check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 984 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-116

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

Symptom 7: SLIP Indicator Lamp Does Not Illuminate

EFS001AY

Inspection procedure

1.SLIP INDICATOR LAMP BURNED-OUT BULB INSPECTION

Check for continuity between t NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-116

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

Symptom 7: SLIP Indicator Lamp Does Not Illuminate

EFS001AY

Inspection procedure

1.SLIP INDICATOR LAMP BURNED-OUT BULB INSPECTION

Check for continuity between t](/img/5/57402/w960_57402-983.png)

BRC-116

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

Symptom 7: SLIP Indicator Lamp Does Not Illuminate

EFS001AY

Inspection procedure

1.SLIP INDICATOR LAMP BURNED-OUT BULB INSPECTION

Check for continuity between the power supply terminal of meter and terminal of ABS warning lamp.

Is inspection result OK?

OK >> GO TO 2.

NG >> Circuit malfunction in SLIP indicator lamp or combination meter

2.SLIP INDICATOR LAMP POWER CIRCUIT INSPECTION

Disconnect the meter connector. Check that the voltage between the vehicle-side harness terminal and body

ground is battery voltage (Approx. 12V).

Is inspection result OK?

YES >> GO TO 3.

NO >>

lFuse inspection

lInspection for harness and connectors between fuse block and meter

lCheck the power supply circuit (battery and ignition switch circuit).

3.SLIP INDICATOR LAMP HARNESS INSPECTION

1. Disconnect connectors for the ESP/TCS/ABS control unit and meter vehicle-side harness.

2. Check the harness between the meter and the ESP/TCS/ABS control unit for an open/shorted circuit.

Is inspection result OK?

OK >> GO TO 4.

NG >> Repair or replace the disconnected harness.

4.SLIP INDICATOR LAMP CONNECTOR INSPECTION

Check connectors for the ESP/TCS/ABS control unit and meter vehicle-side harness.

Is inspection result OK?

YES >> Connect connectors, and perform the self-diagnosis. The vehicle harness has the intermediate

connector. Refer to the vehicle wiring diagram, always check it.

NG >> Repair or replace the disconnected connector.

Symptom 8: During ESP/TCS/ABS Control, Vehicle Behavior is Jerky.EFS001AZ

Inspection procedure

1.ENGINE SPEED SIGNAL INSPECTION

Perform²DATA MONITOR²with CONSULT-II for the ESP/TCS/ABS control unit.

Is the engine speed at idle 400 rpm or higher?

YES >> Normal

NO >> GO TO 2.

2.SELF-DIAGNOSIS RESULT CHECK 1

Perform the ESP/TCS/ABS control unit self-diagnosis.

Is the self-diagnosis results displayed?

YES >> After checking and repairing the applicable item, perform the ESP/TCS/ABS control unit self-

diagnosis again.

NO >> GO TO 3.

Page 985 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-117

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.ECM SELF-DIAGNOSIS RESULT CHECK

Perform the ECM self-diagnosis.

Is the self-diagnosis results indicated?

YES >> Repair or replace t NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-117

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.ECM SELF-DIAGNOSIS RESULT CHECK

Perform the ECM self-diagnosis.

Is the self-diagnosis results indicated?

YES >> Repair or replace t](/img/5/57402/w960_57402-984.png)

TROUBLE DIAGNOSIS

BRC-117

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.ECM SELF-DIAGNOSIS RESULT CHECK

Perform the ECM self-diagnosis.

Is the self-diagnosis results indicated?

YES >> Repair or replace the camshaft position sensor system.

NO >> GO TO 4.

4.SELF-DIAGNOSIS RESULT 2

Disconnect connectors for the ESP/TCS/ABS control unit and ECM, and reconnect them correctly to perform

the self-diagnosis again.

Is inspection result OK?

OK >> GO TO 5.

NG >> Connector malfunction. Repair or replace the connector.

5.SELF-DIAGNOSIS RESULT CHECK 3

Perform the 4WD control unit self-diagnosis.

Is inspection result OK?

OK >> GO TO 6.

NG >> Repair or replace the applicable part.

6.SELF-DIAGNOSIS RESULT CHECK 4

Perform the ESP/TCS/4WD control unit self-diagnosis again.

Is the self-diagnosis results displayed?

YES >> Repair or replace the applicable item.

NO >> GO TO 7.

7.CIRCUIT CHECK BETWEEN ESP/TCS/ABS CONTROL UNIT AND ECM

1. Disconnect connectors for the ESP/TCS/ABS control unit and ECM.

2. Check the engine speed signal harness between the ESP/TCS/ABS control unit and ECM for an open/

shorted circuit.

3. Check connectors for the ESP/TCS/ABS control unit and ECM.

Is inspection result OK?

OK >> Inspection End

NG >> Repair or replace the applicable item and perform the ESP/TCS/ABS control unit self-diagnosis

again.

Page 998 of 3066

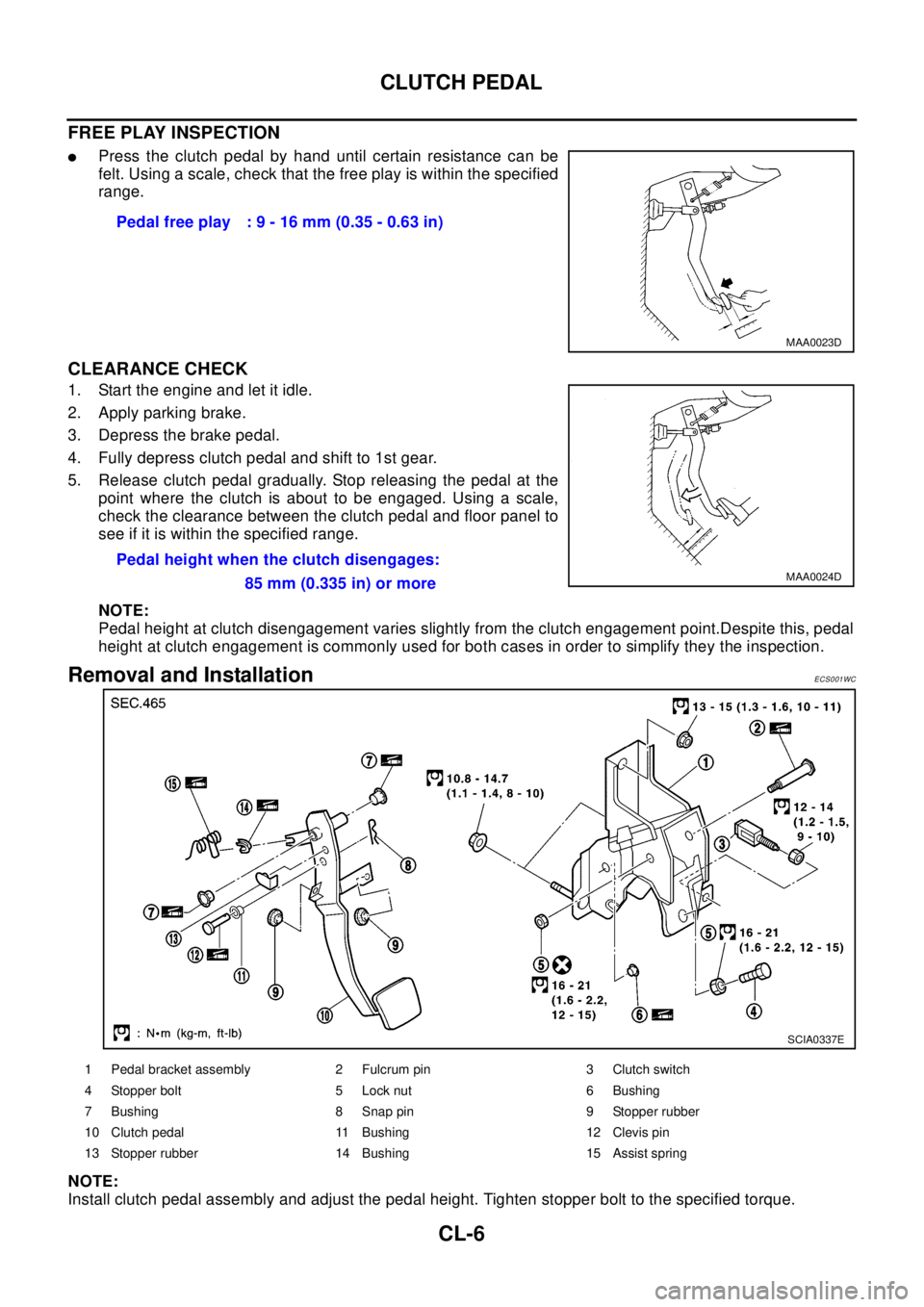

CL-6

CLUTCH PEDAL

FREE PLAY INSPECTION

lPress the clutch pedal by hand until certain resistance can be

felt. Using a scale, check that the free play is within the specified

range.

CLEARANCE CHECK

1. Start the engine and let it idle.

2. Apply parking brake.

3. Depress the brake pedal.

4. Fully depress clutch pedal and shift to 1st gear.

5. Release clutch pedal gradually. Stop releasing the pedal at the

point where the clutch is about to be engaged. Using a scale,

check the clearance between the clutch pedal and floor panel to

see if it is within the specified range.

NOTE:

Pedal height at clutch disengagement varies slightly from the clutch engagement point.Despite this, pedal

height at clutch engagement is commonly used for both cases in order to simplify they the inspection.

Removal and InstallationECS001WC

NOTE:

Install clutch pedal assembly and adjust the pedal height. Tighten stopper bolt to the specified torque.Pedalfreeplay :9-16mm(0.35-0.63in)

MAA0023D

Pedal height when the clutch disengages:

85 mm (0.335 in) or more

MAA0024D

SCIA0337E

1 Pedal bracket assembly 2 Fulcrum pin 3 Clutch switch

4 Stopper bolt 5 Lock nut 6 Bushing

7 Bushing 8 Snap pin 9 Stopper rubber

10 Clutch pedal 11 Bushing 12 Clevis pin

13 Stopper rubber 14 Bushing 15 Assist spring

Page 1008 of 3066

CL-16

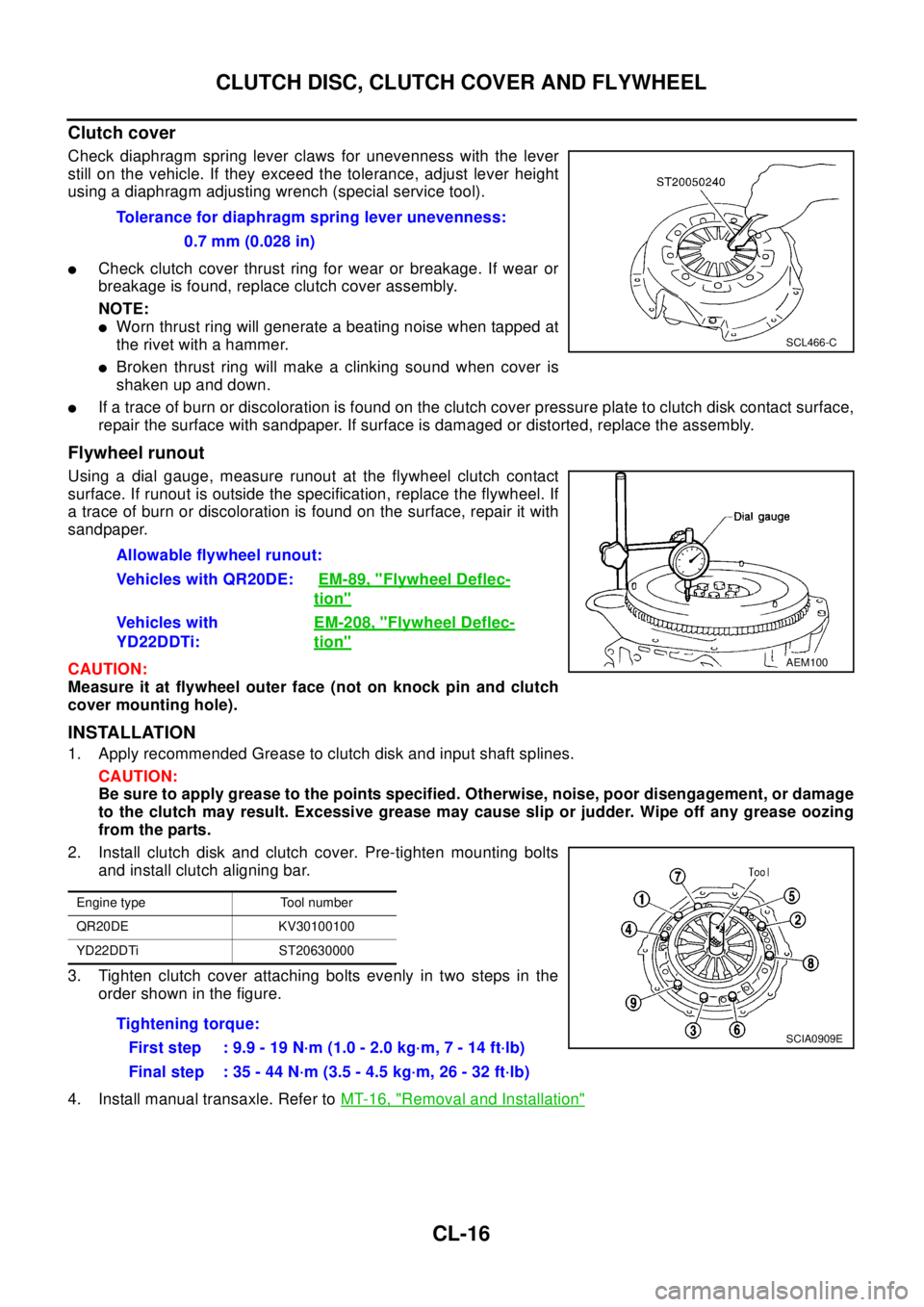

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Clutch cover

Check diaphragm spring lever claws for unevenness with the lever

still on the vehicle. If they exceed the tolerance, adjust lever height

using a diaphragm adjusting wrench (special service tool).

lCheck clutch cover thrust ring for wear or breakage. If wear or

breakage is found, replace clutch cover assembly.

NOTE:

lWorn thrust ring will generate a beating noise when tapped at

therivetwithahammer.

lBroken thrust ring will make a clinking sound when cover is

shaken up and down.

lIf a trace of burn or discoloration is found on the clutch cover pressure plate to clutch disk contact surface,

repair the surface with sandpaper. If surface is damaged or distorted, replace the assembly.

Flywheel runout

Using a dial gauge, measure runout at the flywheel clutch contact

surface. If runout is outside the specification, replace the flywheel. If

a trace of burn or discoloration is found on the surface, repair it with

sandpaper.

CAUTION:

Measure it at flywheel outer face (not on knock pin and clutch

cover mounting hole).

INSTALLATION

1. Apply recommended Grease to clutch disk and input shaft splines.

CAUTION:

Be sure to apply grease to the points specified. Otherwise, noise, poor disengagement, or damage

to the clutch may result. Excessive grease may cause slip or judder. Wipe off any grease oozing

from the parts.

2. Install clutch disk and clutch cover. Pre-tighten mounting bolts

and install clutch aligning bar.

3. Tighten clutch cover attaching bolts evenly in two steps in the

order shown in the figure.

4. Install manual transaxle. Refer toMT-16, "

Removal and Installation"

Tolerance for diaphragm spring lever unevenness:

0.7 mm (0.028 in)

SCL466-C

Allowable flywheel runout:

Vehicles with QR20DE:EM-89, "

Flywheel Deflec-

tion"

Vehicles with

YD22DDTi:EM-208, "Flywheel Deflec-

tion"

AEM100

Engine type Tool number

QR20DE KV30100100

YD22DDTi ST20630000

Tightening torque:

First step : 9.9 - 19 N·m (1.0 - 2.0 kg·m, 7 - 14 ft·lb)

Final step : 35 - 44 N·m (3.5 - 4.5 kg·m, 26 - 32 ft·lb)SCIA0909E

Page 1011 of 3066

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

CO

ENGINE COOLING SYSTEM

QR20DE

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET .......................... 3

LIQUID GASKET APPLICATION PROCEDURE..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

OVERHEATING CAUSE ANALYSIS .......................... 5

Troubleshooting Chart .............................................. 5

COOLING SYSTEM .................................................... 7

Cooling Circuit .......................................................... 7

ENGINE COOLANT .................................................... 9

Inspection ................................................................. 9

LEVEL CHECK ..................................................... 9

LEAK CHECK ....................................................... 9

Changing Engine Coolant ........................................ 9

DRAINING ENGINE COOLANT ........................... 9

REFILLING ENGINE COOLANT ........................ 10

FLUSHING COOLING SYSTEM ......................... 10

RADIATOR ................................................................ 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

Disassembly and Assembly Radiator Fan ............. 13

DISASSEMBLY ................................................... 13

ASSEMBLY ......................................................... 13

INSPECTION ......................................................... 13

CHECKING RADIATOR CAP .............................. 13

CHECKING RADIATOR ...................................... 14

RADIATOR (ALUMINUM TYPE) .............................. 15

Disassembly and Assembly ................................... 15

PREPARATION ................................................... 15

DISASSEMBLY ................................................... 15

ASSEMBLY ......................................................... 16

INSPECTION ...................................................... 18WATER PUMP .......................................................... 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 20

INSTALLATION ................................................... 20

INSPECTION AFTER INSTALLATION ................ 20

THERMOSTAT AND WATER CONTROL VALVE .... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 23

Capacity .................................................................. 23

Thermostat ............................................................. 23

Water Control Valve ................................................ 23

Radiator .................................................................. 23

Tightening Torque ................................................... 23

YD22DDTi

PRECAUTIONS ........................................................ 24

Precautions For Liquid Gasket ............................... 24

REMOVAL AND LIQUID GASKET ...................... 24

LIQUID GASKET APPLICATION PROCEDURE... 24

PREPARATION ......................................................... 25

Special Service Tools ............................................. 25

OVERHEATING CAUSE ANALYSIS ........................ 26

Troubleshooting Chart ............................................ 26

COOLING SYSTEM .................................................. 28

Cooling Circuit ........................................................ 28

ENGINE COOLANT .................................................. 30

Inspection ............................................................... 30

LEVEL CHECK .................................................... 30

LEAK CHECK ...................................................... 30

Changing Engine Coolant ....................................... 30

DRAINING ENGINE COOLANT .......................... 30

REFILLING ENGINE COOLANT ......................... 31

FLUSHING COOLING SYSTEM ......................... 32

RADIATOR ................................................................ 33

Removal and Installation ........................................ 33

Page 1016 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-6

[QR20DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— OverloadonengineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at ex NISSAN X-TRAIL 2003 Electronic Repair Manual CO-6

[QR20DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— OverloadonengineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at ex](/img/5/57402/w960_57402-1015.png)

CO-6

[QR20DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— OverloadonengineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

—

Installed large fog lamp Symptom Check items

Page 1019 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS009SD

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS009SD

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust](/img/5/57402/w960_57402-1018.png)

ENGINE COOLANT

CO-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS009SD

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust coolant if too much or too little.

LEAK CHECK

lTo check for leakage, apply pressure to the cooling system with

atester.

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Changing Engine CoolantEBS009SE

WA RN ING:

lTo avoid being scalded, never change the coolant when the engine is hot.

lWrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove

radiator cap.

lBe careful not to allow coolant to contact drive belts.

SMA412B

Testing pressure

: 157 kPa (1.57bar 1.6 kg/cm2,23psi)

SLC134B

PBIC0236E

Page 1020 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If NISSAN X-TRAIL 2003 Electronic Repair Manual CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If](/img/5/57402/w960_57402-1019.png)

CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If contaminated, flush engine cooling system. Refer toCO-10,

"FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plug.

lUse Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

lUse genuine Nissan anti-freeze coolant or equivalent mixed

with water (distilled or demineralized).

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS".

lPour coolant slowly of less than 2 (2-1/8US qt,1-3/4 lmp

qt) a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hole, install filler cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

lRepeat two or three times.

Watch coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with coolant.

6. Refill reservoir tank to MAX level line with coolant.

7. Repeat steps 5 through 7 two or more times with radiator cap installed until coolant level no longer drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

KBIA0163E

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank:

0.6 (1/2 lmp qt )

SMA412B

Page 1022 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-12

[QR20DE]

RADIATOR

RADIATOR

PFP:21400

Removal and InstallationEBS009SF

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escapi NISSAN X-TRAIL 2003 Electronic Repair Manual CO-12

[QR20DE]

RADIATOR

RADIATOR

PFP:21400

Removal and InstallationEBS009SF

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escapi](/img/5/57402/w960_57402-1021.png)

CO-12

[QR20DE]

RADIATOR

RADIATOR

PFP:21400

Removal and InstallationEBS009SF

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter turn to

allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

REMOVAL

1. Drain coolant. Refer toCO-9, "DRAINING ENGINE COOLANT".

2. Remove air duct with air cleaner assembly.

3. Remove A/T oil cooler hose.

lInstall blind plug to avoid leakage of A/T fluid.

4. Disconnect radiator upper hose, lower hose and mounting bracket.

5. Remove radiator and radiator fan assembly

CAUTION:

lDo not damage or scratch radiator core when removing.

INSTALLATION

lReinstall any parts removed in reverse order of removal.

lCheck for coolant leaks. Refer toCO-9, "LEAK CHECK".

PBIC0237E

1 Radiator 2 Bracket 3 Mounting rubber

4 A/T oil cooler hose 5 Radiator hose (lower) 6 Radiator fan assembly

7 Reservoir tank 8 Radiator hose (upper) 9 Radiator filler cap

Page 1037 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-27

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-27

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear](/img/5/57402/w960_57402-1036.png)

OVERHEATING CAUSE ANALYSIS

CO-27

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

—

Installed large fog lamp Symptom Check items