check oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1391 of 6000

6E–274

ENGINE DRIVEABILITY AND EMISSIONS

Rough, Unstable, or Incorrect Idle, Stalling Symptom

StepNo Ye s Va l u e ( s ) Action

171. Check ignition coils for cracks or carbon tracking.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 18

18Using Tech 2, monitor the throttle position (TP) angle

with the engine idling.

Is the TP angle at the specified value and steady?

0%Go to Step 19

Refer to DTC

P0123

for

further

diagnosis

191. Check the positive crankcase ventilation (PCV)

valve for proper operation. Refer to

Crankcase

Ventilation System

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 20

201. Check the transmission range switch circuit. Use

Tech 2 and be sure Tech 2 indicates that the vehicle

is in drive with the gear selector in drive or overdrive.

2. If a problem is found, diagnose and repair the

transmission range switch as necessary (refer to

4L30-E Automatic Transmission Diagnosis).

Was a problem found?

—Verify repairGo to Step 21

211. Check for the following engine mechanical items.

Refer to

Engine Mechanical for diagnosis

procedures:

EGR valve mounted backward. Compare with

a known-good vehicle.

Low compression

Sticking or leaking valves

Worn camshaft lobe(s)

Camshaft drive belt slipped or stripped

Incorrect valve timing

Worn rocker arms

Broken valve springs

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 22

221. Check for faulty motor mounts. Refer to Engine

Mechanical

for inspection of mounts.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 23

231. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records buffer

All electrical connections within a suspected

circuit and/or system.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance

Page 1392 of 6000

6E–275 ENGINE DRIVEABILITY AND EMISSIONS

Poor Fuel Economy Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Fuel economy, as measured by an actual road test, is

noticeably lower than expected. Also, economy is

noticeably lower than it was on this vehicle at one time,

as previously shown by an actual road test.

(Non-standard tires will cause odometer readings to be

incorrect, and that may cause fuel economy to appear

poor when it is actually normal.)

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

4Check owner’s driving habits.

Is the A/C “ON” full time (defroster mode “ON”)?

Are tires at the correct pressure?

Are excessively heavy loads being carried?

Is acceleration too much, too often?

Was a problem found?

—Go to Step 5Go to Step 6

5Review the items in Step 4 with the customer and

advise as necessary.

Is the action complete?

—System OK—

61. Visually/physically check: Vacuum hoses for splits,

kinks, and improper connections and routing as

shown on the “Vehicle Emission Control

Information” label.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Remove and check the air filter element for dirt or for

restrictions. Refer to

Air Intake System.

2. Replace the air filter element if necessary.

Was a repair required?

—Verify repairGo to Step 8

81. Remove spark plugs and check for wet plugs,

cracks, wear, improper gap, burned electrodes, or

heavy deposits. Refer to

Spark Plug Replacement.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check for low engine coolant level. Refer to Engine

Cooling

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

Page 1394 of 6000

6E–277 ENGINE DRIVEABILITY AND EMISSIONS

Excessive Exhaust Emissions or Odors Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Vehicle fails an emission test. Vehicle has excessive

“rotten egg” smell. (Excessive odors do not necessarily

indicate excessive emissions.)

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Go to Step 12Go to Step 3

3Was a thorough visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check for vacuum leaks. Check vacuum lines,

intake manifold, throttle body, etc.

2. If a problem is found, repair as necessary.

Were any vacuum leaks located?

—Go to Step 12Go to Step 5

51. Check the fuel cap for proper installation.

2. Secure the fuel cap if necessary.

Was the fuel cap installed properly?

—Go to Step 6Go to Step 12

61. Check the fuel pressure. Perform the procedure in

Fuel System Pressure Test.

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 7

71. Check for a faulty, plugged, or incorrectly installed

crankcase ventilation valve; also check the

crankcase ventilation system for plugging.

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 8

81. Check the injector connections.

2. If any of the injectors are connected to an incorrect

cylinder, correct as necessary.

Was a problem found?

—Go to Step 12Go to Step 9

91. Perform the “Injector Coil/Balance Test” in Fuel

Metering System

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 10

101. Refer to Engine Cooling for cooling system

diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Go to Step 12Go to Step 11

111. Remove excessive carbon buildup with a top engine

cleaner. Refer to the instructions on the top engine

cleaner can.

2. Perform the exhaust emission test.

Does the vehicle pass the test?

—System OKGo to Step 13

12Perform the exhaust emission test.

Does the vehicle pass the test?

—System OKGo to Step 13

Page 1397 of 6000

6E–280

ENGINE DRIVEABILITY AND EMISSIONS

Backfire Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Fuel ignites in the intake manifold, or in the exhaust

system, making a loud popping noise.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

41. Check for proper ignition voltage coil output with

spark tester 5-8840-0383-0. Refer to

Electric

Ignition System

for procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Remove spark plugs and check for wet plugs,

cracks, wear, improper gap, burned electrodes, or

heavy deposits. Refer to

Electronic Ignition

System

.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs. Refer to

DTC P0172 to determine the

cause of a rich condition or

Engine Mechanical for an oil

fouling condition.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

61. Visually/physically inspect the ignition coils for

cracks.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Check for an intermittent ignition system

malfunction:

Intermittent CKP 58X signal.

Intermittent ignition feed circuit or sensor

ground circuit to the crankshaft position

sensor.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Check the fuel pressure. Refer to Fuel System

Pressure Test

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

Page 1400 of 6000

6E–283 ENGINE DRIVEABILITY AND EMISSIONS

Cuts Out, Misses Symptom

StepNo Ye s Va l u e ( s ) Action

101. Visually/physically inspect for the following

conditions:

Restricted air intake system. Check for a

possible collapsed air intake duct, restricted

air filter element, or foreign objects blocking

the air intake system.

Throttle body. Check for objects blocking the

IAC passage or throttle bore, excessive

deposits in the IAC passage and on the IAC

pintle, and excessive deposits in the throttle

bore and on the throttle plate.

Large vacuum leak. Check for a condition that

causes a large vacuum leak, such as an

incorrectly installed or faulty PCV valve or

brake booster hose disconnected .

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

11Check the injector connections. If any of the injectors

are connected to an incorrect cylinder, correct as

necessary.

Was a problem found?

—Verify repairGo to Step 12

121. Perform the “Injector Coil/Balance Test” in Fuel

Metering System

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 13

131. Check for fuel in the pressure regulator vacuum

hose.

2. If fuel is present, replace the fuel pressure regulator

assembly. Refer to

Fuel Metering System.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 14

141. Check for proper ignition voltage output with spark

tester J 26792 (ST-125). Refer to

Electronic Ignition

System

for the procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 15

151. Remove spark plugs. Check for wet plugs, cracks,

wear, improper gap, burned electrodes, or heavy

deposits. Refer to

Electronic Ignition System.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 16

161. Check for a loose ignition coil ground.

Refer to

Electronic Ignition System.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 17

Page 1401 of 6000

6E–284

ENGINE DRIVEABILITY AND EMISSIONS

Cuts Out, Misses Symptom

StepNo Ye s Va l u e ( s ) Action

171. Check ignition coils for cracks or carbon tracking.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 18

18Using Tech 2, monitor the TP angle with the engine

idling.

Is the TP angle at the specified value and steady?

0%Go to Step 19

Refer to DTC

P0123

for

further

diagnosis

191. Check the PCV valve for proper operation. Refer to

Crankcase Ventilation System.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 20

201. Check the transmission range switch circuit. Use

Tech 2 and be sure Tech 2 indicates that the vehicle

is in drive with the gear selector in drive or overdrive.

2. If a problem is found, diagnose and repair the

transmission range switch as necessary (refer to

4L30-E Automatic Transmission Diagnosis).

Was a problem found?

—Verify repairGo to Step 21

211. Check the following engine mechanical items.

Refer to

Engine Mechanical for diagnosis

procedures:

Low compression

Sticking or leaking valves

Worn camshaft lobe(s)

Camshaft drive belt slipped or stripped

Incorrect valve timing

Worn rocker arms

Broken valve springs

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 22

221. Check for faulty motor mounts. Refer to Engine

Mechanical

for inspection of mounts.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 23

231. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records butter

All electrical connections within a suspected

circuit and/or system

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance

Page 1403 of 6000

6E–286

ENGINE DRIVEABILITY AND EMISSIONS

Hesitation, Sag, Stumble Symptom

StepNo Ye s Va l u e ( s ) Action

101. Check for proper ignition voltage output with spark

tester J 26792 (ST-125). Refer to

Electronic Ignition

System

for the procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

111. Check for a loose ignition coil ground.

Refer to

Electronic Ignition System.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 12

121. Check the ignition coils for cracks or carbon

tracking.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 13

131. Remove spark plugs and check for wet plugs,

cracks, wear, improper gap, burned electrodes, or

heavy deposits. Refer to

Electronic Ignition

System

.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 14

141. Check the PCM grounds for clearness, tightness

and proper routing. Refer to the PCM wiring

diagrams in Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 15

151. Check the MAF sensor connections.

2. If a problem is found, replace the faulty terminals as

necessary. Refer to

Electrical Diagnosis for wiring

repair procedures.

Was a problem found?

—Verify repairGo to Step 16

161. Visually/physically check vacuum hoses for splits,

kinks, and proper connections and routing as

shown on the “Vehicle Emission Control

Information” label.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 17

Page 1420 of 6000

6E–303 ENGINE DRIVEABILITY AND EMISSIONS

4. Check the transfer case oil level. Add fluid if

necessary.

5. Connect the negative battery cable.

Air Cleaner/Air Filter

Removal Procedure

1. Loosen the clamp between the air cleaner lid and the

mass air flow sensor.

2. Release the four latches securing the lid to the air

cleaner housing.

3. Remove the air cleaner lid.

TS23973

4. Remove the air filter element.

TS23794

5. Remove the retaining bolts and the air cleaner

housing from the vehicle.

130RT002

Installation Procedure

1. Install the air cleaner housing in the vehicle with the

retaining bolts.

130RT002

Page 1431 of 6000

6E–314

ENGINE DRIVEABILITY AND EMISSIONS

3. Connect the wiring connector to the fuel gauge unit.

TS23771

4. Fill the fuel tank with fuel.

Tighten the fuel filler cap.

Check for leaks at the fuel gauge unit gasket.

5. Connect the negative battery cable.

Fuel Injectors

Removal Procedure

NOTE: If the fuel injectors are leaking, the engine oil may

be contaminated with fuel. Check the oil for signs of

contamination and change the oil and the filter if

necessary.

NOTE: Use care in removing the fuel injectors in order to

prevent damage to the fuel injector electrical connector

pins or the fuel injector nozzles. The fuel injector is an

electrical component and should not be immersed in any

type of cleaner as this may damage the fuel injector.

IMPORTANT:Fuel injectors are serviced as a complete

assembly only.

1. Disconnect the negative battery cable.

2. Remove the upper intake manifold. Refer to

Common Chamber in Engine Mechanical..

3. Remove the fuel rail. Refer to

Fuel Rail.

014RW164

4. Remove the injector retainer clip.

055RW009

5. Remove the fuel injector assembly.

6. Remove the O-ring from the fuel injector.

7. Remove the O-ring backup from the fuel injector .

Inspection Procedure

1. Inspect the O-rings for cracks or leaks.

2. Replace worn or damaged O-rings.

3. Lubricate the new O-rings with engine oil before

installation.

Page 1442 of 6000

6E–325 ENGINE DRIVEABILITY AND EMISSIONS

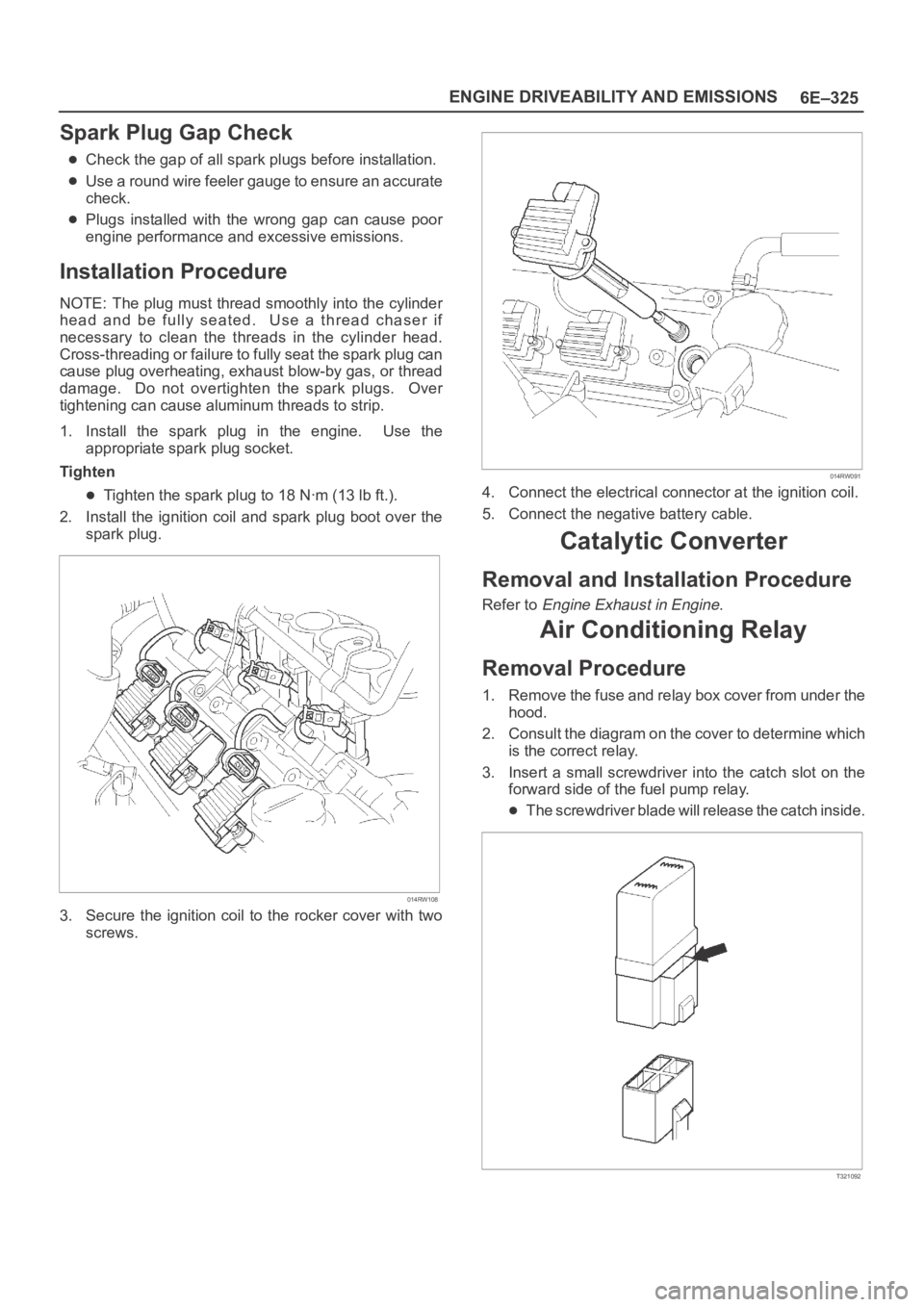

Spark Plug Gap Check

Check the gap of all spark plugs before installation.

Use a round wire feeler gauge to ensure an accurate

check.

Plugs installed with the wrong gap can cause poor

engine performance and excessive emissions.

Installation Procedure

NOTE: The plug must thread smoothly into the cylinder

head and be fully seated. Use a thread chaser if

necessary to clean the threads in the cylinder head.

Cross-threading or failure to fully seat the spark plug can

cause plug overheating, exhaust blow-by gas, or thread

damage. Do not overtighten the spark plugs. Over

tightening can cause aluminum threads to strip.

1. Install the spark plug in the engine. Use the

appropriate spark plug socket.

Tighten

Tighten the spark plug to 18 Nꞏm (13 lb ft.).

2. Install the ignition coil and spark plug boot over the

spark plug.

014RW108

3. Secure the ignition coil to the rocker cover with two

screws.

014RW091

4. Connect the electrical connector at the ignition coil.

5. Connect the negative battery cable.

Catalytic Converter

Removal and Installation Procedure

Refer to Engine Exhaust in Engine.

Air Conditioning Relay

Removal Procedure

1. Remove the fuse and relay box cover from under the

hood.

2. Consult the diagram on the cover to determine which

is the correct relay.

3. Insert a small screwdriver into the catch slot on the

forward side of the fuel pump relay.

The screwdriver blade will release the catch inside.

T321092