engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 720 of 3066

ATC-142

REFRIGERANT LINES

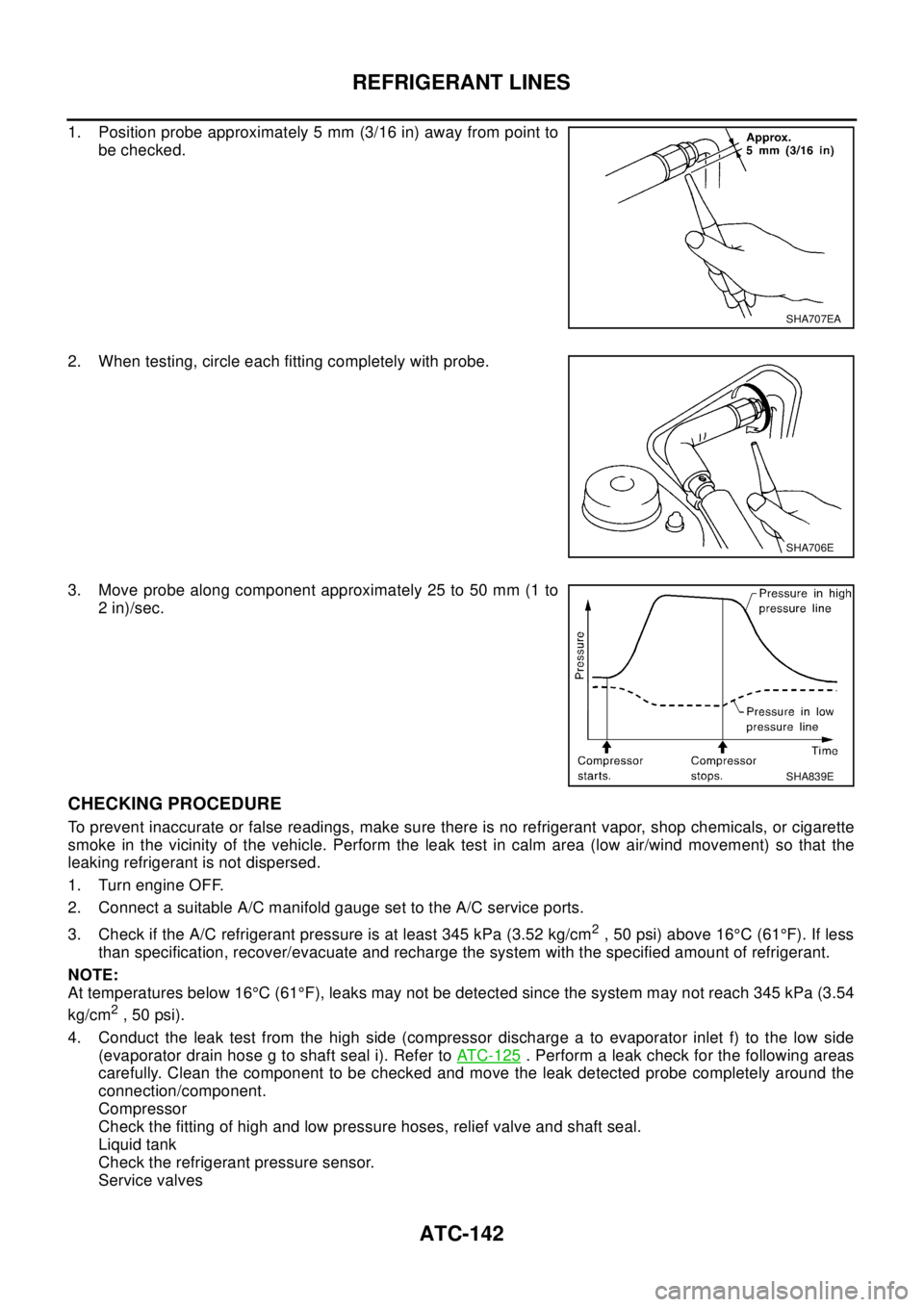

1. Position probe approximately 5 mm (3/16 in) away from point to

be checked.

2. When testing, circle each fitting completely with probe.

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn engine OFF.

2. Connect a suitable A/C manifold gauge set to the A/C service ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.52 kg/cm

2,50psi)above16°C(61°F).Ifless

than specification, recover/evacuate and recharge the system with the specified amount of refrigerant.

NOTE:

At temperatures below 16°C(61°F), leaks may not be detected since the system may not reach 345 kPa (3.54

kg/cm

2,50psi).

4. Conduct the leak test from the high side (compressor discharge a to evaporator inlet f) to the low side

(evaporator drain hose g to shaft seal i). Refer toATC-125

. Perform a leak check for the following areas

carefully. Clean the component to be checked and move the leak detected probe completely around the

connection/component.

Compressor

Check the fitting of high and low pressure hoses, relief valve and shaft seal.

Liquid tank

Check the refrigerant pressure sensor.

Service valves

SHA707EA

SHA706E

SHA839E

Page 721 of 3066

REFRIGERANT LINES

ATC-143

C

D

E

F

G

H

I

K

L

MA

B

AT C

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on "High" for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer's recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. Face mode

c. Intake position: Recirculation

d. Max cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps 4 through 6 above.

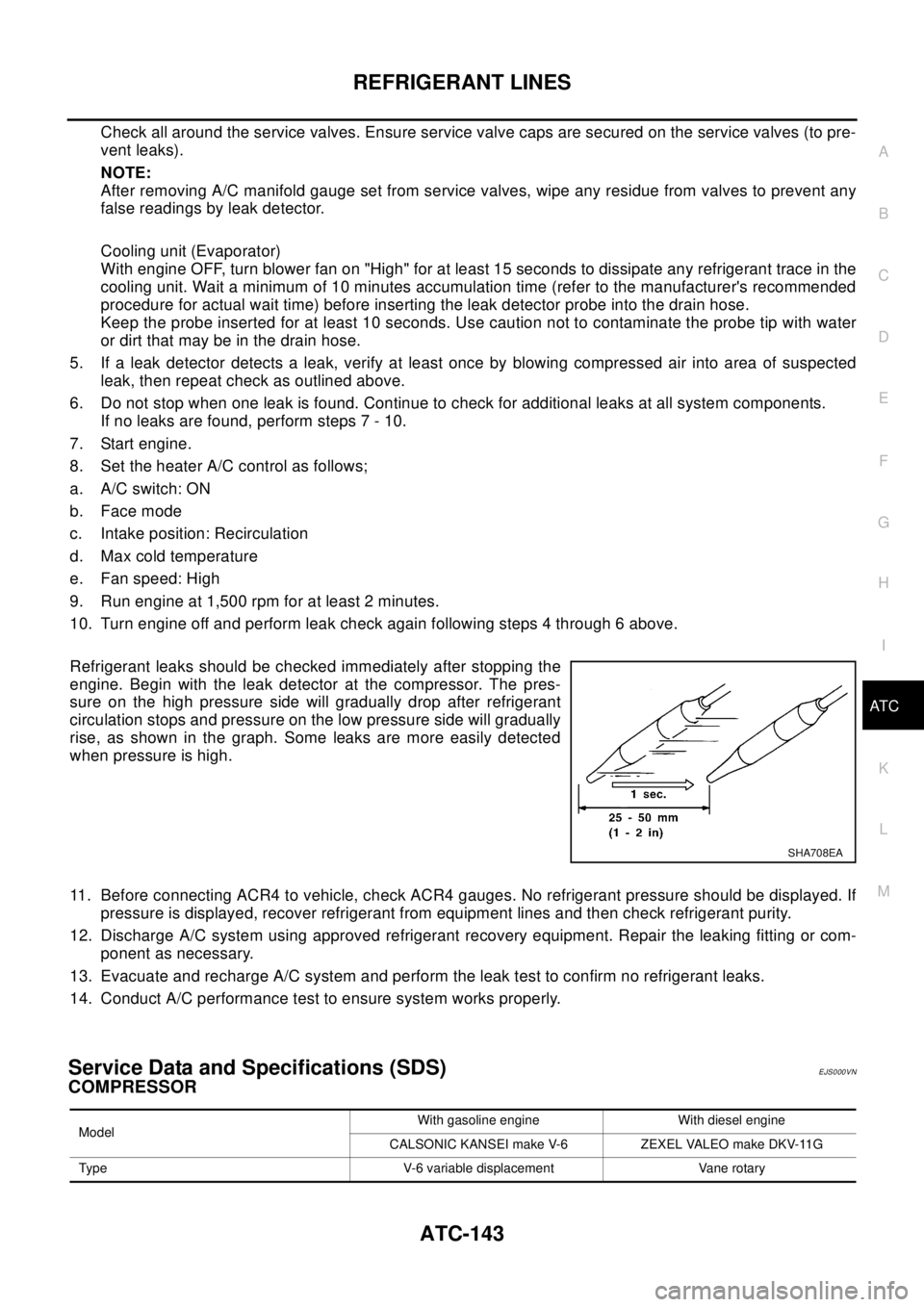

Refrigerant leaks should be checked immediately after stopping the

engine. Begin with the leak detector at the compressor. The pres-

sure on the high pressure side will gradually drop after refrigerant

circulation stops and pressure on the low pressure side will gradually

rise, as shown in the graph. Some leaks are more easily detected

when pressure is high.

11. Before connecting ACR4 to vehicle, check ACR4 gauges. No refrigerant pressure should be displayed. If

pressure is displayed, recover refrigerant from equipment lines and then check refrigerant purity.

12. Discharge A/C system using approved refrigerant recovery equipment. Repair the leaking fitting or com-

ponent as necessary.

13. Evacuate and recharge A/C system and perform the leak test to confirm no refrigerant leaks.

14. Conduct A/C performance test to ensure system works properly.

Service Data and Specifications (SDS)EJS000VN

COMPRESSOR

SHA708EA

ModelWith gasoline engine With diesel engine

CALSONIC KANSEI make V-6 ZEXEL VALEO make DKV-11G

Type V-6 variable displacement Vane rotary

Page 722 of 3066

ATC-144

REFRIGERANT LINES

LUBRICANT

REFRIGERANT

ENGINE IDLING SPEED

Refer toATC-144, "ENGINE IDLING SPEED".

BELT TENSION

Refer to,EM-13, "Tension Adjustment"QR engine;EM-110, "Tension Adjustment"YD engine.

Displacement

cm3 (cu. in)/revMax. 184 (11.228)

110 (6.71)

Min. 14.5 (0.885)

Cylinder bore´stroke

mm (in)37 (1.46)´[2.3 - 28.6 (0.091 - 1.126)] -

Direction of rotation Clockwise (viewed from drive end)

Drive beltPoly V

ModelWith gasoline engine With diesel engine

CALSONIC KANSEI make V-6 ZEXEL VALEO make DKV-11G

Name Nissan A/C System Oil Type S Nissan A/C System Oil Type R

Part number KLH00-PAGS0 KLH00-PAGR0

Capacity

ml (lmp fl oz)Total in system 180 (6.3)

Compressor (Service part) charging

amount180 (6.3)

Ty p eHFC-134a (R-134a)

Capacity

kg (lb)0.50 (1.10)

Page 734 of 3066

AV-12

AUDIO

Trouble Diagnoses

EKS002F5

AUDIO UNIT

InspectionEKS002F6

AUDIO UNIT

All voltage inspections are made with:

lIgnition switch ON or ACC

lAudio unit ON

lAudio unit connected (If audio unit is removed for inspection, supply a ground to the case using a jumper

wire.)

ANTENNA

Using a jumper wire, clip an auxiliary ground between antenna and body.

lIf reception improves, check antenna ground (at body surface).

lIf reception does not improve, check main feeder cable for short circuit or open circuit.

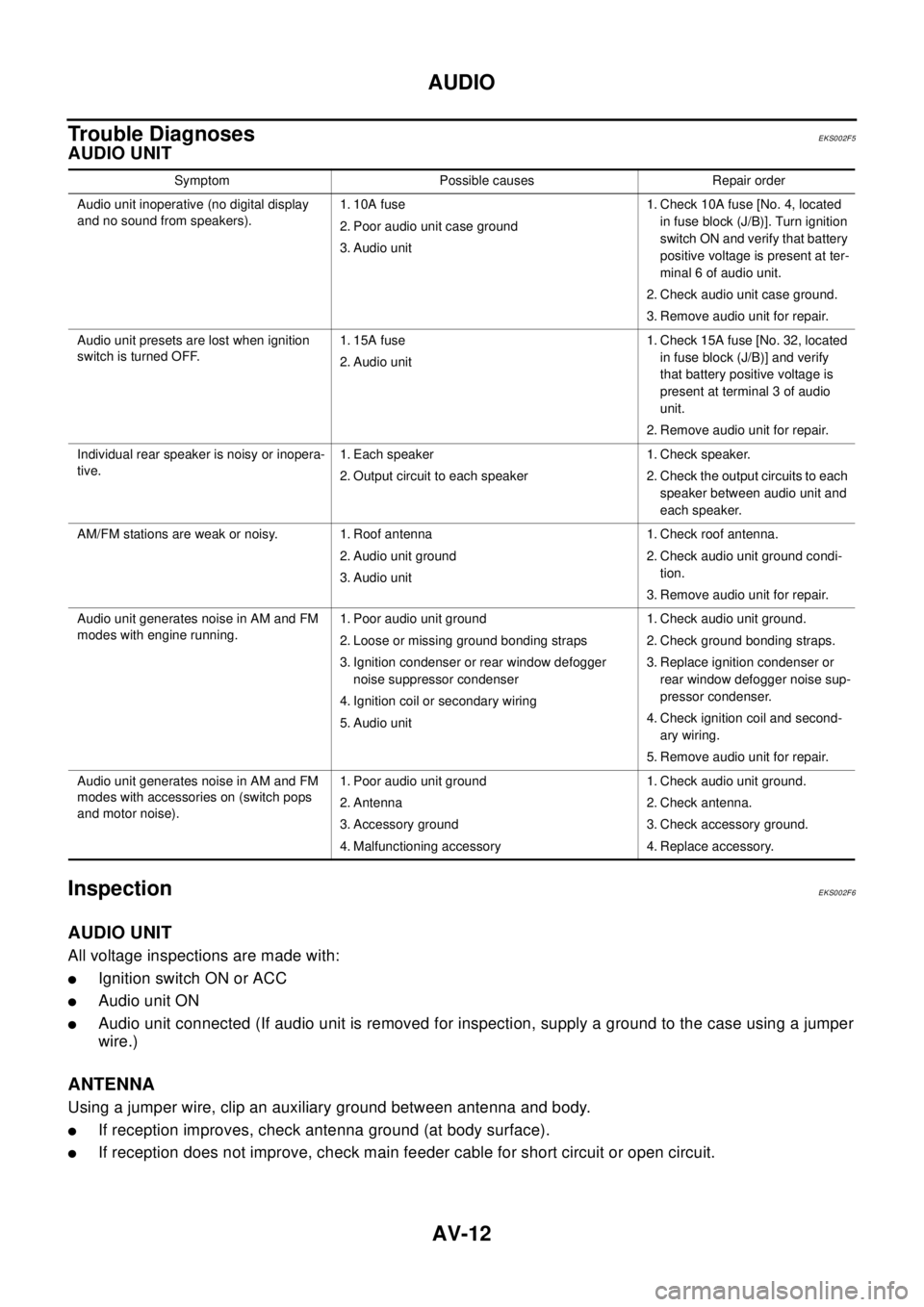

Symptom Possible causes Repair order

Audio unit inoperative (no digital display

and no sound from speakers).1. 10A fuse

2. Poor audio unit case ground

3. Audio unit1. Check 10A fuse [No. 4, located

in fuse block (J/B)]. Turn ignition

switch ON and verify that battery

positive voltage is present at ter-

minal 6 of audio unit.

2. Check audio unit case ground.

3. Remove audio unit for repair.

Audio unit presets are lost when ignition

switch is turned OFF.1. 15A fuse

2. Audio unit1. Check 15A fuse [No. 32, located

in fuse block (J/B)] and verify

that battery positive voltage is

present at terminal 3 of audio

unit.

2. Remove audio unit for repair.

Individual rear speaker is noisy or inopera-

tive.1. Each speaker

2. Output circuit to each speaker1. Check speaker.

2. Check the output circuits to each

speaker between audio unit and

each speaker.

AM/FM stations are weak or noisy. 1. Roof antenna

2. Audio unit ground

3. Audio unit1. Check roof antenna.

2. Check audio unit ground condi-

tion.

3. Remove audio unit for repair.

Audio unit generates noise in AM and FM

modes with engine running.1. Poor audio unit ground

2. Loose or missing ground bonding straps

3. Ignition condenser or rear window defogger

noise suppressor condenser

4. Ignition coil or secondary wiring

5. Audio unit1. Check audio unit ground.

2. Check ground bonding straps.

3. Replace ignition condenser or

rear window defogger noise sup-

pressor condenser.

4. Check ignition coil and second-

ary wiring.

5. Remove audio unit for repair.

Audio unit generates noise in AM and FM

modes with accessories on (switch pops

and motor noise).1. Poor audio unit ground

2. Antenna

3. Accessory ground

4. Malfunctioning accessory1. Check audio unit ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

Page 746 of 3066

BL-2

INSTALLATION .................................................... 55

Disassembly and Assembly .................................... 55

DISASSEMBLY ................................................... 55

ASSEMBLY ......................................................... 56

REAR DOOR LOCK .................................................. 57

Component Parts Location ..................................... 57

Inspection and Adjustment ..................................... 57

OUT SIDE HANDLE ROD ADJUSTMENT .......... 57

Removal and Installation ........................................ 57

REMOVAL ........................................................... 57

INSTALLATION .................................................... 58

Disassembly and Assembly .................................... 58

DISASSEMBLY ................................................... 58

ASSEMBLY ......................................................... 59

BACK DOOR ............................................................. 60

Fitting Adjustment ................................................... 60

VERTICAL/LATERAL CLEARANCE ADJUST-

MENT .................................................................. 60

Back Door Assembly .............................................. 61

REMOVAL AND INSTALLATION ......................... 61

INSPECTION ....................................................... 61

Removal and Installation of Back Door Handle ...... 61

Removal and Installation of Back Door Lock and

Actuator .................................................................. 62

Removal and Installation of Back Door Weatherstrip... 62

FUEL FILLER LID OPENER ..................................... 64

Component Parts Location ..................................... 64

THEFT WARNING SYSTEM ..................................... 65

Wiring Diagram — THEFT —/PRI-WIRE ................ 65

LHD MODELS ..................................................... 66

RHD MODELS ..................................................... 68NATS (NISSAN ANTI-THEFT SYSTEM) ...................70

Component Parts and Harness Connector Location... 70

System Description .................................................70

System Composition ...............................................71

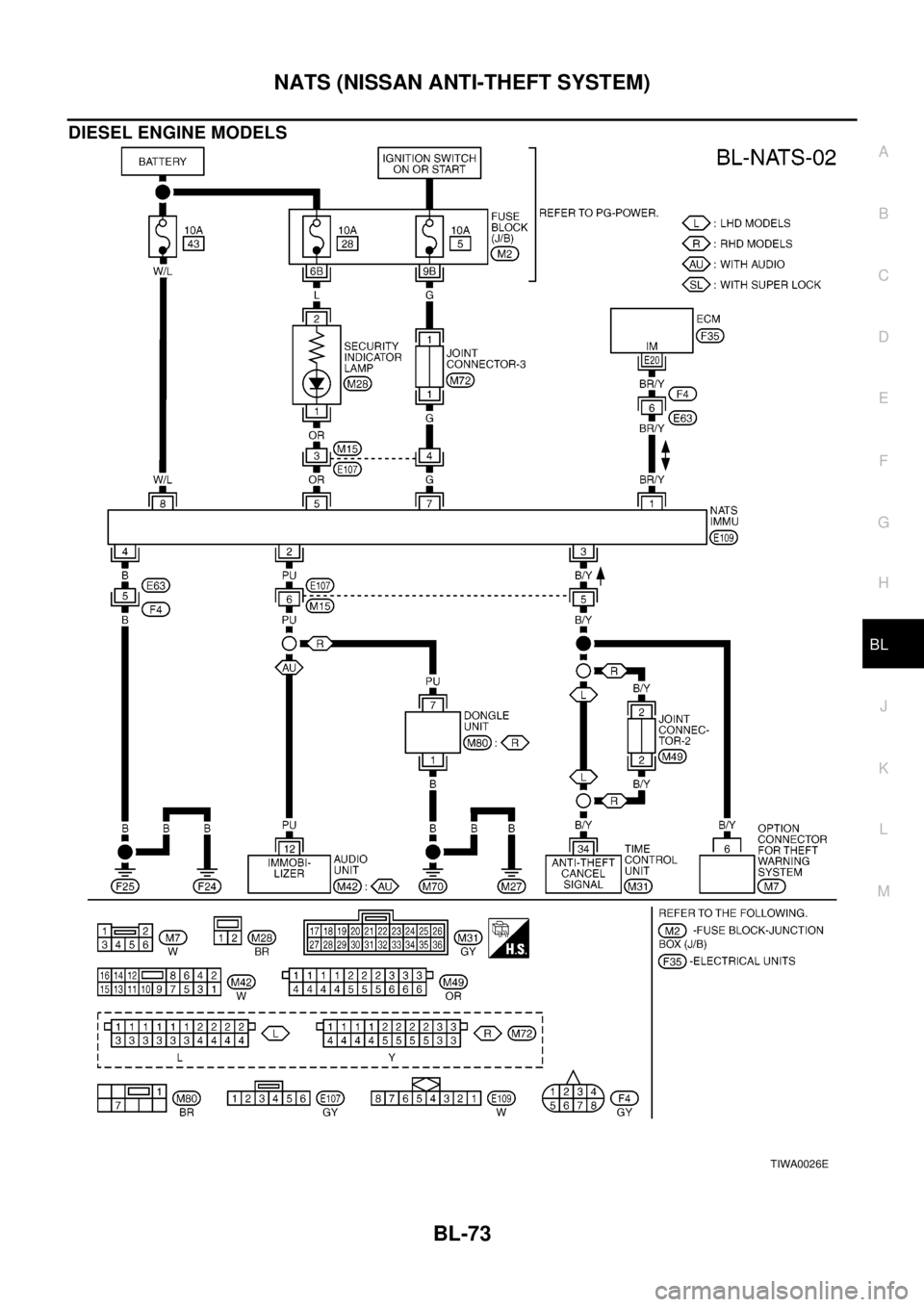

Wiring Diagram — NATS — ....................................72

GASOLINE ENGINE MODELS ............................72

DIESEL ENGINE MODELS .................................73

CONSULT-II ............................................................74

CONSULT-II INSPECTION PROCEDURE ..........74

CONSULT-II DIAGNOSTIC TEST MODE FUNC-

TION ....................................................................74

HOW TO READ SELF-DIAGNOSTIC RESULTS...75

NATS SELF-DIAGNOSTIC RESULTS ITEM

CHART .................................................................75

Work Flow ...............................................................77

Trouble Diagnoses ..................................................78

SYMPTOM MATRIX CHART 1 ............................78

SYMPTOM MATRIX CHART 2 ............................79

DIAGNOSTIC SYSTEM DIAGRAM .....................79

Diagnostic Procedure 1 ...........................................80

Diagnostic Procedure 2 ...........................................80

Diagnostic Procedure 3 ...........................................82

Diagnostic Procedure 4 ...........................................83

Diagnostic Procedure 5 ...........................................85

Diagnostic Procedure 6 ...........................................85

Diagnostic Procedure 7 ...........................................86

Diagnostic Procedure 8 ...........................................88

How to Replace NATS IMMU ..................................89

Page 814 of 3066

BL-70

NATS (NISSAN ANTI-THEFT SYSTEM)

NATS (NISSAN ANTI-THEFT SYSTEM)

PFP:25386

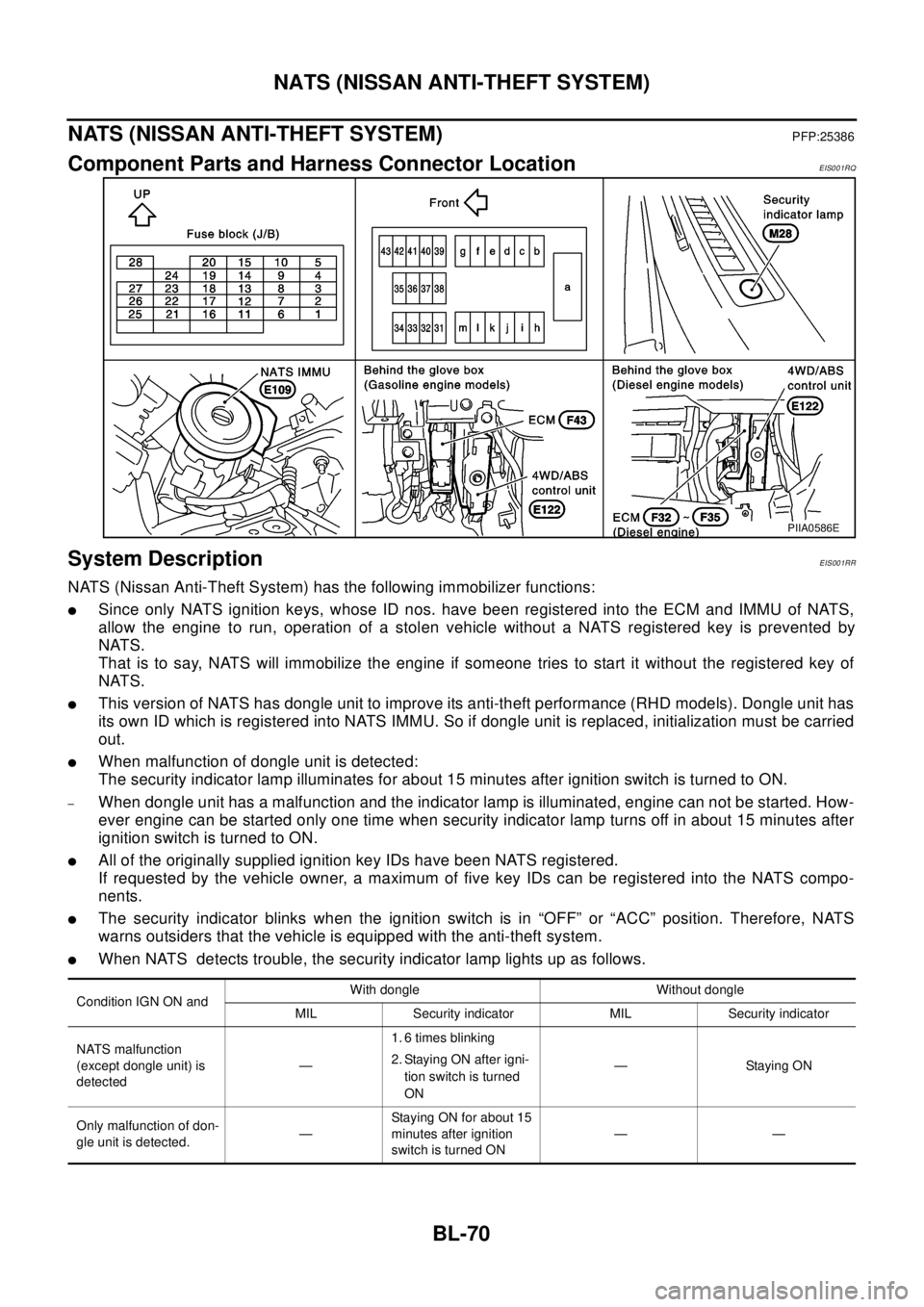

Component Parts and Harness Connector LocationEIS001RQ

System DescriptionEIS001RR

NATS (Nissan Anti-Theft System) has the following immobilizer functions:

lSince only NATS ignition keys, whose ID nos. have been registered into the ECM and IMMU of NATS,

allow the engine to run, operation of a stolen vehicle without a NATS registered key is prevented by

NATS.

That is to say, NATS will immobilize the engine if someone tries to start it without the registered key of

NATS.

lThis version of NATS has dongle unit to improve its anti-theft performance (RHD models). Dongle unit has

its own ID which is registered into NATS IMMU. So if dongle unit is replaced, initialization must be carried

out.

lWhen malfunction of dongle unit is detected:

The security indicator lamp illuminates for about 15 minutes after ignition switch is turned to ON.

–When dongle unit has a malfunction and the indicator lamp is illuminated, engine can not be started. How-

ever engine can be started only one time when security indicator lamp turns off in about 15 minutes after

ignition switch is turned to ON.

lAll of the originally supplied ignition key IDs have been NATS registered.

If requested by the vehicle owner, a maximum of five key IDs can be registered into the NATS compo-

nents.

lThe security indicator blinks when the ignition switch is in “OFF” or “ACC” position. Therefore, NATS

warns outsiders that the vehicle is equipped with the anti-theft system.

lWhen NATS detects trouble, the security indicator lamp lights up as follows.

PIIA0586E

Condition IGN ON andWith dongle Without dongle

MIL Security indicator MIL Security indicator

NATS malfunction

(except dongle unit) is

detected—1. 6 times blinking

2. Staying ON after igni-

tion switch is turned

ON—StayingON

Only malfunction of don-

gle unit is detected.—Staying ON for about 15

minutes after ignition

switch is turned ON——

Page 815 of 3066

NATS (NISSAN ANTI-THEFT SYSTEM)

BL-71

C

D

E

F

G

H

J

K

L

MA

B

BL

lNATS trouble diagnoses, system initialization and additional registration of other NATS ignition key IDs

must be carried out using CONSULT-II hardware and CONSULT-II NATS software.

Regarding the procedures of NATS initialization and NATS ignition key ID registration, refer to CONSULT-

II operation manual, NATS.

lWhen servicing a malfunction of the NATS (indicated by lighting up of Security Indicator Lamp) or

registering another NATS ignition key ID no., it may be necessary to re-register original key iden-

tification. Therefore, be sure to receive ALL KEYS from vehicle owner.

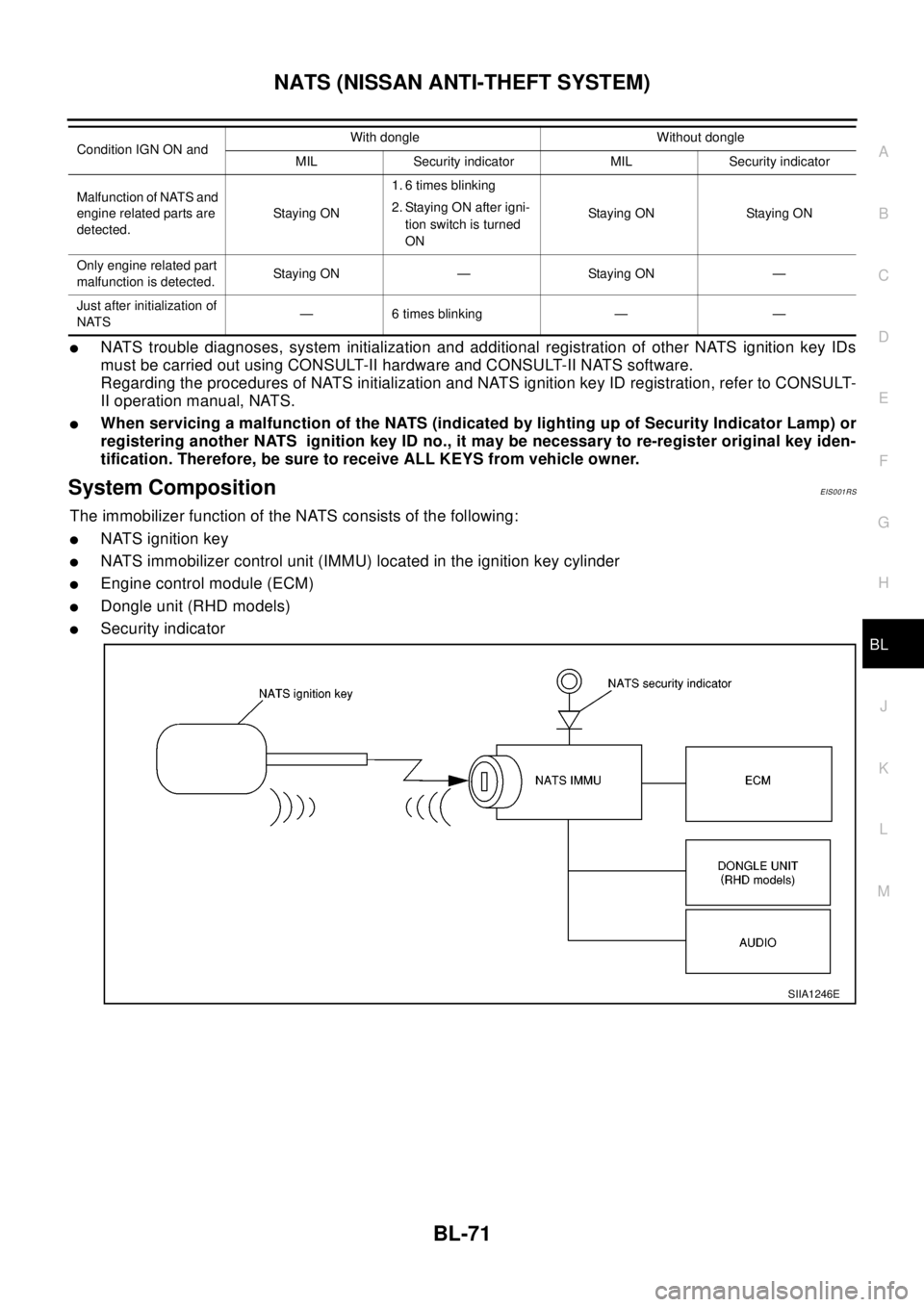

System CompositionEIS001RS

The immobilizer function of the NATS consists of the following:

lNATS ignition key

lNATS immobilizer control unit (IMMU) located in the ignition key cylinder

lEngine control module (ECM)

lDongle unit (RHD models)

lSecurity indicator

Malfunction of NATS and

engine related parts are

detected.Stay ing ON1. 6 times blinking

2. Staying ON after igni-

tion switch is turned

ONStaying ON Staying ON

Only engine related part

malfunction is detected.Stay ing ON — Sta y in g ON —

Just after initialization of

NATS— 6 times blinking — — Condition IGN ON andWith dongle Without dongle

MIL Security indicator MIL Security indicator

SIIA1246E

Page 816 of 3066

BL-72

NATS (NISSAN ANTI-THEFT SYSTEM)

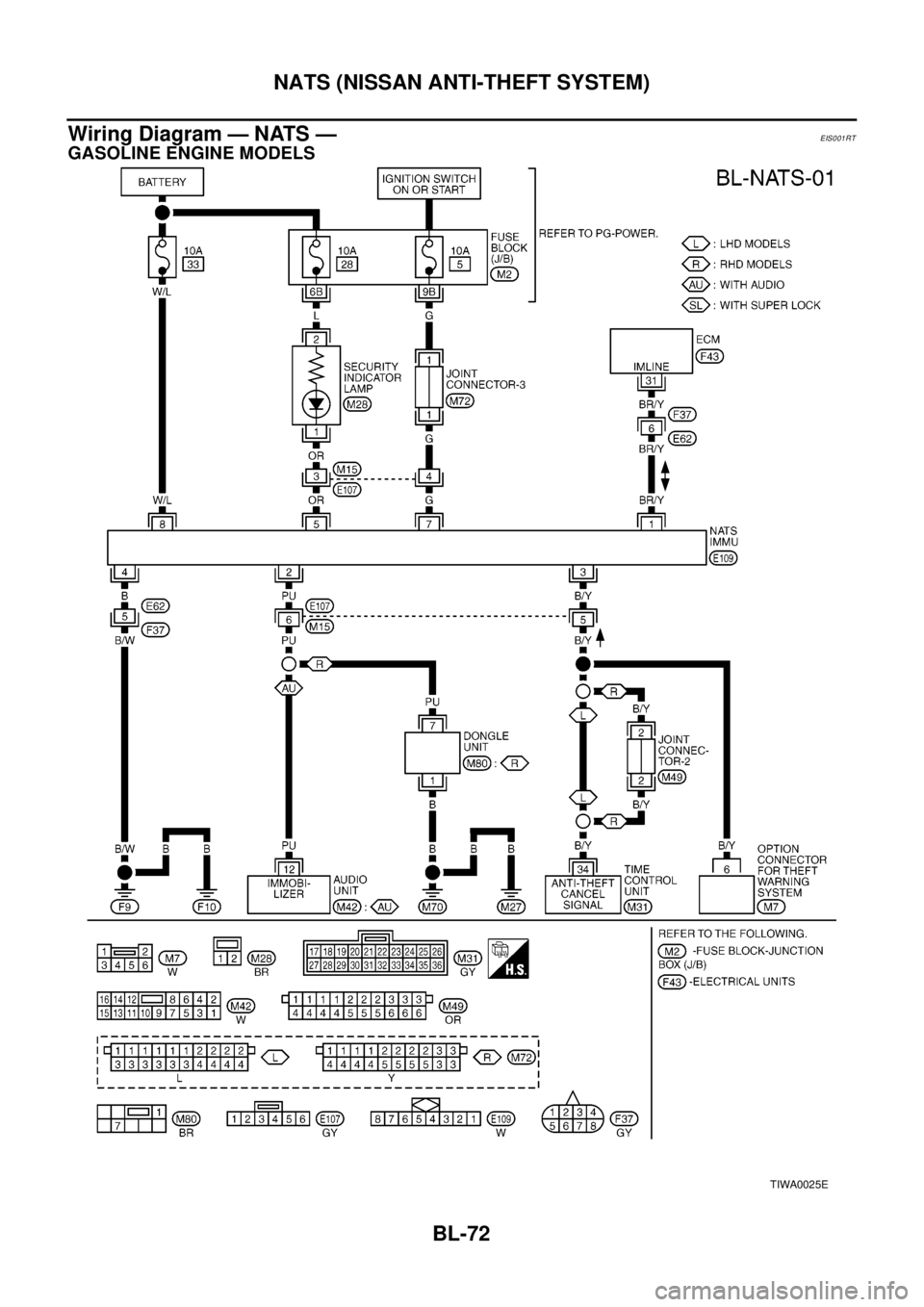

Wiring Diagram — NATS —

EIS001RT

GASOLINE ENGINE MODELS

TIWA0025E

Page 817 of 3066

NATS (NISSAN ANTI-THEFT SYSTEM)

BL-73

C

D

E

F

G

H

J

K

L

MA

B

BL

DIESEL ENGINE MODELS

TIWA0026E

Page 819 of 3066

NATS (NISSAN ANTI-THEFT SYSTEM)

BL-75

C

D

E

F

G

H

J

K

L

MA

B

BL

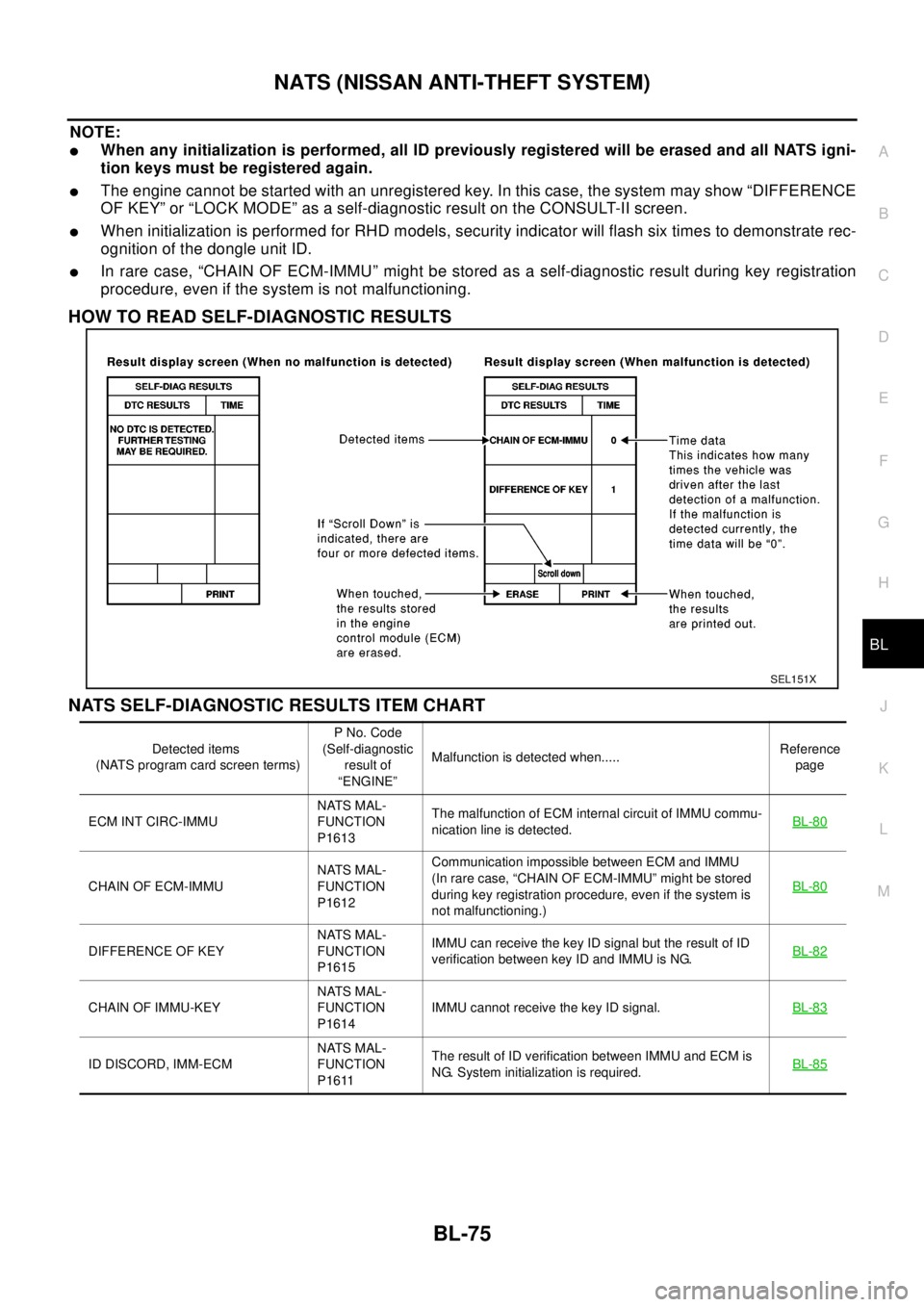

NOTE:

lWhen any initialization is performed, all ID previously registered will be erased and all NATS igni-

tion keys must be registered again.

lThe engine cannot be started with an unregistered key. In this case, the system may show “DIFFERENCE

OF KEY” or “LOCK MODE” as a self-diagnostic result on the CONSULT-II screen.

lWhen initialization is performed for RHD models, security indicator will flash six times to demonstrate rec-

ognition of the dongle unit ID.

lIn rare case, “CHAIN OF ECM-IMMU” might be stored as a self-diagnostic result during key registration

procedure, even if the system is not malfunctioning.

HOW TO READ SELF-DIAGNOSTIC RESULTS

NATS SELF-DIAGNOSTIC RESULTS ITEM CHART

SEL151X

Detected items

(NATS program card screen terms)P No. Code

(Self-diagnostic

result of

“ENGINE”Malfunction is detected when.....Reference

page

ECM INT CIRC-IMMUNATS MAL-

FUNCTION

P1613The malfunction of ECM internal circuit of IMMU commu-

nication line is detected.BL-80

CHAIN OF ECM-IMMUNATS MAL-

FUNCTION

P1612Communication impossible between ECM and IMMU

(In rare case, “CHAIN OF ECM-IMMU” might be stored

during key registration procedure, even if the system is

not malfunctioning.)BL-80

DIFFERENCE OF KEYNATS MAL-

FUNCTION

P1615IMMU can receive the key ID signal but the result of ID

verification between key ID and IMMU is NG.BL-82

CHAIN OF IMMU-KEYNATS MAL-

FUNCTION

P1614IMMU cannot receive the key ID signal.BL-83

ID DISCORD, IMM-ECMNATS MAL-

FUNCTION

P1611The result of ID verification between IMMU and ECM is

NG. System initialization is required.BL-85