engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 623 of 3066

TROUBLE DIAGNOSIS

ATC-45

C

D

E

F

G

H

I

K

L

MA

B

AT C

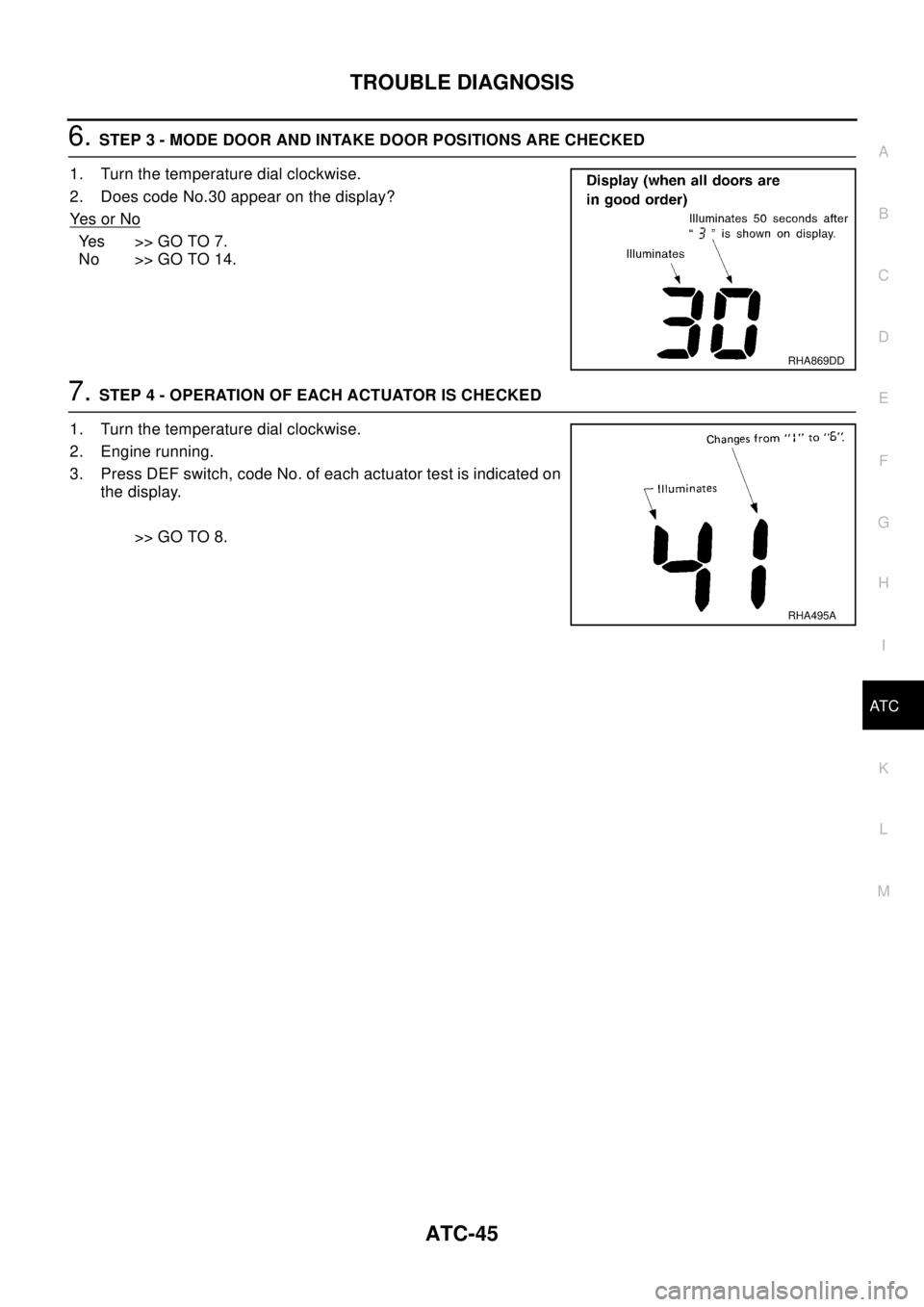

6.STEP 3 - MODE DOOR AND INTAKE DOOR POSITIONS ARE CHECKED

1. Turn the temperature dial clockwise.

2. Does code No.30 appear on the display?

Ye s o r N o

Yes >>GOTO7.

No >> GO TO 14.

7.STEP 4 - OPERATION OF EACH ACTUATOR IS CHECKED

1. Turn the temperature dial clockwise.

2. Engine running.

3. Press DEF switch, code No. of each actuator test is indicated on

the display.

>> GO TO 8.

RHA869DD

RHA495A

Page 629 of 3066

TROUBLE DIAGNOSIS

ATC-51

C

D

E

F

G

H

I

K

L

MA

B

AT C

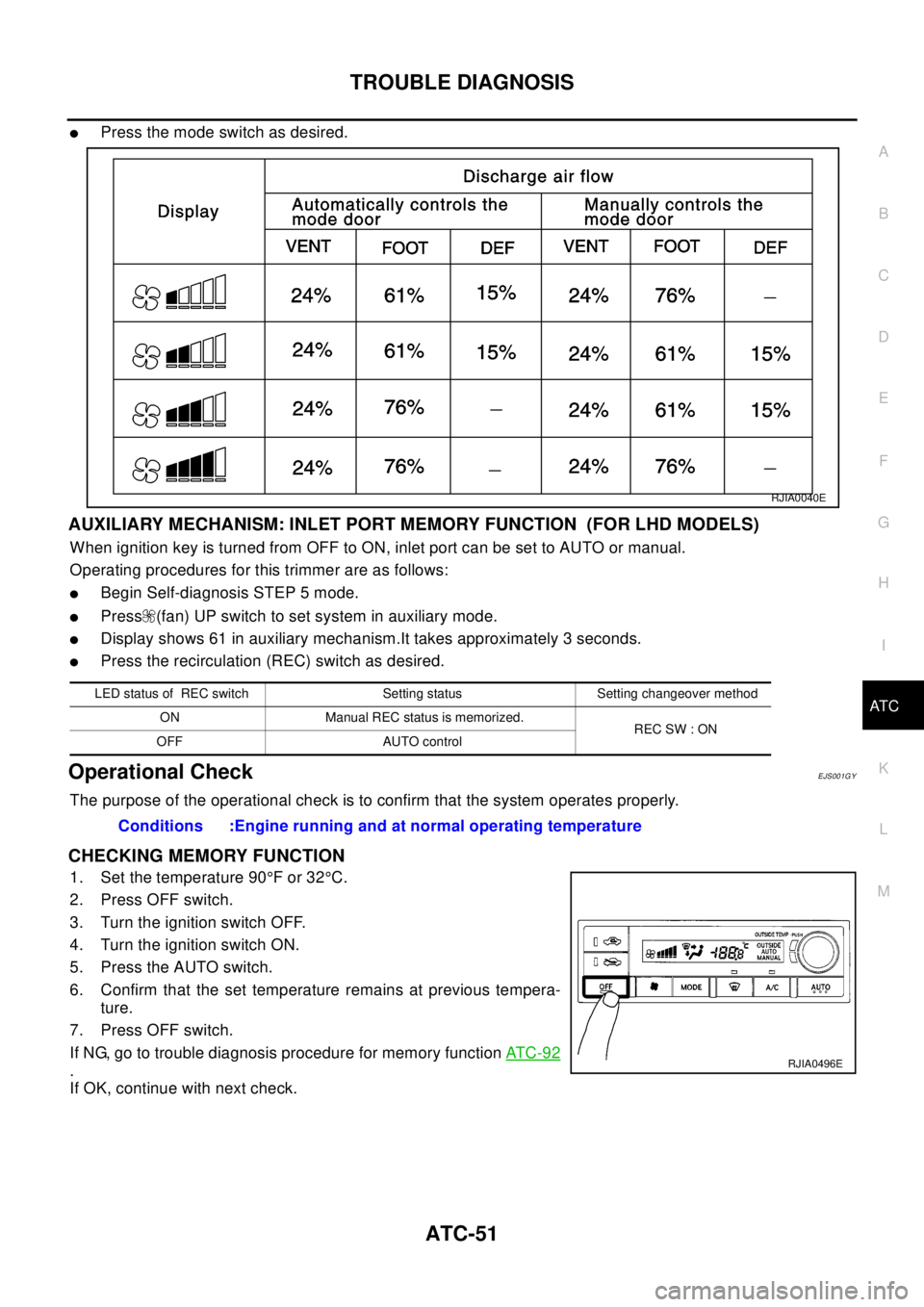

lPress the mode switch as desired.

AUXILIARY MECHANISM: INLET PORT MEMORY FUNCTION (FOR LHD MODELS)

When ignition key is turned from OFF to ON, inlet port can be set to AUTO or manual.

Operating procedures for this trimmer are as follows:

lBegin Self-diagnosis STEP 5 mode.

lPress (fan) UP switch to set system in auxiliary mode.

lDisplay shows 61 in auxiliary mechanism.It takes approximately 3 seconds.

lPress the recirculation (REC) switch as desired.

Operational CheckEJS001GY

The purpose of the operational check is to confirm that the system operates properly.

CHECKING MEMORY FUNCTION

1. Set the temperature 90°For32°C.

2. Press OFF switch.

3. Turn the ignition switch OFF.

4. Turn the ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous tempera-

ture.

7. Press OFF switch.

If NG, go to trouble diagnosis procedure for memory functionAT C - 9 2

.

If OK, continue with next check.

RJIA0040E

LED status of REC switch Setting status Setting changeover method

ON Manual REC status is memorized.

REC SW : ON

OFF AUTO control

Conditions :Engine running and at normal operating temperature

RJIA0496E

Page 633 of 3066

TROUBLE DIAGNOSIS

ATC-55

C

D

E

F

G

H

I

K

L

MA

B

AT C

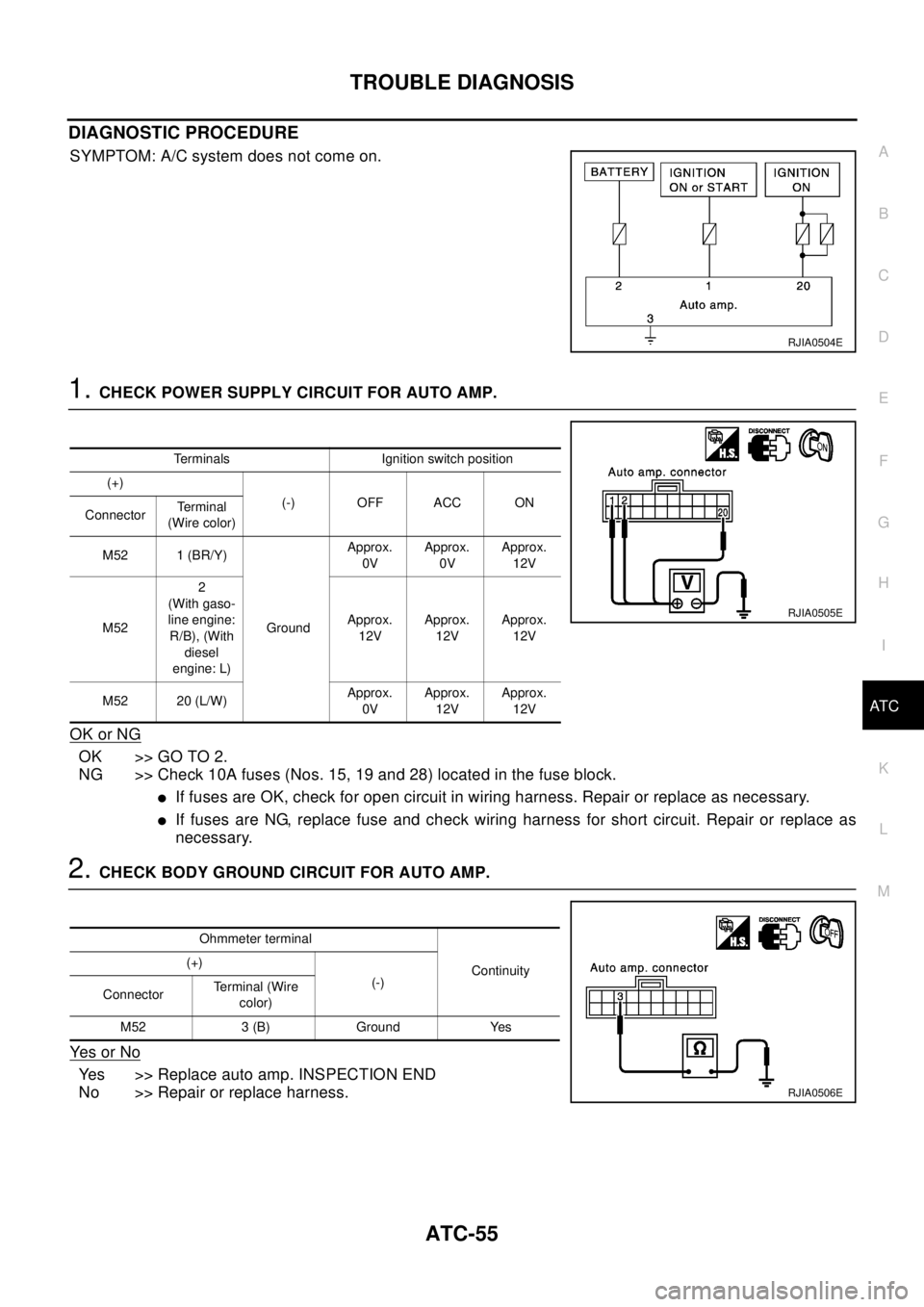

DIAGNOSTIC PROCEDURE

SYMPTOM: A/C system does not come on.

1.CHECK POWER SUPPLY CIRCUIT FOR AUTO AMP.

OK or NG

OK >> GO TO 2.

NG >> Check 10A fuses (Nos. 15, 19 and 28) located in the fuse block.

lIf fuses are OK, check for open circuit in wiring harness. Repair or replace as necessary.

lIf fuses are NG, replace fuse and check wiring harness for short circuit. Repair or replace as

necessary.

2.CHECK BODY GROUND CIRCUIT FOR AUTO AMP.

Ye s o r N o

Yes >> Replace auto amp. INSPECTION END

No >> Repair or replace harness.

RJIA0504E

Terminals Ignition switch position

(+)

(-) OFF ACC ON

ConnectorTe r m i n a l

(Wire color)

M52 1 (BR/Y)

GroundApprox.

0VApprox.

0VApprox.

12V

M522

(With gaso-

line engine:

R/B), (With

diesel

engine: L)Approx.

12VApprox.

12VApprox.

12V

M52 20 (L/W)Approx.

0VApprox.

12VApprox.

12V

RJIA0505E

Ohmmeter terminal

Continuity (+)

(-)

ConnectorTerminal (Wire

color)

M52 3 (B) Ground Yes

RJIA0506E

Page 646 of 3066

ATC-68

TROUBLE DIAGNOSIS

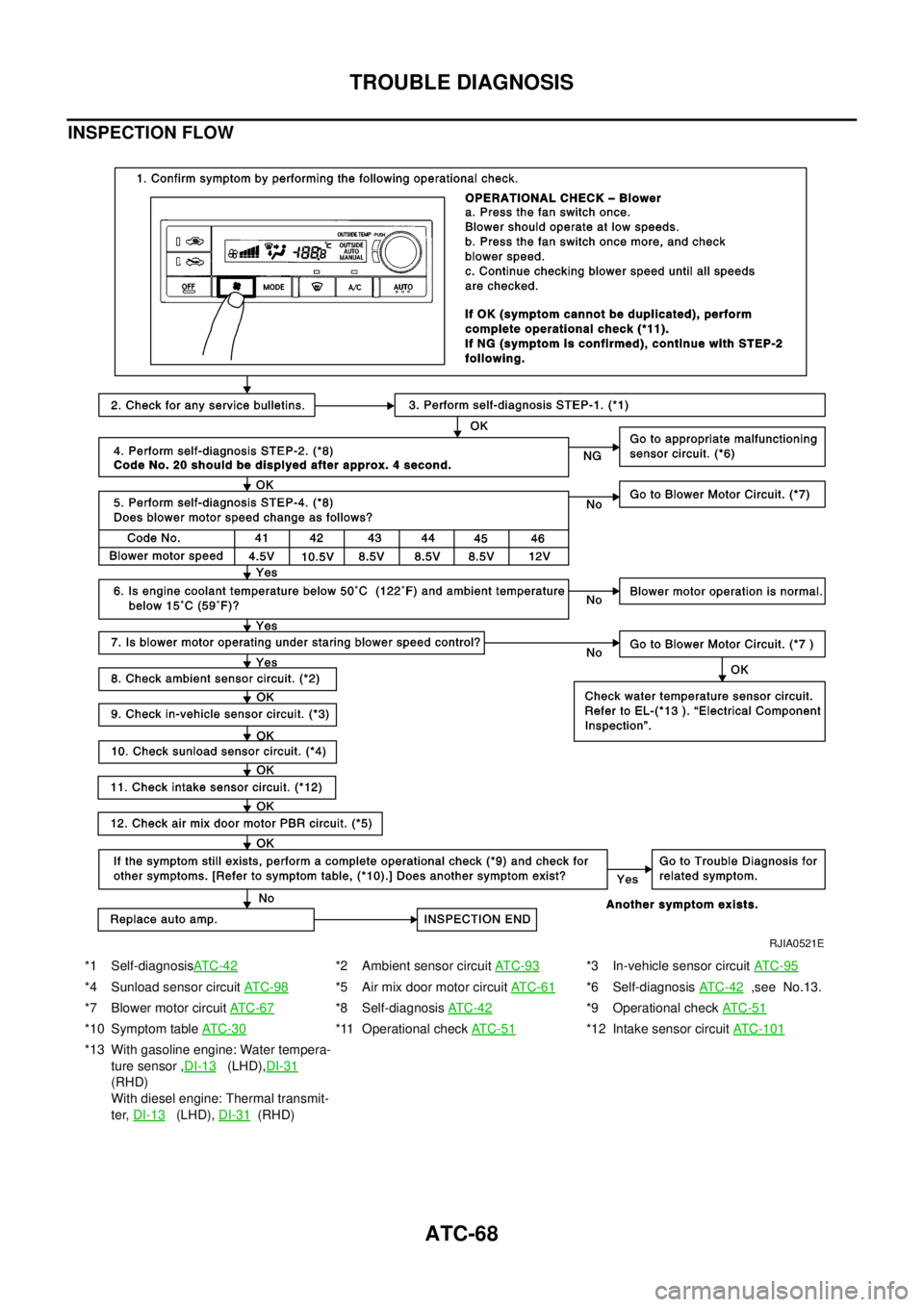

INSPECTION FLOW

*1 Self-diagnosisAT C -4 2*2 Ambient sensor circuitAT C - 9 3*3 In-vehicle sensor circuitAT C - 9 5

*4 Sunload sensor circuitAT C - 9 8*5 Air mix door motor circuitAT C - 6 1*6 Self-diagnosisAT C - 4 2,see No.13.

*7 Blower motor circuitAT C -6 7

*8 Self-diagnosisAT C -4 2*9 Operational checkAT C -5 1

*10 Symptom tableAT C -3 0*11 Operational checkAT C - 5 1*12 Intake sensor circuitATC-101

*13 With gasoline engine: Water tempera-

ture sensor ,DI-13

(LHD),DI-31

(RHD)

With diesel engine: Thermal transmit-

ter,DI-13

(LHD),DI-31(RHD)

RJIA0521E

Page 647 of 3066

TROUBLE DIAGNOSIS

ATC-69

C

D

E

F

G

H

I

K

L

MA

B

AT C

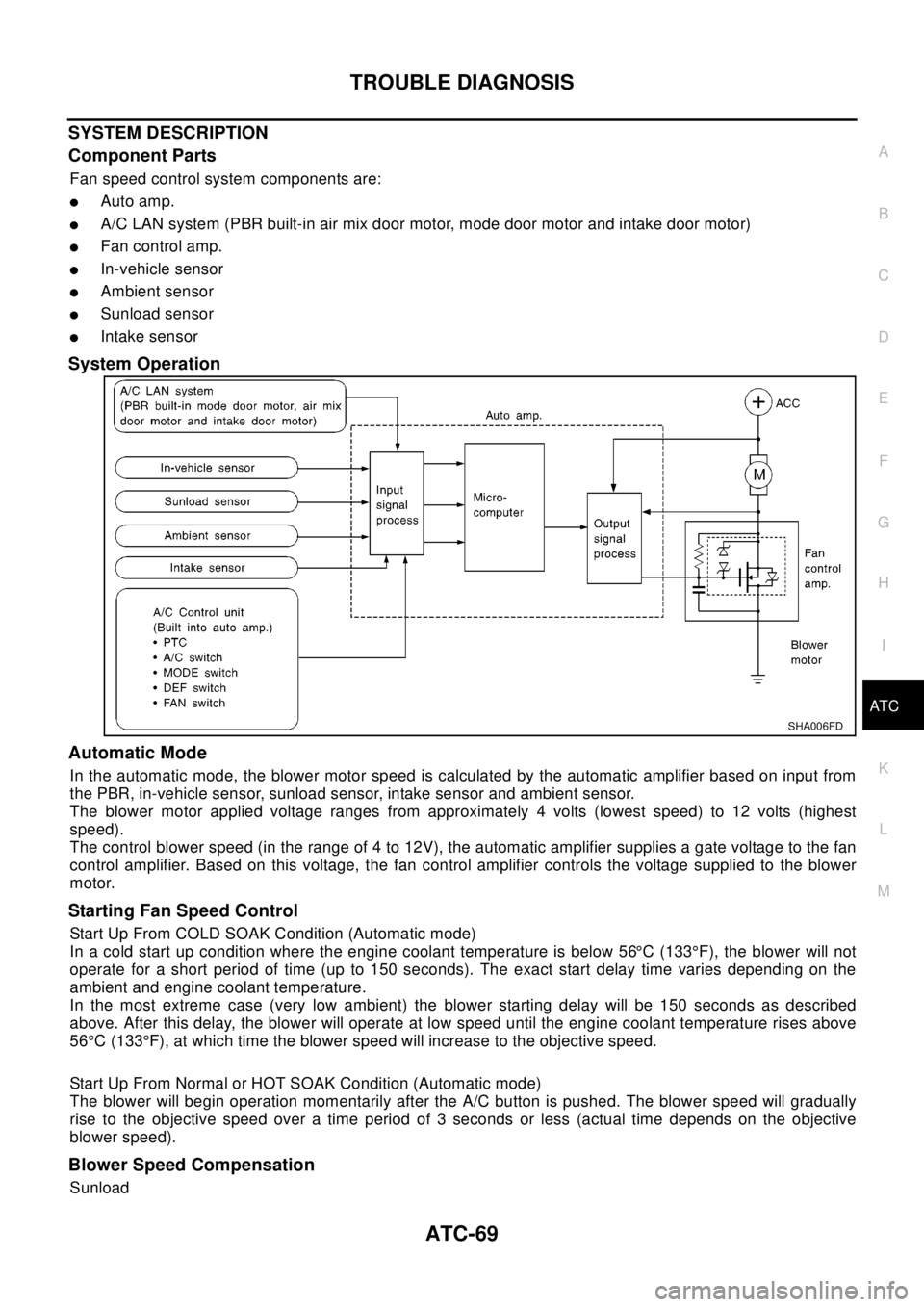

SYSTEM DESCRIPTION

Component Parts

Fan speed control system components are:

lAuto amp.

lA/C LAN system (PBR built-in air mix door motor, mode door motor and intake door motor)

lFan control amp.

lIn-vehicle sensor

lAmbient sensor

lSunload sensor

lIntake sensor

System Operation

Automatic Mode

In the automatic mode, the blower motor speed is calculated by the automatic amplifier based on input from

the PBR, in-vehicle sensor, sunload sensor, intake sensor and ambient sensor.

The blower motor applied voltage ranges from approximately 4 volts (lowest speed) to 12 volts (highest

speed).

The control blower speed (in the range of 4 to 12V), the automatic amplifier supplies a gate voltage to the fan

control amplifier. Based on this voltage, the fan control amplifier controls the voltage supplied to the blower

motor.

Starting Fan Speed Control

Start Up From COLD SOAK Condition (Automatic mode)

In a cold start up condition where the engine coolant temperature is below 56°C (133°F), the blower will not

operate for a short period of time (up to 150 seconds). The exact start delay time varies depending on the

ambient and engine coolant temperature.

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at low speed until the engine coolant temperature rises above

56°C (133°F), at which time the blower speed will increase to the objective speed.

Start Up From Normal or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the A/C button is pushed. The blower speed will gradually

rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

Blower Speed Compensation

Sunload

SHA006FD

Page 653 of 3066

TROUBLE DIAGNOSIS

ATC-75

C

D

E

F

G

H

I

K

L

MA

B

AT C

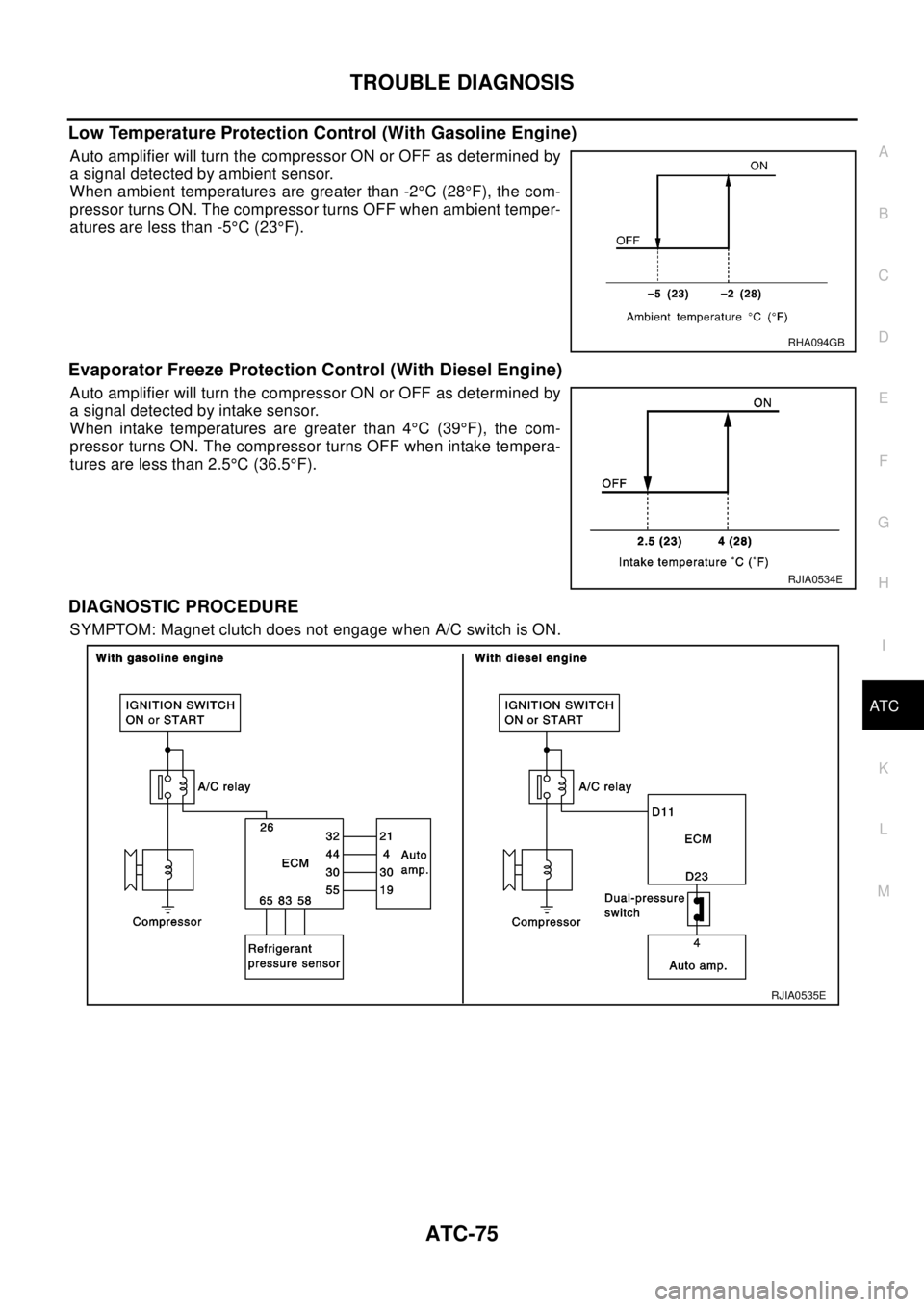

Low Temperature Protection Control (With Gasoline Engine)

Auto amplifier will turn the compressor ON or OFF as determined by

a signal detected by ambient sensor.

When ambient temperatures are greater than -2°C(28°F), the com-

pressor turns ON. The compressor turns OFF when ambient temper-

atures are less than -5°C(23°F).

Evaporator Freeze Protection Control (With Diesel Engine)

Auto amplifier will turn the compressor ON or OFF as determined by

a signal detected by intake sensor.

When intake temperatures are greater than 4°C(39°F), the com-

pressor turns ON. The compressor turns OFF when intake tempera-

tures are less than 2.5°C (36.5°F).

DIAGNOSTIC PROCEDURE

SYMPTOM: Magnet clutch does not engage when A/C switch is ON.

RHA094GB

RJIA0534E

RJIA0535E

Page 655 of 3066

TROUBLE DIAGNOSIS

ATC-77

C

D

E

F

G

H

I

K

L

MA

B

AT C

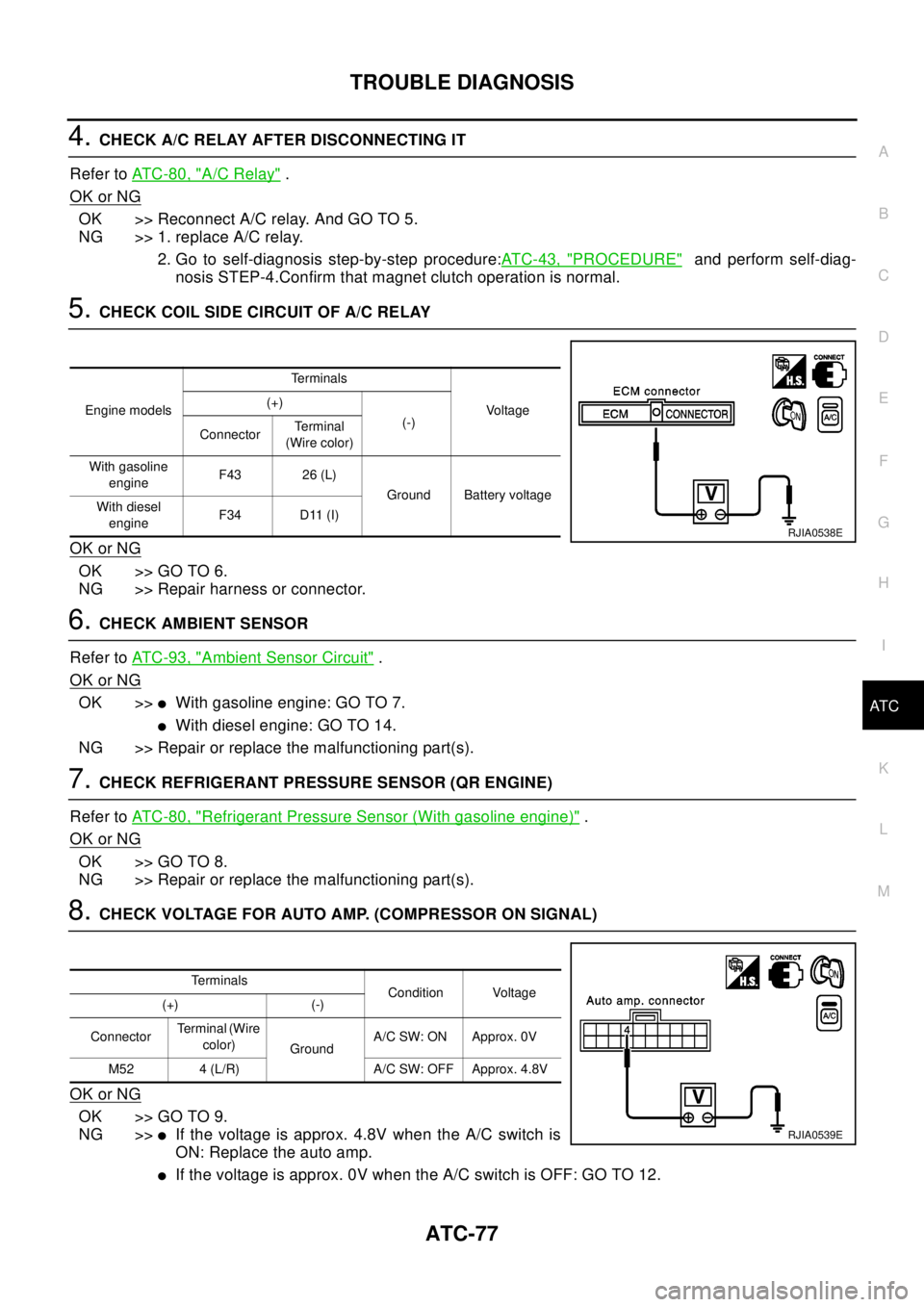

4.CHECK A/C RELAY AFTER DISCONNECTING IT

Refer toAT C - 8 0 , "

A/C Relay".

OK or NG

OK >>ReconnectA/Crelay.AndGOTO5.

NG >> 1. replace A/C relay.

2. Go to self-diagnosis step-by-step procedure:ATC-43, "

PROCEDURE"and perform self-diag-

nosis STEP-4.Confirm that magnet clutch operation is normal.

5.CHECK COIL SIDE CIRCUIT OF A/C RELAY

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK AMBIENT SENSOR

Refer toAT C - 9 3 , "

Ambient Sensor Circuit".

OK or NG

OK >>lWith gasoline engine: GO TO 7.

lWith diesel engine: GO TO 14.

NG >> Repair or replace the malfunctioning part(s).

7.CHECK REFRIGERANT PRESSURE SENSOR (QR ENGINE)

Refer toAT C - 8 0 , "

Refrigerant Pressure Sensor (With gasoline engine)".

OK or NG

OK >> GO TO 8.

NG >> Repair or replace the malfunctioning part(s).

8.CHECK VOLTAGE FOR AUTO AMP. (COMPRESSOR ON SIGNAL)

OK or NG

OK >> GO TO 9.

NG >>

lIf the voltage is approx. 4.8V when the A/C switch is

ON: Replace the auto amp.

lIf the voltage is approx. 0V when the A/C switch is OFF: GO TO 12.

Engine modelsTe r m i n a l s

Vo l ta g e (+)

(-)

ConnectorTe r m i n a l

(Wire color)

With gasoline

engineF43 26 (L)

Ground Battery voltage

With diesel

engineF34 D11 (I)

RJIA0538E

Te r m i n a l s

Condition Voltage

(+) (-)

ConnectorTerminal (Wire

color)

GroundA/C SW: ON Approx. 0V

M52 4 (L/R) A/C SW: OFF Approx. 4.8V

RJIA0539E

Page 657 of 3066

TROUBLE DIAGNOSIS

ATC-79

C

D

E

F

G

H

I

K

L

MA

B

AT C

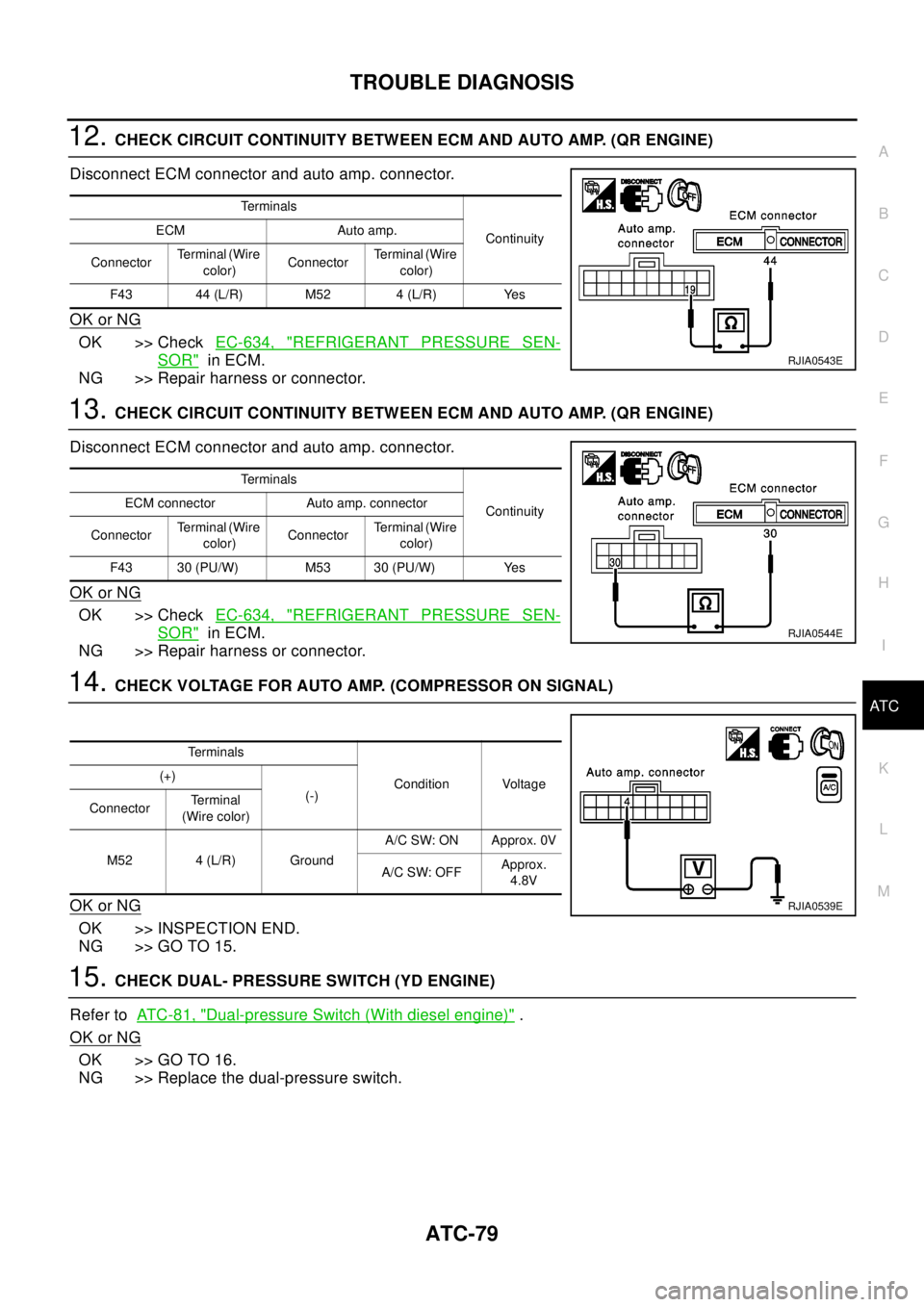

12.CHECK CIRCUIT CONTINUITY BETWEEN ECM AND AUTO AMP. (QR ENGINE)

Disconnect ECM connector and auto amp. connector.

OK or NG

OK >> CheckEC-634, "REFRIGERANT PRESSURE SEN-

SOR"in ECM.

NG >> Repair harness or connector.

13.CHECK CIRCUIT CONTINUITY BETWEEN ECM AND AUTO AMP. (QR ENGINE)

Disconnect ECM connector and auto amp. connector.

OK or NG

OK >> CheckEC-634, "REFRIGERANT PRESSURE SEN-

SOR"in ECM.

NG >> Repair harness or connector.

14.CHECK VOLTAGE FOR AUTO AMP. (COMPRESSOR ON SIGNAL)

OK or NG

OK >> INSPECTION END.

NG >> GO TO 15.

15.CHECK DUAL- PRESSURE SWITCH (YD ENGINE)

Refer toAT C - 8 1 , "

Dual-pressure Switch (With diesel engine)".

OK or NG

OK >> GO TO 16.

NG >> Replace the dual-pressure switch.

Te r m i n a l s

Continuity ECM Auto amp.

ConnectorTerminal (Wire

color)ConnectorTerminal (Wire

color)

F43 44 (L/R) M52 4 (L/R) Yes

RJIA0543E

Te r m i n a l s

Continuity ECM connector Auto amp. connector

ConnectorTerminal (Wire

color)ConnectorTerminal (Wire

color)

F43 30 (PU/W) M53 30 (PU/W) Yes

RJIA0544E

Te r m i n a l s

Condition Voltage (+)

(-)

ConnectorTe r m i n a l

(Wire color)

M52 4 (L/R) GroundA/C SW: ON Approx. 0V

A/C SW: OFFApprox.

4.8V

RJIA0539E

Page 658 of 3066

ATC-80

TROUBLE DIAGNOSIS

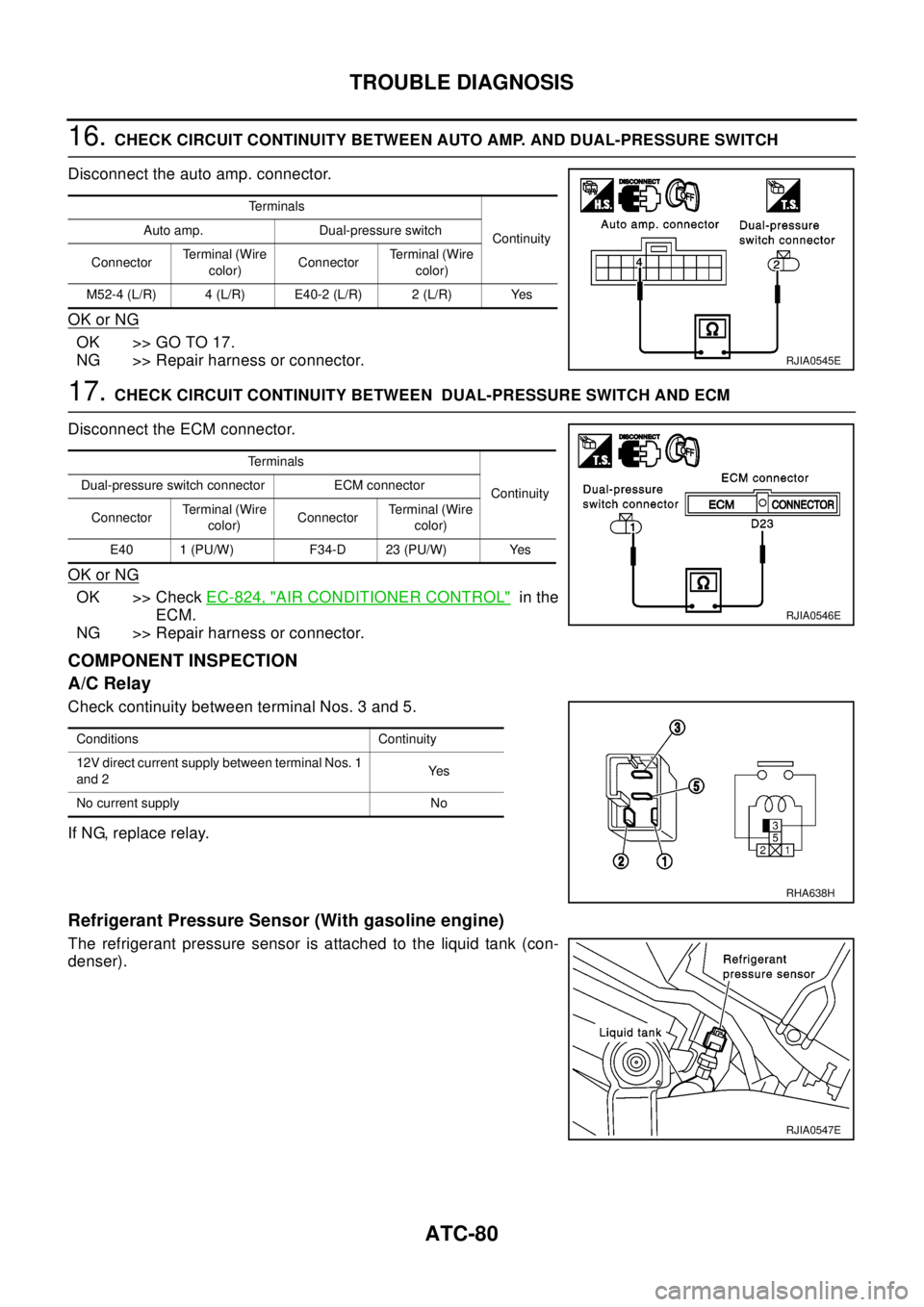

16.CHECK CIRCUIT CONTINUITY BETWEEN AUTO AMP. AND DUAL-PRESSURE SWITCH

Disconnect the auto amp. connector.

OK or NG

OK >> GO TO 17.

NG >> Repair harness or connector.

17.CHECK CIRCUIT CONTINUITY BETWEEN DUAL-PRESSURE SWITCH AND ECM

Disconnect the ECM connector.

OK or NG

OK >> CheckEC-824, "AIR CONDITIONER CONTROL"in the

ECM.

NG >> Repair harness or connector.

COMPONENT INSPECTION

A/C Relay

Check continuity between terminal Nos. 3 and 5.

If NG, replace relay.

Refrigerant Pressure Sensor (With gasoline engine)

The refrigerant pressure sensor is attached to the liquid tank (con-

denser).

Te r m i n a l s

Continuity Auto amp. Dual-pressure switch

ConnectorTerminal (Wire

color)ConnectorTerminal (Wire

color)

M52-4 (L/R) 4 (L/R) E40-2 (L/R) 2 (L/R) Yes

RJIA0545E

Te r m i n a l s

Continuity Dual-pressure switch connector ECM connector

ConnectorTerminal (Wire

color)ConnectorTerminal (Wire

color)

E40 1 (PU/W) F34-D 23 (PU/W) Yes

RJIA0546E

Conditions Continuity

12V direct current supply between terminal Nos. 1

and 2Ye s

No current supply No

RHA638H

RJIA0547E

Page 659 of 3066

TROUBLE DIAGNOSIS

ATC-81

C

D

E

F

G

H

I

K

L

MA

B

AT C

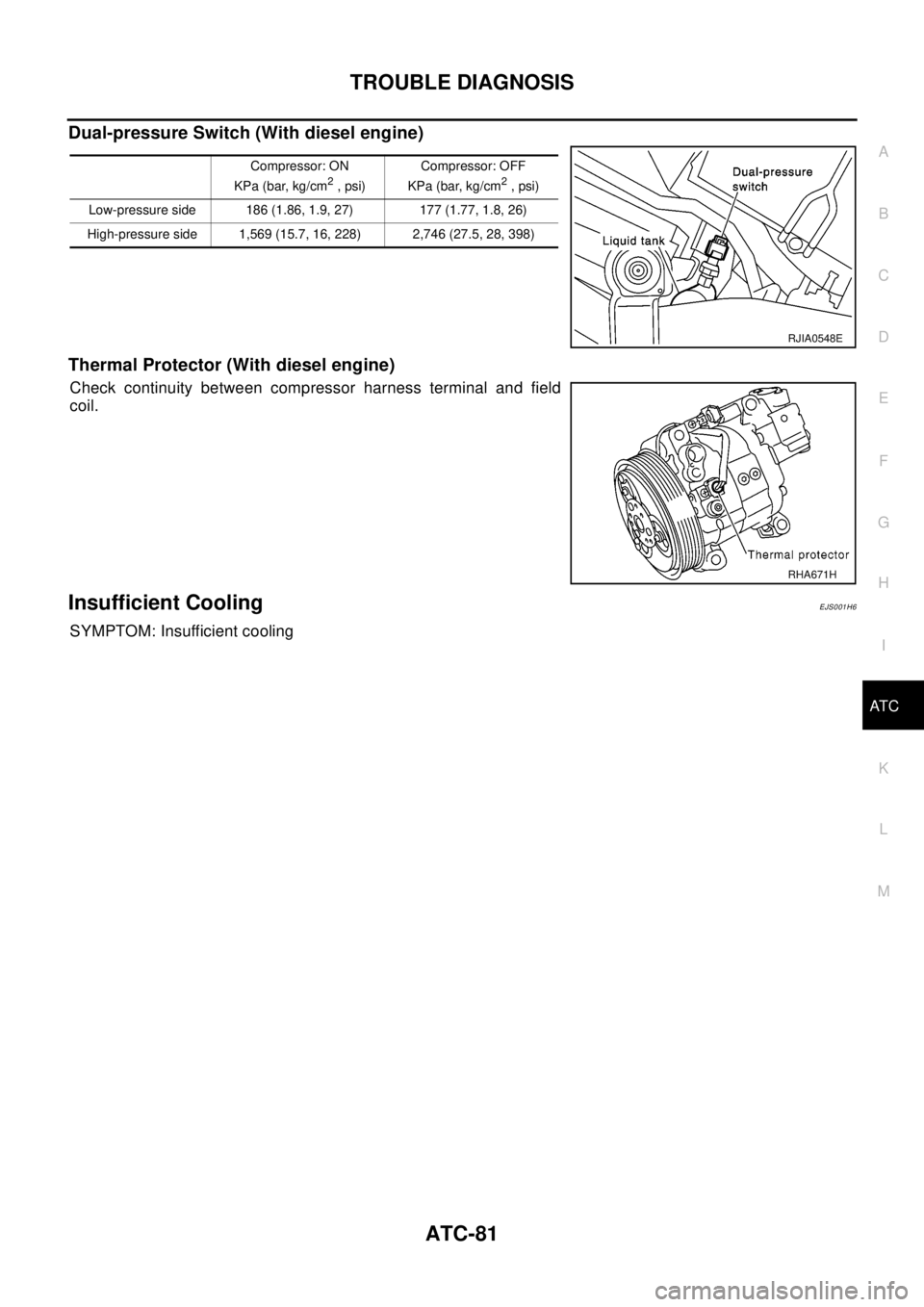

Dual-pressure Switch (With diesel engine)

Thermal Protector (With diesel engine)

Check continuity between compressor harness terminal and field

coil.

Insufficient CoolingEJS001H6

SYMPTOM: Insufficient cooling

Compressor: ON

KPa (bar, kg/cm2,psi)Compressor: OFF

KPa (bar, kg/cm2,psi)

Low-pressure side 186 (1.86, 1.9, 27) 177 (1.77, 1.8, 26)

High-pressure side 1,569 (15.7, 16, 228) 2,746 (27.5, 28, 398)

RJIA0548E

RHA671H