check oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1465 of 6000

6E–348

ENGINE DRIVEABILITY AND EMISSIONS

oil to enter the cylinder, particularly if the deposits are

heavier on the side of the spark plug facing the intake

valve.

TS23995

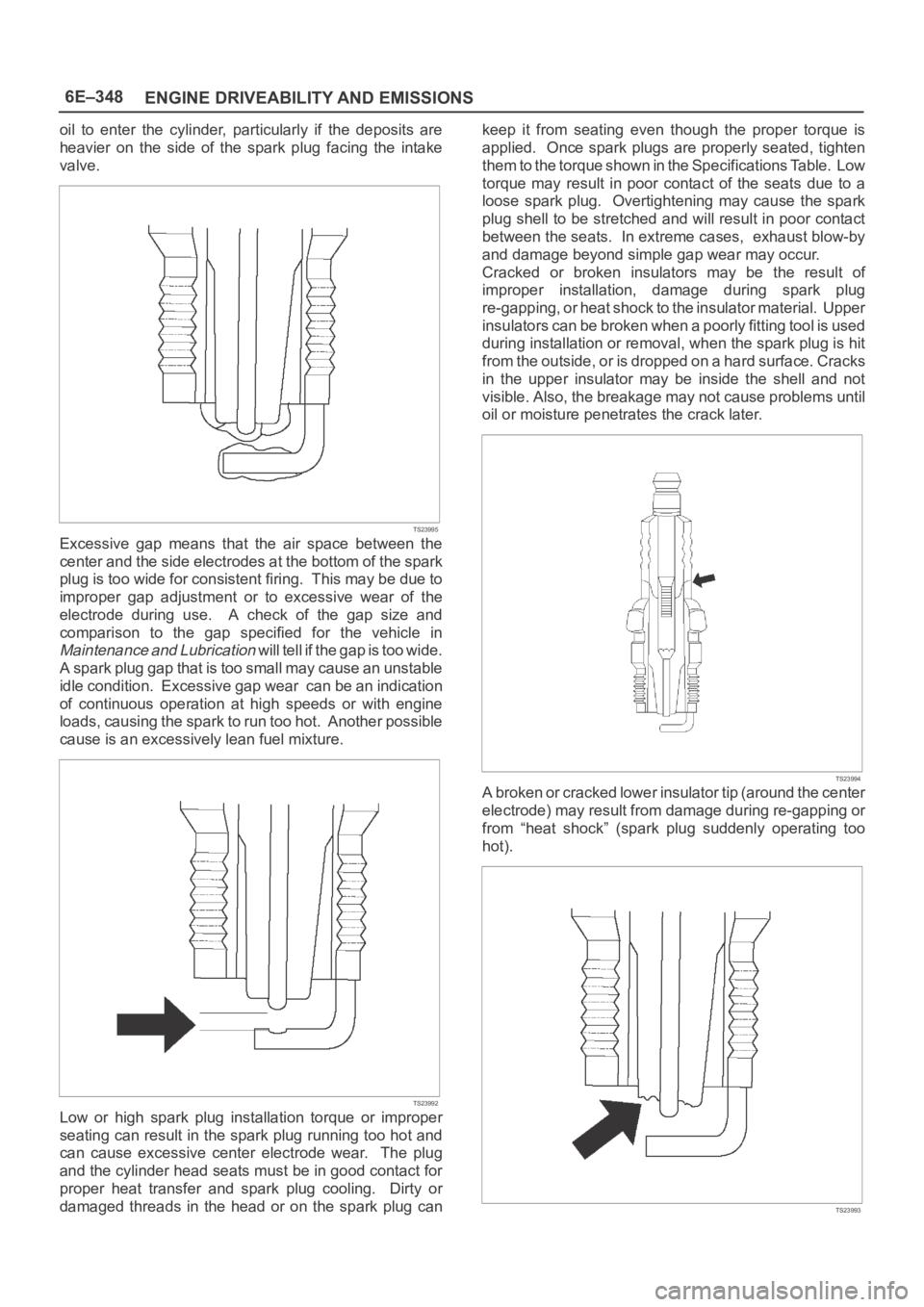

Excessive gap means that the air space between the

center and the side electrodes at the bottom of the spark

plug is too wide for consistent firing. This may be due to

improper gap adjustment or to excessive wear of the

electrode during use. A check of the gap size and

comparison to the gap specified for the vehicle in

Maintenance and Lubrication will tell if the gap is too wide.

A spark plug gap that is too small may cause an unstable

idle condition. Excessive gap wear can be an indication

of continuous operation at high speeds or with engine

loads, causing the spark to run too hot. Another possible

cause is an excessively lean fuel mixture.

TS23992

Low or high spark plug installation torque or improper

seating can result in the spark plug running too hot and

can cause excessive center electrode wear. The plug

and the cylinder head seats must be in good contact for

proper heat transfer and spark plug cooling. Dirty or

damaged threads in the head or on the spark plug cankeep it from seating even though the proper torque is

applied. Once spark plugs are properly seated, tighten

them to the torque shown in the Specifications Table. Low

torque may result in poor contact of the seats due to a

loose spark plug. Overtightening may cause the spark

plug shell to be stretched and will result in poor contact

between the seats. In extreme cases, exhaust blow-by

and damage beyond simple gap wear may occur.

Cracked or broken insulators may be the result of

improper installation, damage during spark plug

re-gapping, or heat shock to the insulator material. Upper

insulators can be broken when a poorly fitting tool is used

during installation or removal, when the spark plug is hit

from the outside, or is dropped on a hard surface. Cracks

in the upper insulator may be inside the shell and not

visible. Also, the breakage may not cause problems until

oil or moisture penetrates the crack later.

TS23994

A broken or cracked lower insulator tip (around the center

electrode) may result from damage during re-gapping or

from “heat shock” (spark plug suddenly operating too

hot).

TS23993

Page 1483 of 6000

6G–4

ENGINE LUBRICATION

11. Remove drive gear.

12. Remove oil seal.

13. Remove O-ring.

Inspection and Repair

CAUTION: Make necessary correction or parts

replacement if wear, damage or any other abnormal

conditions are found during inspection.

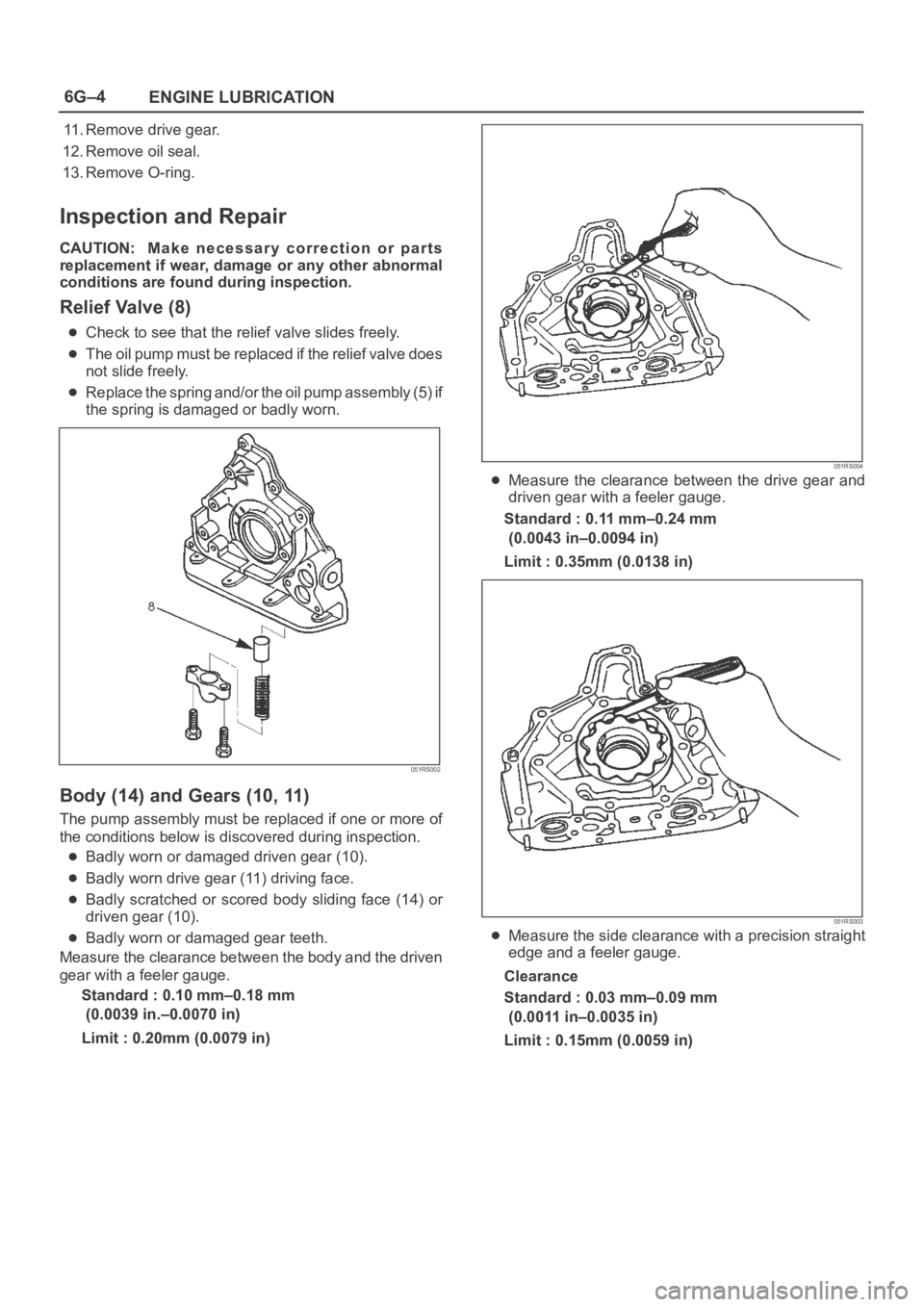

Relief Valve (8)

Check to see that the relief valve slides freely.

The oil pump must be replaced if the relief valve does

not slide freely.

Replace the spring and/or the oil pump assembly (5) if

the spring is damaged or badly worn.

051RS002

Body (14) and Gears (10, 11)

The pump assembly must be replaced if one or more of

the conditions below is discovered during inspection.

Badly worn or damaged driven gear (10).

Badly worn drive gear (11) driving face.

Badly scratched or scored body sliding face (14) or

driven gear (10).

Badly worn or damaged gear teeth.

Measure the clearance between the body and the driven

gear with a feeler gauge.

Standard : 0.10 mm–0.18 mm

(0.0039 in.–0.0070 in)

Limit : 0.20mm (0.0079 in)

051RS004

Measure the clearance between the drive gear and

driven gear with a feeler gauge.

Standard : 0.11 mm–0.24 mm

(0.0043 in–0.0094 in)

Limit : 0.35mm (0.0138 in)

051RS003

Measure the side clearance with a precision straight

edge and a feeler gauge.

Clearance

Standard : 0.03 mm–0.09 mm

(0.0011 in–0.0035 in)

Limit : 0.15mm (0.0059 in)

Page 1484 of 6000

6G–5 ENGINE LUBRICATION

051RS005

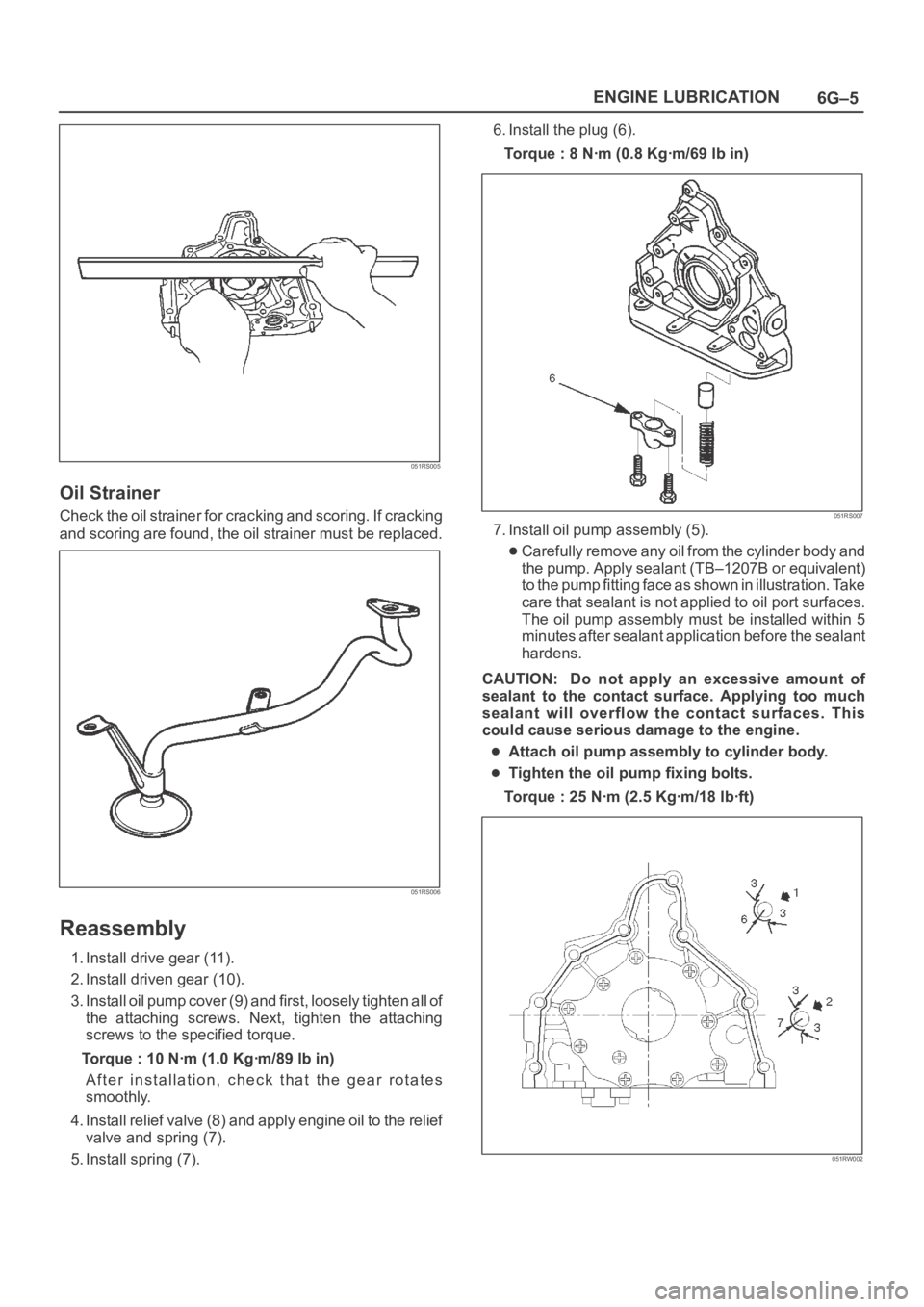

Oil Strainer

Check the oil strainer for cracking and scoring. If cracking

and scoring are found, the oil strainer must be replaced.

051RS006

Reassembly

1. Install drive gear (11).

2. Install driven gear (10).

3. Install oil pump cover (9) and first, loosely tighten all of

the attaching screws. Next, tighten the attaching

screws to the specified torque.

Torque : 10 Nꞏm (1.0 Kgꞏm/89 lb in)

After installation, check that the gear rotates

smoothly.

4. Install relief valve (8) and apply engine oil to the relief

valve and spring (7).

5. Install spring (7).6. Install the plug (6).

Torque : 8 Nꞏm (0.8 Kgꞏm/69 lb in)

051RS007

7. Install oil pump assembly (5).

Carefully remove any oil from the cylinder body and

the pump. Apply sealant (TB–1207B or equivalent)

to the pump fitting face as shown in illustration. Take

care that sealant is not applied to oil port surfaces.

The oil pump assembly must be installed within 5

minutes after sealant application before the sealant

hardens.

CAUTION: Do not apply an excessive amount of

sealant to the contact surface. Applying too much

sealant will overflow the contact surfaces. This

could cause serious damage to the engine.

Attach oil pump assembly to cylinder body.

Tighten the oil pump fixing bolts.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lbꞏft)

051RW002

Page 1736 of 6000

ENGINE MECHANICAL 6A – 3

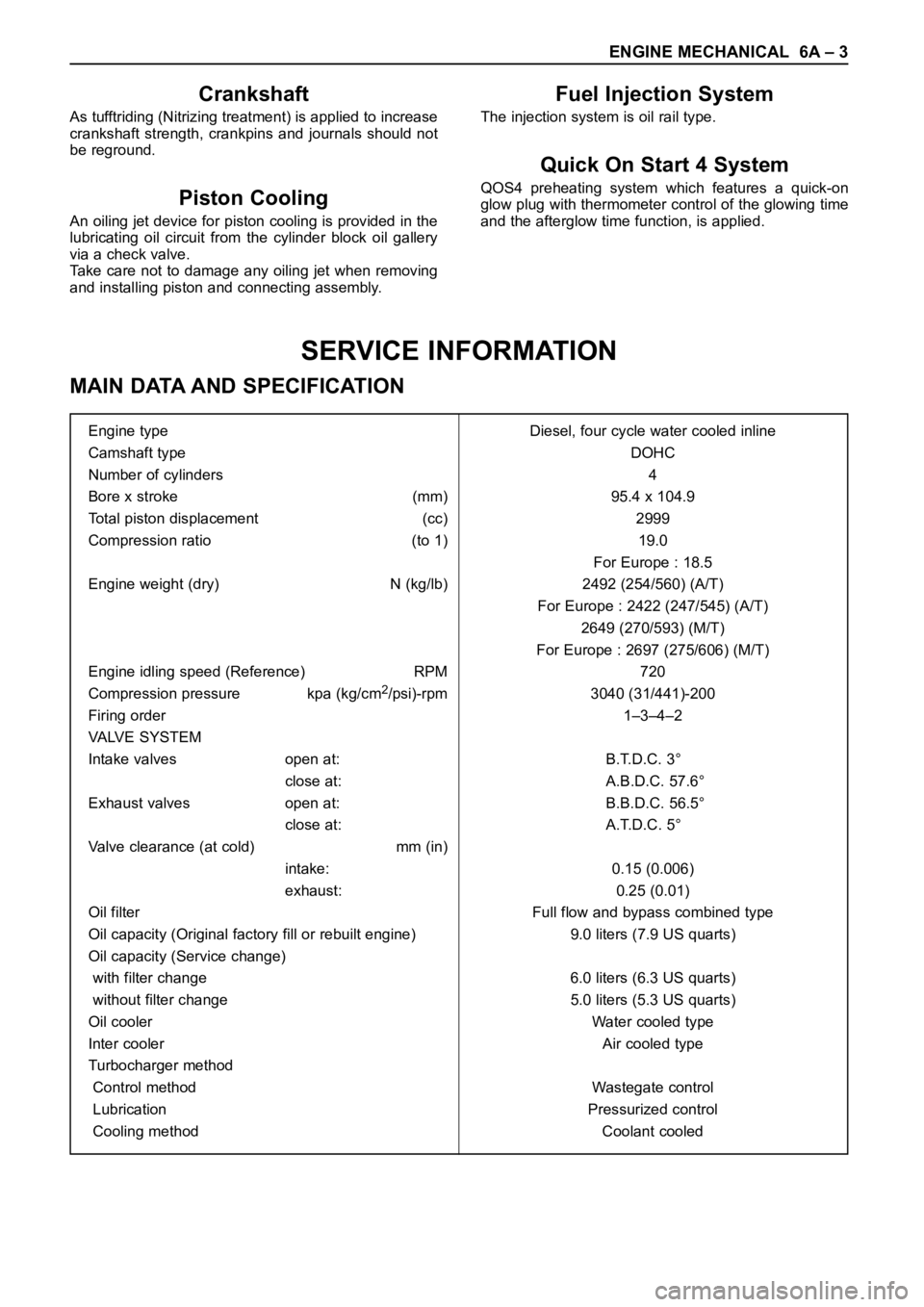

SERVICE INFORMATION

MAIN DATA AND SPECIFICATION

Engine type Diesel, four cycle water cooled inline

Camshaft type DOHC

Number of cylinders 4

Bore x stroke (mm) 95.4 x 104.9

Total piston displacement (cc) 2999

Compression ratio (to 1) 19.0

For Europe : 18.5

Engine weight (dry) N (kg/lb) 2492 (254/560) (A/T)

For Europe : 2422 (247/545) (A/T)

2649 (270/593) (M/T)

For Europe : 2697 (275/606) (M/T)

Engine idling speed (Reference) RPM 720

Compression pressure kpa (kg/cm

2/psi)-rpm 3040 (31/441)-200

Firing order 1–3–4–2

VALVE SYSTEM

Intake valves open at: B.T.D.C. 3°

close at: A.B.D.C. 57.6°

Exhaust valves open at: B.B.D.C. 56.5°

close at: A.T.D.C. 5°

Valve clearance (at cold) mm (in)

intake: 0.15 (0.006)

exhaust: 0.25 (0.01)

Oil filter Full flow and bypass combined type

Oil capacity (Original factory fill or rebuilt engine) 9.0 liters (7.9 US quarts)

Oil capacity (Service change)

with filter change 6.0 liters (6.3 US quarts)

without filter change 5.0 liters (5.3 US quarts)

Oil cooler Water cooled type

Inter cooler Air cooled type

Turbocharger method

Control method Wastegate control

Lubrication Pressurized control

Cooling method Coolant cooled

Crankshaft

As tufftriding (Nitrizing treatment) is applied to increase

crankshaft strength, crankpins and journals should not

be reground.

Piston Cooling

An oiling jet device for piston cooling is provided in the

lubricating oil circuit from the cylinder block oil gallery

via a check valve.

Take care not to damage any oiling jet when removing

and installing piston and connecting assembly.

Fuel Injection System

The injection system is oil rail type.

Quick On Start 4 System

QOS4 preheating system which features a quick-on

glow plug with thermometer control of the glowing time

and the afterglow time function, is applied.

Page 1743 of 6000

6A – 10 ENGINE MECHANICAL

8. Check the engine oil level and replenish to the

specified level if required.

9. Start the engine and check for oil leakage from the

main oil filter.

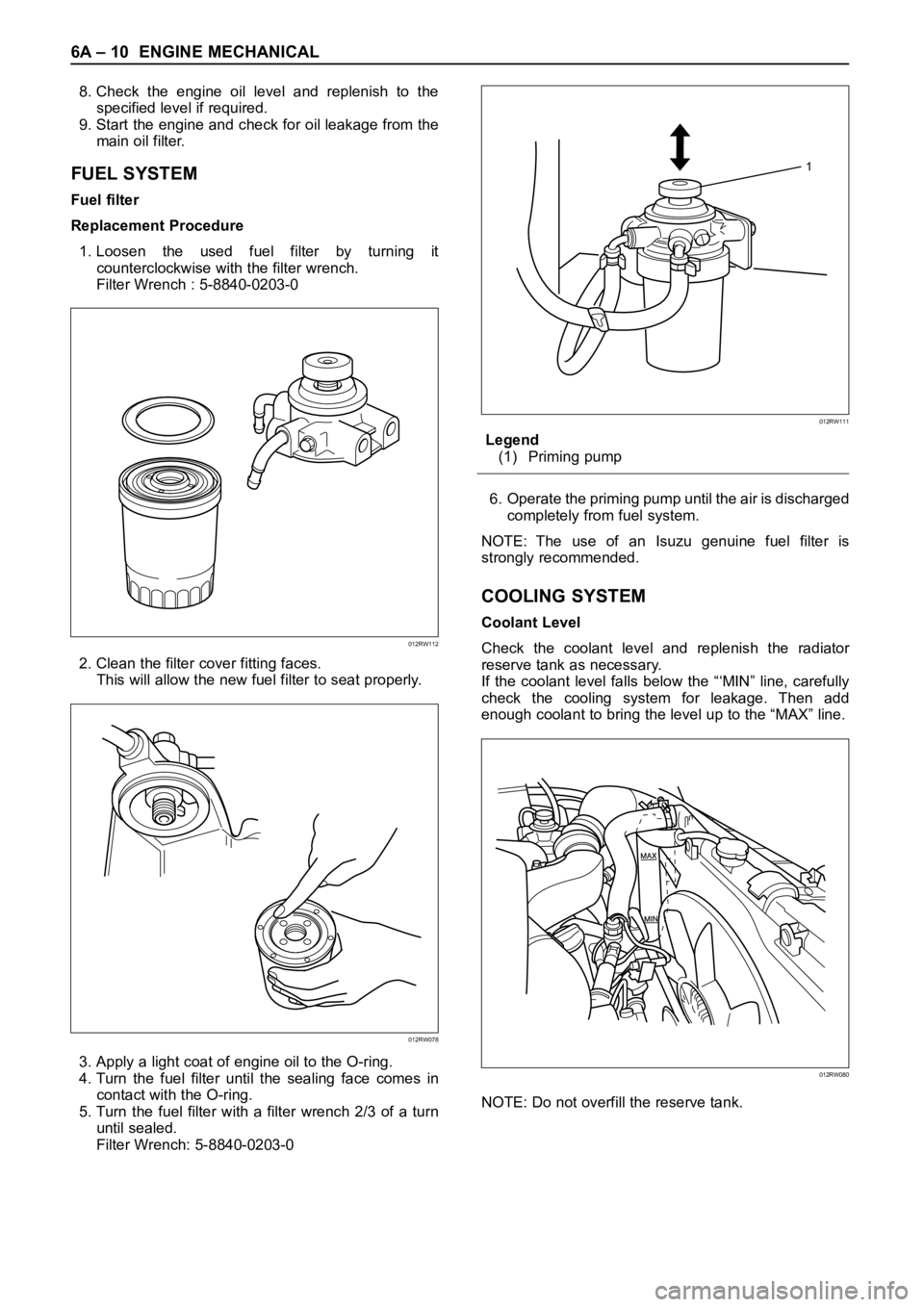

FUEL SYSTEM

Fuel filter

Replacement Procedure

1. Loosen the used fuel filter by turning it

counterclockwise with the filter wrench.

Filter Wrench : 5-8840-0203-0

2. Clean the filter cover fitting faces.

This will allow the new fuel filter to seat properly.

3. Apply a light coat of engine oil to the O-ring.

4. Turn the fuel filter until the sealing face comes in

contact with the O-ring.

5. Turn the fuel filter with a filter wrench 2/3 of a turn

until sealed.

Filter Wrench: 5-8840-0203-0Legend

(1) Priming pump

6. Operate the priming pump until the air is discharged

completely from fuel system.

NOTE: The use of an Isuzu genuine fuel filter is

strongly recommended.

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator

reserve tank as necessary.

If the coolant level falls below the “‘MIN” line, carefully

check the cooling system for leakage. Then add

enough coolant to bring the level up to the “MAX” line.

NOTE: Do not overfill the reserve tank.

012RW112

012RW078

1

012RW111

012RW080

Page 1752 of 6000

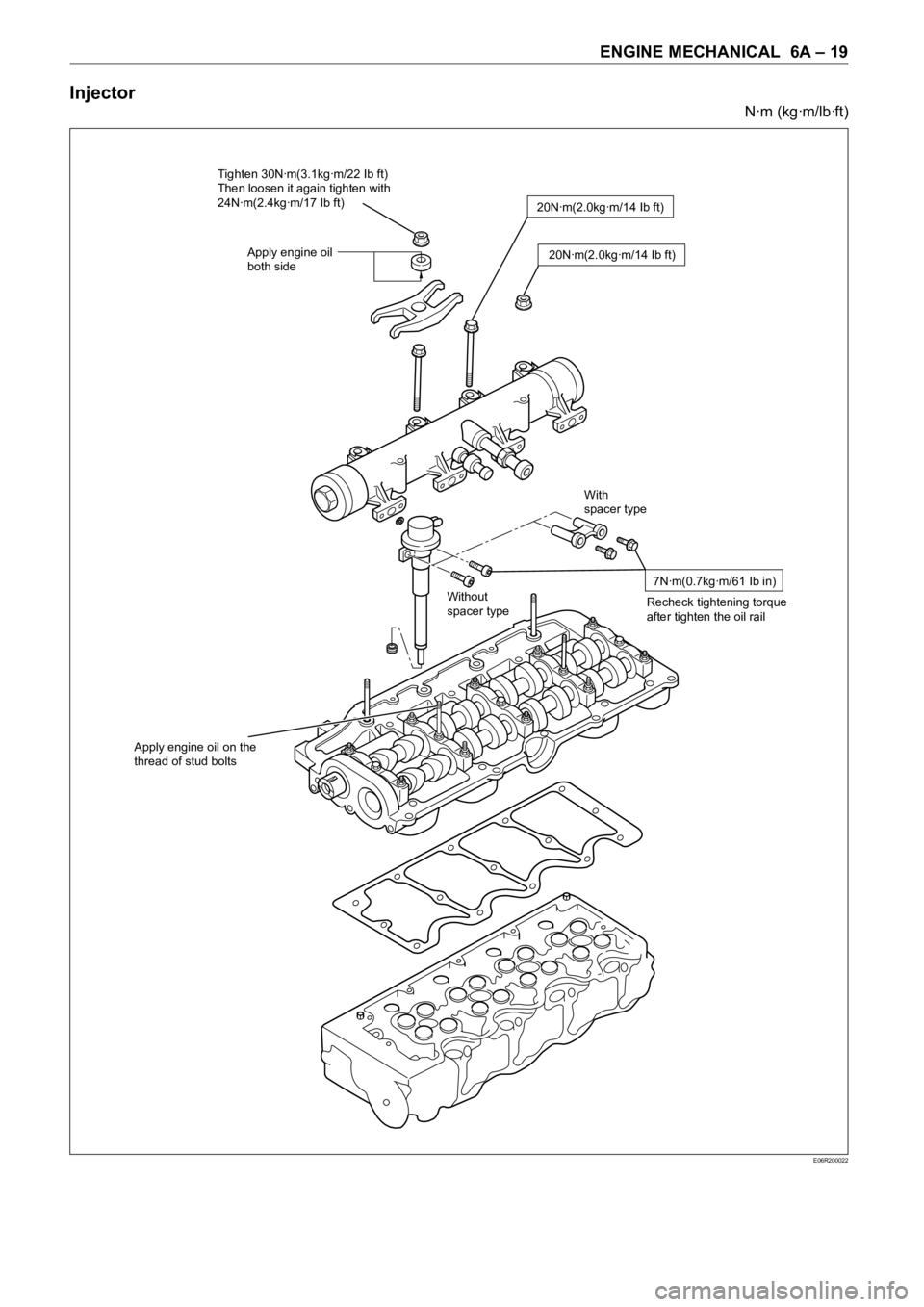

ENGINE MECHANICAL 6A – 19

Injector

Nꞏm (kgꞏm/lbꞏft)

E06R200022

With

spacer type

Without

spacer type

20Nꞏm(2.0kgꞏm/14 Ib ft)

7Nꞏm(0.7kgꞏm/61 Ib in)

Recheck tightening torque

after tighten the oil rail

Apply engine oil on the

thread of stud bolts

20Nꞏm(2.0kgꞏm/14 Ib ft)

Tighten 30Nꞏm(3.1kgꞏm/22 Ib ft)

Then loosen it again tighten with

24Nꞏm(2.4kgꞏm/17 Ib ft)

Apply engine oil

both side

Page 1796 of 6000

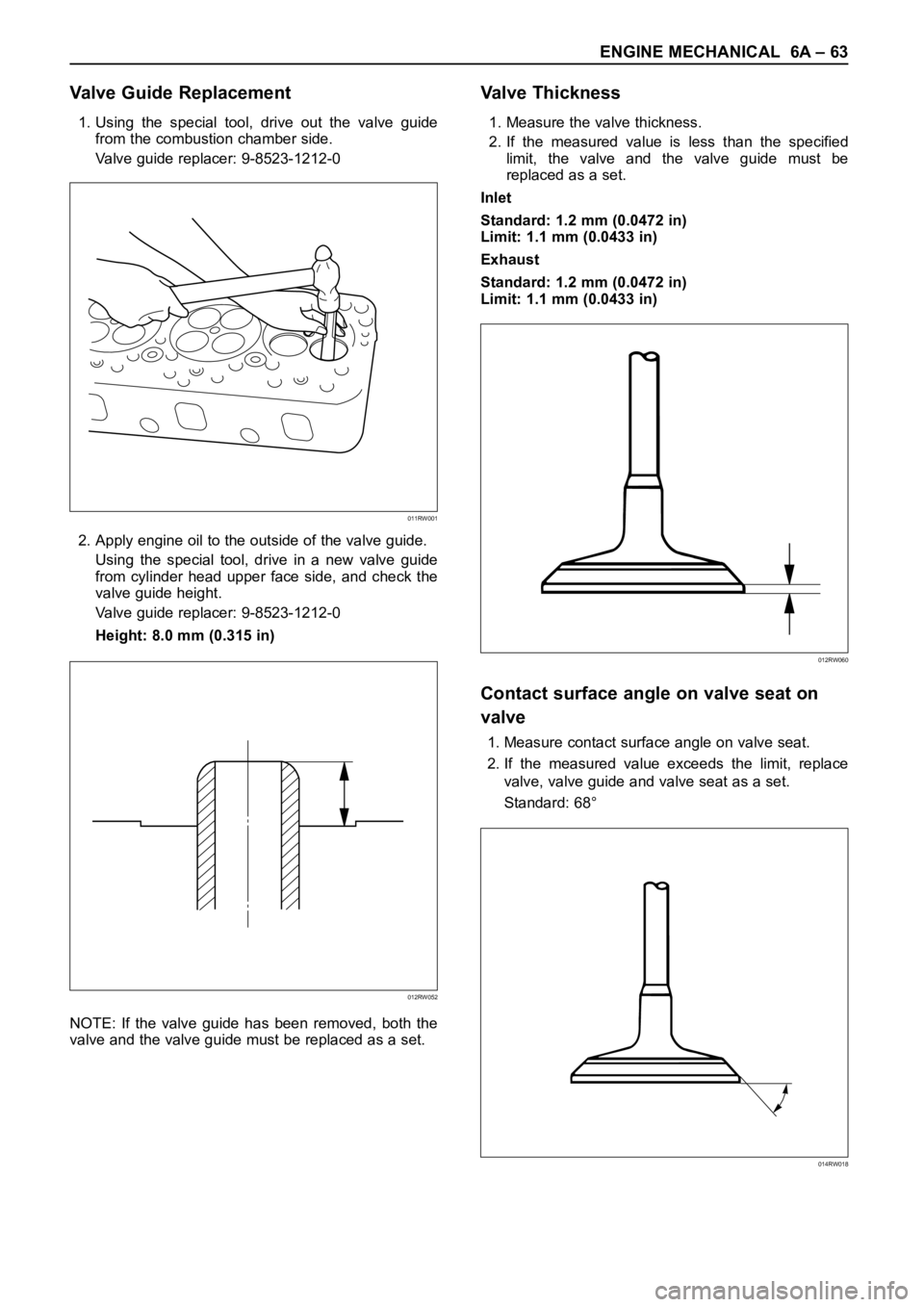

ENGINE MECHANICAL 6A – 63

Valve Guide Replacement

1. Using the special tool, drive out the valve guide

from the combustion chamber side.

Valve guide replacer: 9-8523-1212-0

2. Apply engine oil to the outside of the valve guide.

Using the special tool, drive in a new valve guide

from cylinder head upper face side, and check the

valve guide height.

Valve guide replacer: 9-8523-1212-0

Height: 8.0 mm (0.315 in)

NOTE: If the valve guide has been removed, both the

valve and the valve guide must be replaced as a set.

Va l v e T h i c k n e s s

1. Measure the valve thickness.

2. If the measured value is less than the specified

limit, the valve and the valve guide must be

replaced as a set.

Inlet

Standard: 1.2 mm (0.0472 in)

Limit: 1.1 mm (0.0433 in)

Exhaust

Standard: 1.2 mm (0.0472 in)

Limit: 1.1 mm (0.0433 in)

Contact surface angle on valve seat on

valve

1. Measure contact surface angle on valve seat.

2. If the measured value exceeds the limit, replace

valve, valve guide and valve seat as a set.

Standard: 68°

011RW001

012RW052

012RW060

014RW018

Page 1800 of 6000

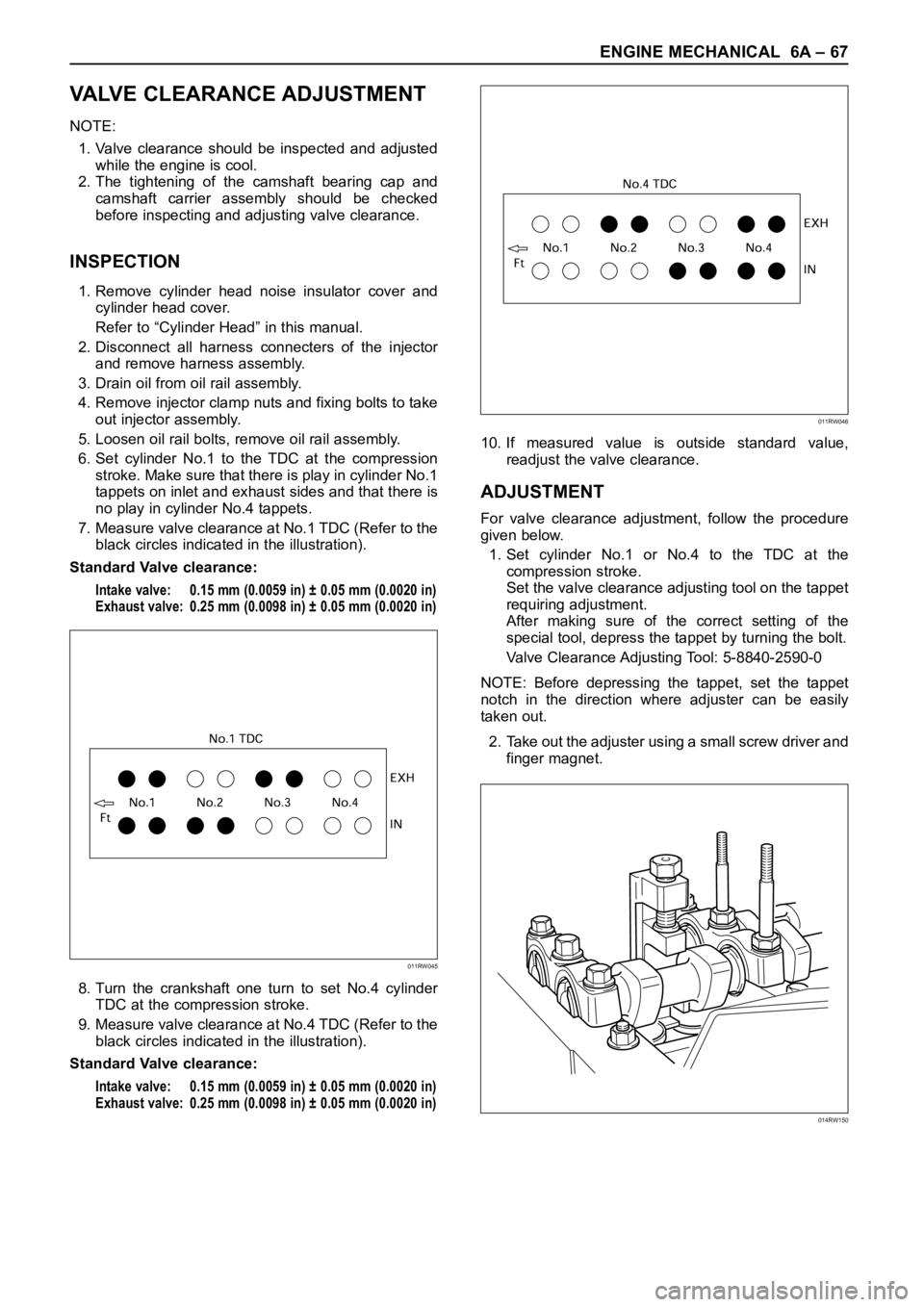

ENGINE MECHANICAL 6A – 67

VALVE CLEARANCE ADJUSTMENT

NOTE:

1. Valve clearance should be inspected and adjusted

while the engine is cool.

2. The tightening of the camshaft bearing cap and

camshaft carrier assembly should be checked

before inspecting and adjusting valve clearance.

INSPECTION

1. Remove cylinder head noise insulator cover and

cylinder head cover.

Refer to “Cylinder Head” in this manual.

2. Disconnect all harness connecters of the injector

and remove harness assembly.

3. Drain oil from oil rail assembly.

4. Remove injector clamp nuts and fixing bolts to take

out injector assembly.

5. Loosen oil rail bolts, remove oil rail assembly.

6. Set cylinder No.1 to the TDC at the compression

stroke. Make sure that there is play in cylinder No.1

tappets on inlet and exhaust sides and that there is

no play in cylinder No.4 tappets.

7. Measure valve clearance at No.1 TDC (Refer to the

black circles indicated in the illustration).

Standard Valve clearance:

Intake valve: 0.15 mm (0.0059 in) ± 0.05 mm (0.0020 in)

Exhaust valve: 0.25 mm (0.0098 in) ± 0.05 mm (0.0020 in)

8. Turn the crankshaft one turn to set No.4 cylinder

TDC at the compression stroke.

9. Measure valve clearance at No.4 TDC (Refer to the

black circles indicated in the illustration).

Standard Valve clearance:

Intake valve: 0.15 mm (0.0059 in) ± 0.05 mm (0.0020 in)

Exhaust valve: 0.25 mm (0.0098 in) ± 0.05 mm (0.0020 in)

10. If measured value is outside standard value,

readjust the valve clearance.

ADJUSTMENT

For valve clearance adjustment, follow the procedure

given below.

1. Set cylinder No.1 or No.4 to the TDC at the

compression stroke.

Set the valve clearance adjusting tool on the tappet

requiring adjustment.

After making sure of the correct setting of the

special tool, depress the tappet by turning the bolt.

Valve Clearance Adjusting Tool: 5-8840-2590-0

NOTE: Before depressing the tappet, set the tappet

notch in the direction where adjuster can be easily

taken out.

2. Take out the adjuster using a small screw driver and

finger magnet.

011RW045

011RW046

014RW150

Page 1808 of 6000

ENGINE MECHANICAL 6A – 75

DISASSEMBLY

1. Cylinder Head

1) Refer to “Cylinder head” in this manual.

2. Crankshaft Front Oil Seal

1) Use a plastic hammer and a screwdriver to tap

around the oil seal to free it from the gear case

cover.

Take care not to damage the oil seal fitting

surfaces.

3. Crankshaft Timing Gear

4. Timing Gear Case

5. Flywheel

6. Cylinder Block Rear Plate

7. Crankshaft Rear Oil Seal

1) Use special tool to remove the crankshaft rear

oil seal.

Oil Seal Remover: 5-8840-2360-0

8. Crank Case

9. Piston Cooling Oil Pipe

10. Piston and Connecting Rod Assembly

11. Main Bearing Cap Assembly

12. Crankshaft

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

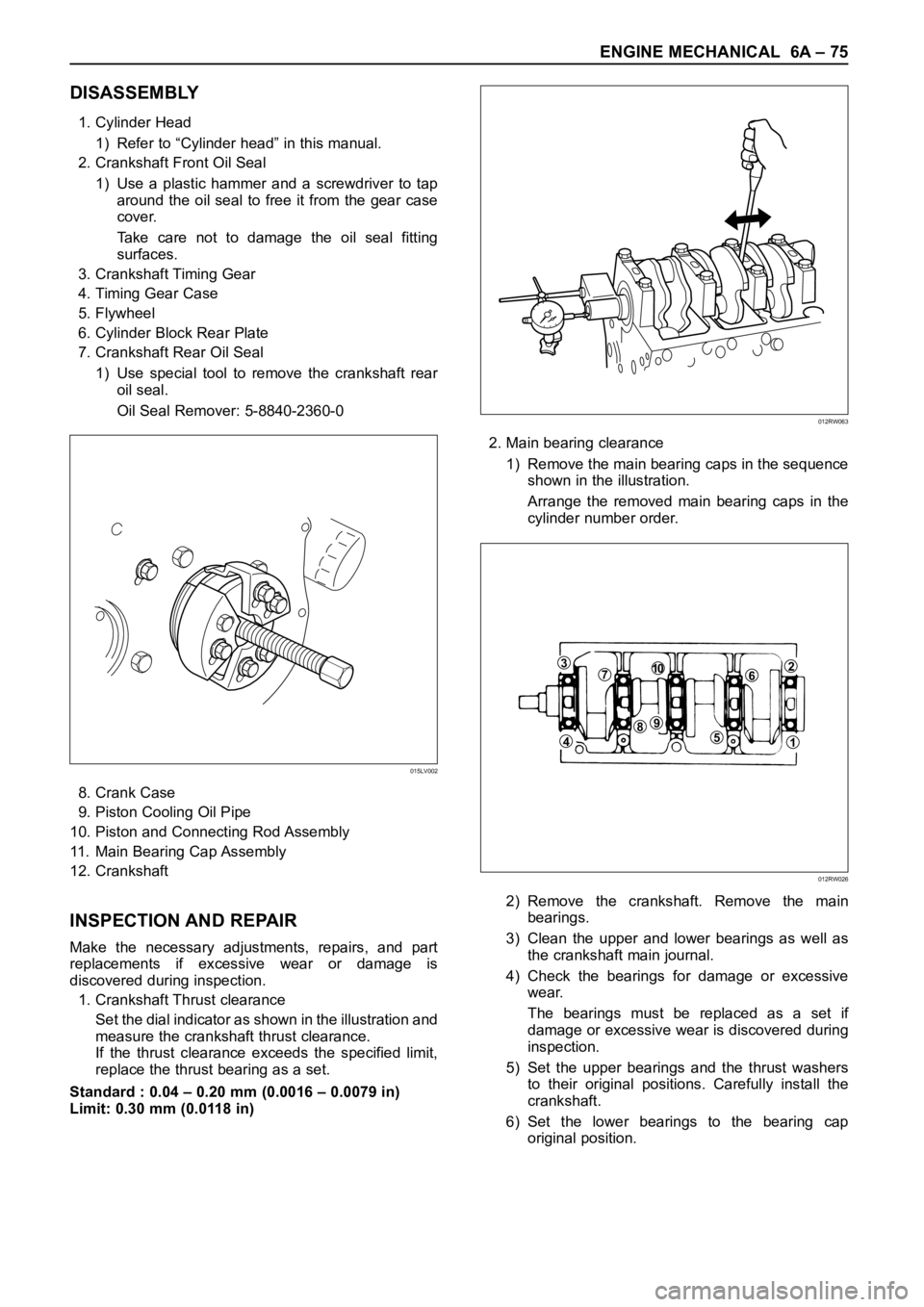

1. Crankshaft Thrust clearance

Set the dial indicator as shown in the illustration and

measure the crankshaft thrust clearance.

If the thrust clearance exceeds the specified limit,

replace the thrust bearing as a set.

Standard : 0.04 – 0.20 mm (0.0016 – 0.0079 in)

Limit: 0.30 mm (0.0118 in)2. Main bearing clearance

1) Remove the main bearing caps in the sequence

shown in the illustration.

Arrange the removed main bearing caps in the

cylinder number order.

2) Remove the crankshaft. Remove the main

bearings.

3) Clean the upper and lower bearings as well as

the crankshaft main journal.

4) Check the bearings for damage or excessive

wear.

The bearings must be replaced as a set if

damage or excessive wear is discovered during

inspection.

5) Set the upper bearings and the thrust washers

to their original positions. Carefully install the

crankshaft.

6) Set the lower bearings to the bearing cap

original position.

015LV002

012RW063

371062

51

984

012RW026

Page 1812 of 6000

ENGINE MECHANICAL 6A – 79

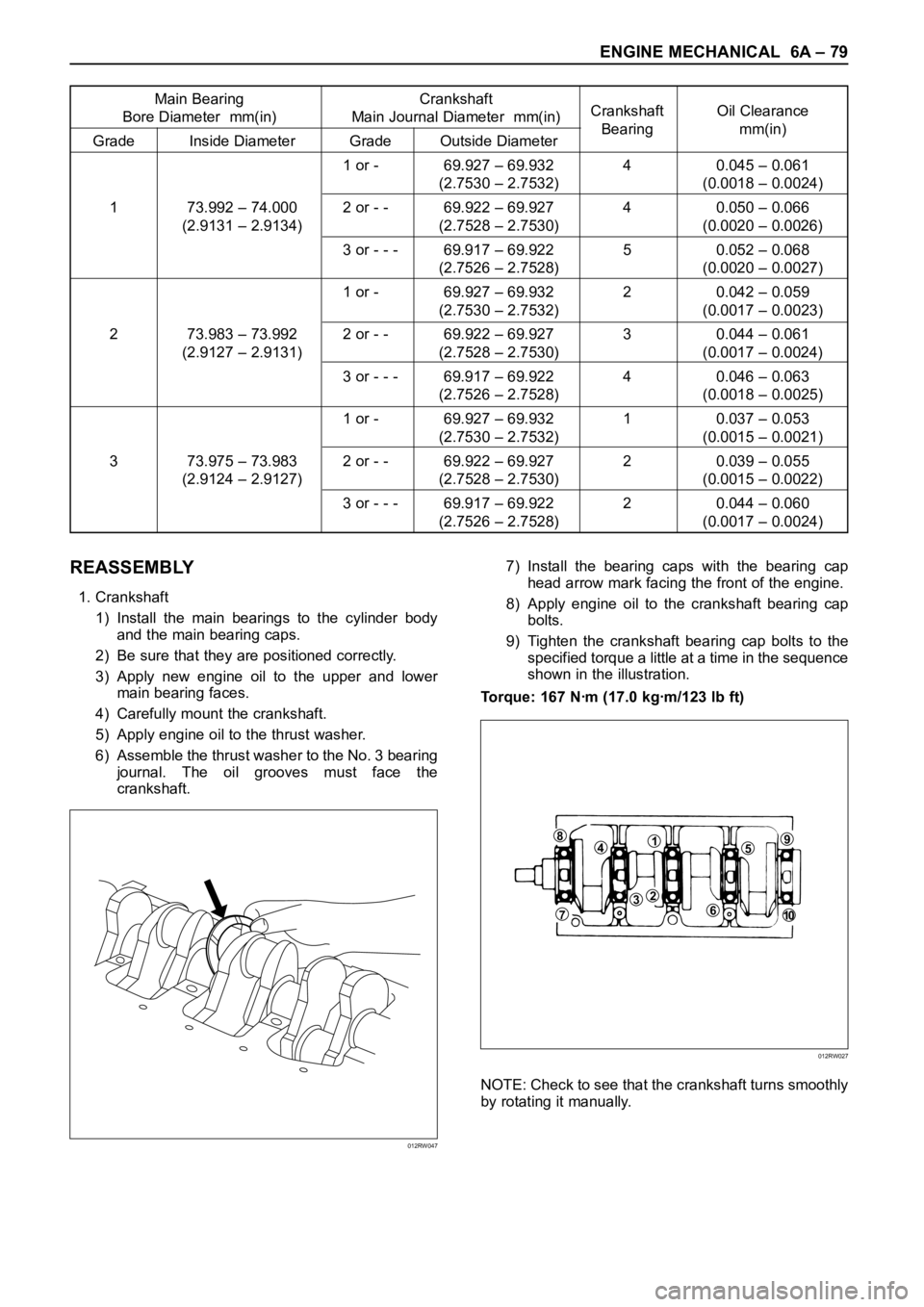

Main Bearing Crankshaft

Bore Diameter mm(in) Main Journal Diameter mm(in)Crankshaft Oil Clearance

Grade Inside Diameter Grade Outside DiameterBearing mm(in)

1 or - 69.927 – 69.932 4 0.045 – 0.061

(2.7530 – 2.7532) (0.0018 – 0.0024)

1 73.992 – 74.000 2 or - - 69.922 – 69.927 4 0.050 – 0.066

(2.9131 – 2.9134) (2.7528 – 2.7530) (0.0020 – 0.0026)

3 or - - - 69.917 – 69.922 5 0.052 – 0.068

(2.7526 – 2.7528) (0.0020 – 0.0027)

1 or - 69.927 – 69.932 2 0.042 – 0.059

(2.7530 – 2.7532) (0.0017 – 0.0023)

2 73.983 – 73.992 2 or - - 69.922 – 69.927 3 0.044 – 0.061

(2.9127 – 2.9131) (2.7528 – 2.7530) (0.0017 – 0.0024)

3 or - - - 69.917 – 69.922 4 0.046 – 0.063

(2.7526 – 2.7528) (0.0018 – 0.0025)

1 or - 69.927 – 69.932 1 0.037 – 0.053

(2.7530 – 2.7532) (0.0015 – 0.0021)

3 73.975 – 73.983 2 or - - 69.922 – 69.927 2 0.039 – 0.055

(2.9124 – 2.9127) (2.7528 – 2.7530) (0.0015 – 0.0022)

3 or - - - 69.917 – 69.922 2 0.044 – 0.060

(2.7526 – 2.7528) (0.0017 – 0.0024)

REASSEMBLY

1. Crankshaft

1) Install the main bearings to the cylinder body

and the main bearing caps.

2) Be sure that they are positioned correctly.

3) Apply new engine oil to the upper and lower

main bearing faces.

4) Carefully mount the crankshaft.

5) Apply engine oil to the thrust washer.

6) Assemble the thrust washer to the No. 3 bearing

journal. The oil grooves must face the

crankshaft.7) Install the bearing caps with the bearing cap

head arrow mark facing the front of the engine.

8) Apply engine oil to the crankshaft bearing cap

bolts.

9) Tighten the crankshaft bearing cap bolts to the

specified torque a little at a time in the sequence

shown in the illustration.

Torque: 167 Nꞏm (17.0 kgꞏm/123 lb ft)

NOTE: Check to see that the crankshaft turns smoothly

by rotating it manually.

012RW047

84159

610

237

012RW027