bulb NISSAN X-TRAIL 2003 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1518 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide EC-404

[QR (WITHOUT EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Malfunction Indicator (MI)

EBS00BMG

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition swi NISSAN X-TRAIL 2003 Electronic User Guide EC-404

[QR (WITHOUT EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Malfunction Indicator (MI)

EBS00BMG

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition swi](/img/5/57402/w960_57402-1517.png)

EC-404

[QR (WITHOUT EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Malfunction Indicator (MI)

EBS00BMG

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON without

the engine running. This is a bulb check.

lIf the MI does not light up, refer toDI-39, "WARNING LAMPS",

or seeEC-526

.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following four functions.

MI Flashing without DTC

If the ECM is in Diagnostic Test Mode II, MI may flash when engine is running. In this case, check ECM diag-

nostic test mode.EC-405, "

HOW TO SWITCH DIAGNOSTIC TEST MODE".

How to switch the diagnostic test (function) modes, and details of the above functions are described laterEC-

405.

The following emission-related diagnostic information is cleared when the ECM memory is erased.

1. Diagnostic trouble codes

2. 1st trip diagnostic trouble codes

3. Freeze frame data

SAT652J

Diagnostic Test

ModeKEY and ENG.

Statu sFunction Explanation of Function

Mode I Ignition switch in

“ON” position

Engine stoppedBULB CHECK This function checks the MI bulb for damage (blown, open

circuit, etc.).

If the MI does not come on, check MI circuit.

Engine running MALFUNCTION

WARNINGThis is a usual driving condition. When a malfunction is

detected twice in two consecutive driving cycles (two trip

detection logic), the MI will light up to inform the driver that

a malfunction has been detected.

The following malfunctions will light up the MI in the 1st

trip.

lFail-safe mode

Mode II Ignition switch in

“ON” position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs and 1st trip DTCs to be read.

Engine running HEATED OXYGEN SENSOR 1

MONITORThis function allows the fuel mixture condition (lean or

rich), monitored by heated oxygen sensor 1, to be read.

Page 1519 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-405

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

4. 1st trip freeze frame data

5. Others

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

lIt is better to count the ti NISSAN X-TRAIL 2003 Electronic User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-405

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

4. 1st trip freeze frame data

5. Others

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

lIt is better to count the ti](/img/5/57402/w960_57402-1518.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-405

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

4. 1st trip freeze frame data

5. Others

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

lIt is better to count the time accurately with a clock.

lIt is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit

has a malfunction.

lAlways ECM returns to Diagnostic Test Mode I after ignition switch is turned “OFF”.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully released, turn ignition switch “ON” and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MI starts

blinking.

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

How to Set Diagnostic Test Mode II (Heated Oxygen Sensor 1 Monitor)

1. Set the ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer toEC-405, "How to Set Diagnostic

Test Mode II (Self-diagnostic Results)".

2. Start Engine.

ECM has entered to Diagnostic Test Mode II (Heated oxygen sensor 1 monitor).

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer toEC-405, "How to Set Diagnostic

Test Mode II (Self-diagnostic Results)".

2. Fully depress the accelerator pedal and keep it for more than 10 seconds.

The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

DIAGNOSTIC TEST MODE I — BULB CHECK

In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer toDI-39,

"WA RN ING LA MPS"or seeEC-526.

DIAGNOSTIC TEST MODE I — MALFUNCTION WARNING

lThese DTC numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

DIAGNOSTIC TEST MODE II — SELF-DIAGNOSTIC RESULTS

In this mode, the DTC and 1st trip DTC are indicated by the number of blinks of the MI as shown below.

PBIB0092E

MI Condition

ON When the malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

Page 1640 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide EC-526

[QR (WITHOUT EURO-OBD)]

DTC P0650 MI

DTC P0650 MI

PFP:24810

Component DescriptionEBS00BIH

Malfunction Indicator (MI) is located on the instrument panel. When the ignition switch is turned ON wi NISSAN X-TRAIL 2003 Electronic User Guide EC-526

[QR (WITHOUT EURO-OBD)]

DTC P0650 MI

DTC P0650 MI

PFP:24810

Component DescriptionEBS00BIH

Malfunction Indicator (MI) is located on the instrument panel. When the ignition switch is turned ON wi](/img/5/57402/w960_57402-1639.png)

EC-526

[QR (WITHOUT EURO-OBD)]

DTC P0650 MI

DTC P0650 MI

PFP:24810

Component DescriptionEBS00BIH

Malfunction Indicator (MI) is located on the instrument panel. When the ignition switch is turned ON without

engine running, MI will light up. This is a bulb check. When the engine is started, MI should go off. If MI

remains on, the on board diagnostic system has detected an engine system malfunction.

On Board Diagnosis LogicEBS00BII

FAIL -S AFE M OD E

ECM enters in fail-safe mode when both DTC P0650 and another DTC, which calls for MI to light up, are

detected at the same time.

DTC Confirmation ProcedureEBS00BIJ

NOTE:

If "DTC Confirmation Procedure" has been previously conducted, always turn ignition switch "OFF" and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch "ON" and wait at least 1 second.

2. Select "DATA MONITOR" mode with CONSULT-II.

3. Start engine and let it idle for 1 second.

4. If DTC is detected, go toEC-528, "

Diagnostic Procedure".

Overall Function CheckEBS00BOZ

Use this procedure to check the overall function of the mass air flow sensor circuit. During this check, a 1st trip

DTC might not be confirmed.

WITHOUT CONSULT-II

1. Turn ignition switch "ON".

2. Check that the MI is illuminated.

3. If NG, go toEC-528, "

Diagnostic Procedure".

IfOK,gotonextstep.

4. Start engine.

5. Check that the MI is not illuminated.

6. If NG, go toEC-528, "

Diagnostic Procedure".

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0650

0650Malfunction indicator

(MI) control circuit

lAn excessively high voltage is sent to ECM

through the MI circuit under the condition

that calls for MI light up.

lAn excessively low voltage is sent to ECM

through the MI circuit under the condition

that calls for MI not to light up.

lHarness or connectors

(MI circuit is open or shorted.)

lMI

Detected items Engine operating condition in fail-safe mode

MI circuit Engine speed will not rise more than 2,500 rpm due to the fuel cut

SEF058Y

Page 1781 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-667

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

Therefore, be sure to receive all keys from vehicle owner. Regarding the procedure of NATS initial-

ization and NATS ignition key NISSAN X-TRAIL 2003 Electronic User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-667

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

Therefore, be sure to receive all keys from vehicle owner. Regarding the procedure of NATS initial-

ization and NATS ignition key](/img/5/57402/w960_57402-1780.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-667

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

Therefore, be sure to receive all keys from vehicle owner. Regarding the procedure of NATS initial-

ization and NATS ignition key ID registration, refer to CONSULT-II operation manual, NATS.

Malfunction Indicator (MI)EBS0036Q

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON without

the engine running. This is a bulb check.

lIf the MI does not light up, refer toDI-39, "WARNING LAMPS"

or seeEC-825.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

On Board Diagnostic System Function

The on board diagnostic system has the following two functions.

Diagnostic Test Mode I - Bulb Check

In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer toDI-39,

"WA RN ING LA MPS"or seeEC-825.

Diagnostic Test Mode I - Malfunction Warning

SAT652J

Diagnostic Test

ModeKEY and ENG.

Sta tusFunction Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK This function checks the MI bulb for damage (blown, open

circuit, etc.).

IftheMIdoesnotcomeon,checkMIcircuit.(SeeEC-825,

"MI&DATA LINK CONNECTORS".)

Engine running MALFUNCTION

WARN IN GThis is a usual driving condition. When ECM detects a mal-

function, the MI will light up to inform the driver that a mal-

function has been detected.

MI Condition

ON When the malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

Page 2283 of 3066

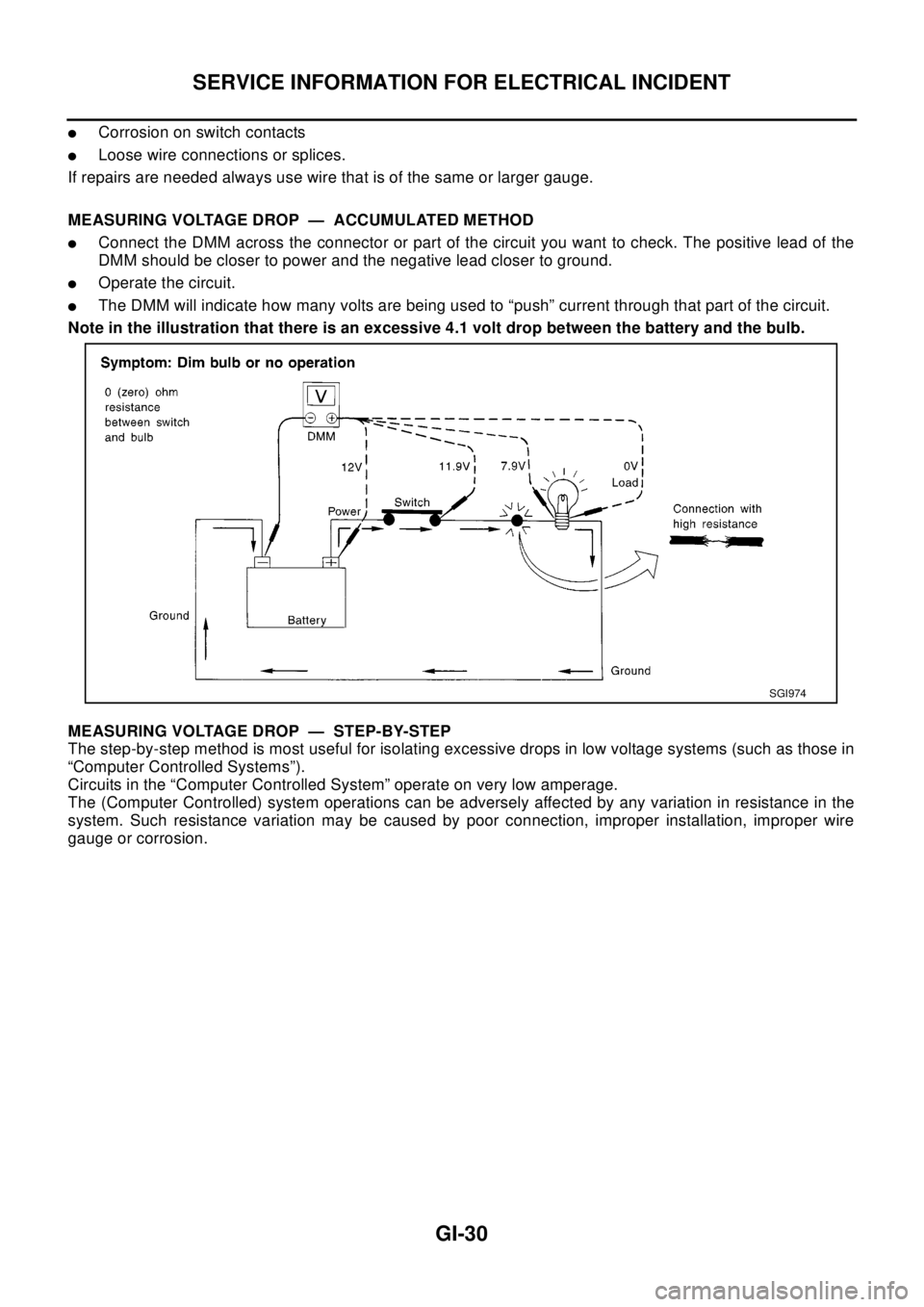

GI-30

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

lCorrosion on switch contacts

lLoose wire connections or splices.

If repairs are needed always use wire that is of the same or larger gauge.

MEASURING VOLTAGE DROP — ACCUMULATED METHOD

lConnect the DMM across the connector or part of the circuit you want to check. The positive lead of the

DMM should be closer to power and the negative lead closer to ground.

lOperate the circuit.

lThe DMM will indicate how many volts are being used to “push” current through that part of the circuit.

Note in the illustration that there is an excessive 4.1 volt drop between the battery and the bulb.

MEASURING VOLTAGE DROP — STEP-BY-STEP

The step-by-step method is most useful for isolating excessive drops in low voltage systems (such as those in

“Computer Controlled Systems”).

Circuits in the “Computer Controlled System” operate on very low amperage.

The (Computer Controlled) system operations can be adversely affected by any variation in resistance in the

system. Such resistance variation may be caused by poor connection, improper installation, improper wire

gauge or corrosion.

SGI974

Page 2360 of 3066

IDX-3

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Brake fluid level and line check ...........................BR-9

Brake hydraulic line ...........................................BR-11

Brake inspection ................................................MA-39

Brake lines and cables inspection .....................MA-39

Brake master cylinder ........................................BR-13

Brake pedal .........................................................BR-6

Brake switch ........................EC-329,EC-562,EC-810

BRK/SW - Wiring diagram ...EC-330,EC-564,EC-811

Bulb specifications ..............................................LT-67

Bumper, front .........................................................EI-6

Bumper, rear ..........................................................EI-9

C

Camshaft inspection(QR20DE) .........................EM-38

Camshaft inspection(YD22DDTi) ....................EM-150

Camshaft position sensor (CMPS) ..................EC-739

Camshaft position sensor (PHASE) ..EC-223,EC-507

Camshaft(QR20DE) ..........................................EM-33

Camshaft(YD22DDTi) ......................................EM-149

CAN - Wiring diagramEC-115,EC-461,LAN-6,LAN-12

CAN (Controller Area Network) .........AT-129,AT-351,

LAN-3

,LAN-5,LAN-11

CAN Communication ..........................................TF-53

CAN communicationEC-28,EC-114,EC-393,EC-460,

AT-129

,AT-351,BRC-53,BRC-59,BRC-90,BRC-108,

LAN-3

,LAN-5,LAN-11

Canister-See EVAP canister .............EC-374,EC-649

CHARGE - Wiring diagram ................................SC-13

Charging system ................................................SC-12

Chassis and body maintenance ........................MA-35

CHIME - Wiring diagram .....................................DI-54

CIGAR - Wiring diagram ..................................WW-25

Cigarette lighter ...............................................WW-25

Circuit breaker ...................................................PG-12

CKPS - Wiring diagram ...................................EC-736

Clearance lamp ........................................LT-4,LT-40

Clock ...................................................................DI-60

CLOCK - Wiring diagram ....................................DI-60

Closed loop control ..............................EC-25,EC-390

Clutch cover .......................................................CL-15

Clutch disc .........................................................CL-15

Clutch master cylinder .........................................CL-9

Clutch operating cylinder ...................................CL-11

Clutch pedal .........................................................CL-5

Clutch release bearing .......................................CL-13

Clutch release mechanism ................................CL-13

Clutch withdrawal lever ......................................CL-13

CMPS - Wiring diagram ...................................EC-741

Coil spring (rear) ...............................................RSU-8

Collision diagnosis ...........................................SRS-46

Combination meter .....................................DI-4,DI-22

Combination switch ................................LT-24,LT-44

Common rail fuel pressure sensor ...................EC-723

Component Location (auto A/C) .........ATC-31,MTC-4

Compression pressure(QR20DE) ......................EM-52

Compression pressure(YD22DDTi) .................EM-173

Compressor clutch removal and installation ..ATC-129

Compressor special service tool ......................ATC-11

Condenser .....................................................ATC-138

Connecting rod bearing clearance(QR20DE) ...EM-83

Connecting rod bearing clearance(YD22DDTi)EM-206

Connecting rod bushing clearance(QR20DE) ..EM-83

Connecting rod bushing clearance(YD22DDTi)EM-200

Connecting rod(QR20DE) .................................EM-82

Connecting rod(YD22DDTi) ..............EM-198,EM-202

Console box - See Instrument panel ..........IP-3,IP-10

CONSULT for engine ............EC-86,EC-434,EC-691

CONSUT for VDC ...........................................BRC-77

Control unit .....................................ATC-104,MTC-19

Control units (terminal arrangement) .................PG-73

Controller Area Network (CAN) ........AT-129,AT-351,

LAN-3

,LAN-5,LAN-11

Converter housing installation ...........AT-459,AT-556

COOL/F - Wiring diagram ...EC-315,EC-552,EC-763

Coolant mixture ratio .........................................MA-19

Coolant replacement(QR20DE) ........................MA-20

Coolant replacement(YD22DDTi) .....................MA-27

Cooling circuit (engine)(QR20DE) ......................CO-7

Cooling circuit (engine)(YD22DDTi) .................CO-28

Cooling fan control system(QR20DE) ...............CO-13

Cooling fan motor ..............................EC-324,EC-561

Cooling fan relay ................................EC-324,EC-561

Cooling fan(QR20DE) .......................................CO-13

Cooling fan(YD22DDTi) ....................................CO-34

Coupling sleeve (M/T) ...........................MT-19,MT-24

Cowl top ..............................................................EI-12

Cowl top cover ....................................................EI-12

Crankcase ventilation system ..........................EC-663

Crankcase ventilation system - See Positive crankcase

ventilation ...........................................EC-375

,EC-650

Crankshaft position sensor (POS) .....EC-217,EC-501

Crankshaft position sensor (TDC) ...................EC-734

Crankshaft(QR20DE) ........................................EM-65

Crankshaft(YD22DDTi) ...................................EM-200

CRFPS - Wiring diagram .................................EC-724

Cylinder block boring(QR20DE) .......................EM-86

Cylinder block boring(YD22DDTi) ...................EM-204

Cylinder block(QR20DE) ..................................EM-64

Cylinder block(YD22DDTi) ..............................EM-188

Cylinder head bolt tightening(QR20DE) ...........EM-54

Cylinder head bolt tightening(YD22DDTi) .......EM-175

Cylinder head gasket selection(YD22DDTi) ...EM-175

Cylinder head(QR20DE) ...................................EM-52

Cylinder head(YD22DDTi) ..............................EM-173

D

Data link connector ............................EC-371

,EC-646

Data link connector for Consult ...........EC-88,EC-435,

EC-691

Daytime light system .............................................LT-9

Daytime running light - See Daytime light systemLT-9

DEF - Wiring diagram .......................................GW-10

Desiccant Assembly .......................ATC-27,ATC-140

Diagnosis sensor unit .....................................SRS-39

Page 2399 of 3066

LT-1

LIGHTING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION

A

B

LT

LIGHTING SYSTEM

PRECAUTION ............................................................ 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precaution ................................................................ 3

Wiring Diagrams and Trouble Diagnosis .................. 3

HEADLAMP ................................................................ 4

System Description .................................................. 4

DESCRIPTION ...................................................... 4

LOW BEAM OPERATION ..................................... 4

HIGH BEAM OPERATION/FLASH-TO-PASS

OPERATION ......................................................... 4

Wiring Diagram — H/LAMP — ................................. 5

Trouble Diagnoses ................................................... 6

Aiming Adjustment ................................................... 6

LOW BEAM ........................................................... 7

Bulb Replacement .................................................... 8

HEAD LAMP ......................................................... 8

CLEARANCE LAMP ............................................. 8

Removal and Installation .......................................... 8

REMOVAL ............................................................. 8

INSTALLATION ..................................................... 8

HEADLAMP - DAYTIME LIGHT SYSTEM - ............... 9

System Description .................................................. 9

DESCRIPTION ...................................................... 9

HEADLAMP OPERATION (DAYTIME LIGHT

CANCEL OPERATION) ........................................ 9

DAYTIME LIGHT OPERATION ............................. 9

Schematic .............................................................. 10

Wiring Diagram -DTRL- ...........................................11

Trouble Diagnoses ................................................. 14

DAYTIME LIGHT UNIT INSPECTION TABLE .... 14

Bulb Replacement .................................................. 14

Aiming Adjustment ................................................. 14

HEADLAMP AIMING CONTROL ............................. 15

Wiring Diagram -H/AIM- ......................................... 15

Removal and Installation ........................................ 16

Switch Circuit Inspection ........................................ 16

TURN SIGNAL AND HAZARD WARNING LAMPS... 17System Description ................................................. 17

TURN SIGNAL OPERATION .............................. 17

HAZARD LAMP OPERATION ............................. 17

Wiring Diagram — TURN — ................................... 19

Trouble Diagnoses ................................................. 21

Electrical Components Inspection .......................... 21

COMBINATION FLASHER UNIT CHECK ........... 21

Bulb Replacement .................................................. 22

FRONT TURN SIGNAL LAMP ............................ 22

SIDE TURN SIGNAL LAMP ................................ 22

REAR TURN SIGNAL LAMP .............................. 22

Removal and Installation for Front Turn Signal Lamp... 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 22

Removal and Installation for Side Turn Signal Lamp... 23

Removal and Installation for Rear Turn Signal Lamp... 23

LIGHTING AND TURN SIGNAL SWITCH ................ 24

Removal and Installation ........................................ 24

Switch Circuit Inspection ........................................ 24

HAZARD SWITCH .................................................... 25

Removal and Installation ........................................ 25

REMOVAL ........................................................... 25

INSTALLATION ................................................... 25

STOP LAMP .............................................................. 26

Wiring Diagram — STOP/L — ................................ 26

Bulb Replacement .................................................. 27

STOP LAMP ........................................................ 27

HIGH-MOUNTED STOP LAMP ........................... 27

Removal and Installation ........................................ 27

STOP LAMP ........................................................ 27

HIGH-MOUNTED STOP LAMP ........................... 27

BACK-UP LAMP ....................................................... 28

Wiring Diagram — BACK/L — ................................ 28

Bulb Replacement .................................................. 29

Removal and Installation ........................................ 29

PARKING, LICENSE PLATE AND TAIL LAMPS ..... 30

Wiring Diagram — TAIL/L — .................................. 30

Bulb Replacement .................................................. 32

PARKING AND TAIL LAMPS .............................. 32

Page 2400 of 3066

LT-2

LICENSE PLATE LAMP ...................................... 32

Removal and Installation ........................................ 32

PARKING AND TAIL LAMPS ............................... 32

LICENSE PLATE LAMP ...................................... 32

FRONT FOG LAMP .................................................. 33

System Description ................................................. 33

DESCRIPTION .................................................... 33

FOG LAMP OPERATION .................................... 33

Wiring Diagram — F/FOG — .................................. 34

Aiming Adjustment .................................................. 35

Bulb Replacement .................................................. 36

Removal and Installation ........................................ 36

REMOVAL ........................................................... 36

INSTALLATION .................................................... 36

REAR FOG LAMP ..................................................... 37

Wiring Diagram -R/FOG-/Without Front Fog Lamp... 37

Wiring Diagram -R/FOG-/With Front Fog Lamp ..... 38

Bulb Replacement .................................................. 39

Removal and Installation ........................................ 39

REMOVAL ........................................................... 39

INSTALLATION .................................................... 39

CLEARANCE LAMP/TAIL LAMP ............................. 40

Bulb Rplacement (Clearance Lamp) ...................... 40

Bulb Replacement (Taillamp) .................................. 40

Removal and Installation of Clearance Lamp ......... 40

Removal and Installation of Taillamp ...................... 40

HIGH-MOUNTED STOP LAMP ................................ 41

Bulb Replacement .................................................. 41

Removal and Installation ........................................ 41

REAR COMBINATION LAMP ................................... 42

Wiring Diagram —STOP/L— .................................. 42

Bulb Replacement .................................................. 43

Removal and Installation ........................................ 43

REMOVAL ........................................................... 43

INSTALLATION .................................................... 43COMBINATION SWITCH ..........................................44

Removal and Installation .........................................44

Switch Circuit Inspection .........................................44

ILLUMINATION ..........................................................45

System Description .................................................45

Schematic ...............................................................46

Wiring Diagram -ILL-/LHD MODELS ......................47

Wiring Diagram -ILL-/RHD MODELS ......................51

INTERIOR ROOM LAMP ..........................................55

System Description .................................................55

POWER SUPPLY AND GROUND .......................55

SWITCH OPERATION .........................................55

INTERIOR ROOM LAMP TIMER OPERATION ... 55

ON-OFF CONTROL .............................................56

Wiring Diagram -ROOM/L- ......................................57

Interior Room Lamp Timer Does Not Operate ........59

Interior Room Lamp Timer Does Not Cancel ..........62

Bulb Replacement ...................................................63

INTERIOR ROOM LAMP .....................................63

LUGGAGE ROOM LAMP ....................................63

Removal and Installation .........................................64

INTERIOR ROOM LAMP .....................................64

LUGGAGE ROOM LAMP ....................................64

SPOT LAMPS ............................................................65

Wiring Diagram -INT/L- ...........................................65

Bulb Replacement ...................................................66

SPOT LAMP (WITHOUT SUNROOF) .................66

SPOT LAMP (WITH SUNROOF) .........................66

Removal and Installation .........................................66

SPOT LAMP (WITHOUT SUNROOF) .................66

SPOT LAMP (WITH SUNROOF) .........................66

BULB SPECIFICATIONS ..........................................67

Headlamp ................................................................67

Exterior Lamp ..........................................................67

Interior Lamp/Illumination ........................................67

Page 2401 of 3066

PRECAUTION

LT-3

C

D

E

F

G

H

I

J

L

MA

B

LT

PRECAUTIONPFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS003KR

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WA RN ING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connectors.

PrecautionEKS003KS

lDo not touch the glass of bulb directly by hand. Keep grease and other oily matters away from it. Do not

touch bulb by hand while it is lit or right after being turned off. Burning may result.

lDo not leave bulb out of headlamp reflector for a long time because dust, moisture smoke, etc. may affect

the performance of the headlamp. When replacing the bulb, be sure to replace it with a new one.

lAdjust aiming by tightening aiming screw. (To adjust it toward loosening side, first loosen adjusting screw,

and then make adjustment by tightening.)

lTo remove soil or sealant of bulbs, do not use organic solvent (thinner, gasoline, etc.)

lWhen replacing bulb, be sure to hold bulb socket and pull it out straight. If wiring harness of the bulb is

pulled at an angle, the bulb may be caught in the lamp, making it difficult to take out.

Wiring Diagrams and Trouble DiagnosisEKS003KT

Whenyoureadwiringdiagrams,refertothefollowings:

lRefer toGI-14, "How to Read Wiring Diagrams"in GI section

lRefer toPG-2, "POWER SUPPLY ROUTING"for power distribution circuit in PG section

When you perform trouble diagnosis, refer to the followings:

lRefer toGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES"in GI section

lRefer toGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"in GI section

Page 2404 of 3066

LT-6

HEADLAMP

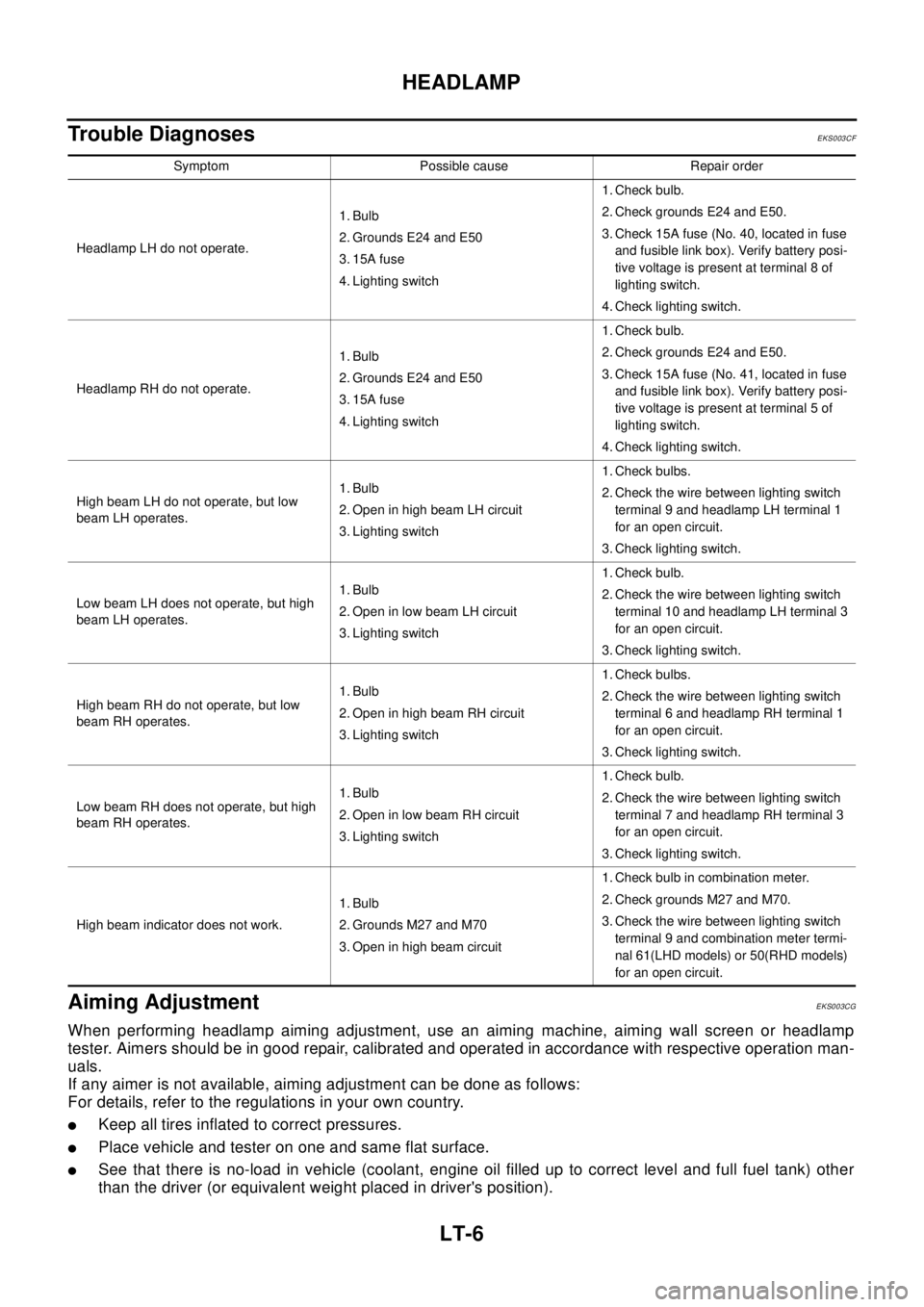

Trouble Diagnoses

EKS003CF

Aiming AdjustmentEKS003CG

When performing headlamp aiming adjustment, use an aiming machine, aiming wall screen or headlamp

tester. Aimers should be in good repair, calibrated and operated in accordance with respective operation man-

uals.

If any aimer is not available, aiming adjustment can be done as follows:

For details, refer to the regulations in your own country.

lKeep all tires inflated to correct pressures.

lPlace vehicle and tester on one and same flat surface.

lSee that there is no-load in vehicle (coolant, engine oil filled up to correct level and full fuel tank) other

than the driver (or equivalent weight placed in driver's position).

Symptom Possible cause Repair order

Headlamp LH do not operate.1. Bulb

2. Grounds E24 and E50

3. 15A fuse

4. Lighting switch1. Check bulb.

2. Check grounds E24 and E50.

3. Check 15A fuse (No. 40, located in fuse

and fusible link box). Verify battery posi-

tive voltage is present at terminal 8 of

lighting switch.

4. Check lighting switch.

Headlamp RH do not operate.1. Bulb

2. Grounds E24 and E50

3. 15A fuse

4. Lighting switch1. Check bulb.

2. Check grounds E24 and E50.

3. Check 15A fuse (No. 41, located in fuse

and fusible link box). Verify battery posi-

tive voltage is present at terminal 5 of

lighting switch.

4. Check lighting switch.

High beam LH do not operate, but low

beam LH operates.1. Bulb

2. Open in high beam LH circuit

3. Lighting switch1. Check bulbs.

2. Check the wire between lighting switch

terminal 9 and headlamp LH terminal 1

for an open circuit.

3. Check lighting switch.

Low beam LH does not operate, but high

beam LH operates.1. Bulb

2. Open in low beam LH circuit

3. Lighting switch1. Check bulb.

2. Check the wire between lighting switch

terminal 10 and headlamp LH terminal 3

for an open circuit.

3. Check lighting switch.

High beam RH do not operate, but low

beam RH operates.1. Bulb

2. Open in high beam RH circuit

3. Lighting switch1. Check bulbs.

2. Check the wire between lighting switch

terminal 6 and headlamp RH terminal 1

for an open circuit.

3. Check lighting switch.

Low beam RH does not operate, but high

beam RH operates.1. Bulb

2. Open in low beam RH circuit

3. Lighting switch1. Check bulb.

2. Check the wire between lighting switch

terminal 7 and headlamp RH terminal 3

for an open circuit.

3. Check lighting switch.

High beam indicator does not work.1. Bulb

2. Grounds M27 and M70

3. Open in high beam circuit1. Check bulb in combination meter.

2. Check grounds M27 and M70.

3. Check the wire between lighting switch

terminal 9 and combination meter termi-

nal 61(LHD models) or 50(RHD models)

for an open circuit.