radiator cap NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 19 of 3066

A/T FLUID

AT-13

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T FLUIDPFP:KLE40

Checking A/T FluidECS004Q7

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of either

range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

lIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-12,

"RADIATOR",CO-15, "RADIATOR (ALUMINUM TYPE)",,.

Changing A/T FluidECS004Q8

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to “Checking A/T Fluid”. If fluid is still dirty, repeat steps 2 through 5.

SMA827CA

SMA853B

Fluid grade:

Genuine Nissan ATF or equivalent. Refer toMA-

17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

Fluid capacity (With torque converter):

Approx. 8.0 (7.01 lmp qt)

Drain plug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

SMA027D

Page 668 of 3066

ATC-90

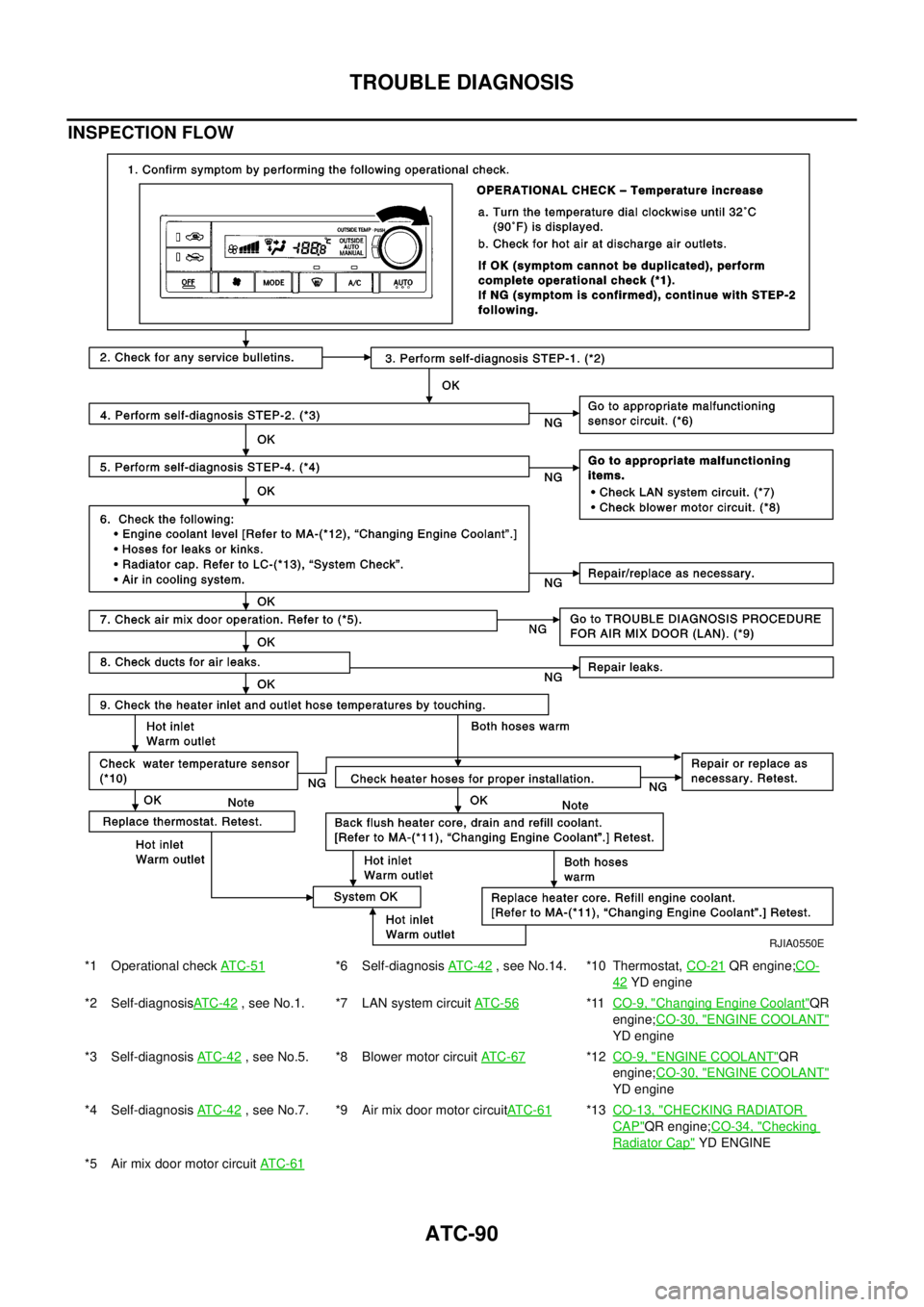

TROUBLE DIAGNOSIS

INSPECTION FLOW

*1 Operational checkAT C - 5 1*6 Self-diagnosisAT C -4 2, see No.14. *10 Thermostat,CO-21QR engine;CO-

42YD engine

*2 Self-diagnosisAT C -4 2

, see No.1. *7 LAN system circuitAT C - 5 6*11CO-9, "Changing Engine Coolant"QR

engine;CO-30, "

ENGINE COOLANT"

YD engine

*3 Self-diagnosisAT C - 4 2

, see No.5. *8 Blower motor circuitAT C - 6 7*12CO-9, "ENGINE COOLANT"QR

engine;CO-30, "

ENGINE COOLANT"

YD engine

*4 Self-diagnosisAT C - 4 2

, see No.7. *9 Air mix door motor circuitAT C - 6 1*13CO-13, "CHECKING RADIATOR

CAP"QR engine;CO-34, "Checking

Radiator Cap"YD ENGINE

*5 Air mix door motor circuitAT C - 6 1

RJIA0550E

Page 716 of 3066

ATC-138

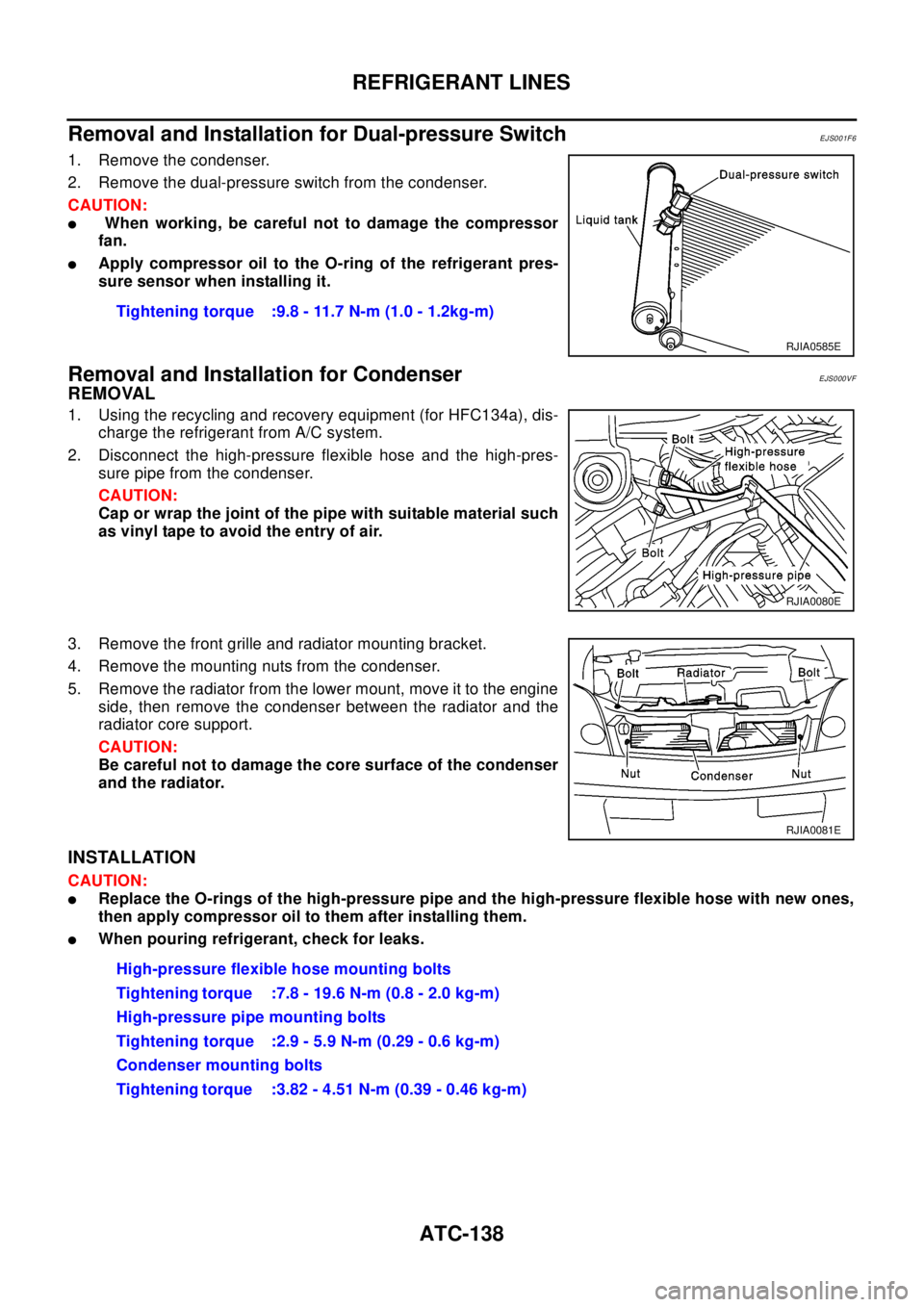

REFRIGERANT LINES

Removal and Installation for Dual-pressure Switch

EJS001F6

1. Remove the condenser.

2. Remove the dual-pressure switch from the condenser.

CAUTION:

lWhen working, be careful not to damage the compressor

fan.

lApply compressor oil to the O-ring of the refrigerant pres-

sure sensor when installing it.

Removal and Installation for CondenserEJS000VF

REMOVAL

1. Using the recycling and recovery equipment (for HFC134a), dis-

charge the refrigerant from A/C system.

2. Disconnect the high-pressure flexible hose and the high-pres-

sure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

3. Remove the front grille and radiator mounting bracket.

4. Remove the mounting nuts from the condenser.

5. Remove the radiator from the lower mount, move it to the engine

side, then remove the condenser between the radiator and the

radiator core support.

CAUTION:

Be careful not to damage the core surface of the condenser

and the radiator.

INSTALLATION

CAUTION:

lReplace the O-rings of the high-pressure pipe and the high-pressure flexible hose with new ones,

then apply compressor oil to them after installing them.

lWhen pouring refrigerant, check for leaks.Tightening torque :9.8 - 11.7 N-m (1.0 - 1.2kg-m)

RJIA0585E

RJIA0080E

RJIA0081E

High-pressure flexible hose mounting bolts

Tightening torque :7.8 - 19.6 N-m (0.8 - 2.0 kg-m)

High-pressure pipe mounting bolts

Tightening torque :2.9 - 5.9 N-m (0.29 - 0.6 kg-m)

Condenser mounting bolts

Tightening torque :3.82 - 4.51 N-m (0.39 - 0.46 kg-m)

Page 1011 of 3066

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

CO

ENGINE COOLING SYSTEM

QR20DE

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET .......................... 3

LIQUID GASKET APPLICATION PROCEDURE..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

OVERHEATING CAUSE ANALYSIS .......................... 5

Troubleshooting Chart .............................................. 5

COOLING SYSTEM .................................................... 7

Cooling Circuit .......................................................... 7

ENGINE COOLANT .................................................... 9

Inspection ................................................................. 9

LEVEL CHECK ..................................................... 9

LEAK CHECK ....................................................... 9

Changing Engine Coolant ........................................ 9

DRAINING ENGINE COOLANT ........................... 9

REFILLING ENGINE COOLANT ........................ 10

FLUSHING COOLING SYSTEM ......................... 10

RADIATOR ................................................................ 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

Disassembly and Assembly Radiator Fan ............. 13

DISASSEMBLY ................................................... 13

ASSEMBLY ......................................................... 13

INSPECTION ......................................................... 13

CHECKING RADIATOR CAP .............................. 13

CHECKING RADIATOR ...................................... 14

RADIATOR (ALUMINUM TYPE) .............................. 15

Disassembly and Assembly ................................... 15

PREPARATION ................................................... 15

DISASSEMBLY ................................................... 15

ASSEMBLY ......................................................... 16

INSPECTION ...................................................... 18WATER PUMP .......................................................... 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 20

INSTALLATION ................................................... 20

INSPECTION AFTER INSTALLATION ................ 20

THERMOSTAT AND WATER CONTROL VALVE .... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 23

Capacity .................................................................. 23

Thermostat ............................................................. 23

Water Control Valve ................................................ 23

Radiator .................................................................. 23

Tightening Torque ................................................... 23

YD22DDTi

PRECAUTIONS ........................................................ 24

Precautions For Liquid Gasket ............................... 24

REMOVAL AND LIQUID GASKET ...................... 24

LIQUID GASKET APPLICATION PROCEDURE... 24

PREPARATION ......................................................... 25

Special Service Tools ............................................. 25

OVERHEATING CAUSE ANALYSIS ........................ 26

Troubleshooting Chart ............................................ 26

COOLING SYSTEM .................................................. 28

Cooling Circuit ........................................................ 28

ENGINE COOLANT .................................................. 30

Inspection ............................................................... 30

LEVEL CHECK .................................................... 30

LEAK CHECK ...................................................... 30

Changing Engine Coolant ....................................... 30

DRAINING ENGINE COOLANT .......................... 30

REFILLING ENGINE COOLANT ......................... 31

FLUSHING COOLING SYSTEM ......................... 32

RADIATOR ................................................................ 33

Removal and Installation ........................................ 33

Page 1012 of 3066

CO-2

REMOVAL ........................................................... 33

INSTALLATION .................................................... 33

Disassembly and Assembly Radiator Fan .............. 34

DISASSEMBLY ................................................... 34

ASSEMBLY ......................................................... 34

Checking Radiator Cap .......................................... 34

Checking Radiator .................................................. 35

RADIATOR (ALLUMINUM TYPE) ............................. 36

Disassembly and Assembly .................................... 36

PREPARATION ................................................... 36

DISASSEMBLY ................................................... 36

ASSEMBLY ......................................................... 37

INSPECTION ....................................................... 39WATER PUMP ...........................................................40

Removal and Installation .........................................40

REMOVAL ............................................................40

INSPECTION AFTER REMOVAL ........................40

INSTALLATION ....................................................40

INSPECTION AFTER INSTALLATION ................41

THERMOSTAT AND WATER PIPING .......................42

Removal and Installation .........................................42

REMOVAL ............................................................42

INSPECTION AFTER REMOVAL ........................43

INSTALLATION ....................................................43

SERVICE DATA AND SPECIFICATIONS (SDS) ......44

Standard and Limit ..................................................44

CAPACITY ...........................................................44

THERMOSTAT .....................................................44

RADIATOR ...........................................................44

Tightening Torque ...................................................44

Page 1014 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-4

[QR20DE]

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEBS009SA

Tool number

Tool nameDescription

WS39930000

Tube presserPressing the tube of liquid gasket

EG17650301

Radiator cap tester NISSAN X-TRAIL 2003 Electronic Repair Manual CO-4

[QR20DE]

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEBS009SA

Tool number

Tool nameDescription

WS39930000

Tube presserPressing the tube of liquid gasket

EG17650301

Radiator cap tester](/img/5/57402/w960_57402-1013.png)

CO-4

[QR20DE]

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEBS009SA

Tool number

Tool nameDescription

WS39930000

Tube presserPressing the tube of liquid gasket

EG17650301

Radiator cap tester adapterAdapting radiator cap tester to radiator filler

neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV99103510

Radiator plate pliers AInstalling radiator upper and lower tanks

KV99103520

Radiator plate pliers BRemoving radiator upper and lower tanks

S-NT052

S-NT564

S-NT224

S-NT225

Page 1015 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartEBS009SB

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat tra NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartEBS009SB

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat tra](/img/5/57402/w960_57402-1014.png)

OVERHEATING CAUSE ANALYSIS

CO-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartEBS009SB

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

—— High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper coolant mixture

ratio———

Poor coolant quality — — —

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 1019 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS009SD

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS009SD

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust](/img/5/57402/w960_57402-1018.png)

ENGINE COOLANT

CO-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS009SD

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust coolant if too much or too little.

LEAK CHECK

lTo check for leakage, apply pressure to the cooling system with

atester.

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Changing Engine CoolantEBS009SE

WA RN ING:

lTo avoid being scalded, never change the coolant when the engine is hot.

lWrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove

radiator cap.

lBe careful not to allow coolant to contact drive belts.

SMA412B

Testing pressure

: 157 kPa (1.57bar 1.6 kg/cm2,23psi)

SLC134B

PBIC0236E

Page 1020 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If NISSAN X-TRAIL 2003 Electronic Repair Manual CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If](/img/5/57402/w960_57402-1019.png)

CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If contaminated, flush engine cooling system. Refer toCO-10,

"FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plug.

lUse Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

lUse genuine Nissan anti-freeze coolant or equivalent mixed

with water (distilled or demineralized).

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS".

lPour coolant slowly of less than 2 (2-1/8US qt,1-3/4 lmp

qt) a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hole, install filler cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

lRepeat two or three times.

Watch coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with coolant.

6. Refill reservoir tank to MAX level line with coolant.

7. Repeat steps 5 through 7 two or more times with radiator cap installed until coolant level no longer drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

KBIA0163E

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank:

0.6 (1/2 lmp qt )

SMA412B

Page 1022 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-12

[QR20DE]

RADIATOR

RADIATOR

PFP:21400

Removal and InstallationEBS009SF

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escapi NISSAN X-TRAIL 2003 Electronic Repair Manual CO-12

[QR20DE]

RADIATOR

RADIATOR

PFP:21400

Removal and InstallationEBS009SF

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escapi](/img/5/57402/w960_57402-1021.png)

CO-12

[QR20DE]

RADIATOR

RADIATOR

PFP:21400

Removal and InstallationEBS009SF

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter turn to

allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

REMOVAL

1. Drain coolant. Refer toCO-9, "DRAINING ENGINE COOLANT".

2. Remove air duct with air cleaner assembly.

3. Remove A/T oil cooler hose.

lInstall blind plug to avoid leakage of A/T fluid.

4. Disconnect radiator upper hose, lower hose and mounting bracket.

5. Remove radiator and radiator fan assembly

CAUTION:

lDo not damage or scratch radiator core when removing.

INSTALLATION

lReinstall any parts removed in reverse order of removal.

lCheck for coolant leaks. Refer toCO-9, "LEAK CHECK".

PBIC0237E

1 Radiator 2 Bracket 3 Mounting rubber

4 A/T oil cooler hose 5 Radiator hose (lower) 6 Radiator fan assembly

7 Reservoir tank 8 Radiator hose (upper) 9 Radiator filler cap