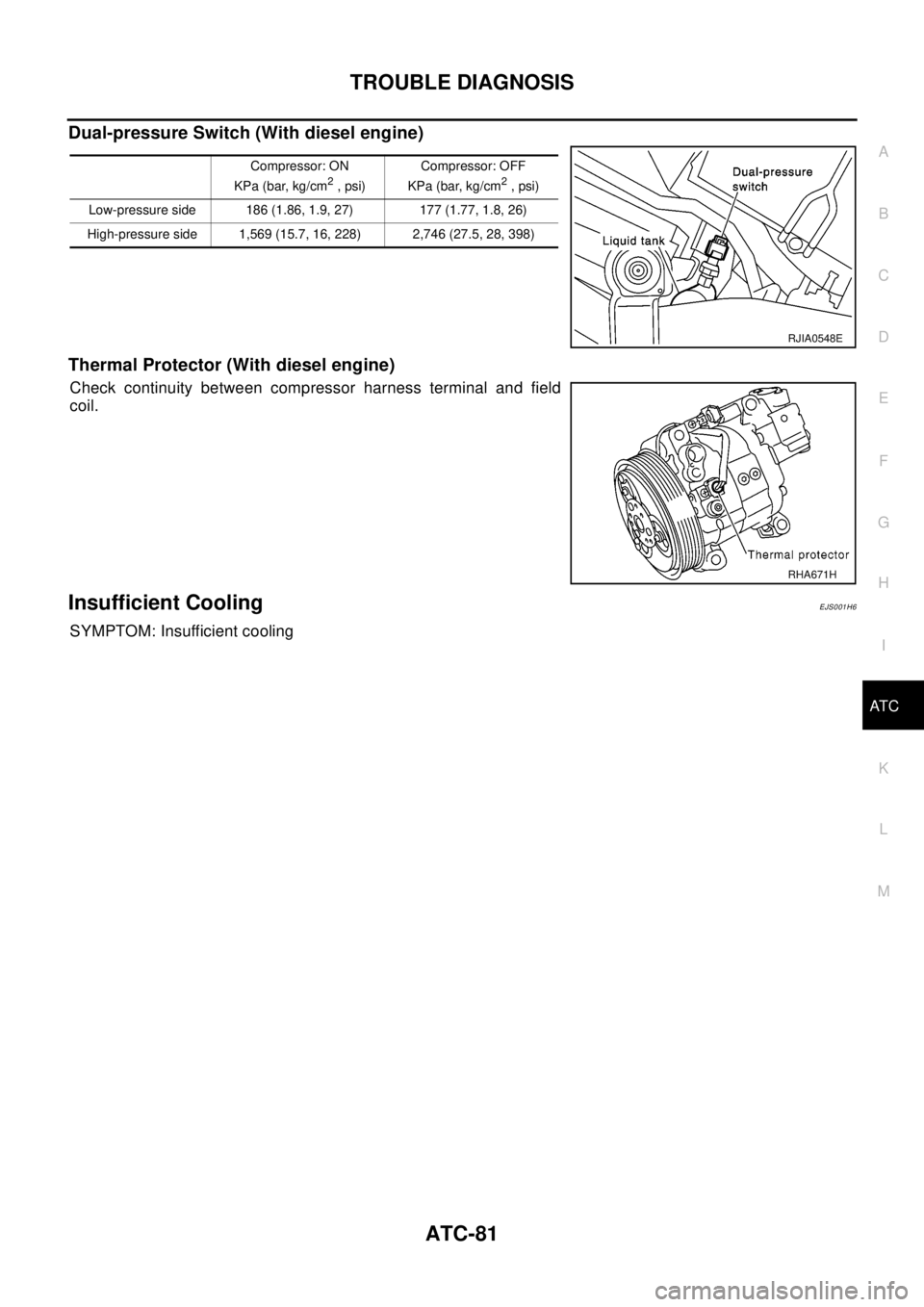

Dual-pressure Switch (With diesel engine)

Thermal Protector (With diesel engine)

Check continuity between compressor harness terminal and field

coil.

Insufficient CoolingEJS001H6

SYMPTOM: Insufficient cooling

Compressor: ON

KPa (bar, kg/cm2,psi)Compressor: OFF

KPa (bar, kg/cm2,psi)

Low-pressure side 186 (1.86, 1.9, 27) 177 (1.77, 1.8, 26)

High-pressure side 1,569 (15.7, 16, 228) 2,746 (27.5, 28, 398)

RJIA0548E

RHA671H

Page 660 of 3066

ATC-82

TROUBLE DIAGNOSIS

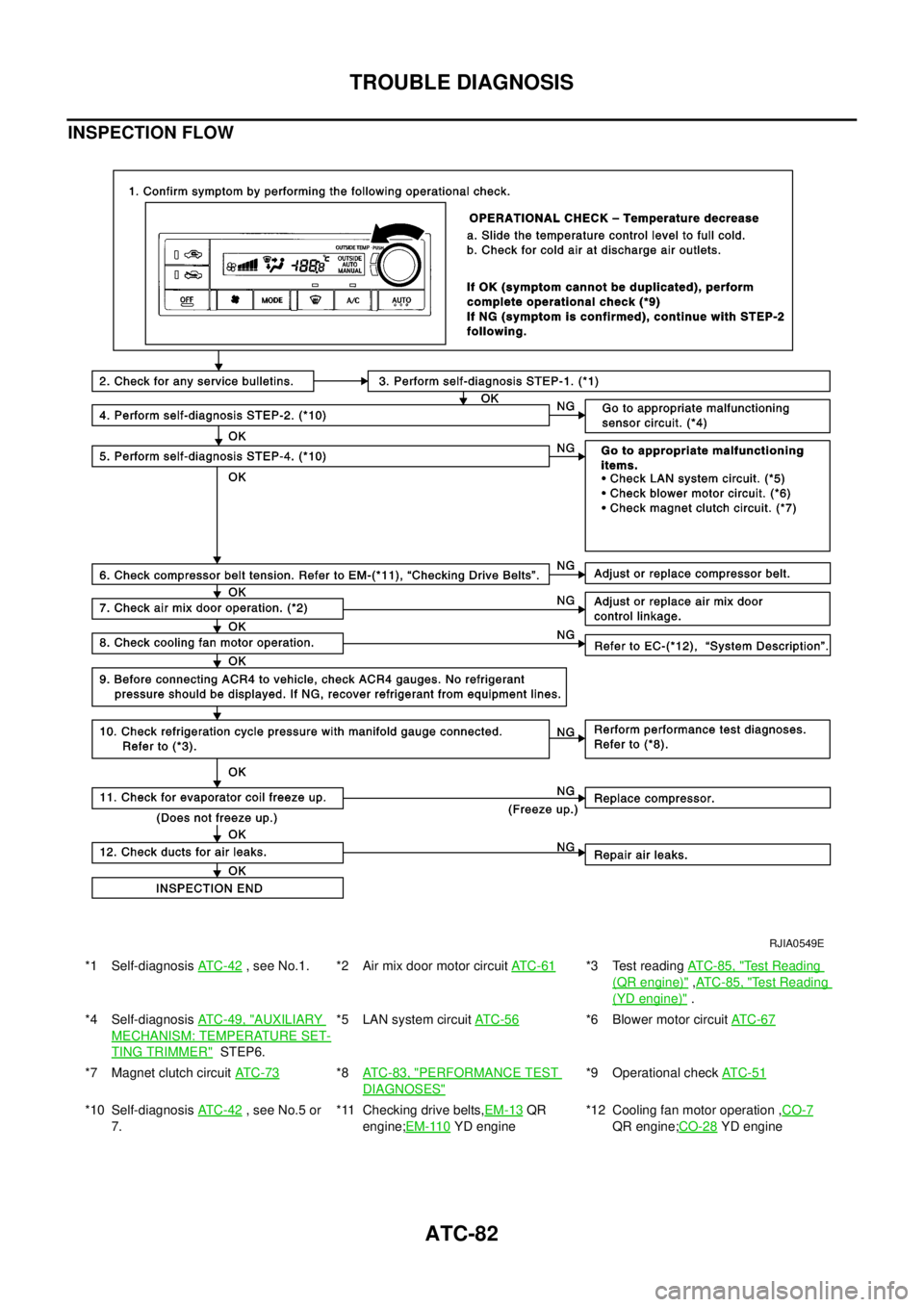

INSPECTION FLOW

*1 Self-diagnosisAT C - 4 2, see No.1. *2 Air mix door motor circuitAT C - 6 1*3 Test readingAT C - 8 5 , "Te s t R e a d i n g

(QR engine)",AT C - 8 5 , "Test Reading

(YD engine)".

*4 Self-diagnosisAT C - 4 9 , "

AUXILIARY

MECHANISM: TEMPERATURE SET-

TING TRIMMER"STEP6.*5 LAN system circuitAT C -5 6

*6 Blower motor circuitAT C -6 7

*7 Magnet clutch circuitAT C - 7 3*8AT C - 8 3 , "PERFORMANCE TEST

DIAGNOSES"

*9 Operational checkAT C - 5 1

*10 Self-diagnosisAT C - 4 2, see No.5 or

7.*11 Checking drive belts,EM-13QR

engine;EM-110

YD engine*12 Cooling fan motor operation ,CO-7QR engine;CO-28YD engine

RJIA0549E

Page 664 of 3066

ATC-86

TROUBLE DIAGNOSIS

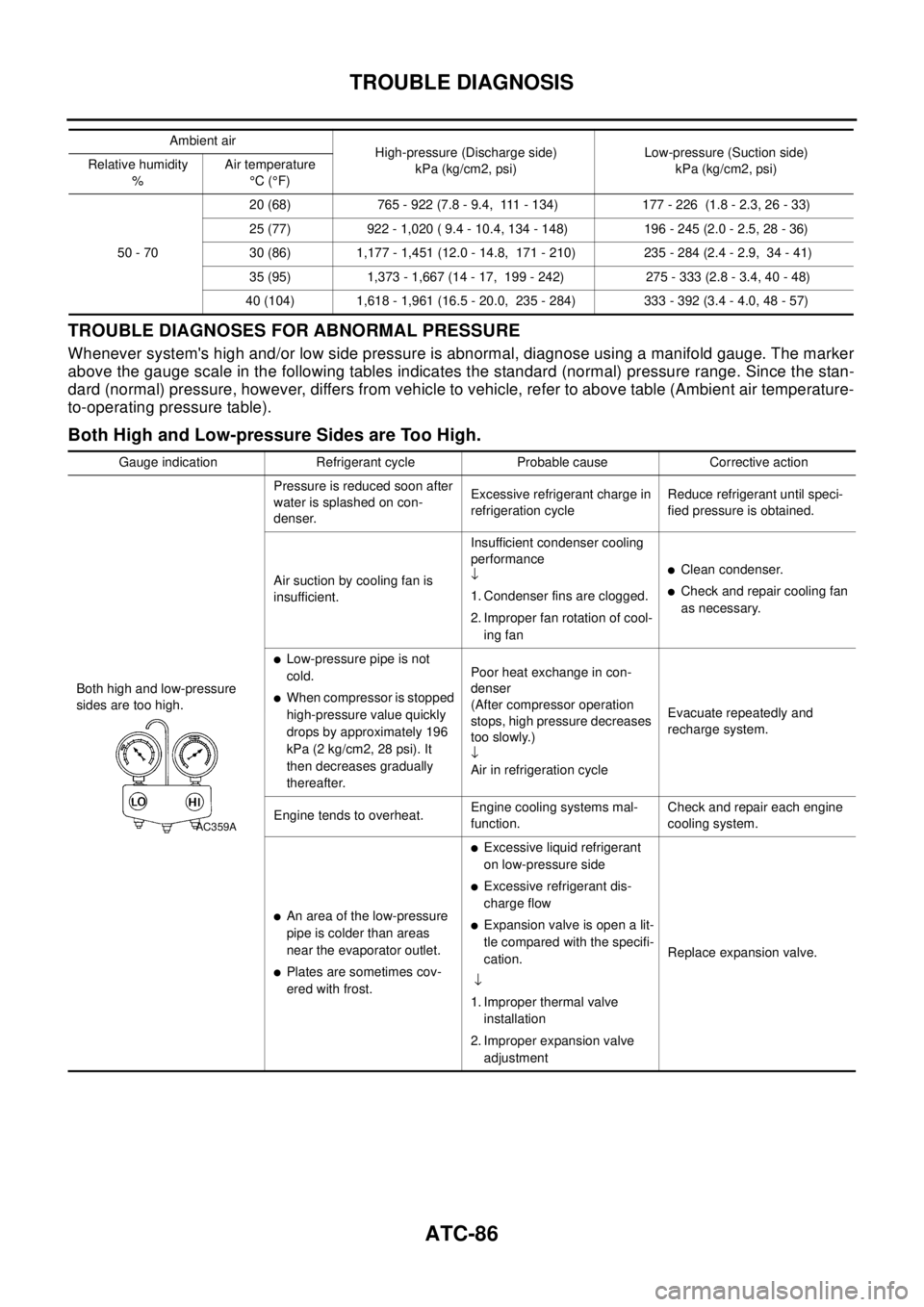

TROUBLE DIAGNOSES FOR ABNORMAL PRESSURE

Whenever system's high and/or low side pressure is abnormal, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicates the standard (normal) pressure range. Since the stan-

dard (normal) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High and Low-pressure Sides are Too High.

Ambient air

High-pressure (Discharge side)

kPa (kg/cm2, psi)Low-pressure (Suction side)

kPa (kg/cm2, psi) Relative humidity

%Air temperature

°C(°F)

50 - 7020 (68) 765 - 922 (7.8 - 9.4, 111 - 134) 177 - 226 (1.8 - 2.3, 26 - 33)

25 (77) 922 - 1,020 ( 9.4 - 10.4, 134 - 148) 196 - 245 (2.0 - 2.5, 28 - 36)

30 (86) 1,177 - 1,451 (12.0 - 14.8, 171 - 210) 235 - 284 (2.4 - 2.9, 34 - 41)

35 (95) 1,373 - 1,667 (14 - 17, 199 - 242) 275 - 333 (2.8 - 3.4, 40 - 48)

40 (104) 1,618 - 1,961 (16.5 - 20.0, 235 - 284) 333 - 392 (3.4 - 4.0, 48 - 57)

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low-pressure

sides are too high.Pressure is reduced soon after

water is splashed on con-

denser.Excessive refrigerant charge in

refrigeration cycleReduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is

insufficient.Insufficient condenser cooling

performance

¯

1. Condenser fins are clogged.

2. Improper fan rotation of cool-

ing fan

lClean condenser.

lCheck and repair cooling fan

as necessary.

lLow-pressure pipe is not

cold.

lWhen compressor is stopped

high-pressure value quickly

drops by approximately 196

kPa (2 kg/cm2, 28 psi). It

then decreases gradually

thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high pressure decreases

too slowly.)

¯

Air in refrigeration cycleEvacuate repeatedly and

recharge system.

Engine tends to overheat.Engine cooling systems mal-

function.Check and repair each engine

cooling system.

lAn area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

lPlates are sometimes cov-

ered with frost.

lExcessive liquid refrigerant

on low-pressure side

lExcessive refrigerant dis-

charge flow

lExpansion valve is open a lit-

tle compared with the specifi-

cation.

¯

1. Improper thermal valve

installation

2. Improper expansion valve

adjustmentReplace expansion valve.

AC359A

Page 668 of 3066

ATC-90

TROUBLE DIAGNOSIS

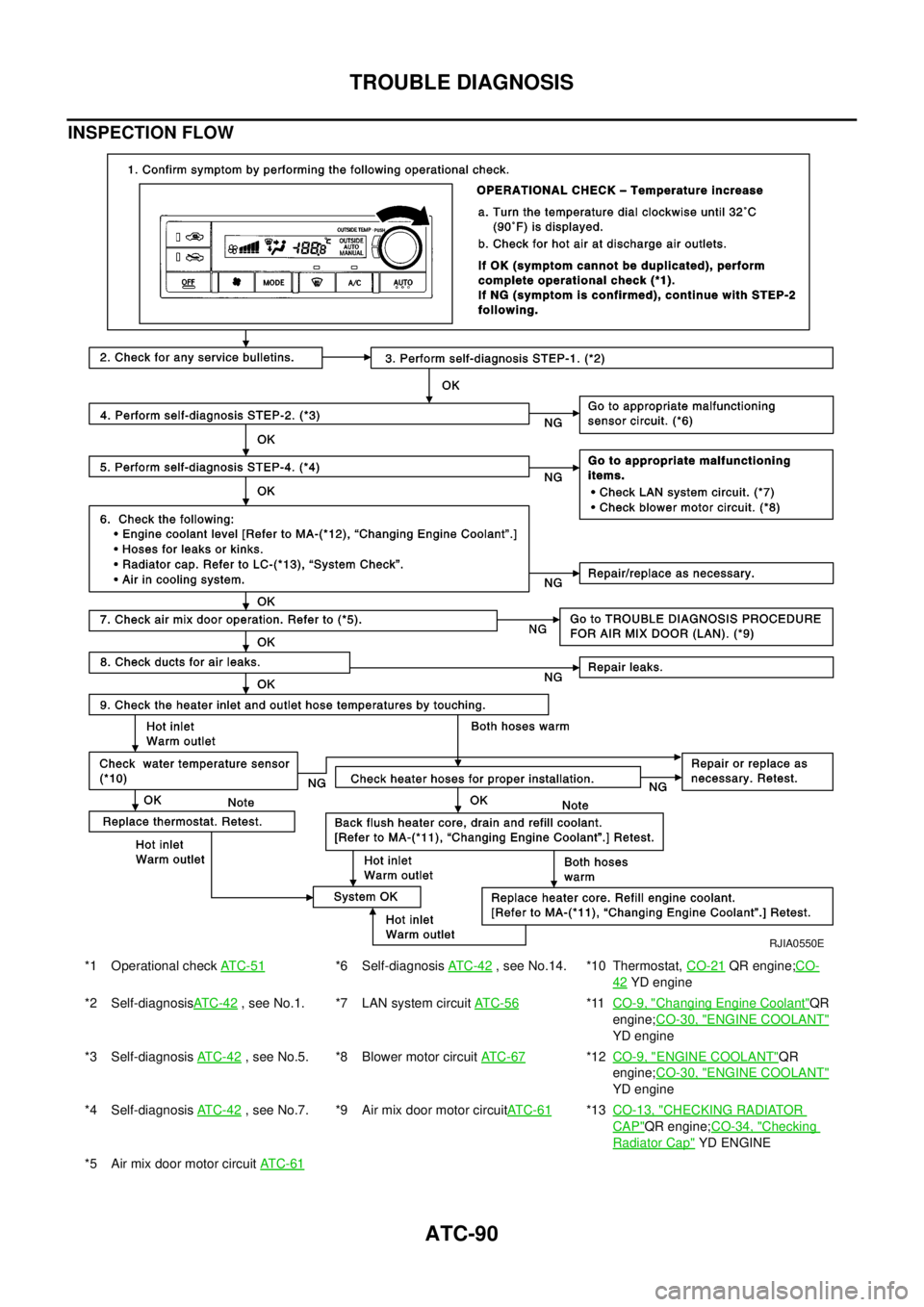

INSPECTION FLOW

*1 Operational checkAT C - 5 1*6 Self-diagnosisAT C -4 2, see No.14. *10 Thermostat,CO-21QR engine;CO-

42YD engine

*2 Self-diagnosisAT C -4 2

, see No.1. *7 LAN system circuitAT C - 5 6*11CO-9, "Changing Engine Coolant"QR

engine;CO-30, "

ENGINE COOLANT"

YD engine

*3 Self-diagnosisAT C - 4 2

, see No.5. *8 Blower motor circuitAT C - 6 7*12CO-9, "ENGINE COOLANT"QR

engine;CO-30, "

ENGINE COOLANT"

YD engine

*4 Self-diagnosisAT C - 4 2

, see No.7. *9 Air mix door motor circuitAT C - 6 1*13CO-13, "CHECKING RADIATOR

CAP"QR engine;CO-34, "Checking

Radiator Cap"YD ENGINE

*5 Air mix door motor circuitAT C - 6 1

RJIA0550E

Page 670 of 3066

ATC-92

TROUBLE DIAGNOSIS

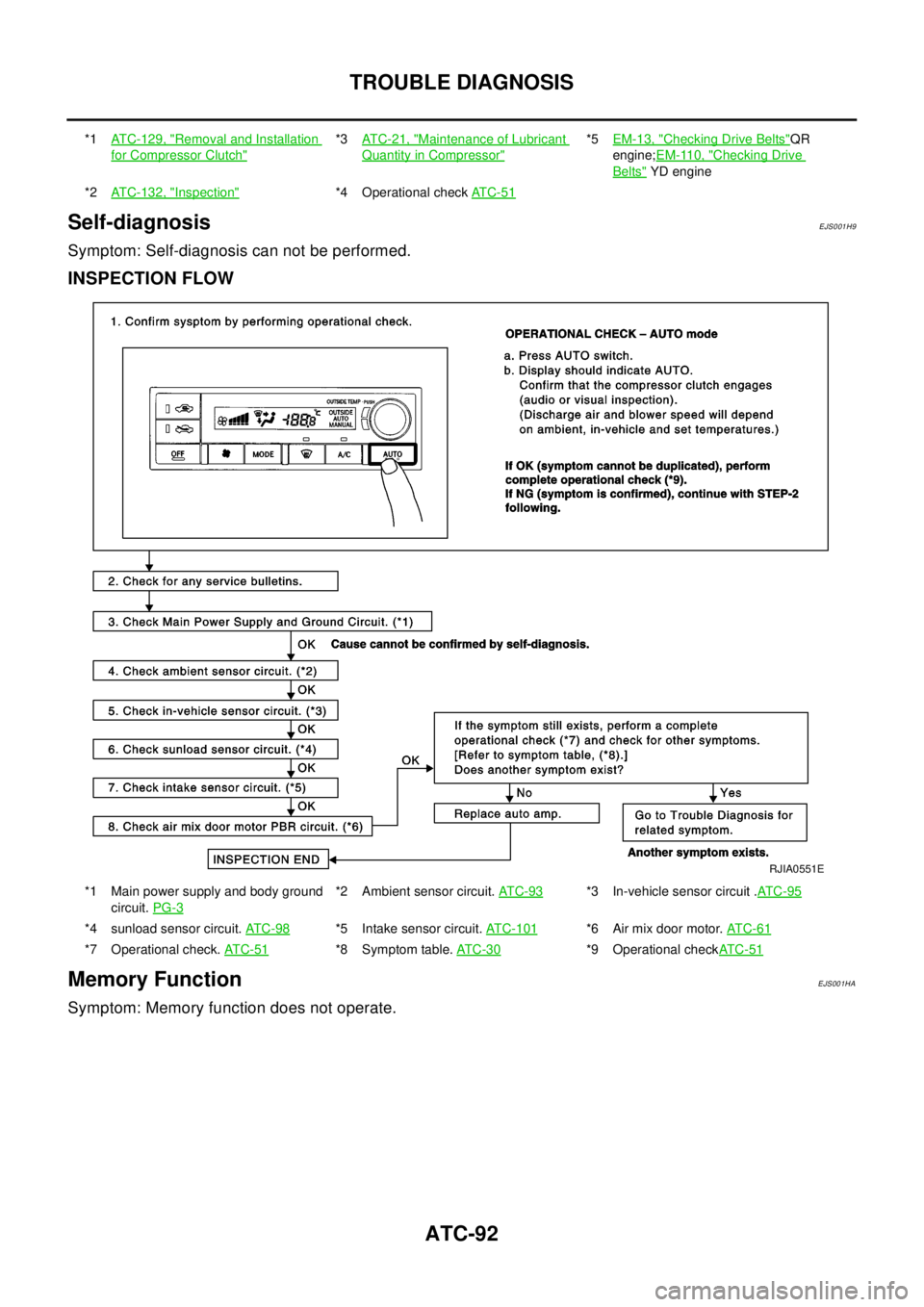

Self-diagnosis

EJS001H9

Symptom: Self-diagnosis can not be performed.

INSPECTION FLOW

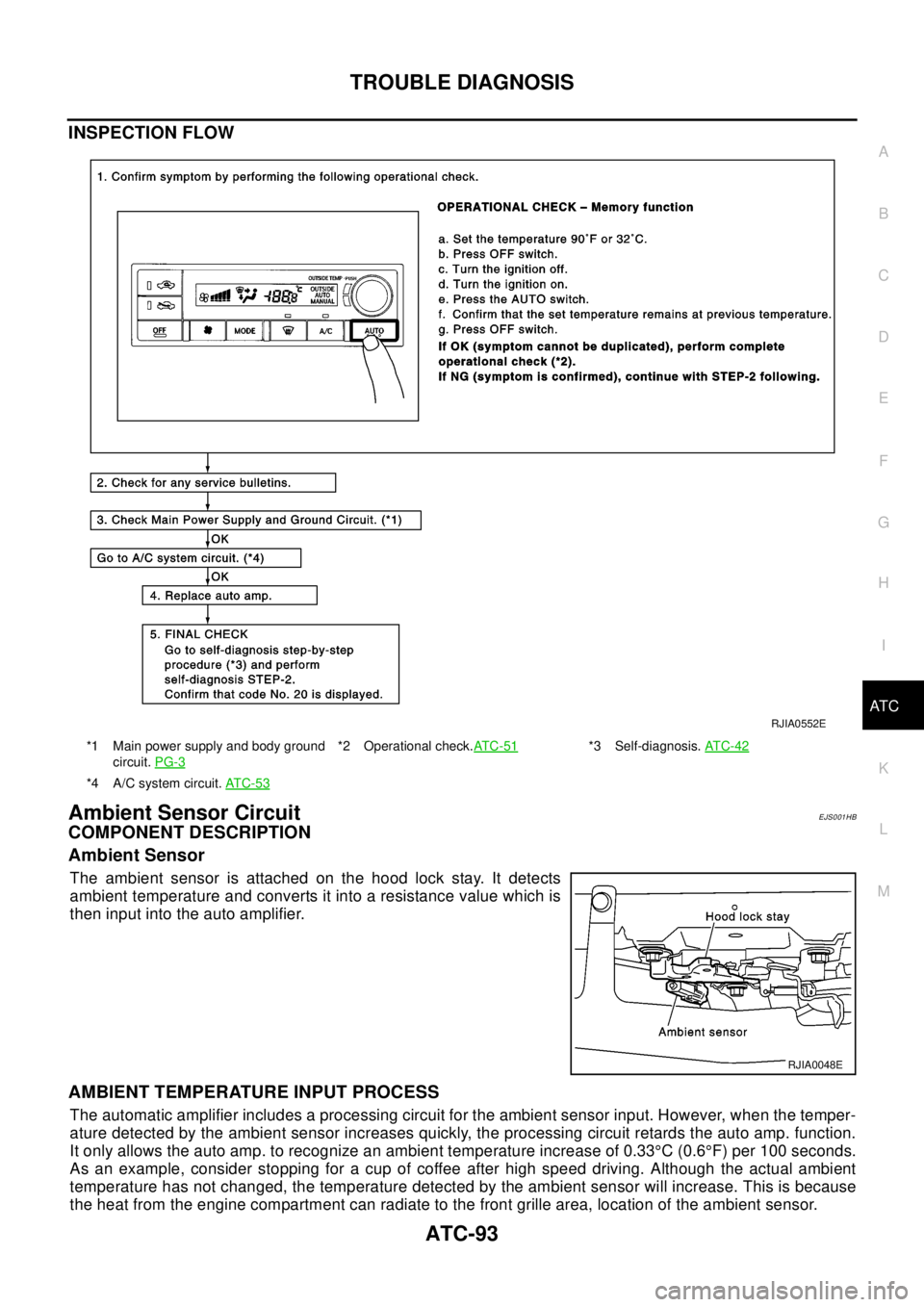

Memory FunctionEJS001HA

Symptom: Memory function does not operate.

*1ATC-129, "Removal and Installation

for Compressor Clutch"

*3AT C - 2 1 , "Maintenance of Lubricant

Quantity in Compressor"

*5EM-13, "Checking Drive Belts"QR

engine;EM-110, "

Checking Drive

Belts"YD engine

*2ATC-132, "

Inspection"*4 Operational checkAT C - 5 1

*1 Main power supply and body ground

circuit.PG-3*2 Ambient sensor circuit.AT C - 9 3*3 In-vehicle sensor circuit .AT C - 9 5

*4 sunload sensor circuit.AT C - 9 8*5 Intake sensor circuit.AT C - 1 0 1*6 Air mix door motor.AT C - 6 1

*7 Operational check.AT C - 5 1*8 Symptom table.AT C -3 0*9 Operational checkAT C - 5 1

RJIA0551E

Page 671 of 3066

TROUBLE DIAGNOSIS

ATC-93

C

D

E

F

G

H

I

K

L

MA

B

AT C

INSPECTION FLOW

Ambient Sensor CircuitEJS001HB

COMPONENT DESCRIPTION

Ambient Sensor

The ambient sensor is attached on the hood lock stay. It detects

ambient temperature and converts it into a resistance value which is

then input into the auto amplifier.

AMBIENT TEMPERATURE INPUT PROCESS

The automatic amplifier includes a processing circuit for the ambient sensor input. However, when the temper-

ature detected by the ambient sensor increases quickly, the processing circuit retards the auto amp. function.

It only allows the auto amp. to recognize an ambient temperature increase of 0.33°C(0.6°F) per 100 seconds.

As an example, consider stopping for a cup of coffee after high speed driving. Although the actual ambient

temperature has not changed, the temperature detected by the ambient sensor will increase. This is because

the heat from the engine compartment can radiate to the front grille area, location of the ambient sensor.

*1 Main power supply and body ground

circuit.PG-3*2 Operational check.AT C - 5 1*3 Self-diagnosis.AT C - 4 2

*4 A/C system circuit.AT C - 5 3

RJIA0552E

RJIA0048E