check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1119 of 3066

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA DTC P1805 BRAKE SWITCH ................................ 329

Description ........................................................... 329

CONSULT-II Reference Value in Data Monitor Mode

. 329

ECM Terminals and Reference Value .................. 329

On Board Diagnosis Logic ................................... 329

DTC Confirmation Procedure ............................... 329

Wiring Diagram .................................................... 330

Diagnostic Procedure ........................................... 331

Component Inspection ......................................... 332

IGNITION SIGNAL .................................................. 334

Component Description ........................................ 334

ECM Terminals and Reference Value .................. 334

Wiring Diagram .................................................... 335

Diagnostic Procedure ........................................... 337

Component Inspection ......................................... 341

Removal and Installation ...................................... 342

INJECTOR CIRCUIT ............................................... 343

Component Description ........................................ 343

CONSULT-II Reference Value in Data Monitor Mode

. 343

ECM Terminals and Reference Value .................. 343

Wiring Diagram .................................................... 344

Diagnostic Procedure ........................................... 345

Component Inspection ......................................... 347

Removal and Installation ...................................... 347

START SIGNAL ...................................................... 348

CONSULT-II Reference Value in Data Monitor Mode

. 348

ECM Terminals and Reference Value .................. 348

Wiring Diagram .................................................... 349

Diagnostic Procedure ........................................... 350

FUEL PUMP CIRCUIT ............................................ 352

Description ........................................................... 352

CONSULT-II Reference Value in Data Monitor Mode

. 352

ECM Terminals and Reference Value .................. 352

Wiring Diagram .................................................... 354

Diagnostic Procedure ........................................... 355

Component Inspection ......................................... 357

Removal and Installation ...................................... 358

REFRIGERANT PRESSURE SENSOR ................. 359

Component Description ........................................ 359

ECM Terminals and Reference Value .................. 359

Wiring Diagram .................................................... 360

Diagnostic Procedure ........................................... 361

Removal and Installation ...................................... 362

ELECTRICAL LOAD SIGNAL ................................ 363

CONSULT-II Reference Value in Data Monitor Mode

. 363

ECM Terminals and Reference Value .................. 363

Wiring Diagram .................................................... 364

Diagnostic Procedure ........................................... 366

DATA LINK CONNECTOR ..................................... 371

Wiring Diagram .................................................... 371

EVAPORATIVE EMISSION SYSTEM ..................... 372

Description ........................................................... 372

Component Inspection ......................................... 374POSITIVE CRANKCASE VENTILATION ...............375

Description ............................................................375

Component Inspection ..........................................375

SERVICE DATA AND SPECIFICATIONS (SDS) ....377

Fuel Pressure .......................................................377

Idle Speed and Ignition Timing .............................377

Calculated Load Value ..........................................377

Mass Air Flow Sensor ...........................................377

Intake Air Temperature Sensor .............................377

Engine Coolant Temperature Sensor ...................377

Heated Oxygen Sensor 1 Heater .........................377

Heated Oxygen sensor 2 Heater ..........................377

Crankshaft Position Sensor (POS) .......................377

Camshaft Position Sensor (PHASE) ....................377

Throttle Control Motor ...........................................378

Injector ..................................................................378

Fuel Pump ............................................................378

QR (WITHOUT EURO-OBD)

INDEX FOR DTC .....................................................379

Alphabetical Index ................................................379

DTC No. Index ......................................................380

PRECAUTIONS ......................................................381

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................381

On Board Diagnostic (OBD) System of Engine and

A/T ........................................................................381

Precaution ............................................................381

Wiring Diagrams and Trouble Diagnosis ..............384

PREPARATION .......................................................385

Special Service Tools ...........................................385

Commercial Service Tools ....................................385

ENGINE CONTROL SYSTEM ................................387

System Diagram ...................................................387

Vacuum Hose Drawing .........................................388

System Chart ........................................................389

Multiport Fuel Injection (MFI) System ...................389

Electronic Ignition (EI) System .............................392

Air Conditioning Cut Control .................................392

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................393

CAN communication .............................................393

BASIC SERVICE PROCEDURE .............................395

Idle Speed and Ignition Timing Check ..................395

Throttle Valve Closed Position Learning ...............396

Accelerator Pedal Released Position Learning ....396

Idle Air Volume Learning ......................................396

Fuel Pressure Check ............................................399

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..........401

Introduction ...........................................................401

Two Trip Detection Logic ......................................401

Emission-related Diagnostic Information ..............401

NATS (Nissan Anti-theft System) .........................403

Malfunction Indicator (MI) .....................................404

TROUBLE DIAGNOSIS ..........................................407

Trouble Diagnosis Introduction .............................407

Page 1120 of 3066

EC-6

DTC Inspection Priority Chart ...............................410

Fail-safe Chart ......................................................411

Basic Inspection ...................................................412

Symptom Matrix Chart ..........................................417

Engine Control Component Parts Location ..........421

Circuit Diagram .....................................................425

ECM Harness Connector Terminal Layout ...........427

ECM Terminals and Reference Value ...................427

CONSULT-II Function ...........................................434

CONSULT-II Reference Value in Data Monitor .....443

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................446

TROUBLE DIAGNOSIS - SPECIFICATION VALUE. 449

Description ............................................................449

Testing Condition ..................................................449

Inspection Procedure ............................................449

Diagnostic Procedure ...........................................450

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................453

Description ............................................................453

Diagnostic Procedure ...........................................453

POWER SUPPLY CIRCUIT FOR ECM ...................454

Wiring Diagram .....................................................454

ECM Terminals and Reference Value ...................455

Diagnostic Procedure ...........................................455

Component Inspection ..........................................459

DTC U1000 CAN COMMUNICATION LINE ............460

Description ............................................................460

On Board Diagnosis Logic ....................................460

DTC Confirmation Procedure ...............................460

Wiring Diagram .....................................................461

Diagnostic Procedure ...........................................462

DTC P0102, P0103 MAF SENSOR .........................463

Component Description ........................................463

CONSULT-II Reference Value in Data Monitor Mode

.463

ECM Terminals and Reference Value ...................463

On Board Diagnosis Logic ....................................464

DTC Confirmation Procedure ...............................464

Wiring Diagram .....................................................466

Diagnostic Procedure ...........................................467

Component Inspection ..........................................469

Removal and Installation ......................................469

DTC P0117, P0118 ECT SENSOR ..........................470

Component Description ........................................470

On Board Diagnosis Logic ....................................470

DTC Confirmation Procedure ...............................471

Wiring Diagram .....................................................472

Diagnostic Procedure ...........................................473

Component Inspection ..........................................474

Removal and Installation ......................................474

DTC P0120 TP SENSOR ........................................475

Component Description ........................................475

CONSULT-II Reference Value in Data Monitor Mode

.475

ECM Terminals and Reference Value ...................475

On Board Diagnosis Logic ....................................476

DTC Confirmation Procedure ...............................476Wiring Diagram ..................................................... 479

Diagnostic Procedure ............................................ 480

Component Inspection .......................................... 482

Remove and Installation ....................................... 483

DTC P0121 APP SENSOR ...................................... 484

Component Description ........................................ 484

CONSULT-II Reference Value in Data Monitor Mode

. 484

ECM Terminals and Reference Value ................... 484

On Board Diagnosis Logic .................................... 485

DTC Confirmation Procedure ................................ 485

Wiring Diagram ..................................................... 486

Diagnostic Procedure ............................................ 487

Component Inspection .......................................... 489

Remove and Installation ....................................... 489

DTC P0134 HO2S1 ................................................. 490

Component Description ........................................ 490

CONSULT-II Reference Value in Data Monitor Mode

. 490

ECM Terminals and Reference Value ................... 490

On Board Diagnosis Logic .................................... 491

Overall Function Check ......................................... 491

Wiring Diagram ..................................................... 492

Diagnostic Procedure ............................................ 493

Component Inspection .......................................... 494

Removal and Installation ....................................... 495

DTC P0327, P0328 KS ............................................ 496

Component Description ........................................ 496

ECM Terminals and Reference Value ................... 496

On Board Diagnosis Logic .................................... 496

DTC Confirmation Procedure ................................ 496

Wiring Diagram ..................................................... 498

Diagnostic Procedure ............................................ 499

Component Inspection .......................................... 500

Removal and Installation ....................................... 500

DTC P0335 CKP SENSOR (POS) .......................... 501

Component Description ........................................ 501

CONSULT-II Reference Value in Data Monitor Mode

. 501

ECM Terminals and Reference Value ................... 501

On Board Diagnosis Logic .................................... 502

DTC Confirmation Procedure ................................ 502

Wiring Diagram ..................................................... 503

Diagnostic Procedure ............................................ 504

Component Inspection .......................................... 505

Removal and Installation ....................................... 506

DTC P0340 CMP SENSOR (PHASE) ..................... 507

Component Description ........................................ 507

ECM Terminals and Reference Value ................... 507

On Board Diagnosis Logic .................................... 507

DTC Confirmation Procedure ................................ 508

Wiring Diagram ..................................................... 509

Diagnostic Procedure ............................................ 510

Component Inspection .......................................... 512

Removal and Installation ....................................... 512

DTC P0500 VSS ...................................................... 513

Component Description ........................................ 513

ECM Terminals and Reference Value ................... 513

Page 1121 of 3066

EC-7

C

D

E

F

G

H

I

J

K

L

M

ECA On Board Diagnosis Logic ................................... 513

DTC Confirmation Procedure ............................... 513

Overall Function Check ........................................ 514

Wiring Diagram .................................................... 515

Diagnostic Procedure ........................................... 517

DTC P0550 PSP SENSOR ..................................... 518

Component Description ........................................ 518

CONSULT-II Reference Value in Data Monitor Mode

. 518

ECM Terminals and Reference Value .................. 518

On Board Diagnosis Logic ................................... 518

DTC Confirmation Procedure ............................... 518

Wiring Diagram .................................................... 520

Diagnostic Procedure ........................................... 521

Component Inspection ......................................... 522

DTC P0605 ECM .................................................... 523

Component Description ........................................ 523

On Board Diagnosis Logic ................................... 523

DTC Confirmation Procedure ............................... 523

Diagnostic Procedure ........................................... 525

DTC P0650 MI ........................................................ 526

Component Description ........................................ 526

On Board Diagnosis Logic ................................... 526

DTC Confirmation Procedure ............................... 526

Overall Function Check ........................................ 526

Wiring Diagram .................................................... 527

Diagnostic Procedure ........................................... 528

DTC P1065 ECM POWER SUPPLY ....................... 530

Component Description ........................................ 530

On Board Diagnosis Logic ................................... 530

DTC Confirmation Procedure ............................... 530

Wiring Diagram .................................................... 531

Diagnostic Procedure ........................................... 532

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR ............................................................ 534

Description ........................................................... 534

On Board Diagnosis Logic ................................... 534

DTC Confirmation Procedure ............................... 534

Diagnostic Procedure ........................................... 535

DTC P1122 ELECTRIC THROTTLE CONTROL

FUNCTION .............................................................. 536

Description ........................................................... 536

ECM Terminals and Reference Value .................. 536

On Board Diagnosis Logic ................................... 536

DTC Confirmation Procedure ............................... 537

Wiring Diagram .................................................... 538

Diagnostic Procedure ........................................... 539

Component Inspection ......................................... 540

DTC P1123 THROTTLE CONTROL MOTOR RELAY. 542

Component Description ........................................ 542

CONSULT-II Reference Value in Data Monitor Mode

. 542

ECM Terminals and Reference Value .................. 542

On Board Diagnosis Logic ................................... 542

DTC Confirmation Procedure ............................... 542

Wiring Diagram .................................................... 544

Diagnostic Procedure ........................................... 545

Component Inspection ......................................... 546DTC P1212 ESP/TCS/ABS COMMUNICATION

LINE ........................................................................547

Description ............................................................547

On Board Diagnosis Logic ....................................547

DTC Confirmation Procedure ...............................547

Diagnostic Procedure ...........................................547

DTC P1217 ENGINE OVER TEMPERATURE ........548

System Description ...............................................548

CONSULT-II Reference Value in Data Monitor Mode

.548

ECM Terminals and Reference Value ...................549

On Board Diagnosis Logic ....................................549

Overall Function Check ........................................549

Wiring Diagram .....................................................552

Diagnostic Procedure ...........................................553

Main 12 Causes of Overheating ...........................560

Component Inspection ..........................................561

DTC P1805 BRAKE SWITCH .................................562

Description ............................................................562

CONSULT-II Reference Value in Data Monitor Mode

.562

ECM Terminals and Reference Value ...................562

On Board Diagnosis Logic ....................................562

DTC Confirmation Procedure ...............................562

Wiring Diagram .....................................................564

Diagnostic Procedure ...........................................565

Component Inspection ..........................................566

HO2S1 HEATER .....................................................568

Description ............................................................568

CONSULT-II Reference Value in Data Monitor Mode

.568

ECM Terminals and Reference Value ...................568

Wiring Diagram .....................................................569

Diagnostic Procedure ...........................................570

Component Inspection ..........................................572

Removal and Installation ......................................572

HO2S2 HEATER .....................................................573

Description ............................................................573

CONSULT-II Reference Value in Data Monitor Mode

.573

ECM Terminals and Reference Value ...................573

Wiring Diagram .....................................................574

Diagnostic Procedure ...........................................575

Component Inspection ..........................................576

Removal and Installation ......................................576

IAT SENSOR ...........................................................577

Component Description ........................................577

Wiring Diagram .....................................................578

Diagnostic Procedure ...........................................579

Component Inspection ..........................................580

Removal and Installation ......................................580

HO2S1 .....................................................................581

Component Description ........................................581

CONSULT-II Reference Value in Data Monitor Mode

.581

ECM Terminals and Reference Value ...................581

Wiring Diagram .....................................................582

Diagnostic Procedure ...........................................583

Page 1126 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-12

[QR (WITH EURO-OBD)]

INDEX FOR DTC

[QR (WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00B0G

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the "Type approval NISSAN X-TRAIL 2003 Electronic Repair Manual EC-12

[QR (WITH EURO-OBD)]

INDEX FOR DTC

[QR (WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00B0G

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the "Type approval](/img/5/57402/w960_57402-1125.png)

EC-12

[QR (WITH EURO-OBD)]

INDEX FOR DTC

[QR (WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00B0G

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the "Type approval number" on the

identification plate. Refer toGI-45, "

IDENTIFICATION PLATE".

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

EC-114

.

Items

(CONSULT-II screen terms)DTC*1

Reference page

CONSULT-II

GST*2ECM*3

APP SEN/CIRCUIT P0121 0121EC-154

A/T 1ST GR FNCTN P0731 0731AT-151

A/T 2ND GR FNCTN P0732 0732AT-158

A/T 3RD GR FNCTN P0733 0733AT-165

A/T 4TH GR FNCTN P0734 0734AT-172

ATF TEMP SEN/CIRC P0710 0710AT-136

BRAKE SW/CIRCUIT P1805 1805EC-329

CAN COMM CIRCUIT*7 U1000 1000*6EC-114

CKP SEN/CIRCUIT P0335 0335EC-217

CMP SEN/CIRCUIT P0340 0340EC-223

CYL 1 MISFIRE P0301 0301EC-206

CYL 2 MISFIRE P0302 0302EC-206

CYL 3 MISFIRE P0303 0303EC-206

CYL 4 MISFIRE P0304 0304EC-206

ECM P0605 0605EC-249

ECM BACK UP/CIRC P1065 1065EC-256

ECT SEN/CIRCUIT*5 P0117 0117EC-141

ECT SEN/CIRCUIT*5 P0118 0118EC-141

ENG OVER TEMP P1217 1217EC-311

ENGINE SPEED SIG P0725 0725AT-147

E T C A C T R P 11 2 1 11 2 1EC-271

ETC FUNCTION/CIRC P1122 1122EC-273

ETC MOT RLY/CIRC P1123 1123EC-279

FUEL SYS-LEAN-B1 P0171 0171EC-194

FUEL SYS-RICH-B1 P0172 0172EC-200

HO2S1 (B1) P0132 0132EC-160

HO2S1 (B1) P0133 0133EC-166

HO2S1 (B1) P0134 0134EC-174

HO2S1 (B1) P1143 1143EC-284

HO2S1 (B1) P1144 1144EC-290

HO2S1 HTR (B1) P0031 0031EC-120

HO2S1 HTR (B1) P0032 0032EC-120

HO2S2 (B1) P0138 0138EC-181

HO2S2 (B1) P0139 0139EC-187

HO2S2 (B1) P1146 1146EC-296

HO2S2 (B1) P1147 1147EC-303

Page 1134 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-20

[QR (WITH EURO-OBD)]

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEBS00B0M

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commer NISSAN X-TRAIL 2003 Electronic Repair Manual EC-20

[QR (WITH EURO-OBD)]

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEBS00B0M

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commer](/img/5/57402/w960_57402-1133.png)

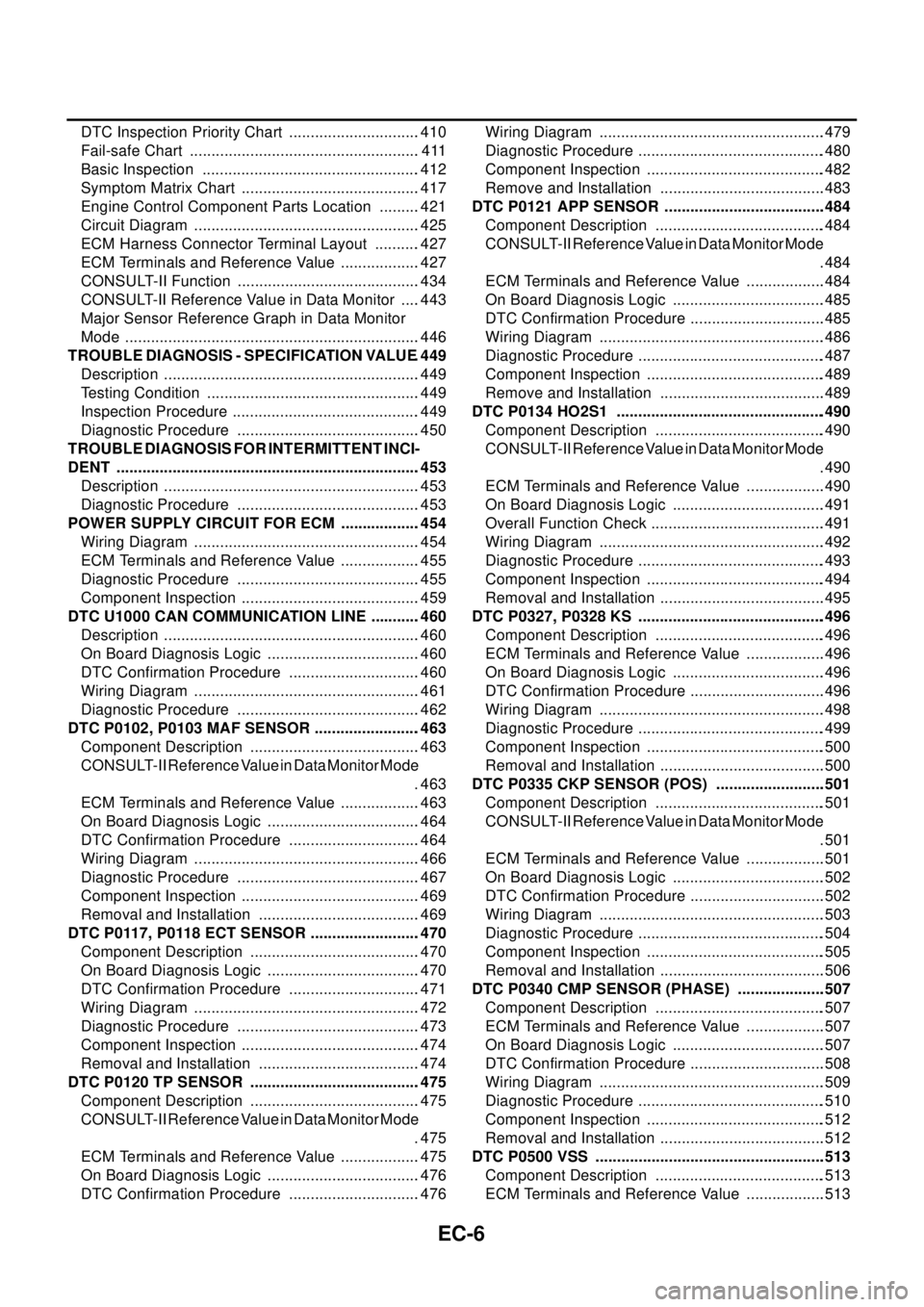

EC-20

[QR (WITH EURO-OBD)]

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEBS00B0M

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsEBS00B0N

Tool number

Tool nameDescription

KV10117100

Heated oxygen

sensor wrenchLoosening or tightening heated oxygen sensors

with 22 mm (0.87 in) hexagon nut

KV10114400

Heated oxygen

sensor wrenchLoosening or tightening heated oxygen sensors

a: 22 mm (0.87 in)

S-NT379

S-NT636

Tool name (Kent-

Moore No.)Description

Quick connector

releaseRemoving fuel tube quick connectors in engine

room

(Available in SEC. 164 of PARTS CATALOG:

Part No. 16441 6N210)

Fuel filler cap adapter Checking fuel tank vacuum relief valve opening

pressure

Socket wrench Removing and installing engine coolant

temperature sensor

PBIC0198E

S-NT653

S-NT705

Page 1145 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BASIC SERVICE PROCEDURE

EC-31

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

–Check ignition timing.

Throttle Valve Closed Position LearningEBS00B0X

DESCRIPTION

“Throttle Valve Closed Position Lea NISSAN X-TRAIL 2003 Electronic Repair Manual BASIC SERVICE PROCEDURE

EC-31

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

–Check ignition timing.

Throttle Valve Closed Position LearningEBS00B0X

DESCRIPTION

“Throttle Valve Closed Position Lea](/img/5/57402/w960_57402-1144.png)

BASIC SERVICE PROCEDURE

EC-31

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

–Check ignition timing.

Throttle Valve Closed Position LearningEBS00B0X

DESCRIPTION

“Throttle Valve Closed Position Learning” is an operation to learn the fully closed position of the throttle valve

by monitoring the throttle position sensor output signal. It must be performed each time harness connector of

electric throttle control actuator or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch “ON”.

3. Turn ignition switch “OFF” wait at least 10 seconds.

Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

Accelerator Pedal Released Position LearningEBS00BLU

DESCRIPTION

“Accelerator Pedal Released Position Learning” is an operation to learn the fully released position of the accel-

erator pedal by monitoring the accelerator pedal position sensor output signal. It must be performed each time

harness connector of accelerator pedal position sensor or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch “ON” and wait at least 2 seconds.

3. Turn ignition switch “OFF” wait at least 10 seconds.

4. Turn ignition switch “ON” and wait at least 2 seconds.

5. Turn ignition switch “OFF” wait at least 10 seconds.

Idle Air Volume LearningEBS00B0Y

DESCRIPTION

“Idle Air Volume Learning” is an operation to learn the idle air volume that keeps each engine within the spe-

cific range. It must be performed under any of the following conditions:

lEach time electric throttle control actuator or ECM is replaced.

lIdle speed or ignition timing is out of specification.

SEF166Y

PBIB0514E

Page 1146 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-32

[QR (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelle NISSAN X-TRAIL 2003 Electronic Repair Manual EC-32

[QR (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelle](/img/5/57402/w960_57402-1145.png)

EC-32

[QR (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

lBattery voltage: More than 12.9V (At idle)

lEngine coolant temperature: 70 - 100°C (158 - 212°F)

lPNP switch: ON

lElectric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, set lighting switch to the 1st position to light

only small lamps.

lSteering wheel: Neutral (Straight-ahead position)

lVehicle speed: Stopped

lTransmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “A/

T” system indicates less than 0.9V.

For A/T models without CONSULT-II and M/T models, drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-II

1. PerformEC-31, "Accelerator Pedal Released Position Learning".

2. PerformEC-31, "

Throttle Valve Closed Position Learning".

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic “PRE-CONDITIONING” (previously mentioned) are in good

order.

5. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

SEF452Y

SEF454Y

Page 1147 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BASIC SERVICE PROCEDURE

EC-33

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

7. Make sure that “CMPLT” is displayed on CONSULT-II screen. If

“INCMP” is displayed, “Idle Air Volume Learning� NISSAN X-TRAIL 2003 Electronic Repair Manual BASIC SERVICE PROCEDURE

EC-33

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

7. Make sure that “CMPLT” is displayed on CONSULT-II screen. If

“INCMP” is displayed, “Idle Air Volume Learning�](/img/5/57402/w960_57402-1146.png)

BASIC SERVICE PROCEDURE

EC-33

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

7. Make sure that “CMPLT” is displayed on CONSULT-II screen. If

“INCMP” is displayed, “Idle Air Volume Learning” will not be car-

ried out successfully. In this case, find the cause of the problem

by referring to the “Diagnostic Procedure” below.

8. Rev up the engine two or three times and make sure that idle

speed and ignition timing are within the specifications.

Without CONSULT-II

NOTE:

lIt is better to count the time accurately with a clock.

lIt is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit

has a malfunction.

1. PerformEC-31, "

Accelerator Pedal Released Position Learning".

2. PerformEC-31, "

Throttle Valve Closed Position Learning".

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic “PRE-CONDITIONING” (previously mentioned) are in good

order.

5. Turn ignition switch “OFF” and wait at least 10 seconds.

6. Confirm that accelerator pedal is fully released, turn ignition switch “ON” and wait 3 seconds.

7. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

8. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MI stops

blinking and turned ON.

9. Fully release the accelerator pedal within 3 seconds after the MI goes off.

10. Start engine and let it idle.

11. Wait 20 seconds.

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the

specifications.

13. If idle speed and ignition timing are not within the specification, the result will be incomplete. In this case,

find the cause of the problem by referring to the “Diagnostic Procedure” below.

ITEM SPECIFICATION

Idle speed M/T: 650±50 rpm

A/T: 700±50 rpm (in “P” or “N” position)

Ignition timing M/T: 14±5°BTDC

A/T: 16±5°BTDC (in “P” or “N” position)

SEF455Y

ITEM SPECIFICATION

Idle speed M/T: 650±50 rpm

A/T: 700±50 rpm (in “P” or “N” position)

Ignition timing M/T: 14±5°BTDC

A/T: 16±5°BTDC (in “P” or “N” position)

PBIB0665E

Page 1148 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-34

[QR (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2 NISSAN X-TRAIL 2003 Electronic Repair Manual EC-34

[QR (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2](/img/5/57402/w960_57402-1147.png)

EC-34

[QR (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2.Check PCV valve operation.

3.Check that downstream of throttle valve is free from air leakage.

4.When the above three items check out OK, engine component parts and their installation condi-

tion are questionable. Check and eliminate the cause of the problem.

It is useful to performEC-103, "

TROUBLE DIAGNOSIS - SPECIFICATION VALUE".

5.If any of the following conditions occur after the engine has started, eliminate the cause of the

problem and perform “Idle air volume learning” all over again:

–Engine stalls.

–Erroneous idle.

Fuel Pressure CheckEBS00B0Z

FUEL PRESSURE RELEASE

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pres-

sure cannot be completely released because QR engine models do not have fuel return system.

With CONSULT-II

1. Turn ignition switch “ON”.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT”

mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition switch “OFF”.

Without CONSULT-II

1. Remove fuel pump fuse located in fuse box.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch “OFF”.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

CAUTION:

lThe fuel hose connection method used when taking fuel pressure check must not be used for

other purposes.

lTake care for not to scratch and not to put debris around connection area when servicing, so that

the quick connector keeps sealability with O-rings inside.

1. Release fuel pressure to zero. Refer toEC-34, "

FUEL PRESSURE RELEASE".

2. Prepare fuel hose for fuel pressure check, and connect fuel pressure gauge.

lUse suitable fuel hose for fuel pressure check (genuine NISSAN fuel hose without quick connector).

SEF214Y

PBIB0508E

Page 1149 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BASIC SERVICE PROCEDURE

EC-35

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

lTo avoid unnecessary force or tension to hose, use moderately long fuel hose for fuel pressure check.

lDo not use the fuel NISSAN X-TRAIL 2003 Electronic Repair Manual BASIC SERVICE PROCEDURE

EC-35

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

lTo avoid unnecessary force or tension to hose, use moderately long fuel hose for fuel pressure check.

lDo not use the fuel](/img/5/57402/w960_57402-1148.png)

BASIC SERVICE PROCEDURE

EC-35

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

lTo avoid unnecessary force or tension to hose, use moderately long fuel hose for fuel pressure check.

lDo not use the fuel hose for checking fuel pressure with damage or cracks on it.

lUse Pressure Gauge to check fuel pressure.

3. Remove fuel hose. Refer toEM-17, "

INTAKE MANIFOLD".

lDo not twist or kink fuel hose because it is plastic hose.

lDo not remove fuel hose from quick connector.

lKeep the original fuel hose to be free from intrusion of dust or foreign substances with a suitable cover.

4. Install the fuel pressure gauge as shown in the figure.

lWipe off oil or dirt from hose insertion part using cloth moist-

ened with gasoline.

lApply proper amount of gasoline between top of the fuel tube

and No.1 spool.

lInsert fuel hose for fuel pressure check until it touches the

No.1 spool on fuel tube.

lUse NISSAN genuine hose clamp (part number: 16439

N4710 or 16439 40U00).

lWhen reconnecting fuel line, always use new clamps.

lWhen reconnecting fuel hose, check the original fuel hose for

damage and abnormality.

lUse a torque driver to tighten clamps.

lInstall hose clamp to the position within 1 - 2 mm (0.04 - 0.08

in).

lMake sure that clamp screw does not contact adjacent parts.

5. After connecting fuel hose for fuel pressure check, pull the hose

with a force of approximately 98 N (10 kg, 22 lb) to confirm fuel

tube does not come off.

6. Turn ignition switch "ON", and check for fuel leakage.

7. Start engine and check for fuel leakage.

8. Read the indication of fuel pressure gauge.

lDo not perform fuel pressure check with system operating. Fuel pressure gauge may indicate false

readings.

lDuring fuel pressure check, confirm for fuel leakage from fuel connection every 3 minutes.

9. If result is unsatisfactory, go to next step.

10. Check the following.

lFuel hoses and fuel tubes for clogging

lFuel filter for clogging

lFuel pump

lFuel pressure regulator for clogging

If OK, replace fuel pressure regulator.

If NG, repair or replace.Tightening torque: 1 - 1.5 N·m (0.1 - 0.15 kg-m,

9-13in-lb)

At idling:

Approximately 350 kPa (3.5 bar, 3.7 kg/cm

2,51psi)

PBIB0669E

PBIB0670E