change time OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1156 of 6000

6E–39 ENGINE DRIVEABILITY AND EMISSIONS

The data displayed on the other Tech 2 will appear the

same, with some exceptions. Some Tech 2s will only be

able to display certain vehicle parameters as values that

are a coded representation of the true or actual value. For

more information on this system of coding, refer to

Decimal/Binary/Hexadecimal Conversions. On this

vehicle Tech 2 displays the actual values for vehicle

parameters. It will not be necessary to perform any

conversions from coded values to actual values.

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The diagnostic test has passed during the current

ignition cycle.

The fault identified by the diagnostic test is not

currently active.

W h e n a d i a g n o s t i c t e s t r e p o r t s a fail result, the diagnostic

executive records the following data:

The diagnostic test has been completed since the last

ignition cycle.

The fault identified by the diagnostic test is currently

active.

The fault has been active during this ignition cycle.

The operating conditions at the time of the failure.

Remember, a fuel trim DTC may be triggered by a list of

vehicle faults. Make use of all information available (other

DTCs stored, rich or lean condition, etc.) when

diagnosing a fuel trim fault.

Comprehensive Component Monitor

Diagnostic Operation

Input Components:

Input components are monitored for circuit continuity and

out-of-range values. This includes rationality checking.

Rationality checking refers to indicating a fault when the

signal from a sensor does not seem reasonable, i.e.

Throttle Position (TP) sensor that indicates high throttle

position at low engine loads or MAP voltage. Input

components may include, but are not limited to the

following sensors:

Vehicle Speed Sensor (VSS)

Crankshaft Position (CKP) sensor

Knock Sensor (KS)

Throttle Position (TP) sensor

Engine Coolant Temperature (ECT) sensor

Camshaft Position (CMP) sensor

Manifold Absolute Pressure (MAP) sensor

Mass Air Flow (MAF) sensorIn addition to the circuit continuity and rationality check,

the ECT sensor is monitored for its ability to achieve a

steady state temperature to enable closed loop fuel

control.

Output Components:

Output components are diagnosed for proper response to

control module commands. Components where

functional monitoring is not feasible will be monitored for

circuit continuity and out-of-range values if applicable.

Output components to be monitored include, but are not

limited to, the following circuits:

Idle Air Control (IAC) Motor

Electronic Transmission controls

A/C relays

Cooling fan relay

VSS output

MIL control

Cruise control inhibit

Refer to PCM and Sensors in General Descriptions.

Passive and Active Diagnostic Tests

A passive test is a diagnostic test which simply monitors a

vehicle system or component. Conversely, an active test,

actually takes some sort of action when performing

diagnostic functions, often in response to a failed passive

test. For example, the EGR diagnostic active test will

force the EGR valve open during closed throttle decel

and/or force the EGR valve closed during a steady state.

Either action should result in a change in manifold

pressure.

Intrusive Diagnostic Tests

This is any on-board test run by the Diagnostic

Management System which may have an effect on

vehicle performance or emission levels.

Warm-Up Cycle

A warm-up cycle means that engine at temperature must

reach a minimum of 70

C (160F) and rise at least 22C

(40

F) over the course of a trip.

Freeze Frame

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emissions-related fault is

stored in memory and when the MIL is commanded on.

These data can help to identify the cause of a fault. Refer

to

Storing And Erasing Freeze Fame Data for more

detailed information.

Failure Records

Failure Records data is an enhancement of the OBD

Freeze Frame feature. Failure Records store the same

vehicle information as does Freeze Frame, but it will store

that information for any fault which is stored in on-board

memory, while Freeze Frame stores information only for

emission-related faults that command the MIL on.

Page 1185 of 6000

6E–68

ENGINE DRIVEABILITY AND EMISSIONS

Exhaust Gas Recirculation (EGR)

Diagnosis (For except EXPORT and

SOUTH AFRICA)

Pintle position error diagnosis is covered by DTC P0402,

P0404, P1404, P0405, P0406. If EGR diagnostic trouble

codes P0402, P0404, P1404, P0405, P0406 are

encountered, refer to the DTC charts.

Engine Tech 2 Data Definitions and

Ranges

A/C CLUTCH – Tech 2 Displays ON or OFF –

Indicates whether the PCM has commanded the A/C

clutch ON. Used in A/C system diagnostic.

A/C REQUEST — Tech 2 Displays YES or NO —

Indicates the state of the A/C request input circuit from the

HVAC controls. The PCM uses the A/C request signal to

determine whether A/C compressor operation is being

requested.

AIR/FUEL RATIO — Tech 2 Range 0.0-25.5 —

Air/fuel ratio indicates the PCM commanded value. In

closed loop, the air/fuel ratio should normally be

displayed around “14.2-14.7.” A lower air/fuel ratio

indicates a richer commanded mixture, which may be

seen during power enrichment or TWC protection modes.

A higher air/fuel ratio indicates a leaner commanded

mixture. This can be seen during deceleration fuel mode.

BAROMETRIC PRESSURE — Tech 2 Range 10-105

kPa/0.00-5.00 Volts —

The barometric pressure reading is determined from the

MAP sensor signal monitored during key up and wide

open throttle (WOT) conditions. The barometric pressure

is used to compensate for altitude differences and is

normally displayed around “61-104” depending on

altitude and barometric pressure.

CHECK TRANS LAMP — AUTO TRANSMISSION —

Indicates the need to check for a DTC with the Tech 2

when the lamp is flashing 0.2 seconds ON and 0.2

seconds OFF.

CMP ACT. COUNTER – Cam Position Activity

DECEL FUEL MODE — Tech 2 Display ACTIVE or

INACTIVE —

“ACTIVE” displayed indicates that the PCM has detected

conditions appropriate to operate in deceleration fuel

mode. The PCM will command the deceleration fuel

mode when it detects a closed throttle position while the

vehicle is traveling over 20 mph. While in the deceleration

fuel delivered by entering open loop and decreasing the

injector pulse width.

DESIRED EGR POS. — Tech 2 Range 0%-100% —

Represents the EGR pintle position that the PCM is

commanding.

DESIRED IDLE — Tech 2 Range 0-3187 RPM —

The idle speed that the PCM is commanding. The PCM

will compensate for various engine loads based on engine

coolant temperature, to keep the engine at the desired

speed.ECT — (Engine Coolant Temperature) Tech 2

Range –40

C to 151C (–40F to 304F) —

The engine coolant temperature (ECT) is mounted in the

coolant stream and sends engine temperature

information to the PCM. The PCM applies 5 volts to the

ECT sensor circuit. The sensor is a thermistor which

changes internal resistance as temperature changes.

When the sensor is cold (high resistance), the PCM

monitors a high signal voltage and interprets that as a cold

engine. As the sensor warms (decreasing resistance),

the voltage signal will decrease and the PCM will interpret

the lower voltage as a warm engine.

EGR DUTY CYCLE — Tech 2 Range 0%-100% —

Represents the EGR valve driver PWM signal from the

PCM. A duty cycle of 0% indicates that no EGR flow is

being commanded; a 100% duty cycle indicates

maximum EGR flow commanded.

EGR FEEDBACK — Tech 2 Range 0.00-5.00 Volts —

Indicates the EGR pintle position sensor signal voltage

being monitored by the PCM. A low voltage indicates a

fully extended pintle (closed valve); a voltage near 5 volts

indicates a retracted pintle (open valve).

ENGINE LOAD — Tech 2 Range 0%-100% —

Engine load is calculated by the PCM from engine speed

and MAF sensor readings. Engine load should increase

with an increase in RPM or air flow.

ENGINE RUN TIME — Tech 2 Range

00:00:00-99:99:99 Hrs:Min:Sec —

Indicates the time elapsed since the engine was started.

If the engine is stopped, engine run time will be reset to

00:00:00.

ENGINE SPEED — Range 0-9999 RPM —

Engine speed is computed by the PCM from the 58X

reference input. It should remain close to desired idle

under various engine loads with engine idling.

FUEL PUMP — Tech 2 Displays ON or OFF —

Indicates the PCM commanded state of the fuel pump

relay driver circuit.

FUEL TRIM CELL — Tech 2 Range 0-21 —

The fuel trim cell is dependent upon engine speed and

MAF sensor readings. A plot of RPM vs. MAF is divided

into 22 cells. Fuel trim cell indicates which cell is currently

active.

FUEL TRIM LEARN — Tech 2 Displays NO or YES

—

When conditions are appropriate for enabling long term

fuel trim corrections, fuel trim learn will display “YES.”

This indicates that the long term fuel trim is responding to

the short term fuel trim. If the fuel trim learn displays

“NO,” then long term fuel trim will not respond to changes

in short term fuel trim.

HO2S BANK 1, SEN. 1 — Tech 2 Range 0-1132 mV

—

Represents the fuel control exhaust oxygen sensor

output voltage. Should fluctuate constantly within a range

between 10 mV (lean exhaust) and 1000 mV (rich

exhaust) while operating in closed loop.

Page 1186 of 6000

6E–69 ENGINE DRIVEABILITY AND EMISSIONS

HO2S BANK2, SEN. 1—Tech 2 Range 0-1132 mV—

Represents the fuel control exhaust oxygen sensor

output voltage. Should fluctuate constantly within a range

between 10mV (lean exhaust) and 1000 mV (rich

exhaust) while operating in closed loop.

HO2S BANK 1, SEN. 1—Tech 2 Displays NOT

READY or READY—

Indicates the status of the exhaust oxygen sensor. The

Tech 2 will indicate that the exhaust oxygen sensor is

ready when the PCM detects a fluctuating HO2S voltage

sufficient to allow closed loop operation. This will not

occur unless the exhaust oxygen sensor is warmed up.

HO2S BANK 2, SEN. 1 — Tech 2 Displays NOT

READY or READY —

Indicates the status of the exhaust oxygen sensor. The

Tech 2 will indicate that the exhaust oxygen sensor is

ready when the PCM detects a fluctuating HO2S voltage

sufficient to allow closed loop operation. This will not

occur unless the exhaust oxygen sensor is warmed up.

HO2S WARM UP TIME BANK 1, SEN. 1/BANK 2

SEN. 1 — Tech 2 Range 00:00:00-99:99:99

HRS:MIN:SEC —

Indicates warm-up time for each HO2S. The HO2S

warm-up time is used for the HO2S heater test. The PCM

will run the heater test only after a cold start (determined

by engine coolant and intake air temperature at the time

of start-up) and only once during an ignition cycle. When

the engine is started the PCM will monitor the HO2S

voltage. When the HO2S voltage indicates a sufficiently

active sensor, the PCM looks at how much time has

elapsed since start-up. If the PCM determines that too

much time was required for the HO2S to become active,

a DTC will set. If the engine was warm when started,

HO2S warm-up will the display “00:00:00”.

IAC POSITION — Tech 2 Range 0-255 Counts —

Displays the commanded position of the idle air control

pintle in counts. A larger number of counts means that

more air is being commanded through the idle air

passage. Idle air control should respond fairly quickly to

changes in engine load to maintain desired idle RPM.

IAT (INTAKE AIR TEMPERATURE) — Tech 2 Range

–40

C to 151C (–40F to 304F) —

The PCM converts the resistance of the intake air

temperature sensor to degrees. Intake air temperature

(IAT) is used by the PCM to adjust fuel delivery and spark

timing according to incoming air density.

IGNITION 1 — Tech 2 Range 0-25.5 Volts —

This represents the system voltage measured by the

PCM at its ignition feed.

INJ. PULSE BANK 1/INJ. PULSE BANK 2 — Tech 2

Range 0-1000 msec. —

Indicates the amount of time the PCM is commanding

each injector “ON” during each engine cycle. A longer

injector pulse width will cause more fuel to be delivered.

Injector pulse width should increase with increased

engine load.KS NOISE CHANNEL (Knock Sensor) —

Indicates the output from the KS noise channel. There is

always some electrical noise in an engine compartment

and to avoid mistaking this as engine knock, the output

from the knock sensor is compared to the output from the

noise channel. A knock condition is not set unless the

knock sensor output is greater than the noise channel

output.

LONG TERM FUEL TRIM BANK 1/BANK 2 —

The long term fuel trim is derived from the short term fuel

trim values and represents a long term correction of fuel

delivery for the bank in question. A value of 0% indicates

that fuel delivery requires no compensation to maintain

the PCM commanded air/fuel ratio. A negative value

significantly below 0% indicates that the fuel system is

rich and fuel delivery is being reduced (decreased injector

pulse width). A positive value significantly greater than

0% indicates that a lean condition exists and the PCM is

compensating by adding fuel (increased injector pulse

width). Because long term fuel trim tends to follow short

term fuel trim, a value in the negative range due to

canister purge at idle should not be considered unusual.

Fuel trim values at maximum authority may indicate an

excessively rich or lean system.

LOOP STATUS — Tech 2 Displays OPEN or

CLOSED —

“CLOSED” indicates that the PCM is controlling fuel

delivery according to oxygen sensor voltage. In “OPEN”

the PCM ignores the oxygen sensor voltage and bases

the amount of fuel to be delivered on TP sensor, engine

coolant, and MAF sensor inputs only.

MAF — Tech 2 Range 0.0-512 gm/s —

MAF (mass air flow) is the MAF input frequency

converted to grams of air per second. This indicates the

amount of air entering the engine.

MAP — Tech 2 Range 10-105 kPa (0.00-4.97 Volts)

—

The manifold absolute pressure (MAP) sensor measures

the change in the intake manifold pressure from engine

load, EGR flow, and speed changes. As intake manifold

pressure increases, intake vacuum decreases, resulting

in a higher MAP sensor voltage and kPa reading. The

MAP sensor signal is used to monitor intake manifold

pressure changes during the EGR flow test, to update the

BARO reading, and as an enabling factor for several of

the diagnostics.

MIL — Tech 2 Displays ON or OFF —

Indicates the PCM commanded state of the malfunction

indicator lamp.

POWER ENRICHMENT — Tech 2 Displays ACTIVE

or INACTIVE —

“ACTIVE” displayed indicates that the PCM has detected

conditions appropriate to operate in power enrichment

mode. The PCM will command power enrichment mode

when a large increase in throttle position and load is

detected. While in power enrichment mode, the PCM will

increase the amount of fuel delivered by entering open

loop and increasing the injector pulse width. This is done

to prevent a possible sag or hesitation from occurring

during acceleration.

Page 1221 of 6000

6E–104

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0101 MAF System Performance

D06RW103

Circuit Description

The mass air flow (MAF) sensor measures the amount of

air which passes through it into the engine during a given

time. The powertrain control module (PCM) uses the

mass air flow information to monitor engine operating

conditions for fuel delivery calculations. A large quantity

of air entering the engine indicates an acceleration or high

load situation, while a small quantity or air indicates

deceleration or idle.

The MAF sensor produces a frequency signal which can

be monitored using a Tech 2. DTC P0101 will be set if the

signal from the MAF sensor does not match a predicted

value based on throttle position and engine RPM.

Conditions for Setting the DTC

The engine is running.

No TP sensor or MAP sensor DTCs are set.

The throttle is steady, TP angle doesn’t change by

more than 1%.

System voltage is between 11.5 volts and 16 volts.

Calculated air flow is between 25 g/second and 40

g/second.

Above conditions present for at least 1 second.

MAF signal frequency indicates an airflow significantly

higher or lower than a predicted value based on throttle

position and engine RPM for a total of 12.5 seconds

over a 25-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM calculates an airflow value based on idle air

control valve position, throttle position, RPM and

barometric pressure.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0101 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An intermittent may be caused by the following:

Poor connections.

Mis-routed harness.

Rubbed through wire insulation.

Broken wire inside the insulation.

Refer to Intermittents under service category Symptoms.

Any un-metered air may cause this DTC to set. Check for

the following:

The duct work at the MAF sensor for leaks.

An engine vacuum leak.

The PCV system for vacuum leaks.

An incorrect PCV valve.

Page 1224 of 6000

6E–107 ENGINE DRIVEABILITY AND EMISSIONS

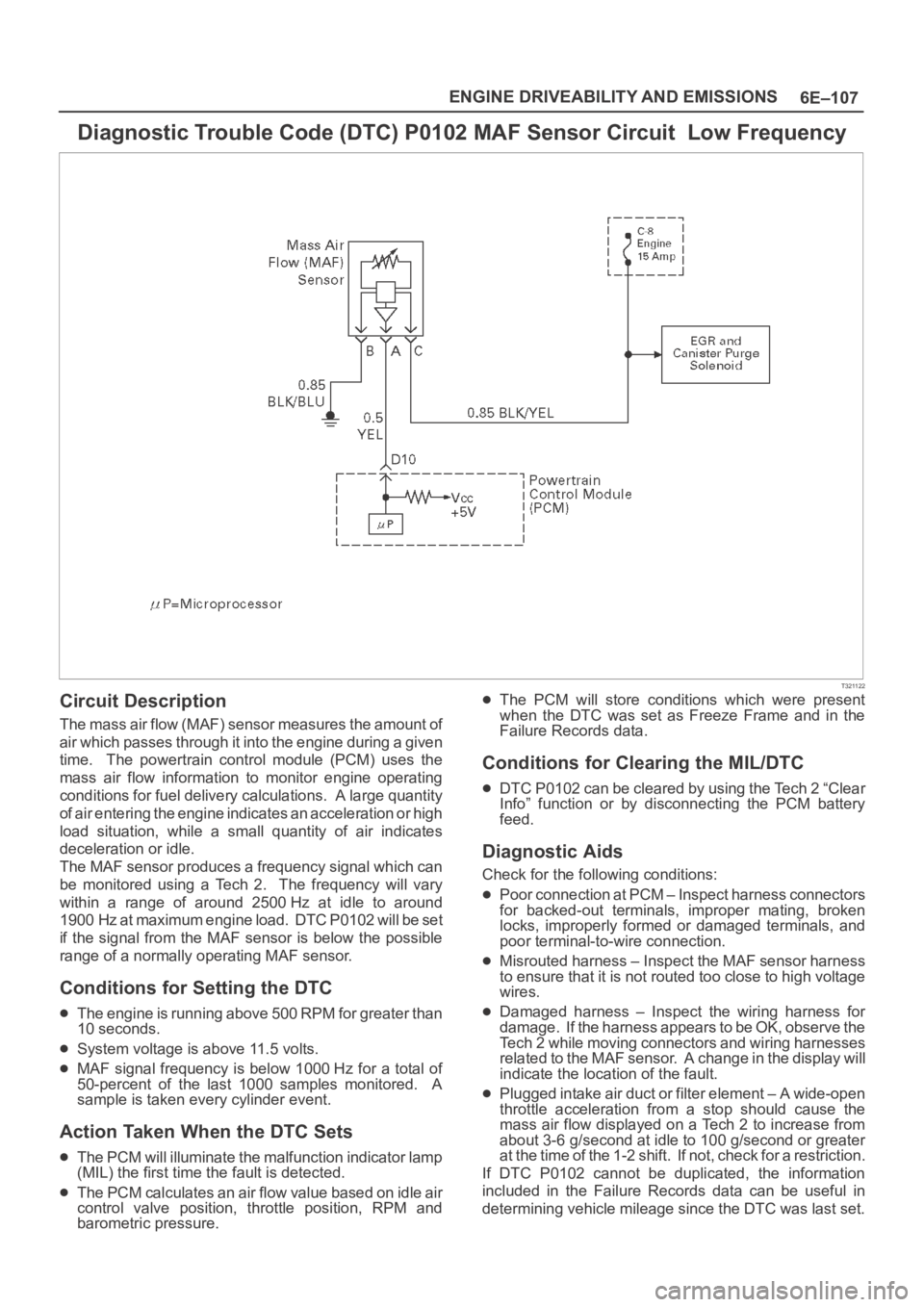

Diagnostic Trouble Code (DTC) P0102 MAF Sensor Circuit Low Frequency

T321122

Circuit Description

The mass air flow (MAF) sensor measures the amount of

air which passes through it into the engine during a given

time. The powertrain control module (PCM) uses the

mass air flow information to monitor engine operating

conditions for fuel delivery calculations. A large quantity

of air entering the engine indicates an acceleration or high

load situation, while a small quantity of air indicates

deceleration or idle.

The MAF sensor produces a frequency signal which can

be monitored using a Tech 2. The frequency will vary

within a range of around 2500 Hz at idle to around

1900 Hz at maximum engine load. DTC P0102 will be set

if the signal from the MAF sensor is below the possible

range of a normally operating MAF sensor.

Conditions for Setting the DTC

The engine is running above 500 RPM for greater than

10 seconds.

System voltage is above 11.5 volts.

MAF signal frequency is below 1000 Hz for a total of

50-percent of the last 1000 samples monitored. A

sample is taken every cylinder event.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM calculates an air flow value based on idle air

control valve position, throttle position, RPM and

barometric pressure.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0102 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Misrouted harness – Inspect the MAF sensor harness

to ensure that it is not routed too close to high voltage

wires.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 while moving connectors and wiring harnesses

related to the MAF sensor. A change in the display will

indicate the location of the fault.

Plugged intake air duct or filter element – A wide-open

throttle acceleration from a stop should cause the

mass air flow displayed on a Tech 2 to increase from

about 3-6 g/second at idle to 100 g/second or greater

at the time of the 1-2 shift. If not, check for a restriction.

If DTC P0102 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 1229 of 6000

6E–112

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0107 MAP Sensor Circuit Low Voltage

D06RW102

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP sensor signal voltage to the powertrain control

module (PCM) varies from below 2 volts at idle (high

vacuum) to above 4 volts with the ignition “ON,” engine

not running or at wide-open throttle (low vacuum).

The MAP sensor is used to determine manifold pressure

changes while the exhaust gas recirculation (EGR) flow

test diagnostic is being run (refer to

DTC P0401), to

determine engine vacuum level for some other

diagnostics and to determine barometric pressure

(BARO). The PCM monitors the MAP signals for voltages

outside the normal range of the MAP sensor. If the PCM

detects a MAP signal voltage that is excessively low, DTC

P0107 will be set.

Conditions for Setting the DTC

No TP sensor DTCs present.

Engine is running.

Throttle angle is above 1% if engine speed is less than

1000 RPM.

Throttle angle is above 2% if engine speed is above

1000 RPM.

The MAP sensor indicates manifold absolute pressure

at or below 11 kPa for a total of approximately 10

seconds over a 16-second period.

Ignition voltage more than 11 volts.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will default to a BARO value of 79.3 kPa.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0107 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check for intermittent codes.

The MAP sensor shares a 5 Volt reference with the

Rough Road Sensor. If these codes are also set, it

could indicate a problem with the 5 Volt reference

circuit .

The MAP sensor shares a ground with the Rough Road

Sensor, the ECT sensor, and the Transmission Fluid

Temperature sensor.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

Page 1232 of 6000

6E–115 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0108 MAP Sensor Circuit High Voltage

D06RW102

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP sensor signal voltage to the powertrain control

module (PCM) varies from below 2 volts at idle (high

vacuum) to above 4 volts with the key “ON,” engine not

running or at wide-open throttle (low vacuum).

The MAP sensor is used to determine manifold pressure

changes while the linear EGR flow test diagnostic is being

run (refer to

DTC P0401), to determine engine vacuum

level for some other diagnostics and to determine

barometric pressure (BARO). The PCM monitors the

MAP signals for voltages outside the normal range of the

MAP sensor. If the PCM detects a MAP signal voltage

that is excessively high, DTC P0108 will be set.

Conditions for Setting the DTC

No TP sensor DTCs present.

Engine is running for more than 10 seconds.

Throttle position is below 3% if engine speed is below

1000 RPM.

Throttle position is below 10% if engine speed is above

1000 RPM.

The MAP sensor indicates an intermittent manifold

absolute pressure above 80kPa for a total of

approximately 10 seconds over a 16-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will default to a BARO value of 79.3 kPa.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0108 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0108 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set. If

it is determined that the DTC occurs intermittently,

performing the DTC P1108 Diagnostic Chart may isolate

the cause of the fault.

Page 1235 of 6000

6E–118

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0112 IAT Sensor Circuit Low Voltage

D06RW026

Circuit Description

The intake air temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the

engine. The powertrain control module (PCM) applies 5

volts through a pull-up resistor to the IAT sensor. When

the intake air is cold, the sensor resistance is high and the

PCM will monitor a high signal voltage on the IAT signal

circuit. If the intake air is warm, the sensor resistance is

lower, causing the PCM to monitor a lower voltage. DTC

P0112 will set when the PCM detects an excessively low

signal voltage on the intake air temperature sensor signal

circuit.

Conditions for Setting the DTC

The engine has been running for over 2 minutes.

Vehicle speed is greater than 30 mph (48 km/h) .

IAT signal voltage indicates and intake air temperature

greater than 148C (298F) (about 5 volts) for a total

of 12.5 seconds over a 25-second period of time.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0112 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-bout terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

IAT display on the Tech 2 while moving connectors and

wiring harnesses related to the IAT sensor. A change

in the IAT display will indicate the location of the fault.

If DTC P0112 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Verifies that the fault is present.

Page 1238 of 6000

6E–121 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0113 IAT Sensor Circuit High Voltage

D06RW026

Circuit Description

The intake air temperature (IAT) sensor is a thermistor

which measures the temperature of the air entering the

engine. The powertrain control module (PCM) applies 5

volts through a pull-up resistor to the IAT sensor. When

the intake air is cold, the sensor resistance is high and the

PCM will monitor a high signal voltage on the IAT signal

circuit. If the intake air is warm, the sensor resistance is

lower causing the PCM to monitor a lower voltage. DTC

P0113 will set when the PCM detects an excessively high

signal voltage on the intake air temperature sensor signal

circuit.

Conditions for Setting the DTC

The engine has been running for over 4 minutes.

Vehicle speed is less than 20 mph (32 km/h).

ECT signal temperature is above 60C (140F).

Mass air flow is less then 20 g/second.

IAT signal voltage indicates an intake air temperature

less than –39C (–38F) for total of 12.5 seconds over

a 25-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0113 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

The IAT sensor shares a ground with the EGR position

sensor and the TP sensor. Check the ground if these

DTC’s are set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

IAT display on the Tech 2 while moving connectors and

wiring harnesses related to the IAT sensor. A change

in the IAT display will indicate the location of the fault.

If DTC P0113 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Verifies that the fault is present.

Page 1241 of 6000

6E–124

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0117 ECT Sensor Circuit Low Voltage

060RY00304

Circuit Description

The engine coolant temperature (ETC) sensor is a

thermistor mounted on a coolant crossover pipe at the

rear of the engine. The powertrain control module (PCM)

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine coolant is cold,

the sensor (thermistor) resistance is high, therefore the

PCM will measure a high signal voltage. As the engine

coolant warms, the sensor resistance becomes lower,

and the ECT signal voltage measured at the PCM drops.

With a fully warmed-up engine, the ECT signal voltage

should measure about 1.5 to 2.0 volts.

Conditions for Setting the DTC

Engine running time is longer than one minute.

The ECT sensor signal indicates an engine coolant

temperature greater than 150C (302F) (about 0.10

V) for a total of 50 seconds over a 100–second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will substitute the ECT reading with a default

engine coolant temperature value. The default value

is based on start-up intake air temperature and running

time.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0117 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

If DTC P0117 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.