engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 595 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual REFRIGERATION SYSTEM

ATC-17

C

D

E

F

G

H

I

K

L

MA

B

AT C

cm2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

V-6 Variable Dis NISSAN X-TRAIL 2003 Electronic Repair Manual REFRIGERATION SYSTEM

ATC-17

C

D

E

F

G

H

I

K

L

MA

B

AT C

cm2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

V-6 Variable Dis](/img/5/57402/w960_57402-594.png)

REFRIGERATION SYSTEM

ATC-17

C

D

E

F

G

H

I

K

L

MA

B

AT C

cm2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into

the atmosphere.

V-6 Variable Displacement Compressor (With Gasoline Engine: CWV-165M

Compressor)

EJS000TF

GENERAL INFORMATION

1. The V-6 variable compressor differs from previous units. The vent temperatures of the V-6 variable com-

pressor do not drop too far below 5°C(41°F) when:

Evaporator intake air temperature is less than 20°C(68°F).

Engine is running at speeds less than 1,500 rpm.

This is because the V-6 compressor provides a means of "capacity" control.

2. The V-6 variable compressor provides refrigerant control under varying conditions. During cold winters, it

may not produce high refrigerant pressure discharge (compared to previous units) when used with air

conditioning systems.

3. A "clanking" sound may occasionally be heard during refrigerant charge. The sound indicates that the tilt

angle of the swash plate has changed and is not a problem.

4. For air conditioning systems with the V-6 compressor, the clutch remains engaged unless: the system

main switch, fan switch or ignition switch is turned OFF. When ambient (outside) temperatures are low or

when the amount of refrigerant is insufficient, the clutch is disengaged to protect the compressor.

5. A constant range of suction pressure is maintained when engine speed is greater than a certain value. It

normally ranges from 147 to 177 kPa (1.5 to 1.8 kg/cm

2, 21 to 26 psi) under varying conditions.

In previous compressors, however, suction pressure was reduced with increases in engine speed.

DESCRIPTION

General

The variable compressor is basically a swash plate type that changes piston stroke in response to the required

cooling capacity.

RJIA0198E

Page 599 of 3066

LUBRICANT

ATC-21

C

D

E

F

G

H

I

K

L

MA

B

AT C

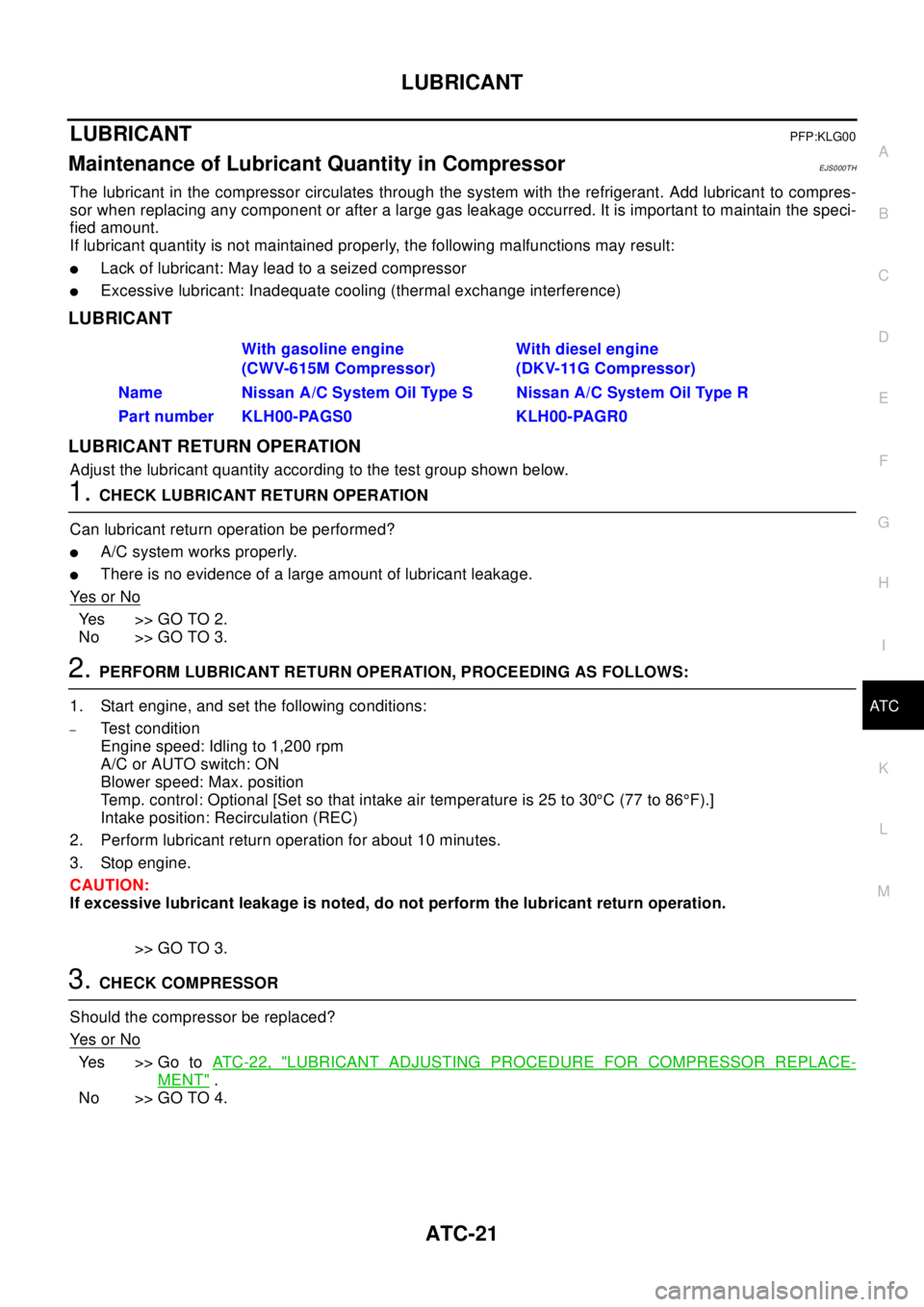

LUBRICANTPFP:KLG00

Maintenance of Lubricant Quantity in CompressorEJS000TH

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large gas leakage occurred. It is important to maintain the speci-

fied amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

LUBRICANT RETURN OPERATION

Adjust the lubricant quantity according to the test group shown below.

1.CHECK LUBRICANT RETURN OPERATION

Can lubricant return operation be performed?

lA/C system works properly.

lThere is no evidence of a large amount of lubricant leakage.

Ye s o r N o

Yes >>GOTO2.

No >> GO TO 3.

2.PERFORM LUBRICANT RETURN OPERATION, PROCEEDING AS FOLLOWS:

1. Start engine, and set the following conditions:

–Test condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to 30°C (77 to 86°F).]

Intake position: Recirculation (REC)

2. Perform lubricant return operation for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

>> GO TO 3.

3.CHECK COMPRESSOR

Should the compressor be replaced?

Ye s o r N o

Ye s > > G o t oAT C - 2 2 , "LUBRICANT ADJUSTING PROCEDURE FOR COMPRESSOR REPLACE-

MENT".

No >> GO TO 4.With gasoline engine

(CWV-615M Compressor)With diesel engine

(DKV-11G Compressor)

Name Nissan A/C System Oil Type S Nissan A/C System Oil Type R

Part number KLH00-PAGS0 KLH00-PAGR0

Page 604 of 3066

ATC-26

AIR CONDITIONER CONTROL

FAN SPEED CONTROL

Blower speed is automatically controlled based on temperature setting, ambient temperature, in-vehicle tem-

perature, intake temperature, amount of sunload and air mix door position.

With FAN switch set to AUTO, the blower motor starts to gradually increase air flow volume.

When engine coolant temperature is low, the blower motor operation is delayed to prevent cool air from flow-

ing.

INTAKE DOOR CONTROL

The intake doors are automatically controlled by: The temperature setting, ambient temperature, in-vehicle

temperature, intake temperature, amount of sunload and ON-OFF operation of the compressor.

OUTLET DOOR CONTROL

The outlet door is automatically controlled by: The temperature setting, ambient temperature, in-vehicle tem-

perature, intake temperature and amount of sunload.

MAGNET CLUTCH CONTROL

The ECM controls compressor operation using input signals from the throttle position sensor and auto ampli-

fier.

SELF-DIAGNOSTIC SYSTEM

The self-diagnostic system is built into the auto amplifier (LCU) to quickly locate the cause of problems.

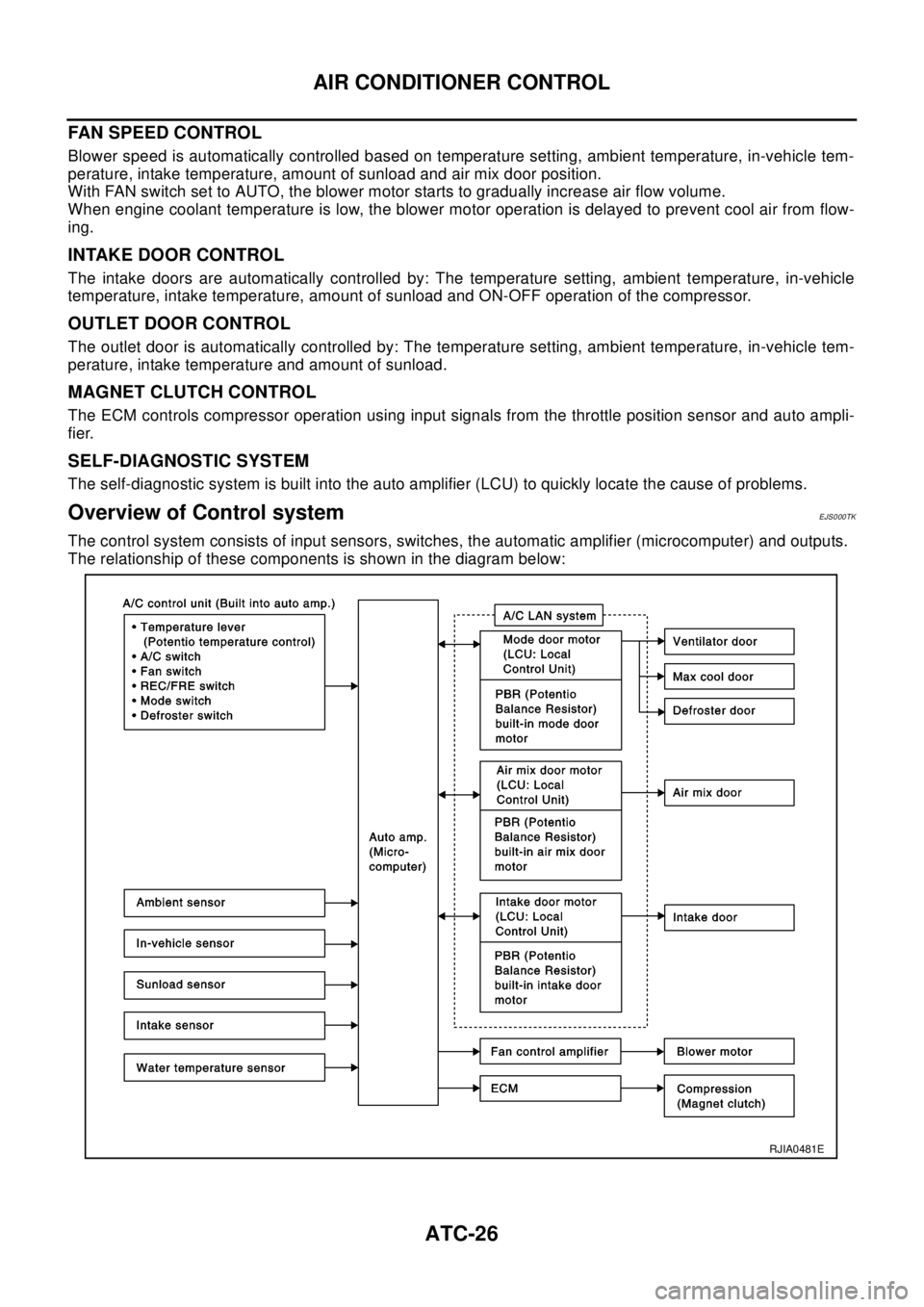

Overview of Control systemEJS000TK

The control system consists of input sensors, switches, the automatic amplifier (microcomputer) and outputs.

The relationship of these components is shown in the diagram below:

RJIA0481E

Page 609 of 3066

TROUBLE DIAGNOSIS

ATC-31

C

D

E

F

G

H

I

K

L

MA

B

AT C

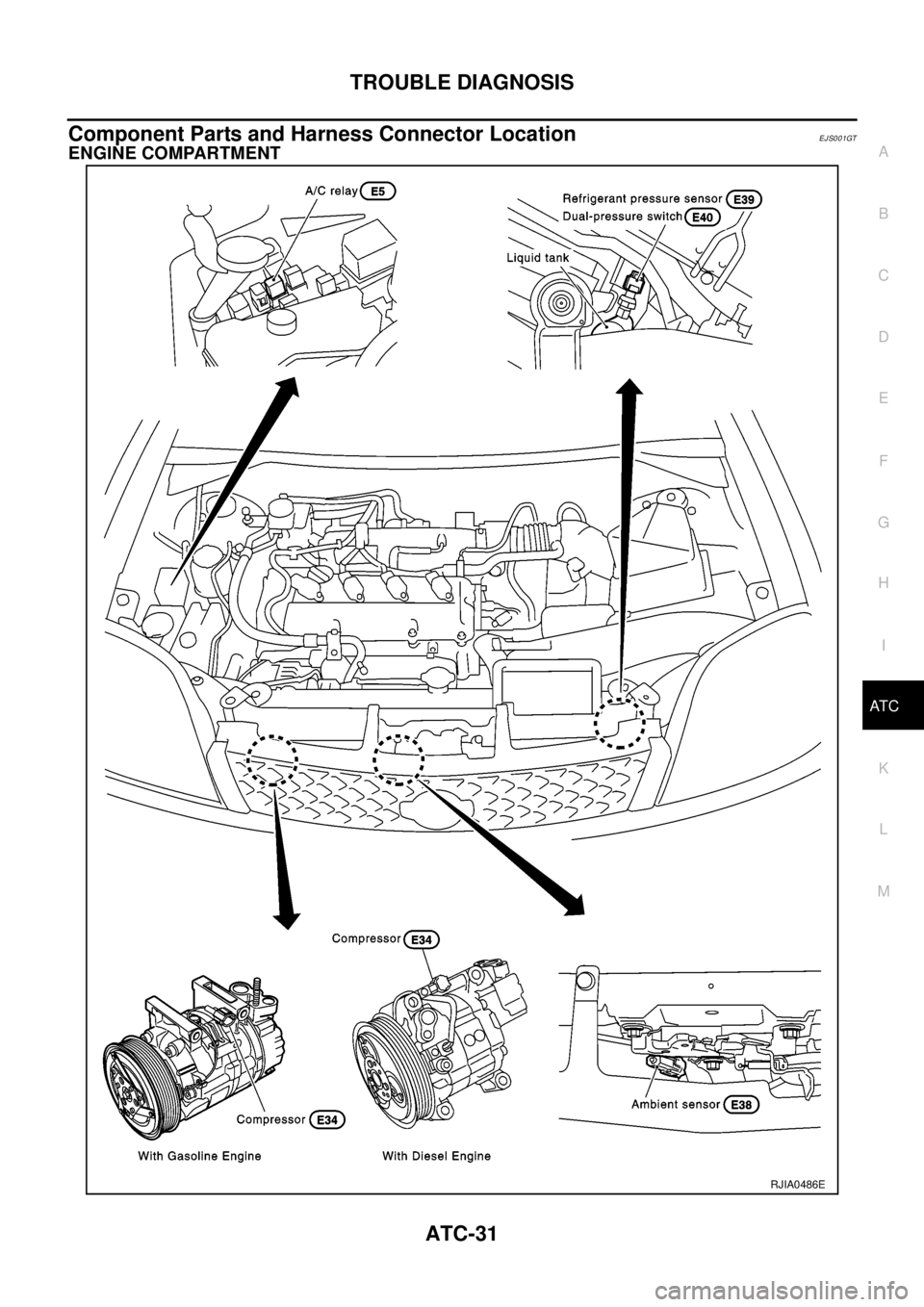

Component Parts and Harness Connector LocationEJS001GT

ENGINE COMPARTMENT

RJIA0486E

Page 611 of 3066

TROUBLE DIAGNOSIS

ATC-33

C

D

E

F

G

H

I

K

L

MA

B

AT C

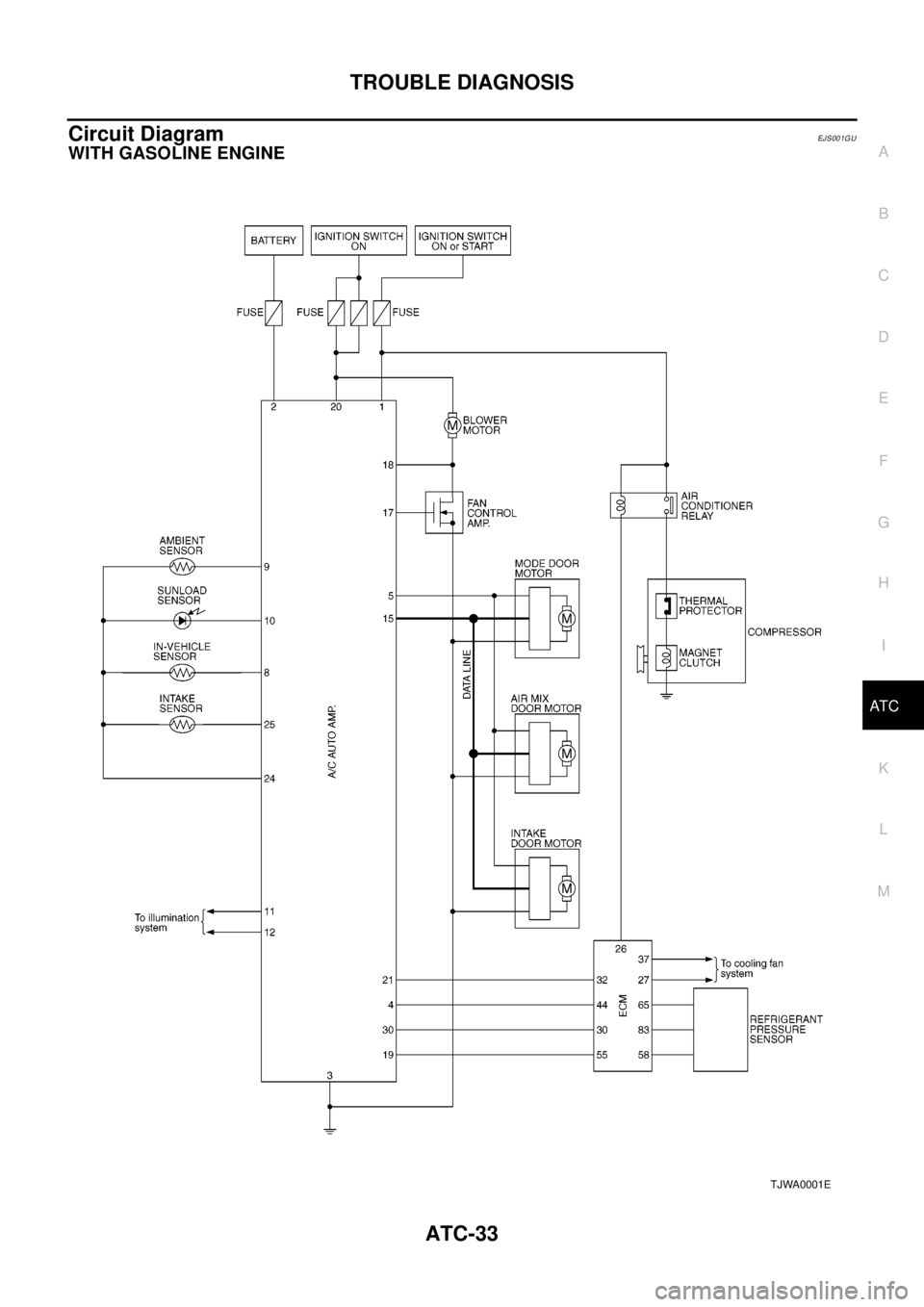

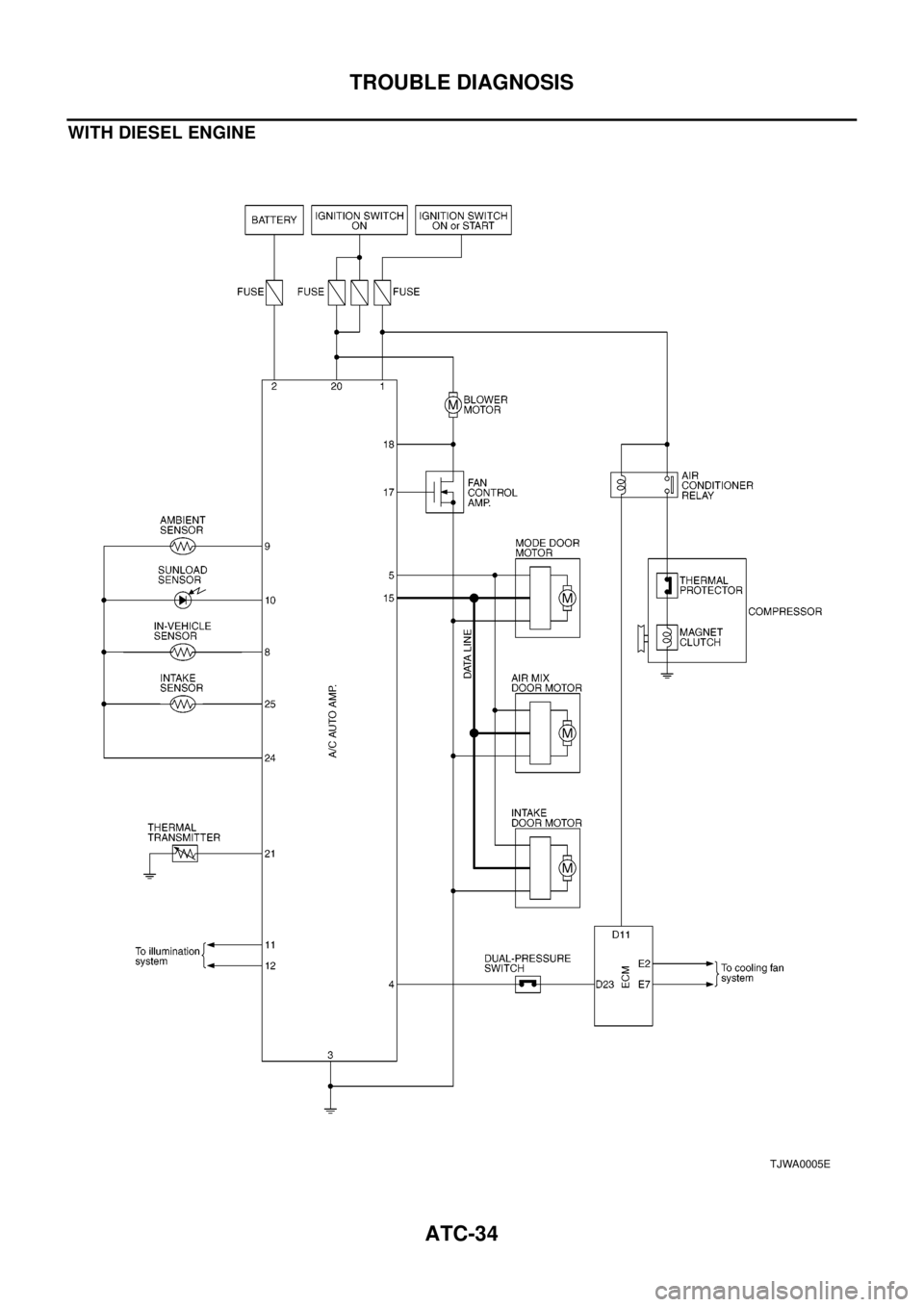

Circuit DiagramEJ S00 1G U

WITH GASOLINE ENGINE

TJWA0001E

Page 612 of 3066

ATC-34

TROUBLE DIAGNOSIS

WITH DIESEL ENGINE

TJWA0005E

Page 613 of 3066

TROUBLE DIAGNOSIS

ATC-35

C

D

E

F

G

H

I

K

L

MA

B

AT C

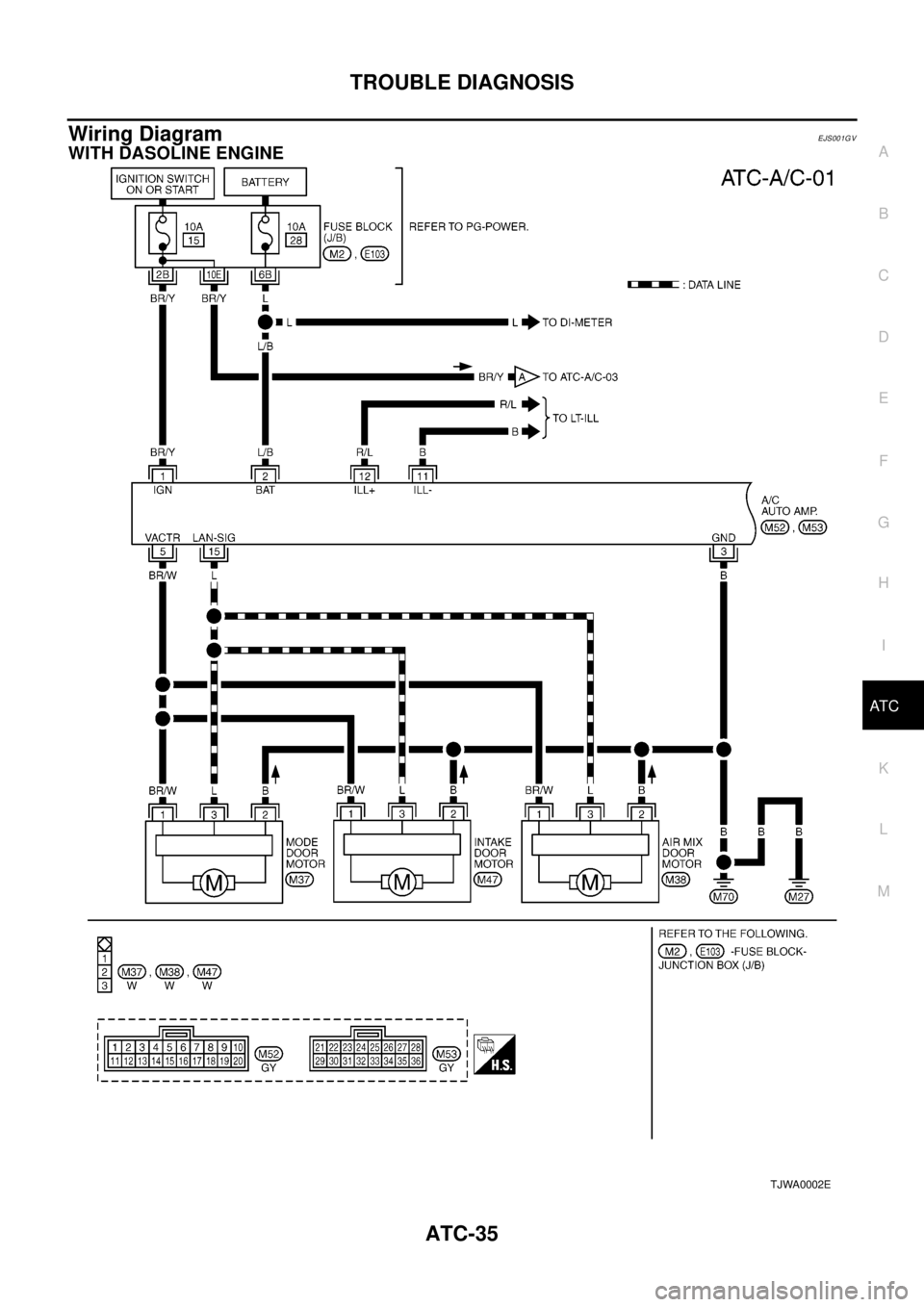

Wiring DiagramEJS001GV

WITH DASOLINE ENGINE

TJWA0002E

Page 616 of 3066

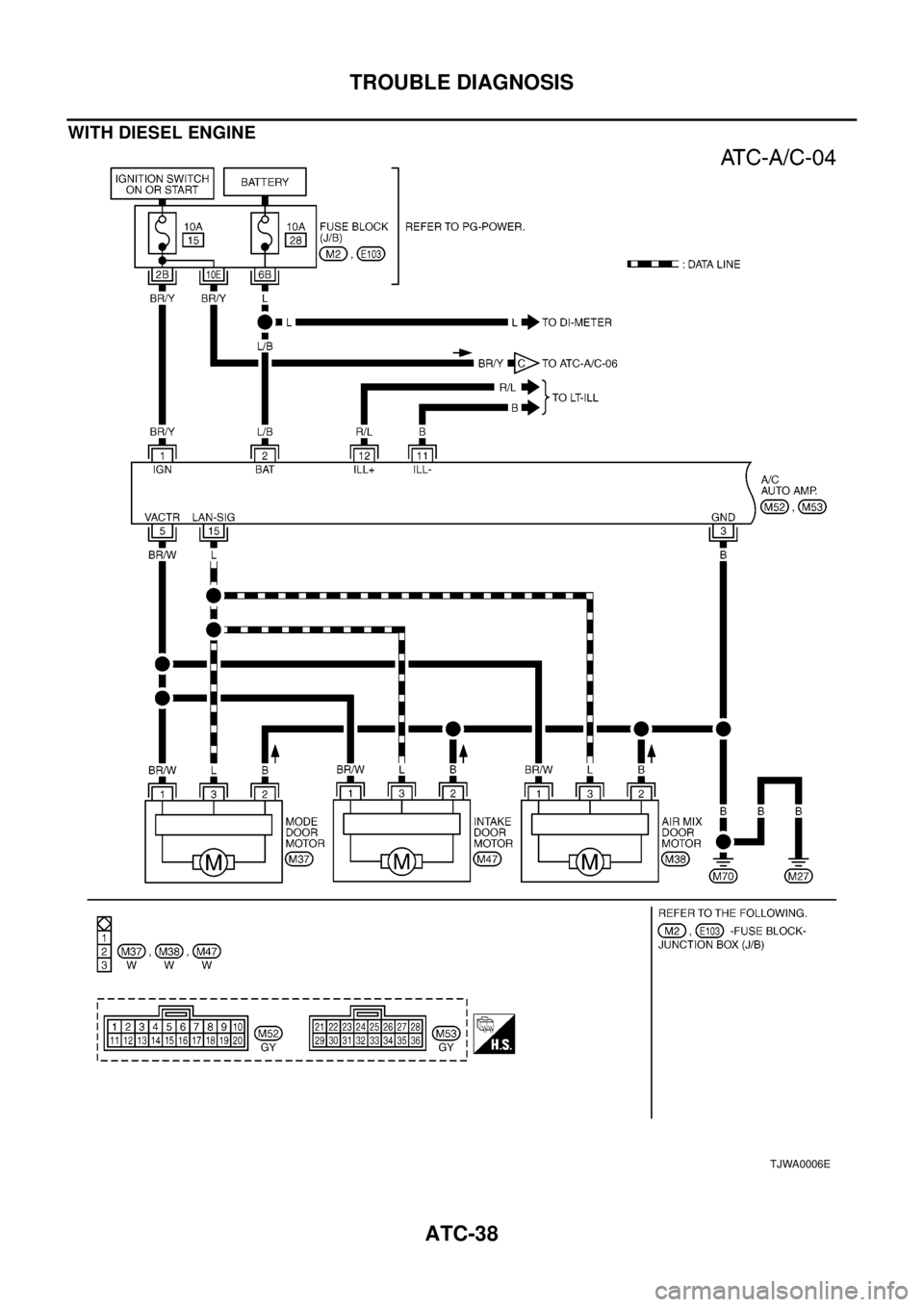

ATC-38

TROUBLE DIAGNOSIS

WITH DIESEL ENGINE

TJWA0006E

Page 620 of 3066

ATC-42

TROUBLE DIAGNOSIS

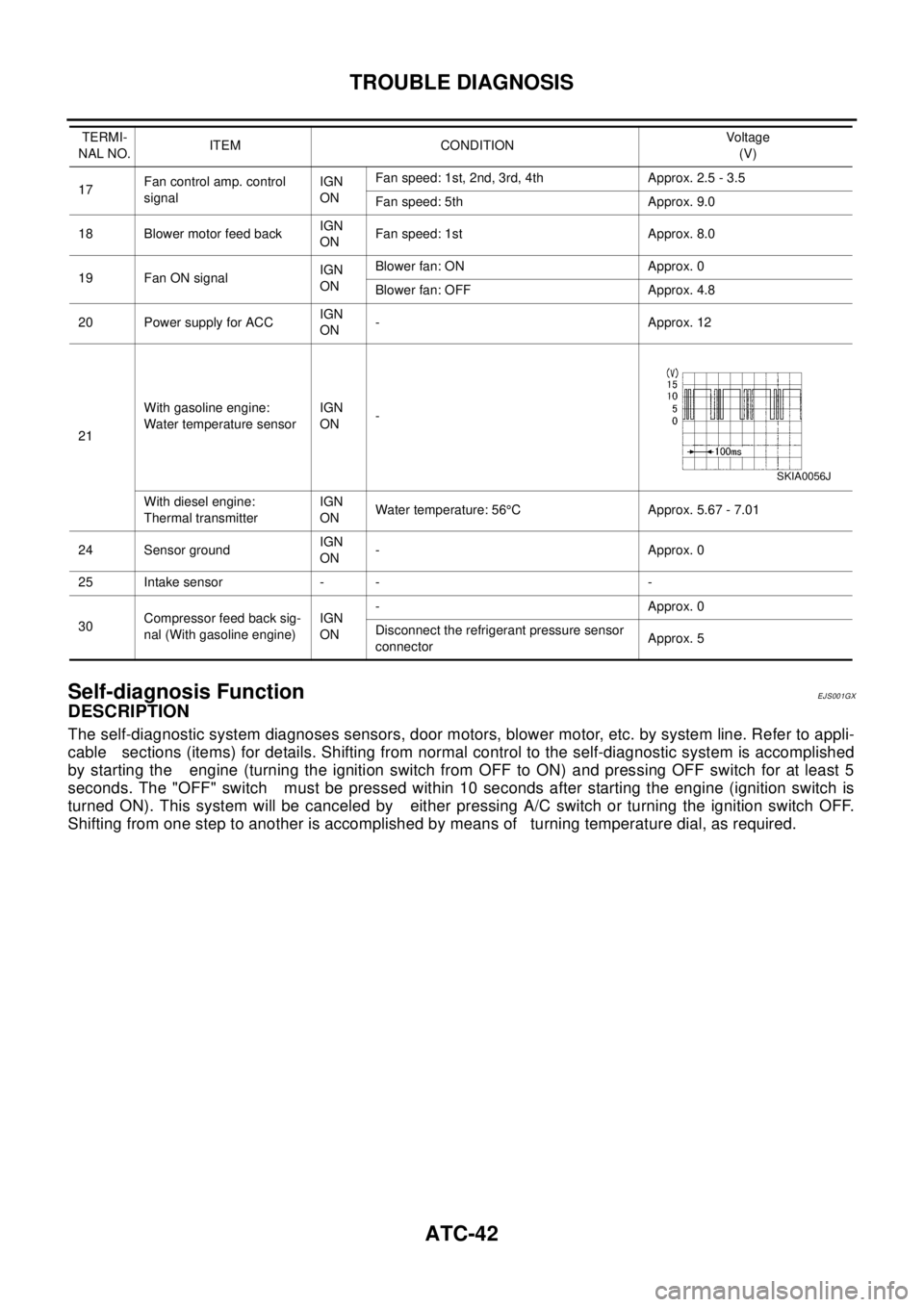

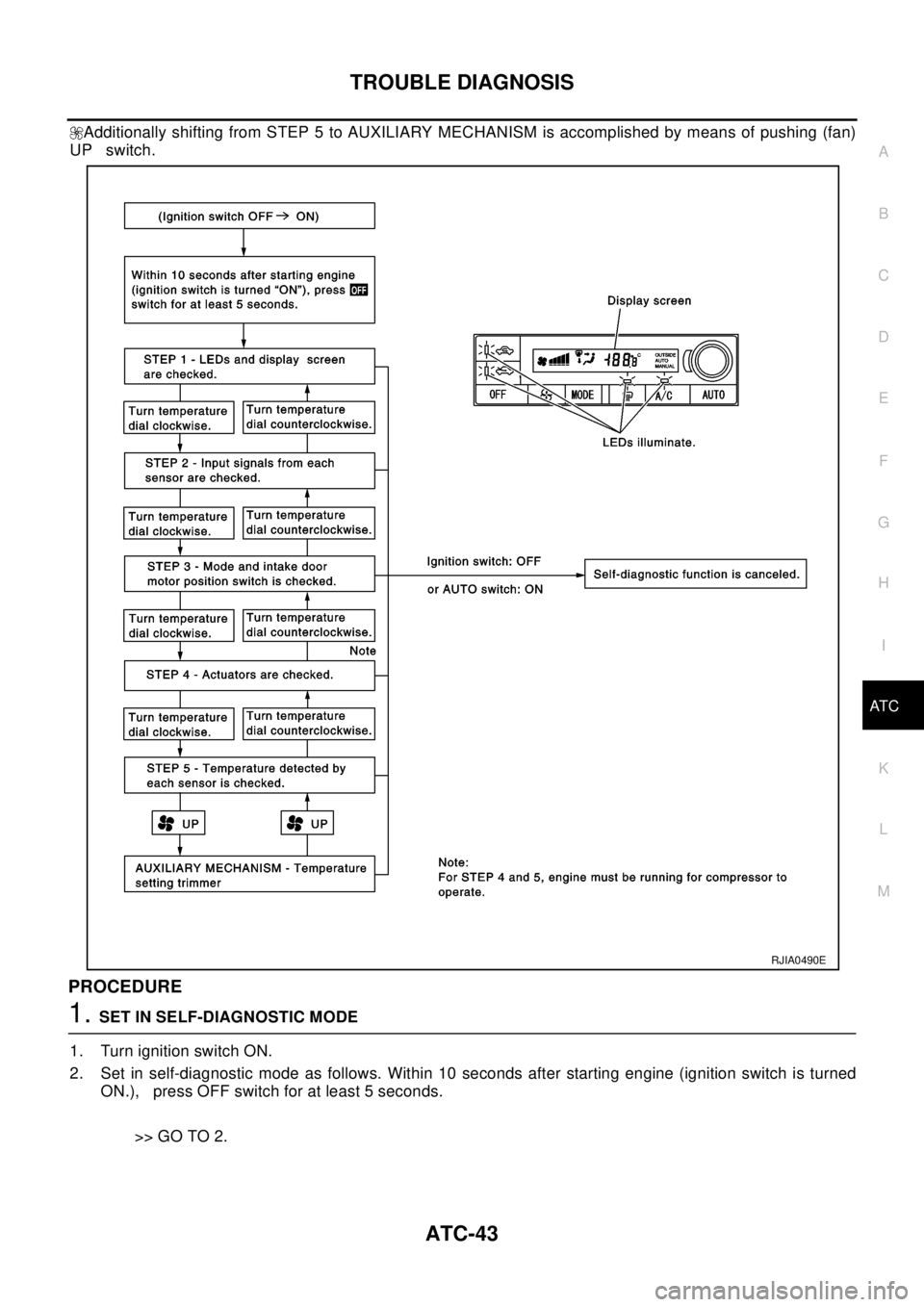

Self-diagnosis Function

EJS001GX

DESCRIPTION

The self-diagnostic system diagnoses sensors, door motors, blower motor, etc. by system line. Refer to appli-

cable sections (items) for details. Shifting from normal control to the self-diagnostic system is accomplished

by starting the engine (turning the ignition switch from OFF to ON) and pressing OFF switch for at least 5

seconds. The "OFF" switch must be pressed within 10 seconds after starting the engine (ignition switch is

turned ON). This system will be canceled by either pressing A/C switch or turning the ignition switch OFF.

Shifting from one step to another is accomplished by means of turning temperature dial, as required.

17Fan control amp. control

signalIGN

ONFan speed: 1st, 2nd, 3rd, 4th Approx. 2.5 - 3.5

Fan speed: 5th Approx. 9.0

18 Blower motor feed backIGN

ONFan speed: 1st Approx. 8.0

19 Fan ON signalIGN

ONBlower fan: ON Approx. 0

Blower fan: OFF Approx. 4.8

20 Power supply for ACCIGN

ON-Approx.12

21With gasoline engine:

Water temperature sensorIGN

ON-

With diesel engine:

Thermal transmitterIGN

ONWater temperature: 56°C Approx. 5.67 - 7.01

24 Sensor groundIGN

ON-Approx.0

25 Intake sensor - - -

30Compressor feed back sig-

nal (With gasoline engine)IGN

ON-Approx.0

Disconnect the refrigerant pressure sensor

connectorApprox. 5 TERMI-

NAL NO.ITEM CONDITIONVo ltag e

(V)

SKIA0056J

Page 621 of 3066

TROUBLE DIAGNOSIS

ATC-43

C

D

E

F

G

H

I

K

L

MA

B

AT C

Additionally shifting from STEP 5 to AUXILIARY MECHANISM is accomplished by means of pushing (fan)

UP switch.

PROCEDURE

1.SET IN SELF-DIAGNOSTIC MODE

1. Turn ignition switch ON.

2. Set in self-diagnostic mode as follows. Within 10 seconds after starting engine (ignition switch is turned

ON.), press OFF switch for at least 5 seconds.

>> GO TO 2.

RJIA0490E