check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 455 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual A/T SHIFT LOCK SYSTEM

AT-449

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to “ON” position.

(Do not start engine.)

lCheck voltage between A/T device harne NISSAN X-TRAIL 2003 Electronic Repair Manual A/T SHIFT LOCK SYSTEM

AT-449

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to “ON” position.

(Do not start engine.)

lCheck voltage between A/T device harne](/img/5/57402/w960_57402-454.png)

A/T SHIFT LOCK SYSTEM

AT-449

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to “ON” position.

(Do not start engine.)

lCheck voltage between A/T device harness terminal 7 and ground.

OK or NG

OK >> GO TO 5

NG >> Check the following items:

1. Harness for short and open between battery and stop

lamp switch harness connector 1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T device har-

ness connector 7.

3. Fuse

4. Stop lamp switch (Refer toAT- 4 5 0 , "

A/T DEVICE CHECK".)

5.CHECK GROUND CIRCUIT

1. Turn ignition switch to “OFF” position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 6 and ground.

If OK, check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6

NG >> Repair open circuit or short to ground or short to power

in harness or connectors. Voltage:

Brake pedal depressd:

Battery voltage

Brake pedal released:

0V

SCIA0783E

Continuity should exist.

SCIA0784E

Page 456 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-450

[ALL]

A/T SHIFT LOCK SYSTEM

6.CHECK RELAY CIRCUIT

1. Turn ignition switch to ON.

Check voltage between terminal 7 - 6 and 5 - 6.

OK or NG

OK >> GO TO 7

NG >> Replace A/T device.

7.CHECKPARKPOSI NISSAN X-TRAIL 2003 Electronic Repair Manual AT-450

[ALL]

A/T SHIFT LOCK SYSTEM

6.CHECK RELAY CIRCUIT

1. Turn ignition switch to ON.

Check voltage between terminal 7 - 6 and 5 - 6.

OK or NG

OK >> GO TO 7

NG >> Replace A/T device.

7.CHECKPARKPOSI](/img/5/57402/w960_57402-455.png)

AT-450

[ALL]

A/T SHIFT LOCK SYSTEM

6.CHECK RELAY CIRCUIT

1. Turn ignition switch to ON.

Check voltage between terminal 7 - 6 and 5 - 6.

OK or NG

OK >> GO TO 7

NG >> Replace A/T device.

7.CHECKPARKPOSITIONSWITCH

Refer toAT-450, "

A/T DEVICE CHECK".

OK or NG

OK >> GO TO 8

NG >> Replace A/T device.

8.CHECK SHIFT LOCK SOLENOID

Refer toAT-450, "

A/T DEVICE CHECK".

OK or NG

OK >> GO TO 9

NG >> Replace A/T device.

9.SHIFT LOCK OPERATION

1. Reconnect shift lock harness connector.

2. Turn ignition switch from “OFF” to “ON” position. (Do not start engine.)

3. Recheck shift lock operation.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform A/T device input/output signal inspection test.

2. If NG, recheck harness connector connection.

A/T DEVICE CHECK

1. Shift Lock Solenoid

lCheck operation sound.

When ignition switch is turned to “ON” position and selector lever is set in “P” position.

SCIA0785E

Brake pedal Operation sound

Depressed Yes

Released No

Page 465 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

t NISSAN X-TRAIL 2003 Electronic Repair Manual REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

t](/img/5/57402/w960_57402-464.png)

REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

toEM-61, "

ENGINE ASSEMBLY".

13. Remove suspension member. Refer toFSU-12, "

FRONT SUS-

PENSION MEMBER".

14. Remove dust cover from converter housing.

Rotate crankshaft to gain access to securing bolts.

15. Remove securing bolts between drive plate and torque con-

verter. when crank shaft rotates, turn to right at the front side of

engine.

16. Support engine with a jack.

17. Remove bolts fixing transaxle to engine.

18. Lower transaxle while supporting it with a jack.

InstallationECS004ND

1. Check drive plate runout.

CAUTION:

Do not allow any magnetic materials to contact the ring

gear teeth.

lIf this runout is out of allowance, replace drive plate with ring

gear.

2. When connecting torque converter to transaxle, measure dis-

tance “A” to be certain that they are correctly assembled.

SCIA0794E

AAT259A

Maximum allowable runout :

Refer to EM-´´, “FLYWHEEL/DRIVE PLATE RUNOUT”.

SAT977H

Distance “A”: 19 mm (0.626 in) or more

SAT573D

Page 466 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-460

[ALL]

REMOVAL AND INSTALLATION

3. Install torque converter to drive plate.

lWith converter installed, rotate crankshaft several turns

to check that transaxle rotates freely without binding.

4. NISSAN X-TRAIL 2003 Electronic Repair Manual AT-460

[ALL]

REMOVAL AND INSTALLATION

3. Install torque converter to drive plate.

lWith converter installed, rotate crankshaft several turns

to check that transaxle rotates freely without binding.

4.](/img/5/57402/w960_57402-465.png)

AT-460

[ALL]

REMOVAL AND INSTALLATION

3. Install torque converter to drive plate.

lWith converter installed, rotate crankshaft several turns

to check that transaxle rotates freely without binding.

4. Tighten belts fixing transaxle.

5. Reinstall any part removed.

6. Adjust control cable. Refer toAT-456, "

Control Cable Adjust-

ment".

7. Check continuity of PNP switch. Refer toAT-130, "

DTC P0705

PARK/NEUTRAL POSITION (PNP) SWITCH".

8. Refill transaxle with ATF and check fluid level.

9. Move selector lever through all positions to be sure that tran-

saxle operates correctly. With parking brake applied, idle

engine. Move selector lever through “N” to “D”, to “2”, to “1” and

“R” positions. A slight shock should be felt through the hand

gripping the selector each time the transaxle is shifted.

10. Perform road test. Refer toAT-69, "

Road Test".

AAT266A

Bolt No.Tightening torque

N-m (kg-m, ft-lb)Bolt length “ L ”

mm (in)

1

69.6 - 79.4 (7.1 - 8.1, 51.4 - 58.6)49 (1.93)

245(1.77)

3

39.2 - 46.1 (4.0 - 4.7, 29.0 - 34.0)40 (1.57)

430(1.18)

5

30.4 - 40.2 (3.1 - 4.1, 22.4 - 29.7)40 (1.57)

645(1.97)

SCIA0795E

SAT638A

Page 580 of 3066

ATC-2

DEFROSTER (DEF) SWITCH ............................. 27

MODE SWITCH ................................................... 27

FAN SWITCH ...................................................... 27

OFF SWITCH ...................................................... 27

FRESH (FRE) SWITCH ....................................... 27

RECIRCULATION (REC) SWITCH ..................... 27

Discharge Air Flow ................................................. 28

System Description ................................................. 29

SWITCHES AND THEIR CONTROL FUNCTION... 29

TROUBLE DIAGNOSIS ............................................ 30

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ...................................................... 30

WORK FLOW ...................................................... 30

SYMPTOM TABLE .............................................. 30

Component Parts and Harness Connector Location... 31

ENGINE COMPARTMENT .................................. 31

PASSENGER COMPARTMENT .......................... 32

Circuit Diagram ....................................................... 33

WITH GASOLINE ENGINE ................................. 33

WITH DIESEL ENGINE ....................................... 34

Wiring Diagram ....................................................... 35

WITH DASOLINE ENGINE ................................. 35

WITH DIESEL ENGINE ....................................... 38

Auto Amp. Terminals and Reference Value ............ 41

PIN CONNECTOR TERMINAL LAYOUT ............ 41

AUTO AMP. INSPECTION TABLE ...................... 41

Self-diagnosis Function .......................................... 42

DESCRIPTION .................................................... 42

PROCEDURE ...................................................... 43

AUXILIARY MECHANISM: TEMPERATURE

SETTING TRIMMER ........................................... 49

AUXILIARY MECHANISM: FOOT POSITION

SETTING TRIMMER ........................................... 50

AUXILIARY MECHANISM: INLET PORT MEM-

ORY FUNCTION (FOR LHD MODELS) .............. 51

Operational Check .................................................. 51

CHECKING MEMORY FUNCTION ..................... 51

CHECKING BLOEWER ....................................... 52

CHECKING DISCHARGE AIR ............................ 52

CHECKING RECIRCULATION ............................ 52

CHECKING TEMPERATURE DECREASE ......... 53

CHECKING TEMPERATURE INCREASE .......... 53

CHECKING AUTO MODE ................................... 53

Power Supply and Ground Circuit for Auto Amp. ... 53

INSPECTION FLOW ........................................... 54

COMPONENT DESCRIPTION ............................ 54

DIAGNOSTIC PROCEDURE .............................. 55

LAN System Circuit ................................................ 56

DIAGNOSTIC PROCEDURE .............................. 56

Mode Door Motor Circuit ........................................ 58

INSPECTION FLOW ........................................... 59

SYSTEM DESCRIPTION .................................... 60

COMPONENT DESCRIPTION ............................ 61

DIAGNOSTIC PROCEDURE .............................. 61

Air Mix Door Motor Circuit ...................................... 61

INSPECTION FLOW ........................................... 62

SYSTEM DESCRIPTION .................................... 62

COMPONENT DESCRIPTION ............................ 64DIAGNOSTIC PROCEDURE ...............................64

Intake Door Motor Circuit ........................................64

INSPECTION FLOW ............................................65

SYSTEM DESCRIPTION .....................................65

COMPONENT DESCRIPTION ............................66

DIAGNOSTIC PROCEDURE ...............................67

Blower Motor Circuit ................................................67

INSPECTION FLOW ............................................68

SYSTEM DESCRIPTION .....................................69

COMPONENT DESCRIPTION ............................70

DIAGNOSTIC PROCEDURE ...............................70

COMPONENT INSPECTION ...............................73

Magnet Clutch Circuit ..............................................73

INSPECTION FLOW ............................................74

SYSTEM DESCRIPTION .....................................74

DIAGNOSTIC PROCEDURE ...............................75

COMPONENT INSPECTION ...............................80

Insufficient Cooling ..................................................81

INSPECTION FLOW ............................................82

PERFORMANCE TEST DIAGNOSES ................83

PERFORMANCE CHART ....................................84

TROUBLE DIAGNOSES FOR ABNORMAL

PRESSURE .........................................................86

Insufficient Heating .................................................89

INSPECTION FLOW ............................................90

Noise .......................................................................91

INSPECTION FLOW ............................................91

Self-diagnosis .........................................................92

INSPECTION FLOW ............................................92

Memory Function ....................................................92

INSPECTION FLOW ............................................93

Ambient Sensor Circuit ...........................................93

COMPONENT DESCRIPTION ............................93

AMBIENT TEMPERATURE INPUT PROCESS...93

DIAGNOSTIC PROCEDURE ...............................94

COMPONENT INSPECTION ...............................95

In-vehicle Sensor Circuit .........................................95

COMPONENT DESCRIPTION ............................95

DIAGNOSTIC PROCEDURE ...............................96

COMPONENT INSPECTION ...............................97

Sunload Sensor Circuit ...........................................98

COMPONENT DESCRIPTION ............................98

SUNLOAD INPUT PROCESS .............................98

DIAGNOSTIC PROCEDURE ...............................98

COMPONENT INSPECTION ............................. 100

Intake Sensor Circuit ............................................. 101

COMPONENT DESCRIPTION .......................... 101

DIAGNOSTIC PROCEDURE ............................. 101

CONTROLLER ........................................................ 104

Removal and Installation ....................................... 104

Disassembly and Assembly .................................. 104

AMBIENT SENSOR ................................................ 105

Removal and Installation ....................................... 105

IN-VEHICLE SENSOR ............................................ 106

Removal and Installation ....................................... 106

SUNLOAD SENSOR ............................................... 107

Removal and Installation ....................................... 107

Page 581 of 3066

ATC-3

C

D

E

F

G

H

I

K

L

MA

B

AT C INTAKE SENSOR CIRCUIT ................................... 108

Removal and Installation ...................................... 108

BLOWER UNIT ....................................................... 109

Removal and Installation ...................................... 109

REMOVAL ......................................................... 109

INSTALLATION ................................................. 109

Disassembly and Assembly ................................. 109

BLOWER MOTOR ................................................... 111

Removal and Installation ...................................... . 111

INTAKE DOOR MOTOR .......................................... 112

Removal and Installation ....................................... 112

FAN CONTROL AMPLIFIER ................................... 113

Removal and Installation ....................................... 113

VENTILATION AIR FILTER ..................................... 114

Removal and Installation ....................................... 114

Function ................................................................ 114

Replacement Timing ............................................. 114

Replacement Procedures ...................................... 114

HEATER & COOLING UNIT ASSEMBLY ............... 115

Removal and Installation ....................................... 115

REMOVAL .......................................................... 115

INSTALLATION .................................................. 116

Disassembly and Assembly .................................. 116

MODE DOOR MOTOR ............................................ 118

Removal and Installation ....................................... 118

AIR MIX DOOR MOTOR .......................................... 119

Removal and Installation ....................................... 119

HEATER CORE ...................................................... 120

Removal and Installation ...................................... 120

DUCTS AND GRILLES .......................................... 121

Removal and Installation ...................................... 121

Ventilator Duct, Defroster Nozzle and Defroster

Ducts .................................................................... 121

Center Ventilator Grille ......................................... 121

Side Ventilator Grille ............................................. 121

Foot Duct .............................................................. 122

Floor duct ............................................................. 122

REFRIGERANT LINES ........................................... 123

HFC-134a (R-134a) Service Procedure ............... 123

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................ 123

Components ......................................................... 125

Removal and Installation for Compressor ............ 126REMOVAL .........................................................126

INSTALLATION .................................................128

Removal and Installation for Compressor Clutch . 129

REMOVAL .........................................................129

INSTALLATION .................................................132

Removal and Installation for Low-pressure flexible

hose ......................................................................135

REMOVAL .........................................................135

INSTALLATION .................................................136

Removal and Installation for High-pressure flexible

hose ......................................................................136

REMOVAL .........................................................136

INSTALLATION .................................................136

Removal and Installation for High-pressure pipe ..137

REMOVAL .........................................................137

INSTALLATION .................................................137

Removal and Installation for Refrigerant Pressure

Sensor ..................................................................137

Removal and Installation for Dual-pressure Switch.138

Removal and Installation for Condenser ..............138

REMOVAL .........................................................138

INSTALLATION .................................................138

Removal and Installation for Evaporator ..............139

REMOVAL .........................................................139

INSTALLATION .................................................139

Removal and Installation for Expansion Valve ......140

Removal and Installation for Desiccant Assembly. 140

REMOVAL .........................................................140

INSTALLATION .................................................140

Checking for Refrigerant Leaks ............................140

Checking System for Leaks Using the Fluorescent

Leak Detector .......................................................141

Dye Injection .........................................................141

Electronic Refrigerant Leak Detector ....................141

PRECAUTIONS FOR HANDLING LEAK

DETECTOR .......................................................141

CHECKING PROCEDURE ...............................142

Service Data and Specifications (SDS) ................143

COMPRESSOR ................................................143

LUBRICANT ......................................................144

REFRIGERANT .................................................144

ENGINE IDLING SPEED ..................................144

BELT TENSION .................................................144

Page 599 of 3066

LUBRICANT

ATC-21

C

D

E

F

G

H

I

K

L

MA

B

AT C

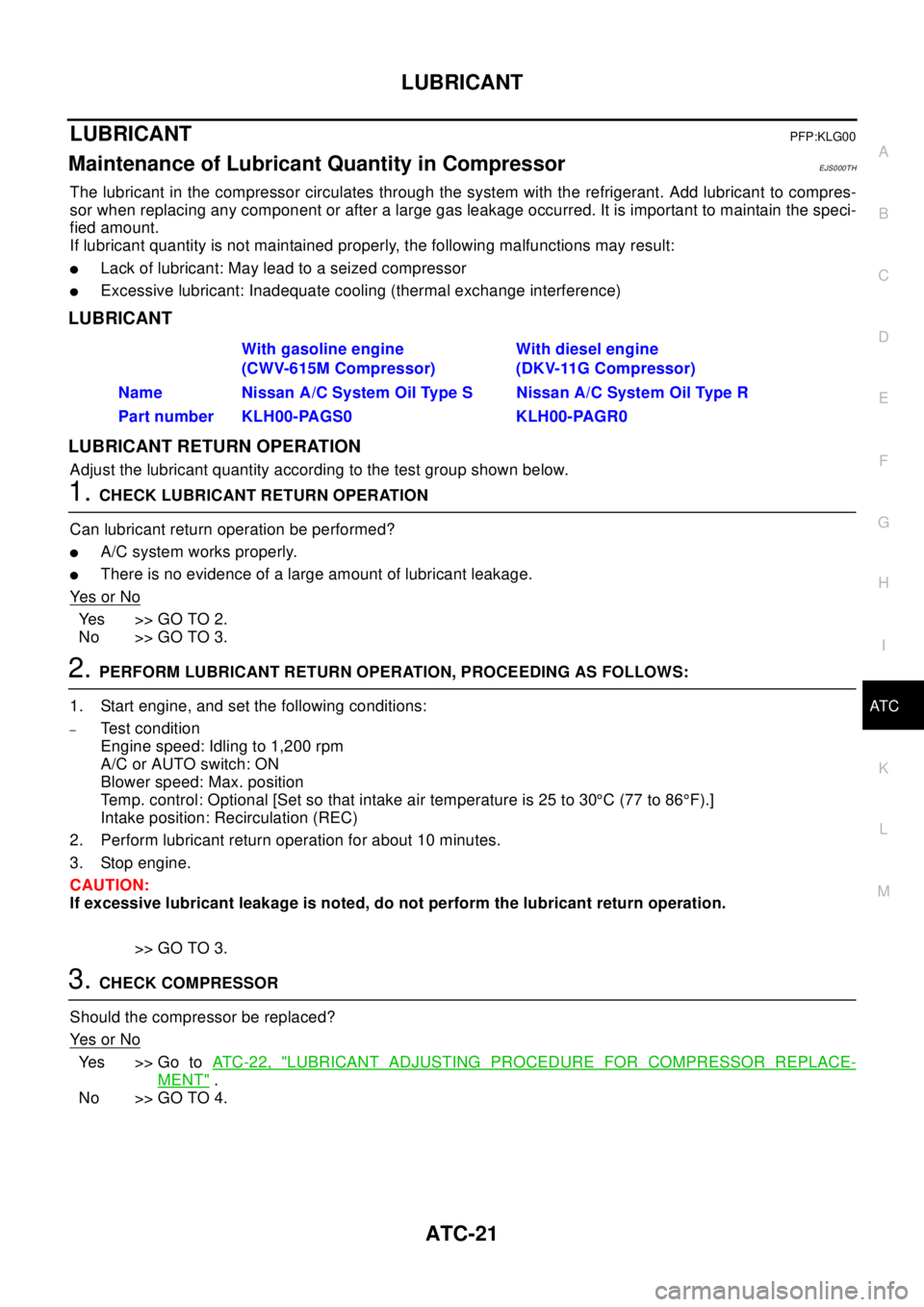

LUBRICANTPFP:KLG00

Maintenance of Lubricant Quantity in CompressorEJS000TH

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large gas leakage occurred. It is important to maintain the speci-

fied amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

LUBRICANT RETURN OPERATION

Adjust the lubricant quantity according to the test group shown below.

1.CHECK LUBRICANT RETURN OPERATION

Can lubricant return operation be performed?

lA/C system works properly.

lThere is no evidence of a large amount of lubricant leakage.

Ye s o r N o

Yes >>GOTO2.

No >> GO TO 3.

2.PERFORM LUBRICANT RETURN OPERATION, PROCEEDING AS FOLLOWS:

1. Start engine, and set the following conditions:

–Test condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to 30°C (77 to 86°F).]

Intake position: Recirculation (REC)

2. Perform lubricant return operation for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

>> GO TO 3.

3.CHECK COMPRESSOR

Should the compressor be replaced?

Ye s o r N o

Ye s > > G o t oAT C - 2 2 , "LUBRICANT ADJUSTING PROCEDURE FOR COMPRESSOR REPLACE-

MENT".

No >> GO TO 4.With gasoline engine

(CWV-615M Compressor)With diesel engine

(DKV-11G Compressor)

Name Nissan A/C System Oil Type S Nissan A/C System Oil Type R

Part number KLH00-PAGS0 KLH00-PAGR0

Page 623 of 3066

TROUBLE DIAGNOSIS

ATC-45

C

D

E

F

G

H

I

K

L

MA

B

AT C

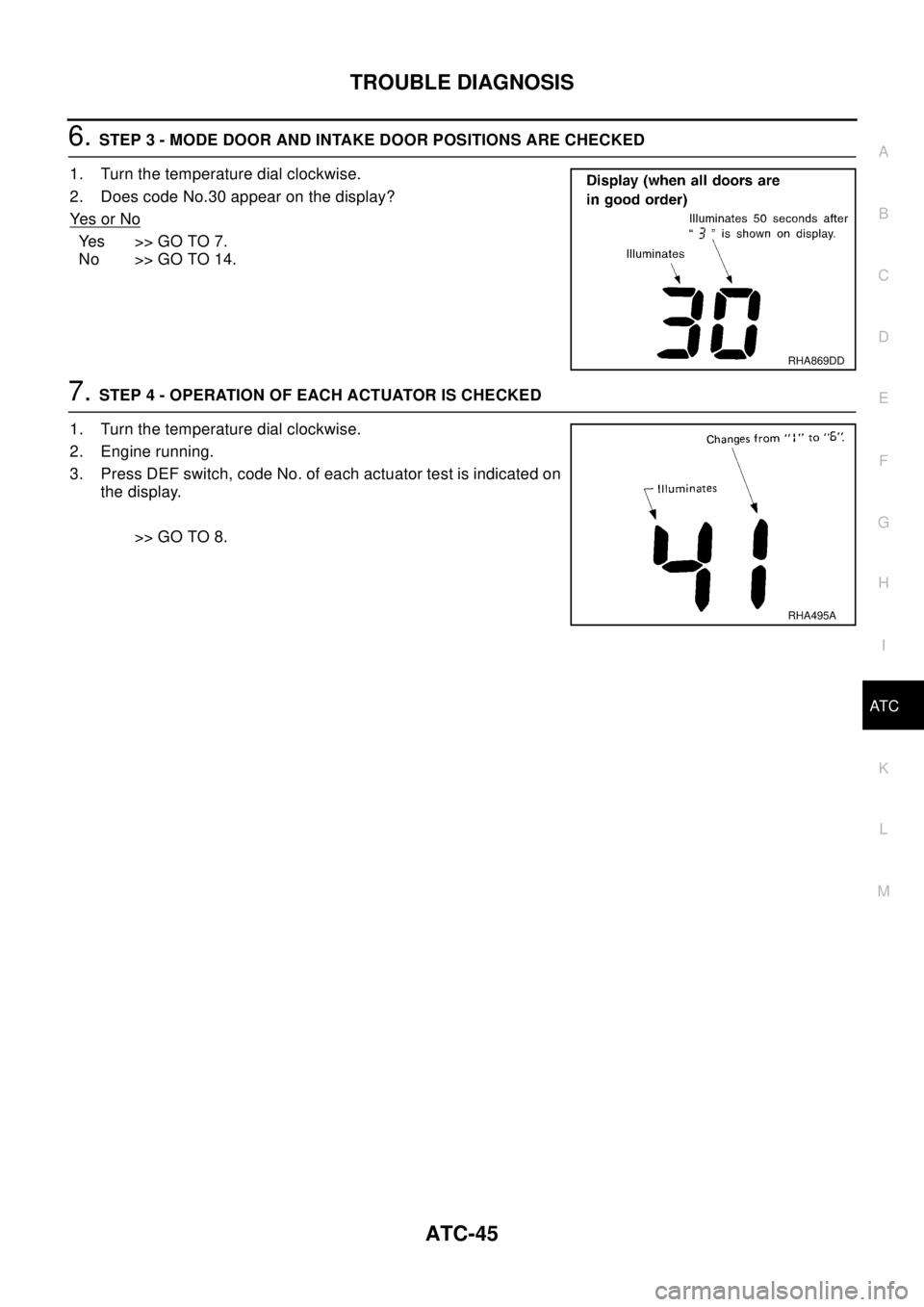

6.STEP 3 - MODE DOOR AND INTAKE DOOR POSITIONS ARE CHECKED

1. Turn the temperature dial clockwise.

2. Does code No.30 appear on the display?

Ye s o r N o

Yes >>GOTO7.

No >> GO TO 14.

7.STEP 4 - OPERATION OF EACH ACTUATOR IS CHECKED

1. Turn the temperature dial clockwise.

2. Engine running.

3. Press DEF switch, code No. of each actuator test is indicated on

the display.

>> GO TO 8.

RHA869DD

RHA495A

Page 629 of 3066

TROUBLE DIAGNOSIS

ATC-51

C

D

E

F

G

H

I

K

L

MA

B

AT C

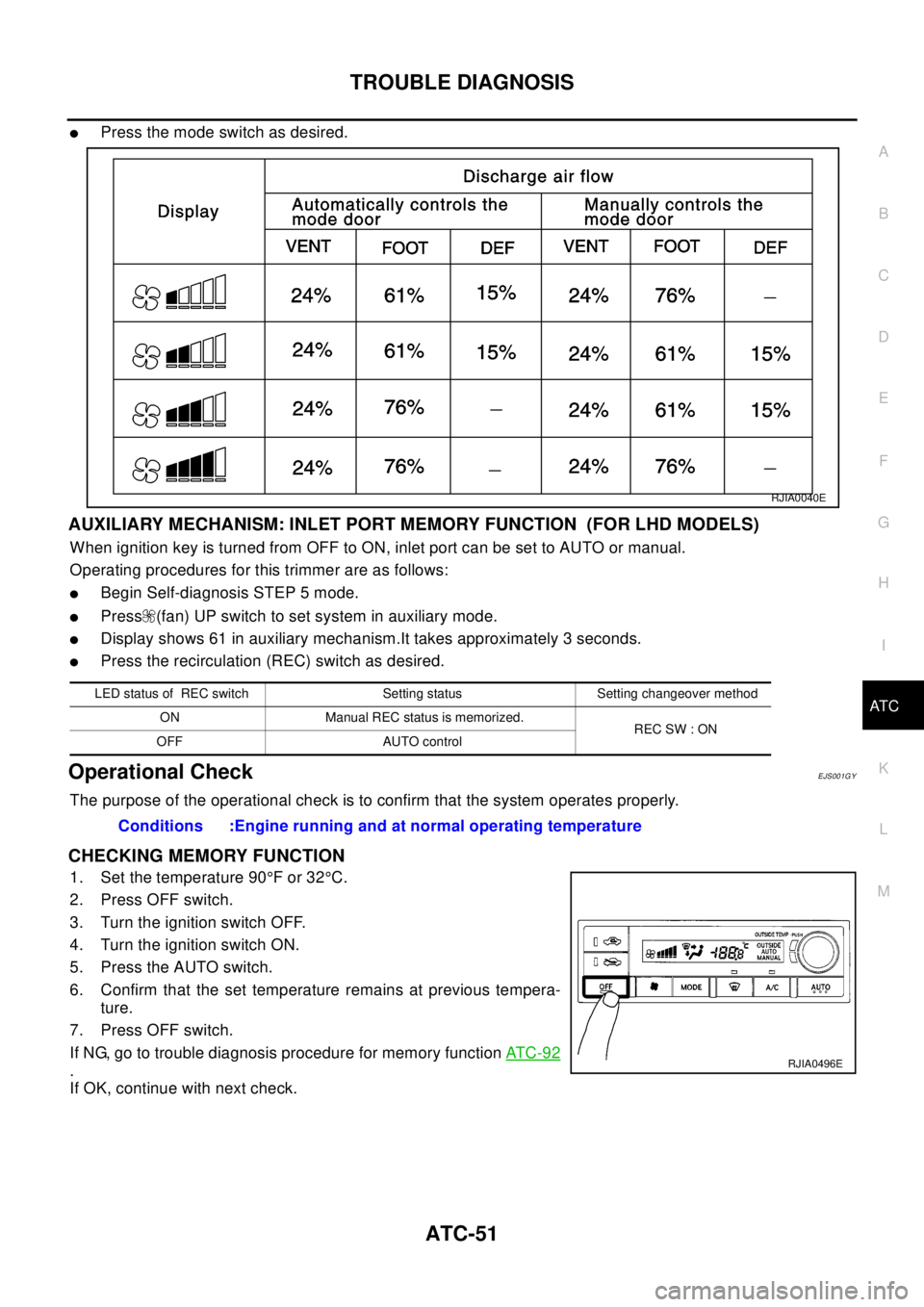

lPress the mode switch as desired.

AUXILIARY MECHANISM: INLET PORT MEMORY FUNCTION (FOR LHD MODELS)

When ignition key is turned from OFF to ON, inlet port can be set to AUTO or manual.

Operating procedures for this trimmer are as follows:

lBegin Self-diagnosis STEP 5 mode.

lPress (fan) UP switch to set system in auxiliary mode.

lDisplay shows 61 in auxiliary mechanism.It takes approximately 3 seconds.

lPress the recirculation (REC) switch as desired.

Operational CheckEJS001GY

The purpose of the operational check is to confirm that the system operates properly.

CHECKING MEMORY FUNCTION

1. Set the temperature 90°For32°C.

2. Press OFF switch.

3. Turn the ignition switch OFF.

4. Turn the ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous tempera-

ture.

7. Press OFF switch.

If NG, go to trouble diagnosis procedure for memory functionAT C - 9 2

.

If OK, continue with next check.

RJIA0040E

LED status of REC switch Setting status Setting changeover method

ON Manual REC status is memorized.

REC SW : ON

OFF AUTO control

Conditions :Engine running and at normal operating temperature

RJIA0496E

Page 633 of 3066

TROUBLE DIAGNOSIS

ATC-55

C

D

E

F

G

H

I

K

L

MA

B

AT C

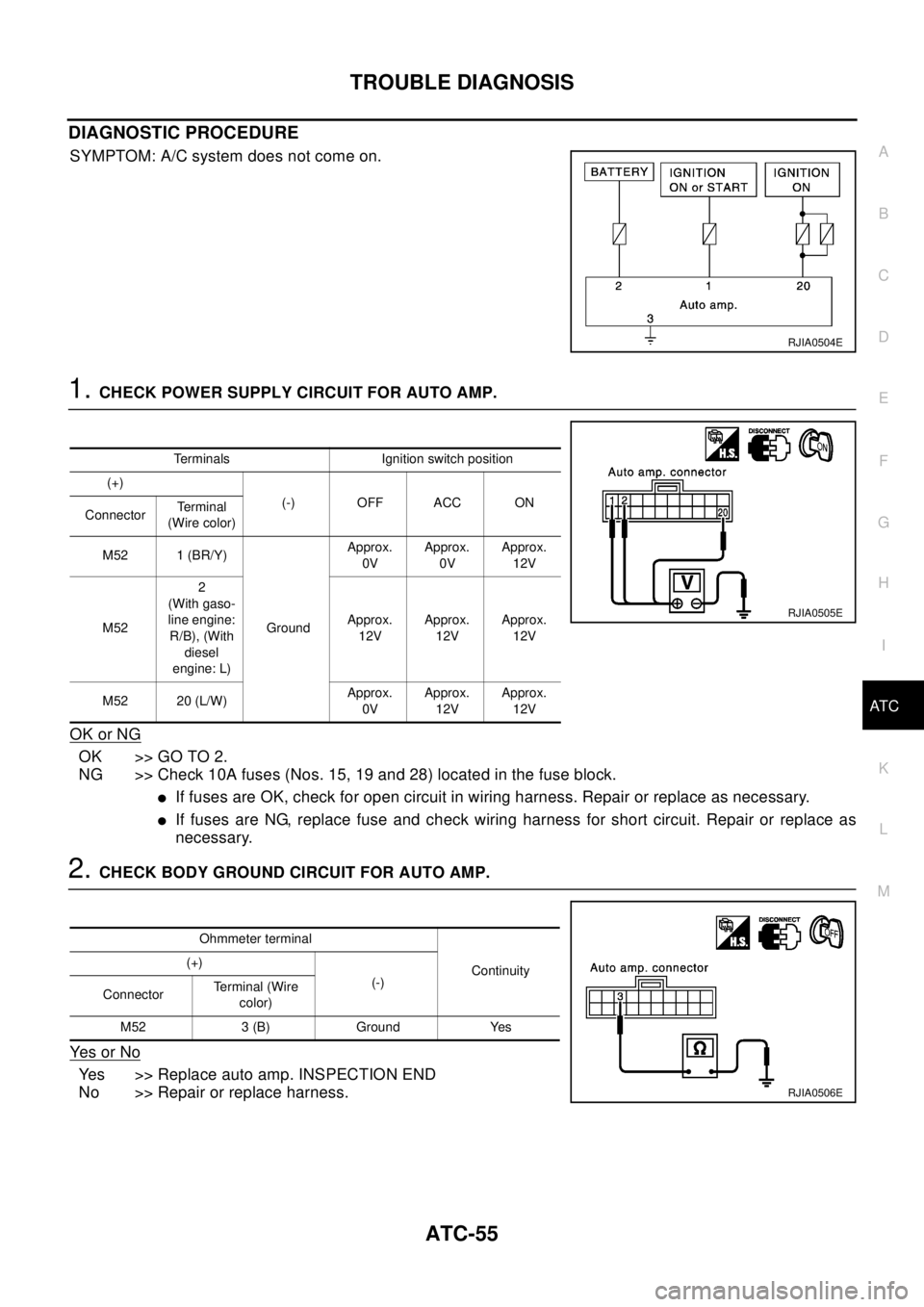

DIAGNOSTIC PROCEDURE

SYMPTOM: A/C system does not come on.

1.CHECK POWER SUPPLY CIRCUIT FOR AUTO AMP.

OK or NG

OK >> GO TO 2.

NG >> Check 10A fuses (Nos. 15, 19 and 28) located in the fuse block.

lIf fuses are OK, check for open circuit in wiring harness. Repair or replace as necessary.

lIf fuses are NG, replace fuse and check wiring harness for short circuit. Repair or replace as

necessary.

2.CHECK BODY GROUND CIRCUIT FOR AUTO AMP.

Ye s o r N o

Yes >> Replace auto amp. INSPECTION END

No >> Repair or replace harness.

RJIA0504E

Terminals Ignition switch position

(+)

(-) OFF ACC ON

ConnectorTe r m i n a l

(Wire color)

M52 1 (BR/Y)

GroundApprox.

0VApprox.

0VApprox.

12V

M522

(With gaso-

line engine:

R/B), (With

diesel

engine: L)Approx.

12VApprox.

12VApprox.

12V

M52 20 (L/W)Approx.

0VApprox.

12VApprox.

12V

RJIA0505E

Ohmmeter terminal

Continuity (+)

(-)

ConnectorTerminal (Wire

color)

M52 3 (B) Ground Yes

RJIA0506E