NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 861 of 3066

REAR DISC BRAKE

BR-27

C

D

E

G

H

I

J

K

L

MA

B

BR

REAR DISC BRAKEPFP:44000

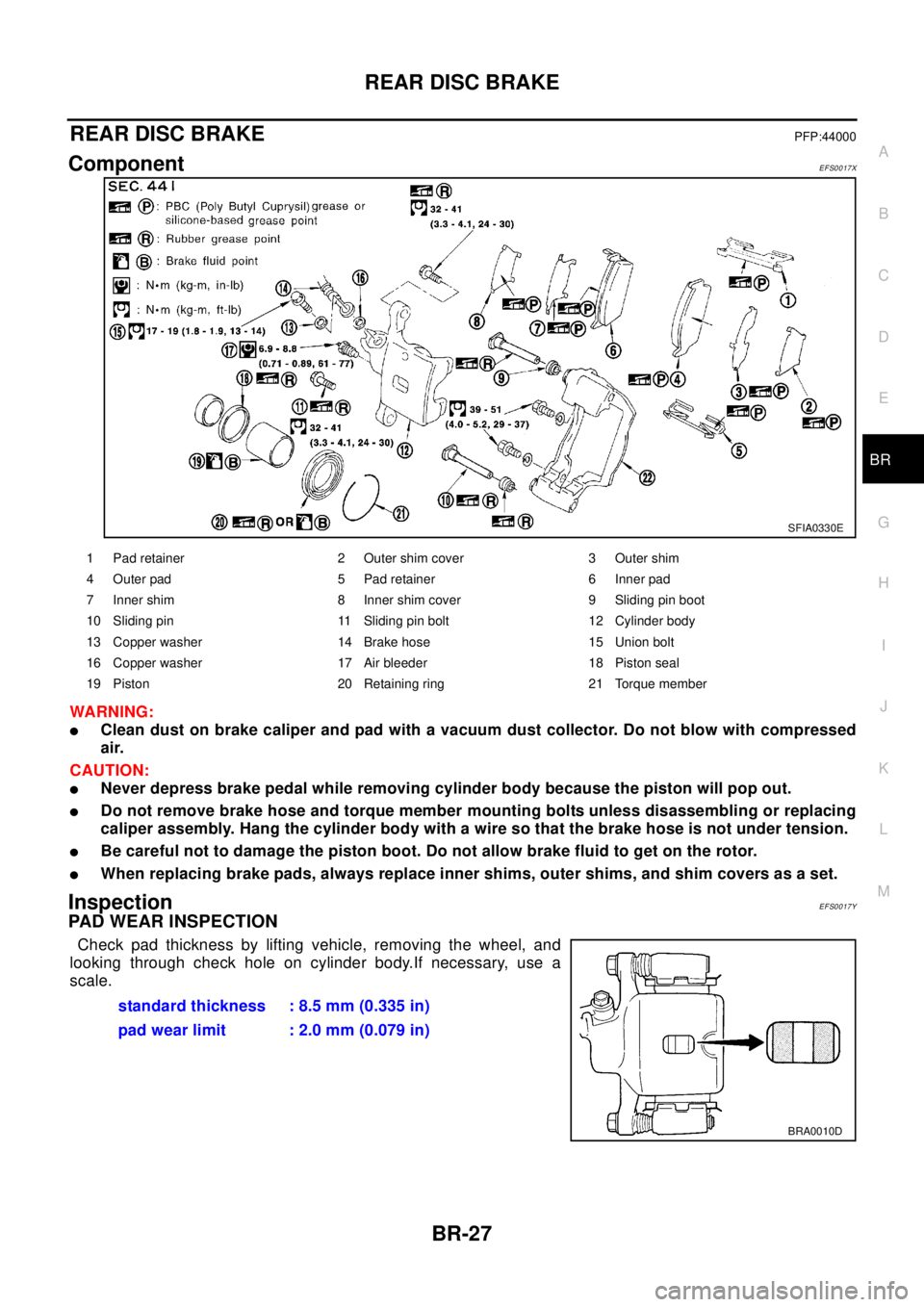

ComponentEFS0017X

WA RN ING:

lClean dust on brake caliper and pad with a vacuum dust collector. Do not blow with compressed

air.

CAUTION:

lNever depress brake pedal while removing cylinder body because the piston will pop out.

lDo not remove brake hose and torque member mounting bolts unless disassembling or replacing

caliper assembly. Hang the cylinder body with a wire so that the brake hose is not under tension.

lBe careful not to damage the piston boot. Do not allow brake fluid to get on the rotor.

lWhen replacing brake pads, always replace inner shims, outer shims, and shim covers as a set.

InspectionEFS0017Y

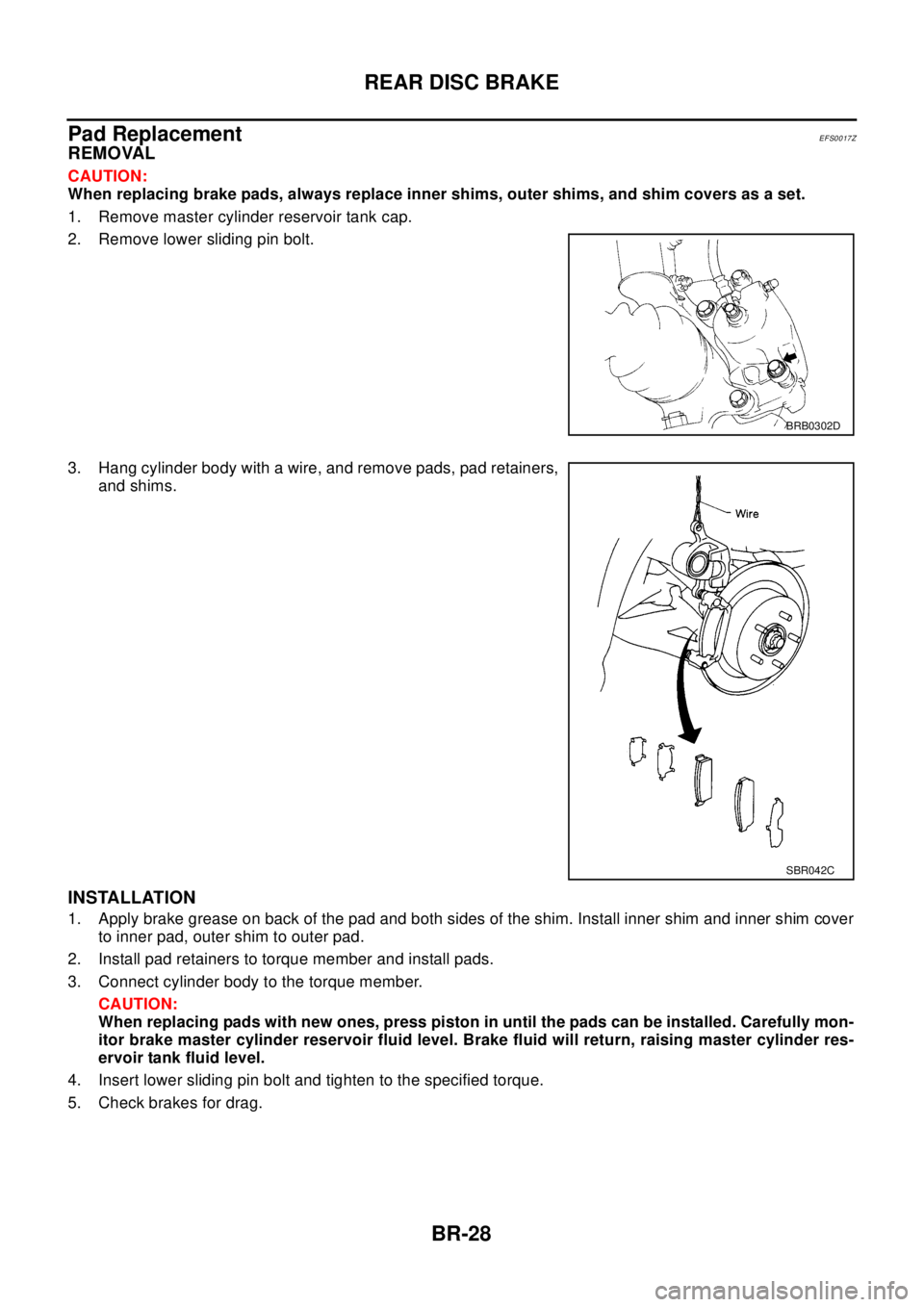

PAD WEAR INSPECTION

Check pad thickness by lifting vehicle, removing the wheel, and

looking through check hole on cylinder body.If necessary, use a

scale.

SFIA0330E

1 Pad retainer 2 Outer shim cover 3 Outer shim

4 Outer pad 5 Pad retainer 6 Inner pad

7 Inner shim 8 Inner shim cover 9 Sliding pin boot

10 Sliding pin 11 Sliding pin bolt 12 Cylinder body

13 Copper washer 14 Brake hose 15 Union bolt

16 Copper washer 17 Air bleeder 18 Piston seal

19 Piston 20 Retaining ring 21 Torque member

standard thickness : 8.5 mm (0.335 in)

pad wear limit : 2.0 mm (0.079 in)

BRA0010D

Page 862 of 3066

BR-28

REAR DISC BRAKE

Pad Replacement

EFS0017Z

REMOVAL

CAUTION:

When replacing brake pads, always replace inner shims, outer shims, and shim covers as a set.

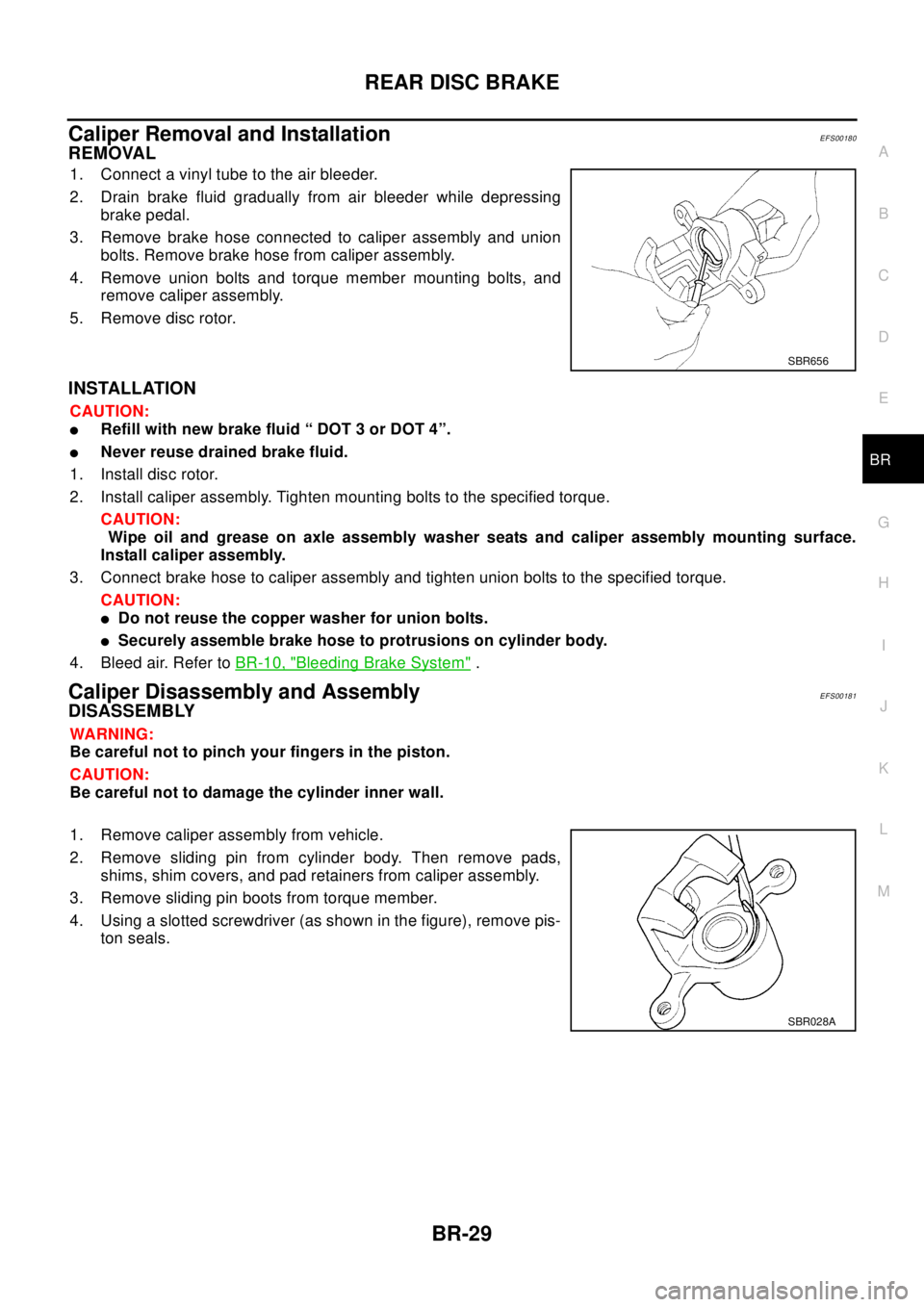

1. Remove master cylinder reservoir tank cap.

2. Remove lower sliding pin bolt.

3. Hang cylinder body with a wire, and remove pads, pad retainers,

and shims.

INSTALLATION

1. Apply brake grease on back of the pad and both sides of the shim. Install inner shim and inner shim cover

to inner pad, outer shim to outer pad.

2. Install pad retainers to torque member and install pads.

3. Connect cylinder body to the torque member.

CAUTION:

When replacing pads with new ones, press piston in until the pads can be installed. Carefully mon-

itor brake master cylinder reservoir fluid level. Brake fluid will return, raising master cylinder res-

ervoir tank fluid level.

4. Insert lower sliding pin bolt and tighten to the specified torque.

5. Check brakes for drag.

BRB0302D

SBR042C

Page 863 of 3066

REAR DISC BRAKE

BR-29

C

D

E

G

H

I

J

K

L

MA

B

BR

Caliper Removal and InstallationEFS00180

REMOVAL

1. Connect a vinyl tube to the air bleeder.

2. Drain brake fluid gradually from air bleeder while depressing

brake pedal.

3. Remove brake hose connected to caliper assembly and union

bolts. Remove brake hose from caliper assembly.

4. Remove union bolts and torque member mounting bolts, and

remove caliper assembly.

5. Remove disc rotor.

INSTALLATION

CAUTION:

lRefill with new brake fluid “ DOT 3 or DOT 4”.

lNever reuse drained brake fluid.

1. Install disc rotor.

2. Install caliper assembly. Tighten mounting bolts to the specified torque.

CAUTION:

Wipe oil and grease on axle assembly washer seats and caliper assembly mounting surface.

Install caliper assembly.

3. Connect brake hose to caliper assembly and tighten union bolts to the specified torque.

CAUTION:

lDo not reuse the copper washer for union bolts.

lSecurely assemble brake hose to protrusions on cylinder body.

4. Bleed air. Refer toBR-10, "

Bleeding Brake System".

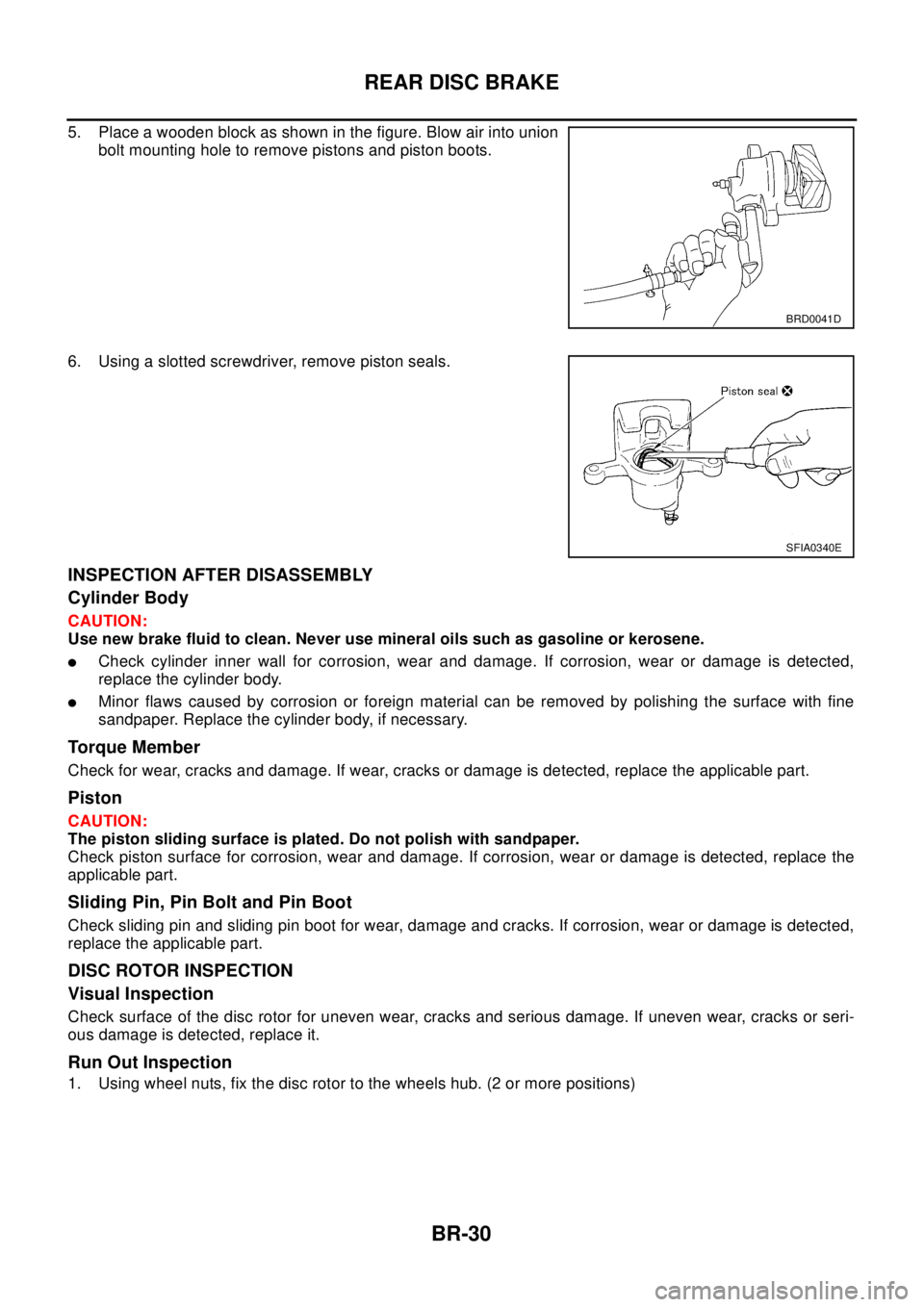

Caliper Disassembly and AssemblyEFS00181

DISASSEMBLY

WA RN ING:

Be careful not to pinch your fingers in the piston.

CAUTION:

Be careful not to damage the cylinder inner wall.

1. Remove caliper assembly from vehicle.

2. Remove sliding pin from cylinder body. Then remove pads,

shims, shim covers, and pad retainers from caliper assembly.

3. Remove sliding pin boots from torque member.

4. Using a slotted screwdriver (as shown in the figure), remove pis-

ton seals.

SBR656

SBR028A

Page 864 of 3066

BR-30

REAR DISC BRAKE

5. Place a wooden block as shown in the figure. Blow air into union

bolt mounting hole to remove pistons and piston boots.

6. Using a slotted screwdriver, remove piston seals.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

CAUTION:

Use new brake fluid to clean. Never use mineral oils such as gasoline or kerosene.

lCheck cylinder inner wall for corrosion, wear and damage. If corrosion, wear or damage is detected,

replace the cylinder body.

lMinor flaws caused by corrosion or foreign material can be removed by polishing the surface with fine

sandpaper. Replace the cylinder body, if necessary.

Torque Member

Check for wear, cracks and damage. If wear, cracks or damage is detected, replace the applicable part.

Piston

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Check piston surface for corrosion, wear and damage. If corrosion, wear or damage is detected, replace the

applicable part.

Sliding Pin, Pin Bolt and Pin Boot

Check sliding pin and sliding pin boot for wear, damage and cracks. If corrosion, wear or damage is detected,

replace the applicable part.

DISC ROTOR INSPECTION

Visual Inspection

Check surface of the disc rotor for uneven wear, cracks and serious damage. If uneven wear, cracks or seri-

ous damage is detected, replace it.

Run Out Inspection

1. Using wheel nuts, fix the disc rotor to the wheels hub. (2 or more positions)

BRD0041D

SFIA0340E

Page 865 of 3066

REAR DISC BRAKE

BR-31

C

D

E

G

H

I

J

K

L

MA

B

BR

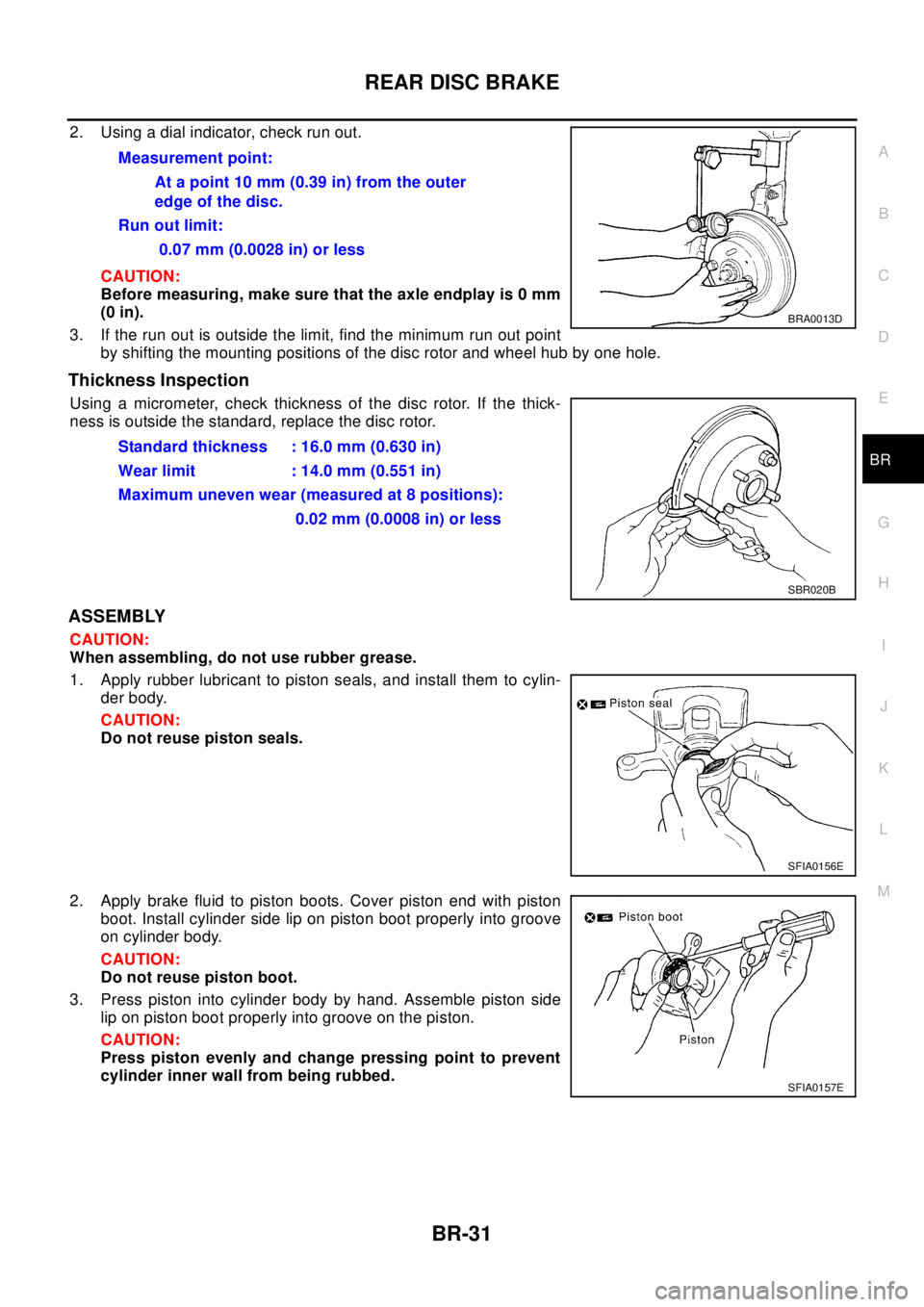

2. Using a dial indicator, check run out.

CAUTION:

Before measuring, make sure that the axle endplay is 0 mm

(0 in).

3. If the run out is outside the limit, find the minimum run out point

by shifting the mounting positions of the disc rotor and wheel hub by one hole.

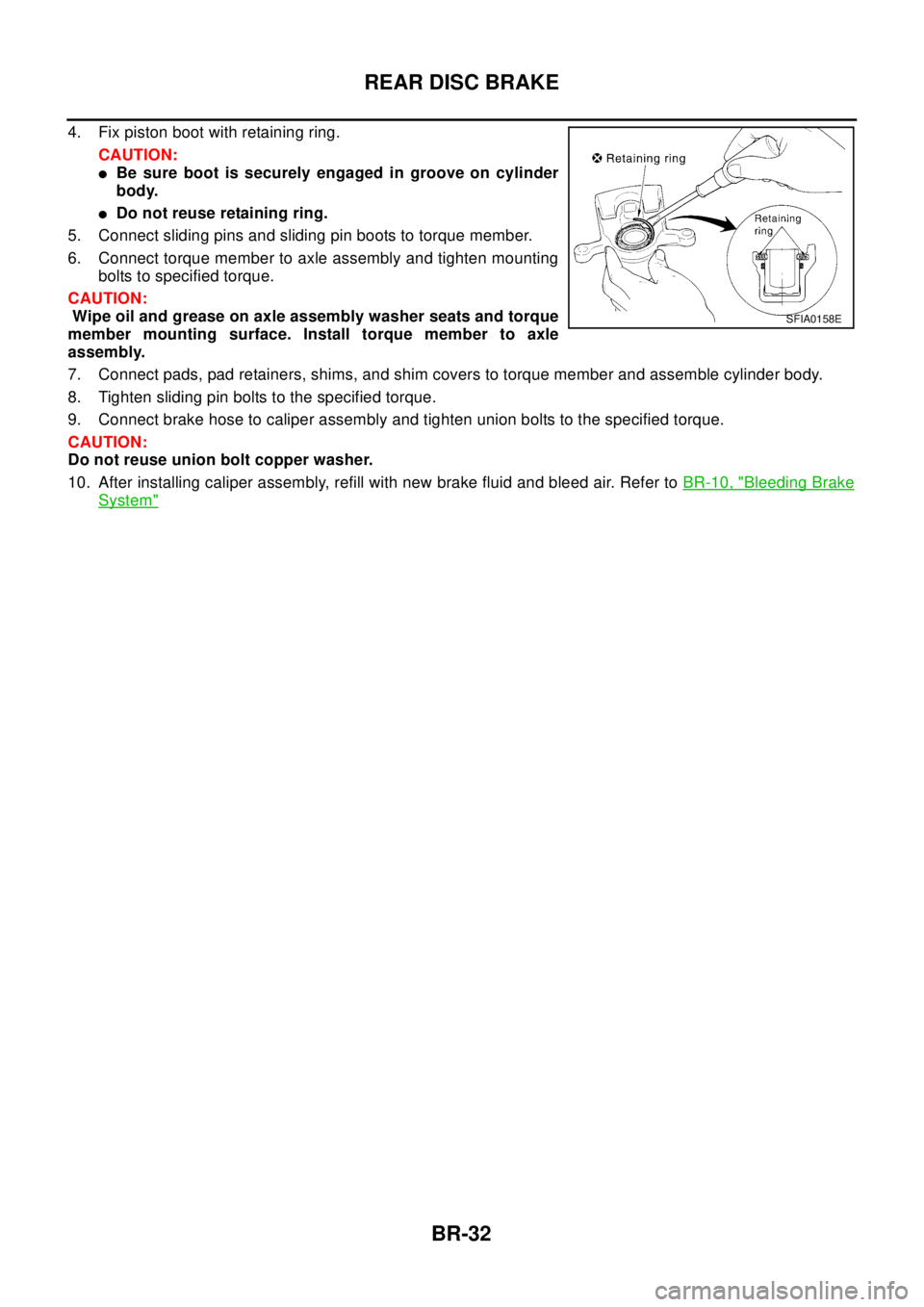

Thickness Inspection

Using a micrometer, check thickness of the disc rotor. If the thick-

ness is outside the standard, replace the disc rotor.

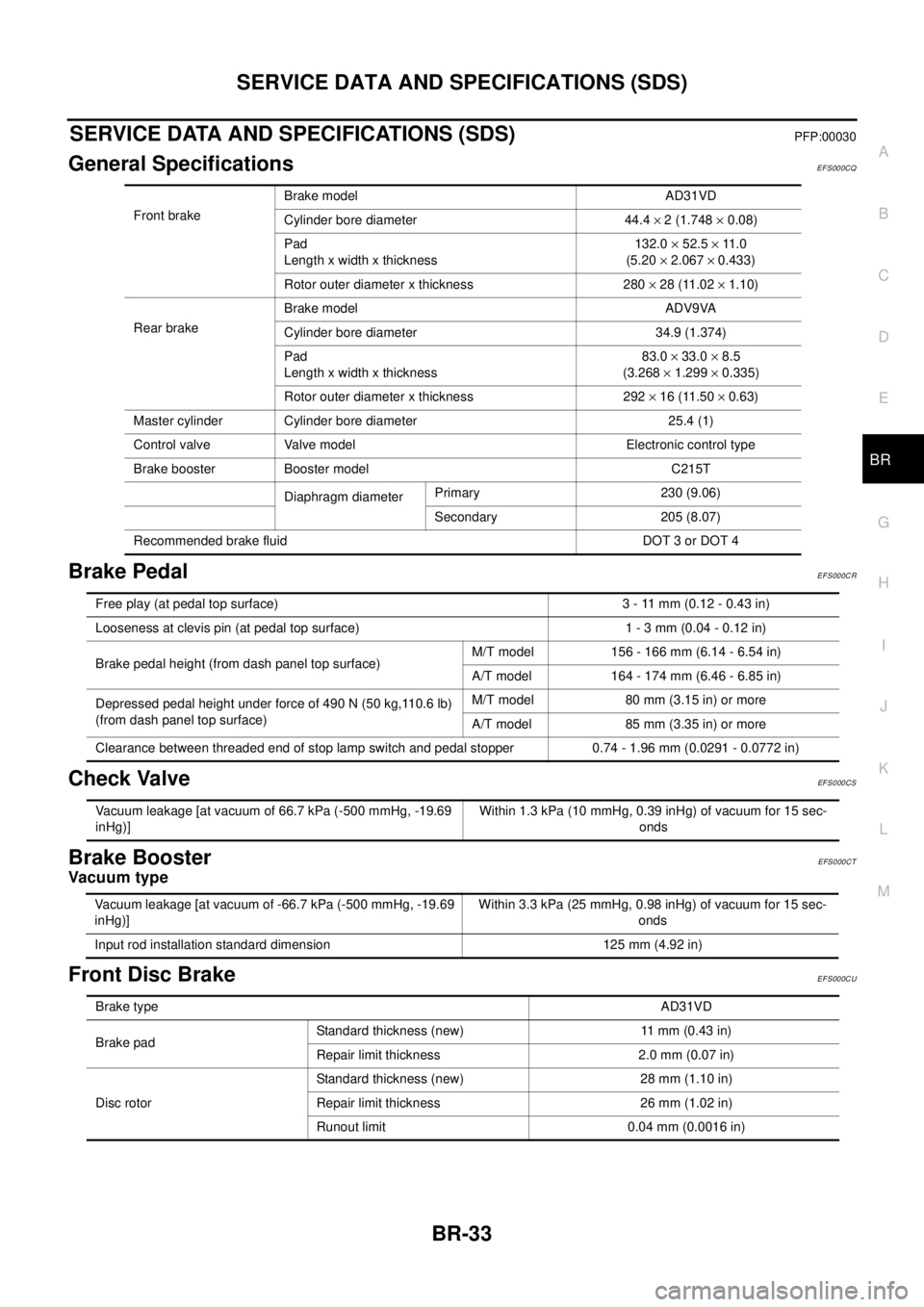

ASSEMBLY

CAUTION:

When assembling, do not use rubber grease.

1. Apply rubber lubricant to piston seals, and install them to cylin-

der body.

CAUTION:

Do not reuse piston seals.

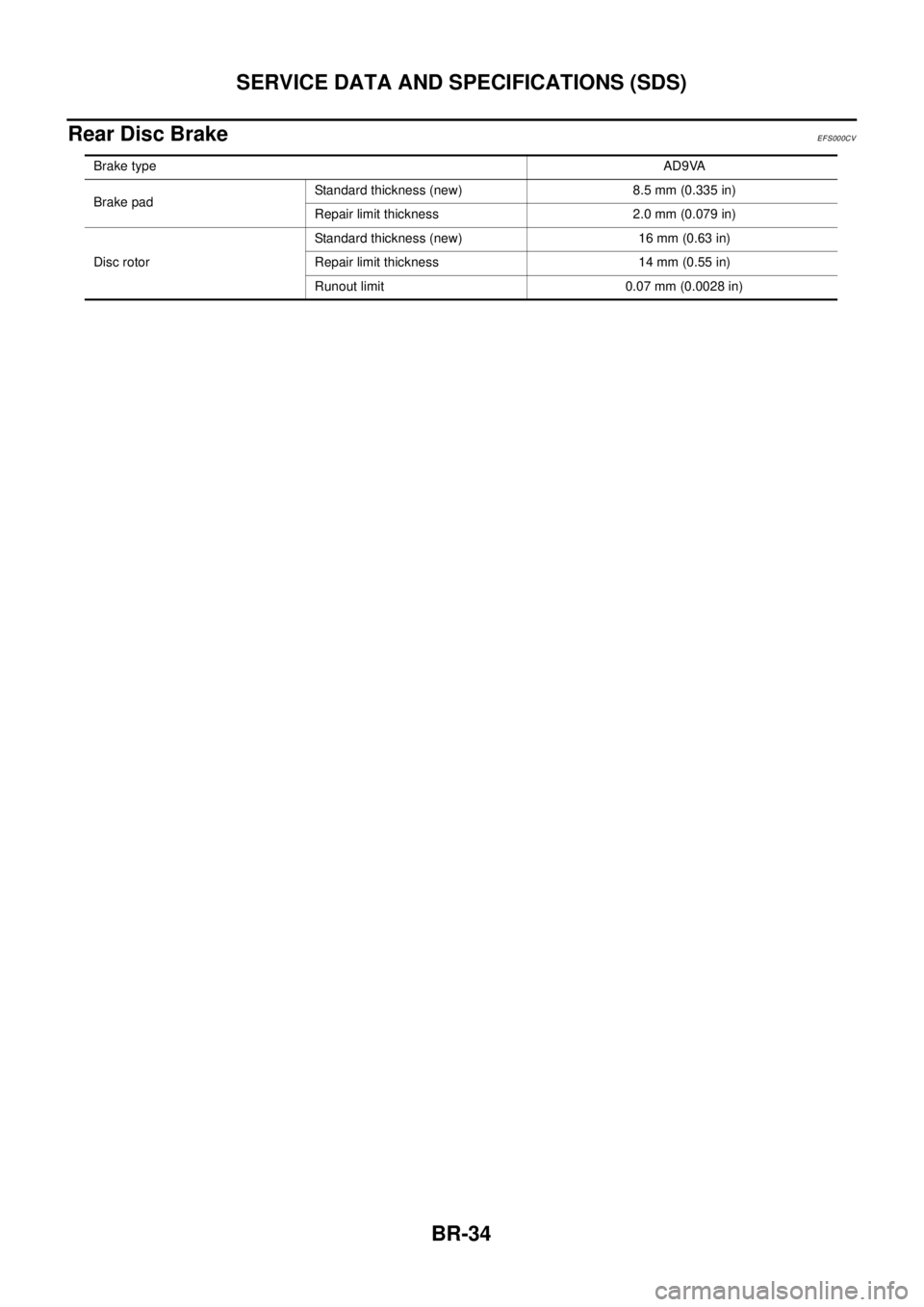

2. Apply brake fluid to piston boots. Cover piston end with piston

boot. Install cylinder side lip on piston boot properly into groove

on cylinder body.

CAUTION:

Do not reuse piston boot.

3. Press piston into cylinder body by hand. Assemble piston side

lip on piston boot properly into groove on the piston.

CAUTION:

Press piston evenly and change pressing point to prevent

cylinder inner wall from being rubbed.Measurement point:

At a point 10 mm (0.39 in) from the outer

edge of the disc.

Run out limit:

0.07 mm (0.0028 in) or less

BRA0013D

Standard thickness : 16.0 mm (0.630 in)

Wear limit : 14.0 mm (0.551 in)

Maximum uneven wear (measured at 8 positions):

0.02 mm (0.0008 in) or less

SBR020B

SFIA0156E

SFIA0157E

Page 866 of 3066

BR-32

REAR DISC BRAKE

4. Fix piston boot with retaining ring.

CAUTION:

lBe sure boot is securely engaged in groove on cylinder

body.

lDo not reuse retaining ring.

5. Connect sliding pins and sliding pin boots to torque member.

6. Connect torque member to axle assembly and tighten mounting

bolts to specified torque.

CAUTION:

Wipe oil and grease on axle assembly washer seats and torque

member mounting surface. Install torque member to axle

assembly.

7. Connect pads, pad retainers, shims, and shim covers to torque member and assemble cylinder body.

8. Tighten sliding pin bolts to the specified torque.

9. Connect brake hose to caliper assembly and tighten union bolts to the specified torque.

CAUTION:

Do not reuse union bolt copper washer.

10. After installing caliper assembly, refill with new brake fluid and bleed air. Refer toBR-10, "

Bleeding Brake

System"

SFIA0158E

Page 867 of 3066

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-33

C

D

E

G

H

I

J

K

L

MA

B

BR

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEFS000CQ

Brake PedalEFS000CR

Check ValveEF S0 00 CS

Brake BoosterEFS000CT

Vacuum type

Front Disc BrakeEFS000CU

Front brakeBrake model AD31VD

Cylinder bore diameter 44.4´2(1.748´0.08)

Pad

Length x width x thickness132.0´52.5´11 . 0

(5.20´2.067´0.433)

Rotor outer diameter x thickness 280´28 (11.02´1.10)

Rear brakeBrake model ADV9VA

Cylinder bore diameter 34.9 (1.374)

Pad

Length x width x thickness83.0´33.0´8.5

(3.268´1.299´0.335)

Rotor outer diameter x thickness 292´16 (11.50´0.63)

Master cylinder Cylinder bore diameter 25.4 (1)

Control valve Valve model Electronic control type

Brake booster Booster model C215T

Diaphragm diameterPrimary 230 (9.06)

Secondary 205 (8.07)

Recommended brake fluid DOT 3 or DOT 4

Free play (at pedal top surface) 3 - 11 mm (0.12 - 0.43 in)

Looseness at clevis pin (at pedal top surface) 1 - 3 mm (0.04 - 0.12 in)

Brake pedal height (from dash panel top surface)M/T model 156 - 166 mm (6.14 - 6.54 in)

A/T model 164 - 174 mm (6.46 - 6.85 in)

Depressed pedal height under force of 490 N (50 kg,110.6 lb)

(from dash panel top surface)M/T model 80 mm (3.15 in) or more

A/T model 85 mm (3.35 in) or more

Clearance between threaded end of stop lamp switch and pedal stopper 0.74 - 1.96 mm (0.0291 - 0.0772 in)

Vacuum leakage [at vacuum of 66.7 kPa (-500 mmHg, -19.69

inHg)]Within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 sec-

onds

Vacuum leakage [at vacuum of -66.7 kPa (-500 mmHg, -19.69

inHg)]Within 3.3 kPa (25 mmHg, 0.98 inHg) of vacuum for 15 sec-

onds

Input rod installation standard dimension 125 mm (4.92 in)

Brake typeAD31VD

Brake padStandard thickness (new) 11 mm (0.43 in)

Repair limit thickness 2.0 mm (0.07 in)

Disc rotorStandard thickness (new) 28 mm (1.10 in)

Repair limit thickness 26 mm (1.02 in)

Runout limit 0.04 mm (0.0016 in)

Page 868 of 3066

BR-34

SERVICE DATA AND SPECIFICATIONS (SDS)

Rear Disc Brake

EFS000CV

Brake typeAD9VA

Brake padStandard thickness (new) 8.5 mm (0.335 in)

Repair limit thickness 2.0 mm (0.079 in)

Disc rotorStandard thickness (new) 16 mm (0.63 in)

Repair limit thickness 14 mm (0.55 in)

Runout limit 0.07 mm (0.0028 in)

Page 869 of 3066

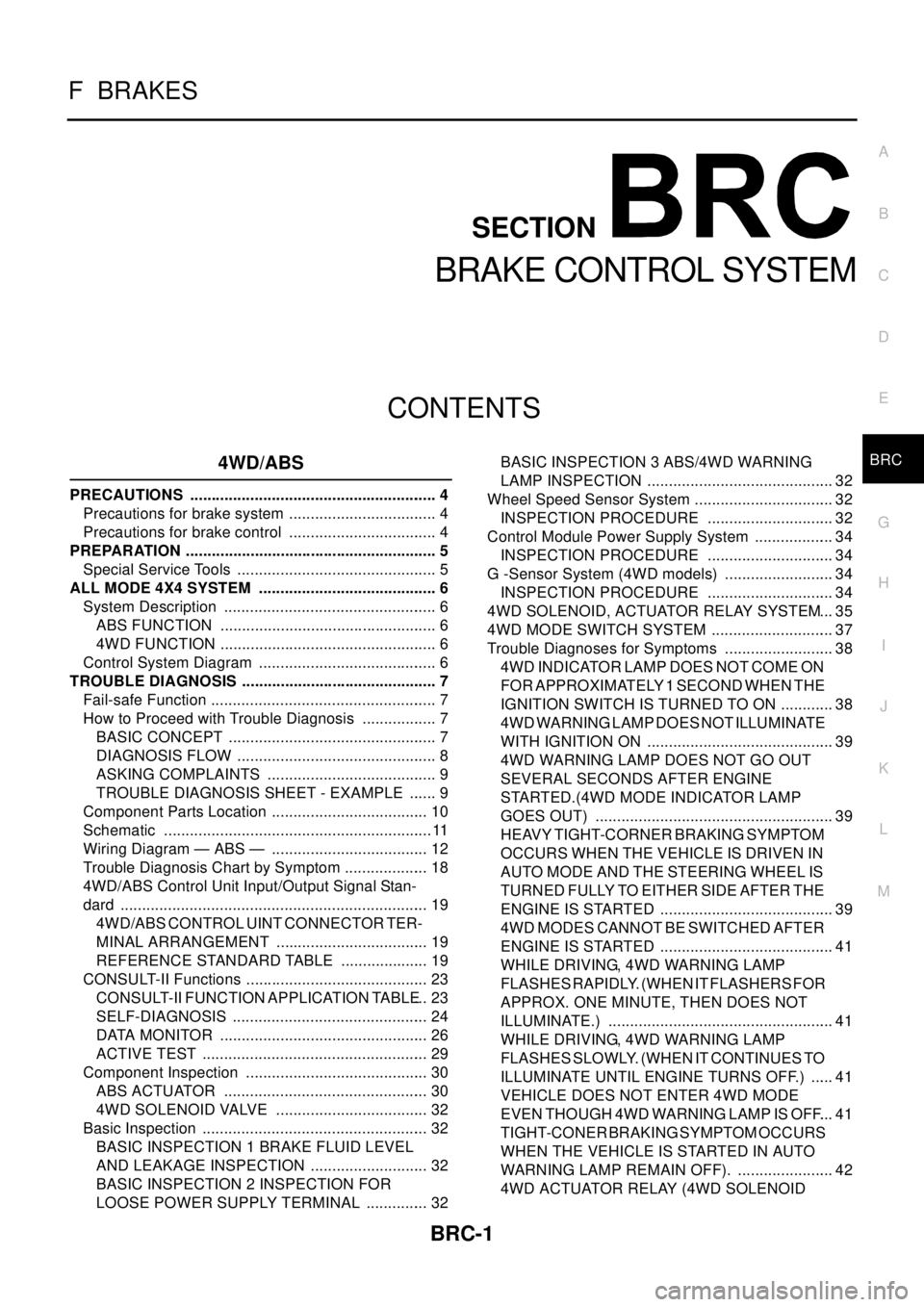

BRC-1

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTION

A

B

BRC

BRAKE CONTROL SYSTEM

4WD/ABS

PRECAUTIONS .......................................................... 4

Precautions for brake system ................................... 4

Precautions for brake control ................................... 4

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

ALL MODE 4X4 SYSTEM .......................................... 6

System Description .................................................. 6

ABS FUNCTION ................................................... 6

4WD FUNCTION ................................................... 6

Control System Diagram .......................................... 6

TROUBLE DIAGNOSIS .............................................. 7

Fail-safe Function ..................................................... 7

How to Proceed with Trouble Diagnosis .................. 7

BASIC CONCEPT ................................................. 7

DIAGNOSIS FLOW ............................................... 8

ASKING COMPLAINTS ........................................ 9

TROUBLE DIAGNOSIS SHEET - EXAMPLE ....... 9

Component Parts Location ..................................... 10

Schematic ...............................................................11

Wiring Diagram — ABS — ..................................... 12

Trouble Diagnosis Chart by Symptom .................... 18

4WD/ABS Control Unit Input/Output Signal Stan-

dard ........................................................................ 19

4WD/ABS CONTROL UINT CONNECTOR TER-

MINAL ARRANGEMENT .................................... 19

REFERENCE STANDARD TABLE ..................... 19

CONSULT-II Functions ........................................... 23

CONSULT-II FUNCTION APPLICATION TABLE... 23

SELF-DIAGNOSIS .............................................. 24

DATA MONITOR ................................................. 26

ACTIVE TEST ..................................................... 29

Component Inspection ........................................... 30

ABS ACTUATOR ................................................ 30

4WD SOLENOID VALVE .................................... 32

Basic Inspection ..................................................... 32

BASIC INSPECTION 1 BRAKE FLUID LEVEL

AND LEAKAGE INSPECTION ............................ 32

BASIC INSPECTION 2 INSPECTION FOR

LOOSE POWER SUPPLY TERMINAL ............... 32BASIC INSPECTION 3 ABS/4WD WARNING

LAMP INSPECTION ............................................ 32

Wheel Speed Sensor System ................................. 32

INSPECTION PROCEDURE .............................. 32

Control Module Power Supply System ................... 34

INSPECTION PROCEDURE .............................. 34

G -Sensor System (4WD models) .......................... 34

INSPECTION PROCEDURE .............................. 34

4WD SOLENOID, ACTUATOR RELAY SYSTEM... 35

4WD MODE SWITCH SYSTEM ............................. 37

Trouble Diagnoses for Symptoms .......................... 38

4WD INDICATOR LAMP DOES NOT COME ON

FORAPPROXIMATELY1SECONDWHENTHE

IGNITION SWITCH IS TURNED TO ON ............. 38

4WD WARNING LAMP DOES NOT ILLUMINATE

WITH IGNITION ON ............................................ 39

4WD WARNING LAMP DOES NOT GO OUT

SEVERAL SECONDS AFTER ENGINE

STARTED.(4WD MODE INDICATOR LAMP

GOES OUT) ........................................................ 39

HEAVY TIGHT-CORNER BRAKING SYMPTOM

OCCURS WHEN THE VEHICLE IS DRIVEN IN

AUTO MODE AND THE STEERING WHEEL IS

TURNED FULLY TO EITHER SIDE AFTER THE

ENGINE IS STARTED ......................................... 39

4WD MODES CANNOT BE SWITCHED AFTER

ENGINE IS STARTED ......................................... 41

WHILE DRIVING, 4WD WARNING LAMP

FLASHES RAPIDLY. (WHEN IT FLASHERSFOR

APPROX. ONE MINUTE, THEN DOES NOT

ILLUMINATE.) ..................................................... 41

WHILE DRIVING, 4WD WARNING LAMP

FLASHES SLOWLY. (WHEN IT CONTINUES TO

ILLUMINATE UNTIL ENGINE TURNS OFF.) ...... 41

VEHICLE DOES NOT ENTER 4WD MODE

EVEN THOUGH 4WD WARNING LAMP IS OFF.... 41

TIGHT-CONER BRAKING SYMPTOM OCCURS

WHEN THE VEHICLE IS STARTED IN AUTO

WARNING LAMP REMAIN OFF). ....................... 42

4WD ACTUATOR RELAY (4WD SOLENOID

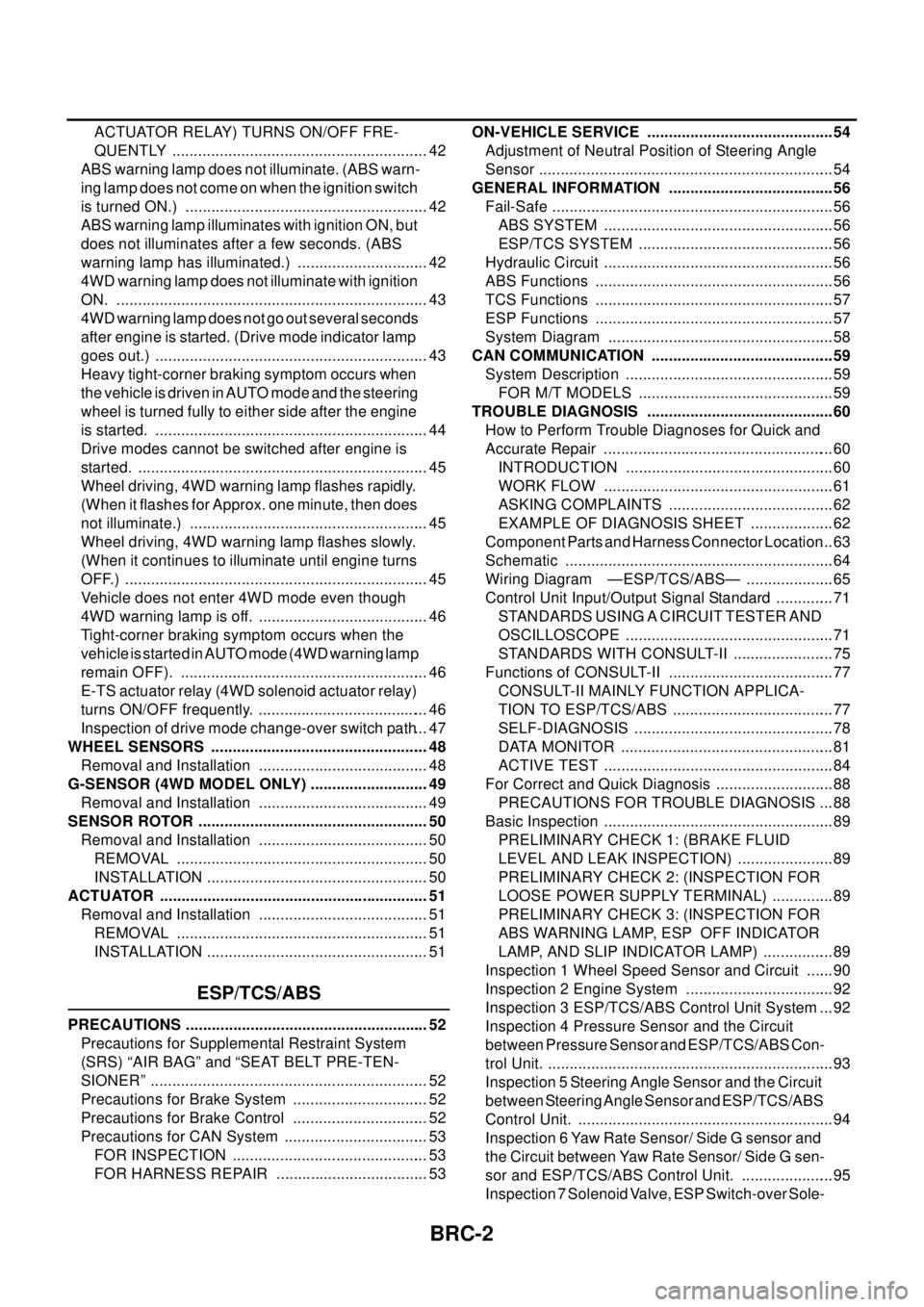

Page 870 of 3066

BRC-2

ACTUATOR RELAY) TURNS ON/OFF FRE-

QUENTLY ............................................................ 42

ABS warning lamp does not illuminate. (ABS warn-

ing lamp does not come on when the ignition switch

is turned ON.) ......................................................... 42

ABS warning lamp illuminates with ignition ON, but

does not illuminates after a few seconds. (ABS

warning lamp has illuminated.) ............................... 42

4WD warning lamp does not illuminate with ignition

ON. ......................................................................... 43

4WD warning lamp does not go out several seconds

after engine is started. (Drive mode indicator lamp

goes out.) ................................................................ 43

Heavy tight-corner braking symptom occurs when

the vehicle is driven in AUTO mode and the steering

wheel is turned fully to either side after the engine

is started. ................................................................ 44

Drive modes cannot be switched after engine is

started. .................................................................... 45

Wheel driving, 4WD warning lamp flashes rapidly.

(When it flashes for Approx. one minute, then does

not illuminate.) ........................................................ 45

Wheel driving, 4WD warning lamp flashes slowly.

(When it continues to illuminate until engine turns

OFF.) ....................................................................... 45

Vehicle does not enter 4WD mode even though

4WD warning lamp is off. ........................................ 46

Tight-corner braking symptom occurs when the

vehicle is started in AUTO mode (4WD warning lamp

remain OFF). .......................................................... 46

E-TS actuator relay (4WD solenoid actuator relay)

turns ON/OFF frequently. ........................................ 46

Inspection of drive mode change-over switch path... 47

WHEEL SENSORS ................................................... 48

Removal and Installation ........................................ 48

G-SENSOR (4WD MODEL ONLY) ............................ 49

Removal and Installation ........................................ 49

SENSOR ROTOR ...................................................... 50

Removal and Installation ........................................ 50

REMOVAL ........................................................... 50

INSTALLATION .................................................... 50

ACTUATOR ............................................................... 51

Removal and Installation ........................................ 51

REMOVAL ........................................................... 51

INSTALLATION .................................................... 51

ESP/TCS/ABS

PRECAUTIONS ......................................................... 52

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................. 52

Precautions for Brake System ................................ 52

Precautions for Brake Control ................................ 52

Precautions for CAN System .................................. 53

FOR INSPECTION .............................................. 53

FOR HARNESS REPAIR .................................... 53ON-VEHICLE SERVICE ............................................54

Adjustment of Neutral Position of Steering Angle

Sensor .....................................................................54

GENERAL INFORMATION .......................................56

Fail-Safe ..................................................................56

ABS SYSTEM ......................................................56

ESP/TCS SYSTEM ..............................................56

Hydraulic Circuit ......................................................56

ABS Functions ........................................................56

TCS Functions ........................................................57

ESP Functions ........................................................57

System Diagram .....................................................58

CAN COMMUNICATION ...........................................59

System Description .................................................59

FOR M/T MODELS ..............................................59

TROUBLE DIAGNOSIS ............................................60

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ......................................................60

INTRODUCTION .................................................60

WORK FLOW ......................................................61

ASKING COMPLAINTS .......................................62

EXAMPLE OF DIAGNOSIS SHEET ....................62

Component Parts and Harness Connector Location... 63

Schematic ...............................................................64

Wiring Diagram —ESP/TCS/ABS— .....................65

Control Unit Input/Output Signal Standard ..............71

STANDARDS USING A CIRCUIT TESTER AND

OSCILLOSCOPE .................................................71

STANDARDS WITH CONSULT-II ........................75

Functions of CONSULT-II .......................................77

CONSULT-II MAINLY FUNCTION APPLICA-

TION TO ESP/TCS/ABS ......................................77

SELF-DIAGNOSIS ...............................................78

DATA MONITOR ..................................................81

ACTIVE TEST ......................................................84

For Correct and Quick Diagnosis ............................88

PRECAUTIONS FOR TROUBLE DIAGNOSIS ... 88

Basic Inspection ......................................................89

PRELIMINARY CHECK 1: (BRAKE FLUID

LEVEL AND LEAK INSPECTION) .......................89

PRELIMINARY CHECK 2: (INSPECTION FOR

LOOSE POWER SUPPLY TERMINAL) ...............89

PRELIMINARY CHECK 3: (INSPECTION FOR

ABS WARNING LAMP, ESP OFF INDICATOR

LAMP, AND SLIP INDICATOR LAMP) .................89

Inspection 1 Wheel Speed Sensor and Circuit .......90

Inspection 2 Engine System ...................................92

Inspection 3 ESP/TCS/ABS Control Unit System ...92

Inspection 4 Pressure Sensor and the Circuit

between Pressure Sensor and ESP/TCS/ABS Con-

trol Unit. ...................................................................93

Inspection 5 Steering Angle Sensor and the Circuit

between Steering Angle Sensor and ESP/TCS/ABS

Control Unit. ............................................................94

Inspection 6 Yaw Rate Sensor/ Side G sensor and

the Circuit between Yaw Rate Sensor/ Side G sen-

sor and ESP/TCS/ABS Control Unit. ......................95

Inspection 7 Solenoid Valve, ESP Switch-over Sole-