check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1040 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-30

[YD22DDTi]

ENGINE COOLANT

ENGINE COOLANT

PFP:KQ100

InspectionEBS00BAY

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust coolant if too much or NISSAN X-TRAIL 2003 Electronic Repair Manual CO-30

[YD22DDTi]

ENGINE COOLANT

ENGINE COOLANT

PFP:KQ100

InspectionEBS00BAY

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust coolant if too much or](/img/5/57402/w960_57402-1039.png)

CO-30

[YD22DDTi]

ENGINE COOLANT

ENGINE COOLANT

PFP:KQ100

InspectionEBS00BAY

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust coolant if too much or too little.

LEAK CHECK

lTo check for leakage, apply pressure to the cooling system with

atester.

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Changing Engine CoolantEBS00BAZ

WAR NIN G:

lTo avoid being scalded, never change the coolant when the engine is hot.

lWrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove

radiator cap.

lBe careful not to allow coolant to contact drive belts.

lCover the exhaust tube heat shield to prevent from splashing

coolant.

2. Remove reservoir tank, drain coolant, then clean reservoir tank.

SMA412B

Testing pressure

: 157 kPa (1.57bar 1.6 kg/cm2,23psi)

SLC134B

PBIC0236E

Page 1041 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-31

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

3. Open drain plugs on cylinder block and air relief plug.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration. NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-31

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

3. Open drain plugs on cylinder block and air relief plug.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.](/img/5/57402/w960_57402-1040.png)

ENGINE COOLANT

CO-31

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

3. Open drain plugs on cylinder block and air relief plug.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If contaminated, flush engine cooling system. Refer toCO-32,

"FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plug.

lUse Genuine Liquid Gasket or equivalent.

2. Fill radiator slowly with coolant until coolant spills from the air

relief plugs, then install air relief plugs.

CAUTION:

If the filling rate is too fast, this could lead to air being

mixed in the coolant. Be sure to fill the coolant slowly

according to the rate indicated above.

lReplace the copper washer of the air bleeding plug.

lUse genuine Nissan anti-freeze coolant or equivalent mixed with water (distilled or demineralized).

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lPour coolant through coolant filler neck slowly of less than 2 (1-3/4 lmp qt) a minute to allow air

in system to escape.

SBIA0129E

SBIA0130E

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Air relief plug :

: 6.7 - 7.9 N·m (0.68 - 0.81 kg-m, 59 - 70 in-lb)

Engine coolant capacity (With reservoir tank):

9.5 ( 8-3/8 Imp qt)

SMA182B

Reservoir tank : 0.6 (1/2 lmp qt )

Page 1042 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-32

[YD22DDTi]

ENGINE COOLANT

3. Fill reservoir tank to specified level.

4. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hol NISSAN X-TRAIL 2003 Electronic Repair Manual CO-32

[YD22DDTi]

ENGINE COOLANT

3. Fill reservoir tank to specified level.

4. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hol](/img/5/57402/w960_57402-1041.png)

CO-32

[YD22DDTi]

ENGINE COOLANT

3. Fill reservoir tank to specified level.

4. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hole, install filler cap.

5. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

lRepeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

6. Stop engine and cool down to less than approximately

50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with coolant.

7. Refill reservoir tank to MAX level line with coolant.

8. Repeat steps 5 through 7 two or more times with radiator cap installed until coolant level no longer drops.

9. Check cooling system for leaks with engine running.

10. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

11. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief flag. Fill radiator and

reservoir tank with water and reinstall radiator cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

SMA412B

Page 1043 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual RADIATOR

CO-33

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

RADIATORPFP:21400

Removal and InstallationEBS00BB0

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from h NISSAN X-TRAIL 2003 Electronic Repair Manual RADIATOR

CO-33

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

RADIATORPFP:21400

Removal and InstallationEBS00BB0

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from h](/img/5/57402/w960_57402-1042.png)

RADIATOR

CO-33

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

RADIATORPFP:21400

Removal and InstallationEBS00BB0

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter turn to

allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

REMOVAL

1. Drain engine coolant. Refer toCO-30, "DRAINING ENGINE COOLANT".

2. Remove under cover.

3. Disconnect radiator upper hose, lower hose, reservoir tank hose and mounting bracket.

4. Remove radiator and radiator fan assembly

CAUTION:

lDo not damage or scratch radiator core when removing.

INSTALLATION

lReinstall any parts removed in reverse order of removal.

lCheck for engine coolant leaks. Refer toCO-30, "LEAK CHECK".

SBIA0131E

1 Radiator 2 Bracket 3 Mounting rubber

4 Drain plug 5 Radiator hose (lower) 6 Radiator fan assembly

7 Reservoir tank 8 Radiator hose (upper) 9 Radiator Cap

Page 1050 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-40

[YD22DDTi]

WATER PUMP

WAT ER PU M P

PFP:21020

Removal and InstallationEBS00BB4

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coola NISSAN X-TRAIL 2003 Electronic Repair Manual CO-40

[YD22DDTi]

WATER PUMP

WAT ER PU M P

PFP:21020

Removal and InstallationEBS00BB4

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coola](/img/5/57402/w960_57402-1049.png)

CO-40

[YD22DDTi]

WATER PUMP

WAT ER PU M P

PFP:21020

Removal and InstallationEBS00BB4

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator.

REMOVAL

1. Remove the under cover, splash cover (right), and drive belt.

2. Drain engine coolant. Refer toCO-30, "

DRAINING ENGINE COOLANT".

CAUTION:

Perform when the engine is cold.

3. Support the bottom of the oil pan with a floor jack etc, and remove the right engine mount bracket (front

side of the engine).

4. Remove the water pump pulley.

lLoosen the pulley bolts after fixing the pulley using a screwdriver etc.

5. Remove engine mount bracket.

6. Remove the water pump.

lCoolant will leak from the cylinder block, so have a receptacle ready below.

CAUTION:

lHandle the water pump vane so that it does not contact any other parts.

lWater pump cannot be disassembled and should be replaced as a unit.

INSPECTION AFTER REMOVAL

lVisually check that there is no significant dirt or rusting on the

water pump body and vane.

lCheck that there is no looseness in the vane shaft, and that it

turns smoothly when rotated by hand.

lIf there are any unusualness, replace the water pump assembly.

INSTALLATION

lInstall in the reverse order of removal

JLC294B

SBIA0132E

Page 1051 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual WATER PUMP

CO-41

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

lInstall the water pump pulley with the front mark (painted white, used to prevent errors during assembly)

facing the front of the engine. Refer t NISSAN X-TRAIL 2003 Electronic Repair Manual WATER PUMP

CO-41

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

lInstall the water pump pulley with the front mark (painted white, used to prevent errors during assembly)

facing the front of the engine. Refer t](/img/5/57402/w960_57402-1050.png)

WATER PUMP

CO-41

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

lInstall the water pump pulley with the front mark (painted white, used to prevent errors during assembly)

facing the front of the engine. Refer to the figure above.

INSPECTION AFTER INSTALLATION

lCheck for engine coolant leaks using radiator cap tester. Refer toCO-30, "LEAK CHECK".

Page 1055 of 3066

DI-1

DRIVER INFORMATION SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION

A

B

DI

DRIVER INFORMATION SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

COMBINATION METERS (LHD MODELS) ................ 4

System Description .................................................. 4

UNIFIED CONTROL METER ................................ 4

HOW TO CHANGE THE DISPLAY FOR ODO/

TRIP METER ........................................................ 4

POWER SUPPLY AND GROUND CIRCUIT ........ 4

WATER TEMPERATURE GAUGE ........................ 4

TACHOMETER ..................................................... 5

FUEL GAUGE ....................................................... 5

SPEEDOMETER ................................................... 5

Component Parts and Harness Connector Location..... 5

Combination Meter ................................................... 6

CHECK .................................................................. 6

Schematic ................................................................ 7

Wiring Diagram — METER — .................................. 8

Meter/Gauge Operation and Odo/Trip Meter Seg-

ment Check in Diagnosis Mode ............................. 10

DIAGNOSIS FUNCTION ..................................... 10

HOW TO ALTERNATE DIAGNOSIS MODE ....... 10

Trouble Diagnoses ................................................. 10

PRELIMINARY CHECK ...................................... 10

SYMPTOM CHART ..............................................11

Power Supply and Ground Circuit Check ............... 12

Inspection/Engine Speed Signal ............................ 12

Inspection/Water Temperature Gauge /Gasoline

Engine Models ....................................................... 13

Inspection/Water Temperature Gauge (Diesel

Engine Models) ...................................................... 13

Inspection/Vehicle speed signal ............................. 14

Inspection/Fuel Level Sensor Unit ......................... 15

FUEL LEVEL SENSOR UNIT ............................. 15

LOW-FUEL WARNING LAMP ............................. 15

The Fuel Gauge Pointer Fluctuates·Indicator

Wrong Value·or Varies. ........................................... 17

The Fuel Gauge Does Not Move to F-position. ...... 18The Fuel Gauge Does Not Work. ........................... 18

Low Fuel Warning Lamp Illuminate or Not Illuminate... 19

Electrical Components Inspection .......................... 19

FUEL LEVEL SENSOR UNIT CHECK / GASO-

LINE ENGINE MODELS ..................................... 19

FUEL LEVEL SENSOR UNIT CHECK / DIESEL

ENGINE MODELS EXCEPT FOR NORTHERN

EUROPE ............................................................. 19

FUEL LEVEL SENSOR UNIT CHECK / DIESEL

ENGINE MODELS FOR NORTHERN EUROPE... 20

THERMAL TRANSMITTER CHECK ................... 20

Removal and Installation for Combination Meter .... 21

Disassembly and Assembly for Combination Meter... 21

COMBINATION METERS (RHD MODELS) .............. 22

System Description ................................................. 22

UNIFIED CONTROL METER .............................. 22

HOW TO CHANGE THE DISPLAY FOR ODO/

TRIP METER ....................................................... 22

POWER SUPPLY AND GROUND CIRCUIT ....... 22

WATER TEMPERATURE GAUGE ...................... 22

TACHOMETER .................................................... 23

FUEL GAUGE ..................................................... 23

SPEEDOMETER ................................................. 23

Component Parts and Harness Connector Location... 23

Combination Meter ................................................. 24

CHECK ................................................................ 24

Schematic ............................................................... 25

Wiring Diagram — METER — ................................ 26

Meter/Gauge Operation and Odo/Trip Meter Seg-

ment Check in Diagnosis Mode .............................. 28

DIAGNOSIS FUNCTION ..................................... 28

HOW TO ALTERNATE DIAGNOSIS MODE ....... 28

Trouble Diagnoses ................................................. 28

PRELIMINARY CHECK ....................................... 28

SYMPTOM CHART ............................................. 29

Power Supply and Ground Circuit Check ............... 30

Inspection/Engine Speed Signal ............................. 30

Inspection/Water Temperature Gauge /Gasoline

Engine Models ........................................................ 31

Inspection/Water Temperature Gauge (Diesel

Page 1056 of 3066

DI-2

Engine Models) ....................................................... 31

Inspection/Vehicle speed signal ............................. 32

Inspection/Fuel Level Sensor Unit .......................... 33

FUEL LEVEL SENSOR UNIT .............................. 33

LOW-FUEL WARNING LAMP ............................. 33

The Fuel Gauge Pointer Fluctuates·Indicator

Wrong Value·or Varies. ........................................... 35

The Fuel Gauge Does Not Move to F-position. ...... 36

The Fuel Gauge Does Not Work. ........................... 36

Low Fuel Warning Lamp Illuminate or Not Illuminate... 37

Electrical Components Inspection .......................... 37

FUEL LEVEL SENSOR UNIT CHECK / GASO-

LINE ENGINE MODELS ...................................... 37

FUEL LEVEL SENSOR UNIT CHECK / DIESEL

ENGINE MODELS ............................................... 37

THERMAL TRANSMITTER CHECK ................... 38

Removal and Installation for Combination Meter .... 38

Disassembly and Assembly for Combination Meter... 38

WARNING LAMPS .................................................... 39

Schematic ............................................................... 39

Wiring Diagram — WARN —/ LHD Models ............ 40Wiring Diagram — WARN — / RHD Models ...........45

Electrical Components Inspection ...........................50

FUEL WARNING LAMP OPERATION CHECK ... 50

OIL PRESSURE SWITCH CHECK ......................50

DIODE CHECK ....................................................50

A/T INDICATOR .........................................................51

Wiring Diagram — AT/IND — .................................51

WARNING CHIME .....................................................52

System Description .................................................52

POWER SUPPLY AND GROUND CIRCUIT .......52

IGNITION KEY WARNING CHIME ......................52

LIGHT WARNING CHIME ...................................52

Component Parts and Harness Connector Location... 53

Wiring Diagram — CHIME — .................................54

Symptom Chart .......................................................56

Power Supply and Ground Circuit Check ...............56

Lighting Switch Input Signal Check .........................57

Key Switch Insert Signal Check ..............................57

Door Unlock Sensor Check .....................................58

Front Door Switch (driver side) Check ....................59

CLOCK ......................................................................60

Wiring Diagram — CLOCK — .................................60

Page 1058 of 3066

DI-4

COMBINATION METERS (LHD MODELS)

COMBINATION METERS (LHD MODELS)

PFP:24810

System DescriptionEKS002Z7

UNIFIED CONTROL METER

lSpeedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled totally

by control unit built-in combination meter.

lDigital meter is adopted for odo/trip meter.*

*The record of the odo meter is kept even if the battery cable is disconnected. The record of the trip meter

is erased when the battery cable is disconnected.

lOdo/trip meter segment can be checked in diagnosis mode.

lMeter/gauge can be checked in diagnosis mode.

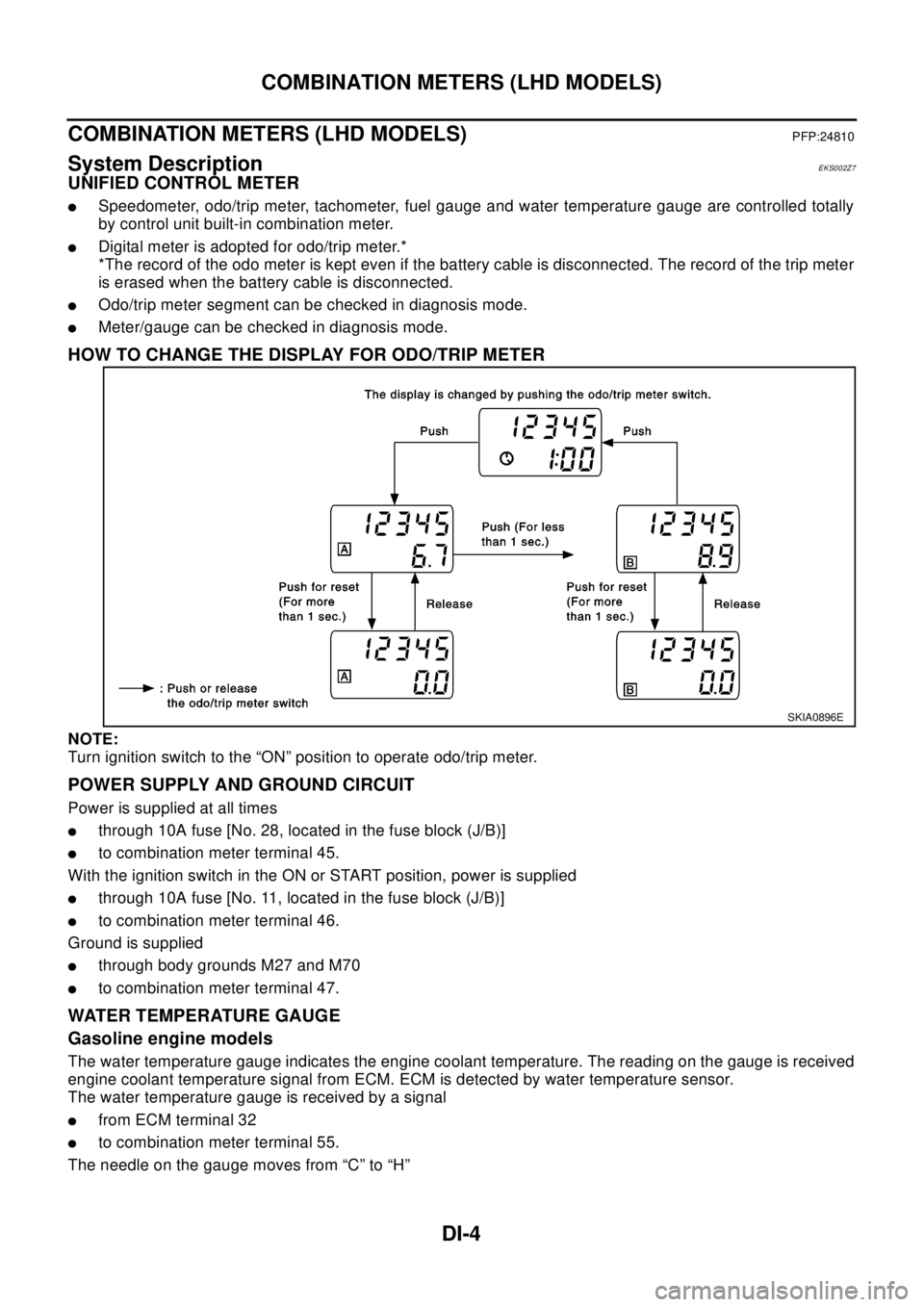

HOW TO CHANGE THE DISPLAY FOR ODO/TRIP METER

NOTE:

Turn ignition switch to the “ON” position to operate odo/trip meter.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

lthrough 10A fuse [No. 28, located in the fuse block (J/B)]

lto combination meter terminal 45.

With the ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No. 11, located in the fuse block (J/B)]

lto combination meter terminal 46.

Ground is supplied

lthrough body grounds M27 and M70

lto combination meter terminal 47.

WATER TEMPERATURE GAUGE

Gasoline engine models

The water temperature gauge indicates the engine coolant temperature. The reading on the gauge is received

engine coolant temperature signal from ECM. ECM is detected by water temperature sensor.

The water temperature gauge is received by a signal

lfrom ECM terminal 32

lto combination meter terminal 55.

The needle on the gauge moves from “C” to “H”

SKIA0896E

Page 1065 of 3066

COMBINATION METERS (LHD MODELS)

DI-11

C

D

E

F

G

H

I

J

L

MA

B

DI

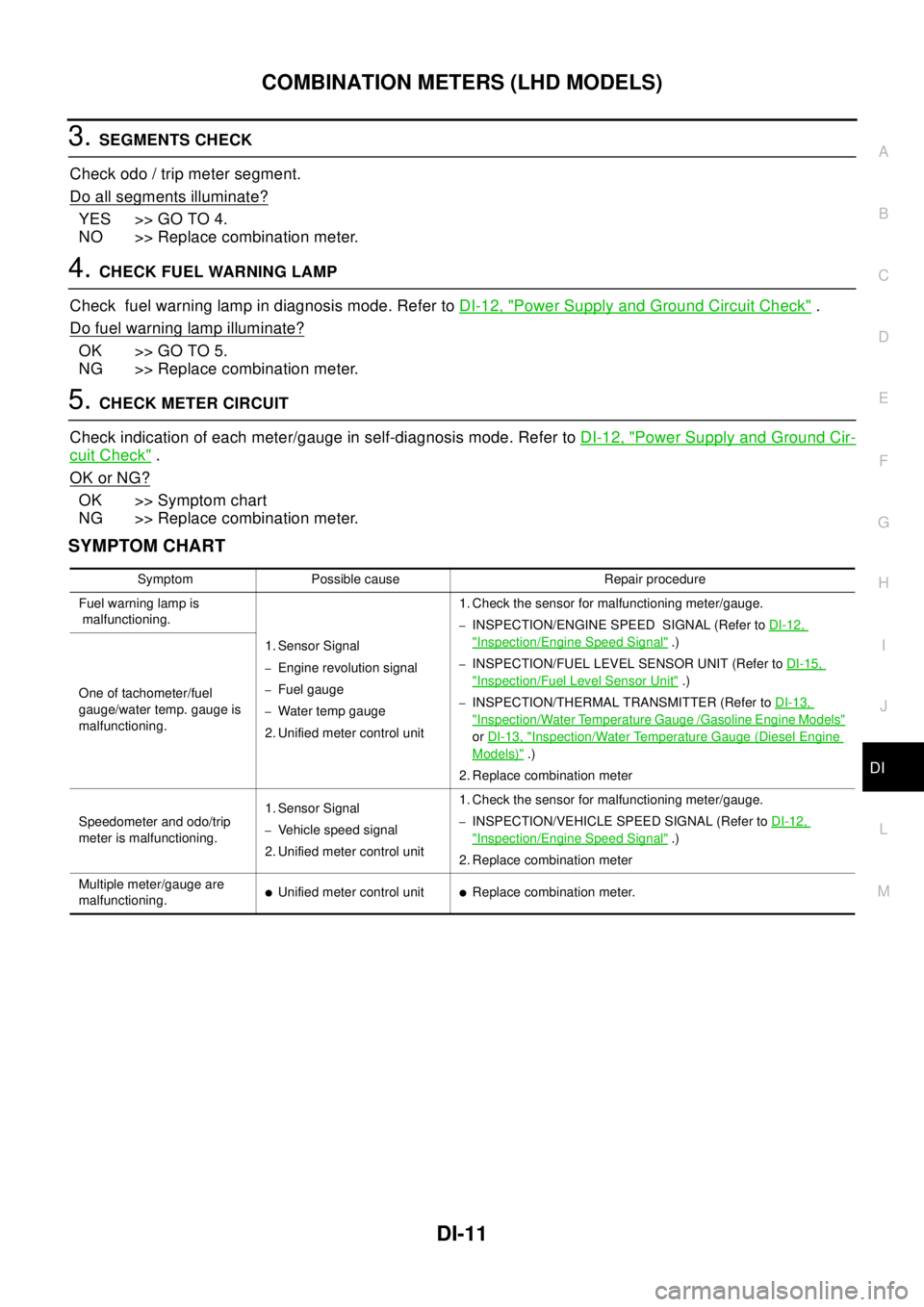

3.SEGMENTS CHECK

Check odo / trip meter segment.

Do all segments illuminate?

YES >> GO TO 4.

NO >> Replace combination meter.

4.CHECK FUEL WARNING LAMP

Check fuel warning lamp in diagnosis mode. Refer toDI-12, "

Power Supply and Ground Circuit Check".

Do fuel warning lamp illuminate?

OK >> GO TO 5.

NG >> Replace combination meter.

5.CHECK METER CIRCUIT

Check indication of each meter/gauge in self-diagnosis mode. Refer toDI-12, "

Power Supply and Ground Cir-

cuit Check".

OK or NG?

OK >> Symptom chart

NG >> Replace combination meter.

SYMPTOM CHART

Symptom Possible cause Repair procedure

Fuel warning lamp is

malfunctioning.

1. Sensor Signal

–Engine revolution signal

–Fuel gauge

–Water temp gauge

2. Unified meter control unit1. Check the sensor for malfunctioning meter/gauge.

–INSPECTION/ENGINE SPEED SIGNAL (Refer toDI-12,

"Inspection/Engine Speed Signal".)

–INSPECTION/FUEL LEVEL SENSOR UNIT (Refer toDI-15,

"Inspection/Fuel Level Sensor Unit".)

–INSPECTION/THERMAL TRANSMITTER (Refer toDI-13,

"Inspection/Water Temperature Gauge /Gasoline Engine Models"

orDI-13, "Inspection/Water Temperature Gauge (Diesel Engine

Models)".)

2. Replace combination meter One of tachometer/fuel

gauge/water temp. gauge is

malfunctioning.

Speedometer and odo/trip

meter is malfunctioning.1. Sensor Signal

–Vehicle speed signal

2. Unified meter control unit1. Check the sensor for malfunctioning meter/gauge.–INSPECTION/VEHICLE SPEED SIGNAL (Refer toDI-12,

"Inspection/Engine Speed Signal".)

2. Replace combination meter

Multiple meter/gauge are

malfunctioning.

lUnified meter control unitlReplace combination meter.