OPEL ANTARA 2009 Owners Manual

Manufacturer: OPEL, Model Year: 2009, Model line: ANTARA, Model: OPEL ANTARA 2009Pages: 234, PDF Size: 3.01 MB

Page 171 of 234

Self-help, vehicle care171

Self-help, vehicle care

Diesel fuel system, bleeding

Never let the fuel tank run dry. If control

indicator Y illuminates, refuel as soon as

possible.

It is possible to restart the engine if the tank

has been run dry. A delayed start can be

expected. Switch on the ignition three times

for approx. 15 seconds. Then try to start

the engine for no more than 40 seconds. If

the engine will not start, wait at least

10 seconds before trying again. If the

engine will still not start, consult a

workshop.

Bonnet

To open the bonnet, pull release lever /

located on the left-hand side below the

instrument panel.

The bonnet will then be unlocked and will

partially open. Return release lever to its

original position.

Do not pull release lever while the vehicle is

moving.

Diesel fuel system, bleeding .............. 171

Bonnet ................................................. 171

Starting ................................................ 172

Starting the engine with jump leads

3 172

Towing ................................................. 174

Jack and vehicle tools ........................ 176

Warning triangle ¨ 3 ,

First aid kit +3................................ 177

Temporary spare wheel ..................... 177

Wheel changing .................................. 178

Electrical system ................................. 181

Fuses and the most important circuits they protect ...................................... 182

Bulb replacement ............................... 185

Opel genuine parts and accessories . 191

A note on safety ................................. 191

Checking and topping up fluids ........ 191

Windscreen wipers .............................. 198

Windscreen washer system ................ 199

Battery ................................................. 200

Protection of electr onic components 201

Vehicle storage ................................... 201

Vehicle care......................................... 201

9 Warning

Disregard of the instructions may lead to

injuries or endanger life. Vehicle

passengers must be informed

accordingly.

Page 172 of 234

Self-help, vehicle care172

To open completely, locate the safety

catch, found slightly left of centre on the

underside of the bonnet, push the catch

upwards and lift the bonnet gently. The

bonnet is held open automatically.

When the bonnet is opened, leaves, dirt or

snow on the bonnet can slide down and

obstruct the air intake. Remove any leaves,

dirt or snow. Air intake - see page 114.

Never drive with bonnet open.

To close bonnet, lower it gradually,

allowing it to drop from a height of approx.

30 cm.

Check that the bonnet is locked in position

before driving, by pulling at its front edge.

If it is not engaged, repeat closing

procedure.

Starting

Do not start with quick charger

This prevents damage to electronic

components.

Do not start by pushing or towing

Because your vehicle is fitted with a

catalytic converter, it must not be started

by pushing or towing - see page 133.

The vehicle can only be started using jump

leads - see following pages.

Starting the engine with jump

leads 3

A vehicle with a discha rged battery can be

started using jump leads and the battery of

another vehicle.

Start attempts should be made at intervals

of 1 minute and should not last longer than

15 seconds.

9 Warning

If the vehicle battery requires charging

whilst still in the vehicle, ensure there is

adequate ventilation in and around the

battery compartment, to prevent risk of

explosion.

9 Warning

This must be done with extreme care. Any

deviation from the following instructions

could lead to personal injury or damage

resulting from battery explosion, as well

as to damage to the electrical systems in

both vehicles.

Page 173 of 234

Self-help, vehicle care173

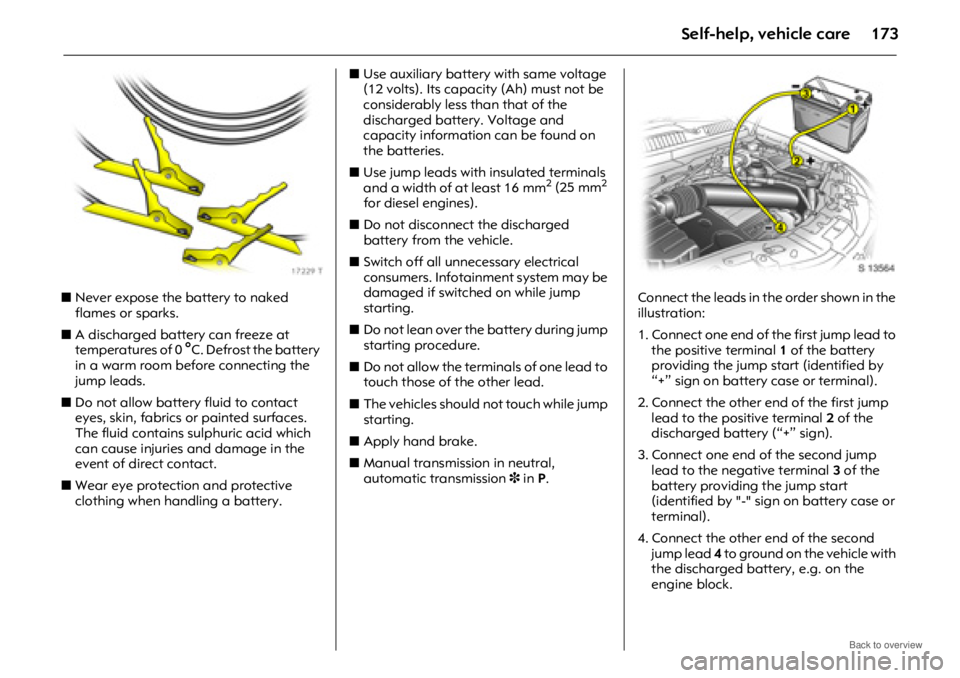

zNever expose the battery to naked

flames or sparks.

z A discharged battery can freeze at

temperatures of 0

°C. Defrost the battery

in a warm room before connecting the

jump leads.

z Do not allow battery fluid to contact

eyes, skin, fabrics or painted surfaces.

The fluid contains sulphuric acid which

can cause injuries and damage in the

event of direct contact.

z Wear eye protection and protective

clothing when handling a battery. z

Use auxiliary battery with same voltage

(12 volts). Its capacity (Ah) must not be

considerably less than that of the

discharged battery. Voltage and

capacity information can be found on

the batteries.

z Use jump leads with insulated terminals

and a width of at least 16 mm

2 (25 mm2

for diesel engines).

z Do not disconnect the discharged

battery from the vehicle.

z Switch off all unnecessary electrical

consumers. Infotainment system may be

damaged if switched on while jump

starting.

z Do not lean over the battery during jump

starting procedure.

z Do not allow the terminals of one lead to

touch those of the other lead.

z The vehicles should not touch while jump

starting.

z Apply hand brake.

z Manual transmissi on in neutral,

automatic transmission 3 in P. Connect the leads in th

e order shown in the

illustration:

1. Connect one end of the first jump lead to the positive terminal 1 of the battery

providing the jump start (identified by

“+” sign on battery case or terminal).

2. Connect the other end of the first jump lead to the positive terminal 2 of the

discharged battery (“+” sign).

3. Connect one end of the second jump lead to the negative terminal 3 of the

battery providing the jump start

(identified by "-" sign on battery case or

terminal).

4. Connect the other end of the second jump lead 4 to ground on the vehicle with

the discharged battery, e.g. on the

engine block.

Page 174 of 234

Self-help, vehicle care174

zDo not connect leads to negative

terminal of discharged battery.

z The last connection point should be as

far away from the discharged battery as

possible.

z Route leads so they cannot catch on

rotating parts in engine compartment.

z Start the engine of the vehicle providing

the jump start.

z After 5 minutes, start the other engine.

Start attempts shou ld be made at

intervals of 1 minute and should not last

longer than 15 seconds.

z After starting, allow both engines to idle

for approx. 3 minutes with leads

connected.

z In order to avoid excess voltage in the

electrical system, before removing a

lead, switch on an electrical consumer

(e.g. lamps, heated rear window) in the

vehicle receiving the jump start.

z Operate discharged vehicle for approx.

20 minutes to allow for recharging.

z Reverse above sequence exactly when

removing leads.

Towing

Towing the vehicle

Attach a tow rope 3 - or better still a tow

rod 3 - to the front towing eye (located

under the front bumper). Do not tow the

vehicle from the rear.

The front towing eye must only be used for

towing and not recovering the vehicle. Place gearshift lever in neutral. Switch on

the ignition to release the steering column

lock and to permit operation of the brake

lamps and windscreen wipers.

Drive off slowly and avoid jerky

movements. Impermissible tractive forces

could damage

the vehicles.

9 Warning

Care must be taken to ensure that the

leads do not inadvertently contact metal

surfaces within the compartment area.

9 Warning

Never lift vehicle using the towing eye.

9 Warning

More brake pedal pressure is necessary

when braking since the brake servo unit is

operative only when engine is running.

Considerably greater steering force is

necessary since this unit is operative only

when the engine is running.

Page 175 of 234

Self-help, vehicle care175

Keep tow rope 3 clear of front bumper,

and ensure it is secure ly fixed to the towing

eye at both ends. Pull on the tow rope 3 to

check.

To prevent entry of exhaust fumes from

towing vehicle, switch on air recirculation

mode (see page 109) and close the

windows.

Never let passengers ride in a vehicle that

is being towed.

Never tow a vehicle with damaged parts

that are not secured to the vehicle or if

wheels, brakes or steering are damaged.

Do not tow the vehicle with a tow rope 3 or

tow rod 3 for extended periods, to avoid

damage to the vehicle. Only tow in this

manner on hard-surfaced roads.

For vehicles with automatic transmission 3:

use flatbed or wheel lift equipment only.

Towing can cause severe damage to the

transmission.

Seek the assistance of a workshop. Towing service

Entrust your vehicle only to the towing

service of your choice and obtain an

estimate on towing costs before employing

any towing service. This will prevent

unnecessary expense and possible

insurance problems during claim

processing.

Use flatbed equipment whenever possible.

If vehicle is to be towed using a wheel lift,

tow with all wheels off the road, using a

towing dolly.

Never use sling-type equipment to tow the

vehicle or tow the vehicle with the front or

rear wheels on the road, to avoid causing

serious damage to the vehicle.

Place the gearshift lever in neutral

(automatic transmission 3

in N), switch on

hazard warning lamps, turn key to ignition

switch position ACC and release the

hand brake before towing the vehicle. Towing another vehicle

In emergency situations only, attach a tow

rope

3 - or better still a tow rod 3 - to the

rear towing eye.

The rear towing eye attachment 3 is stored

below the floor cover in the luggage

compartment.

Remove the cover located on the rear

bumper by pressing the lower part of the

cover.

Page 176 of 234

Self-help, vehicle care176

Screw the rear towing eye attachment anti-

clockwise until it is firmly in place.

Drive off slowly and avoid jerky

movements. Impermissible tractive forces

could damage the vehicles.

To prevent damage, do not take up slack

in the tow rope too quickly.

After towing, unscrew the rear towing eye

attachment clockwise to remove, and

reinstall the cover.

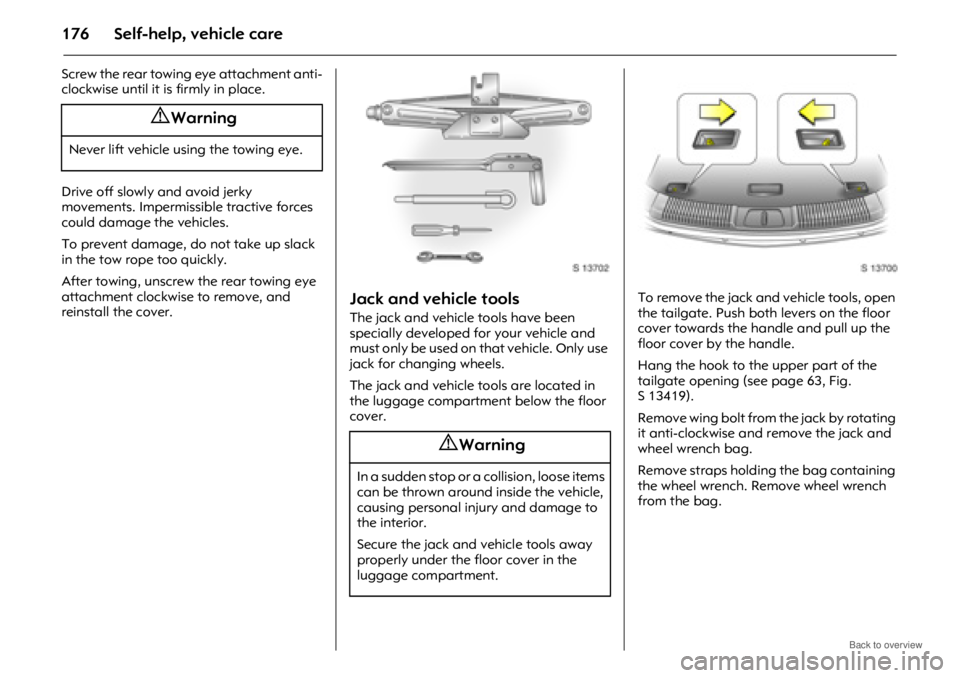

Jack and vehicle tools

The jack and vehicle tools have been

specially developed for your vehicle and

must only be used on that vehicle. Only use

jack for changing wheels.

The jack and vehicle tools are located in

the luggage compartment below the floor

cover. To remove the jack and vehicle tools, open

the tailgate. Push both levers on the floor

cover towards the handle and pull up the

floor cover by the handle.

Hang the hook to the upper part of the

tailgate opening (see page 63, Fig.

S 13419).

Remove wing bolt from the jack by rotating

it anti-clockwise and remove the jack and

wheel wrench bag.

Remove straps holding the bag containing

the wheel wrench. Remove wheel wrench

from the bag.

9 Warning

Never lift vehicle using the towing eye.

9 Warning

In a sudden stop or a collision, loose items

can be thrown around inside the vehicle,

causing personal injury and damage to

the interior.

Secure the jack and vehicle tools away

properly under the floor cover in the

luggage compartment.

Page 177 of 234

Self-help, vehicle care177

Warning triangle

¨ 3 ,

First aid kit

+3

Your first aid kit and warning triangle can

be accommodated below the floor cover in

the luggage compartment.

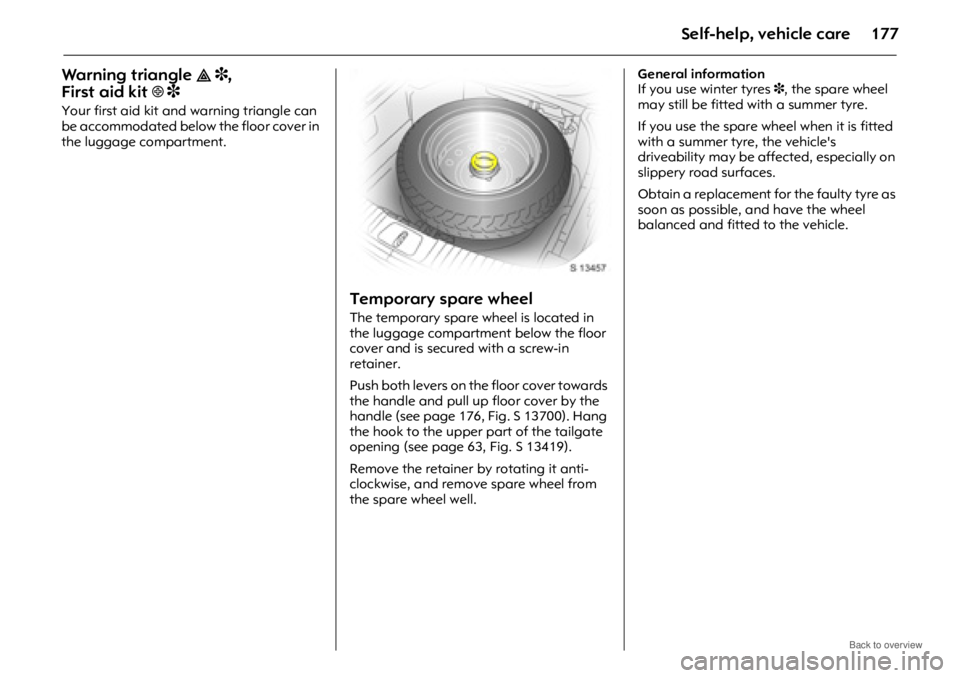

Temporary spare wheel

The temporary spare wheel is located in

the luggage compartment below the floor

cover and is secured with a screw-in

retainer.

Push both levers on the floor cover towards

the handle and pull up floor cover by the

handle (see page 176, Fig. S 13700). Hang

the hook to the upper part of the tailgate

opening (see page 63, Fig. S 13419).

Remove the retainer by rotating it anti-

clockwise, and remove spare wheel from

the spare wheel well. General information

If you use winter tyres

3, the spare wheel

may still be fitted with a summer tyre.

If you use the spare wheel when it is fitted

with a summer tyre, the vehicle's

driveability may be affected, especially on

slippery road surfaces.

Obtain a replacement for the faulty tyre as

soon as possible, and have the wheel

balanced and fitted to the vehicle.

Page 178 of 234

Self-help, vehicle care178

Notes on temporary spare wheel

zUsing a temporary spare wheel may

change the driving behaviour of the

vehicle, particularly if using winter

tyres 3. Replace defective tyre as quickly

as possible, balanc e wheel and fit to

vehicle.

z Fit only one temporary spare wheel.

z Do not drive faster than 80 km/h

(50 mph).

z Take curves slowly.

z Do not use the temporary spare wheel

for a lengthy period.

z Replace temporary spare wheel with full

specification wheel without delay.

z When temporary spare wheel is fitted, do

not take the vehicle through an

automatic car wash with guide rails. The

temporary spare wheel may get caught

on the rails, causing damage to the tyre,

wheel and other vehicle parts.

z Tyre chains are not permitted on the

temporary spare wheel.

If tyre chains are necessary after a front

wheel puncture, fit the temporary spare

wheel to the rear and a rear wheel to the

front. Check tyre pressure and adjust if

necessary - see page 224.

z Follow the temporary spare wheel

instructions on pages 153, 181, 223. Notes on directional tyres

3

Tyres with a prescribed rotating direction

can only achieve their maximum

performance if they are fitted in the

prescribed rotating direction.

If a tyre or spare wheel is fitted that is

rotating in the wrong direction due to a

puncture, the following must be noted:

z The handling of the vehicle may be

different. Replace defective tyres as soon

as possible, have wheel balanced and

fitted to the vehicle.

z Do not drive faster than 80 km/h

(50 mph).

z Drive particularly carefully on wet and

snow-covered road surfaces.

z For more information on tyres with a

prescribed rotating direction -

see page 149.Wheel changing

In order to reduce the chance of possible

injuries, make the following preparations

and note the procedure:

zPark on a level, firm and non-slippery

surface.

z Switch on hazard warning lamps and

apply hand brake. Engage 1st gear or

reverse (automatic transmission 3 in P).

z Correctly set up warning triangle 3.

z Ensure all vehicle passengers are out of

the vehicle and clear of the vehicle and

other traffic.

z Take the spare wheel from under the

luggage compartment floor cover -

see page 177.

z Before raising the vehicle, turn front

wheels to straight-ahead position.

Page 179 of 234

Self-help, vehicle care179

zRemove wheel trim 3.

z Slacken wheel nuts one turn only before

raising the vehicle, but do not totally

unscrew or remove the nuts until the

wheel is off the ground.

z Never change more th an one wheel at a

time.

z Block wheel diagonally opposite the

wheel to be changed, by placing wedge

blocks or equivalent in front and behind

the wheel.

z Do not jack-up the vehicle when traffic is

too close.

z Use jack only when changing wheels.

z Never exceed jack maximum working

load (900 kg).

z If the ground on which the vehicle is

standing is soft, a solid board (max. 1 cm

thick) should be placed under the jack.

Using a thicker board could lead to

damage of the jack and the vehicle. z

Do not raise the vehicle more than is

necessary to change a wheel.

z No people or animals may be in the

vehicle when it is jacked-up.

z Never start or run the engine or crawl

under a jacked-up vehicle.

z Before screwing on the wheel nuts when

changing a wheel, ap ply a light coating

of grease to the cone of each wheel nut.

z Fully tighten the wheel nuts after

lowering the vehicle all the way, ensuring

nuts have been tightened to the correct

torque (see page 223).

z If conditions are not satisfactory to

change a wheel safely, consult a

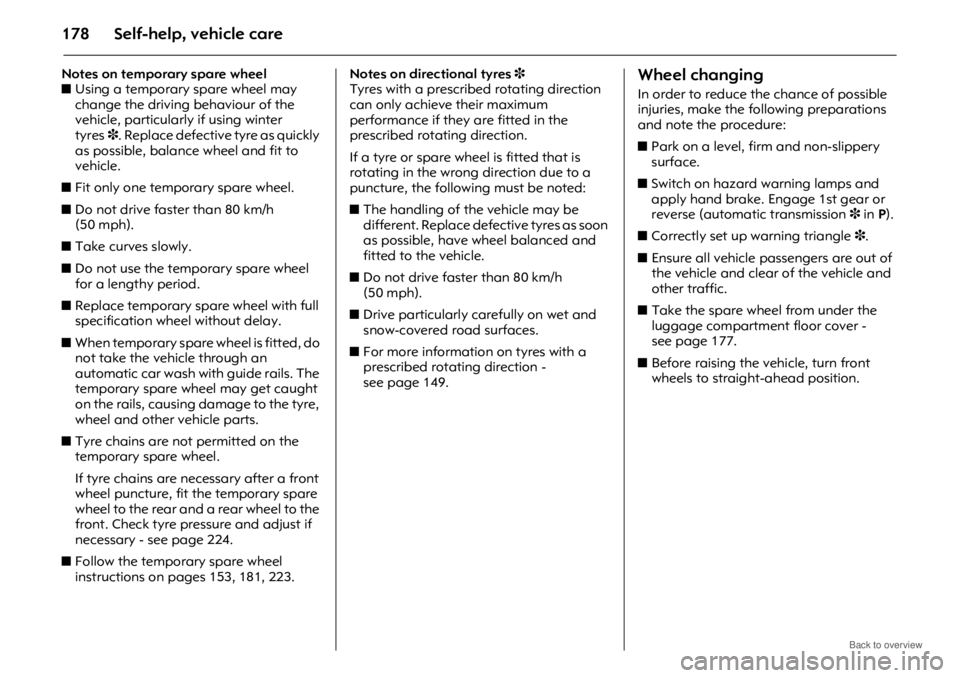

workshop. 1. Prise off the wheel trim 3

.

2. Slacken the wheel nuts by one turn each using the wrench, putting the

wrench on as far as possible.

Page 180 of 234

Self-help, vehicle care180

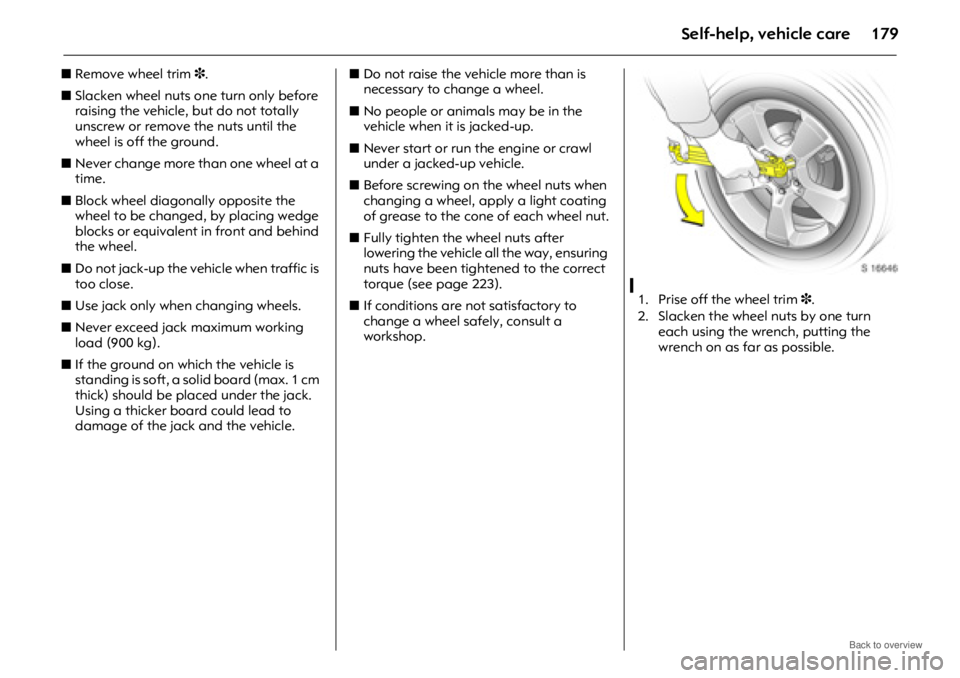

3. The location of front and rear jacking points is indicated by notches on the

bottom edge of the vehicle, under the

doors.4. Before positioning the jack, set it to the necessary height by rotating the eye by

hand.

Position jack at the front or rear jacking

point located nearest to the wheel

concerned so that the jack claw spans

the vertical base. Make sure it is properly

positioned.

The jack base must be on the ground

directly below the jacking point in a

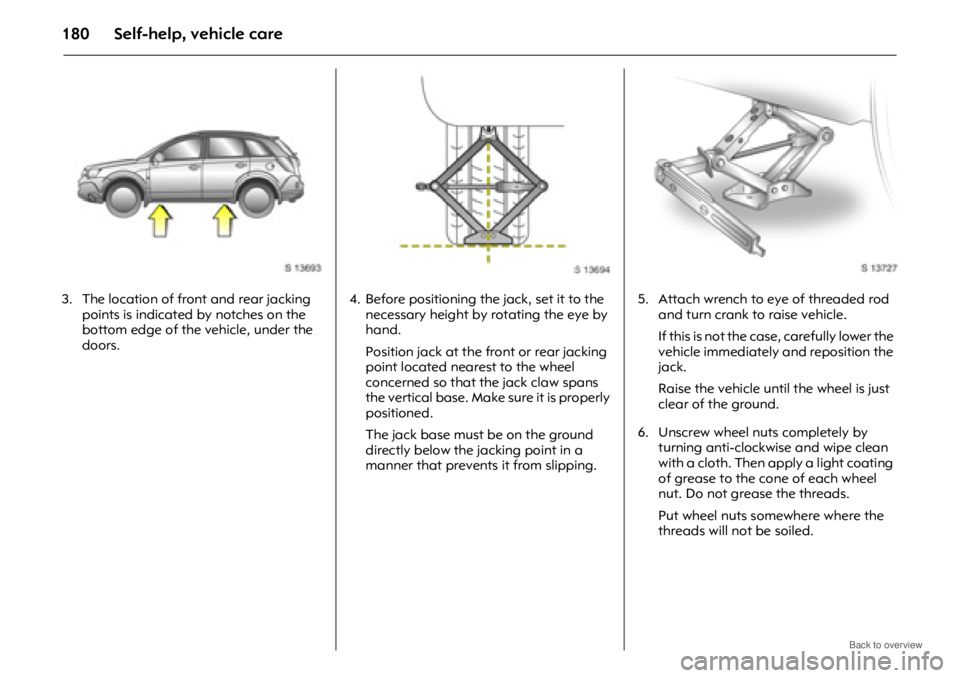

manner that prevents it from slipping.5. Attach wrench to eye of threaded rod and turn crank to raise vehicle.

If this is not the case, carefully lower the

vehicle immediately and reposition the

jack.

Raise the vehicle until the wheel is just

clear of the ground.

6. Unscrew wheel nuts completely by turning anti-clockwise and wipe clean

with a cloth. Then apply a light coating

of grease to the cone of each wheel

nut. Do not grease the threads.

Put wheel nuts somewhere where the

threads will not be soiled.