change time OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2056 of 6000

6E–163 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1588 (Flash DTC 25)

Brake SW Malfunction

060RW130

Circuit Description

Brake Stop Lamp SW Circuit receives through Stop Lamp

10A fuse from the battery.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1588 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Brake SW display on the Tech 2 while moving

connectors and wiring harnesses related to the Brake

SW. A change in the display will indicate the location

of the fault.

If DTC P1588 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 2059 of 6000

6E–166

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0650 (Flash DTC 77)

Check Engine Lamp Circuit Open/Short

060RW136

Circuit Description

The check engine lamp circuit receives through Meter

10A fuse the battery, current flowing in the order of Meter

and check engine lamp.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0650 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

lamp test display on the Tech 2 while moving

connectors and wiring harnesses related to the check

engine lamp. A change in the display will indicate the

location of the fault.

If the Tech 2 indicate DTCs P0650 and P0381, check the

meter circuit necessarily.

Page 2067 of 6000

6E–174

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1589 (Flash DTC 47)

Transmission SW Circuit Open/Short

060RW131

Circuit Description

The trans mission SW circuit receives current through

ELEC IG 10A fuse from the battery, current flowing in the

order of the trans mission SW and ECM.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1589 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

throttle position display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

If DTC P1589 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

DTC P1589 – Transmission Circuit Open/Short

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Check the Fuse 10A for a open circuit and replace the

Fuse if necessary.

Did the Fuse require replacement?

—Verify repairGo to Step 3

Page 2164 of 6000

7A–10

AUTOMATIC TRANSMISSION (4L30–E)

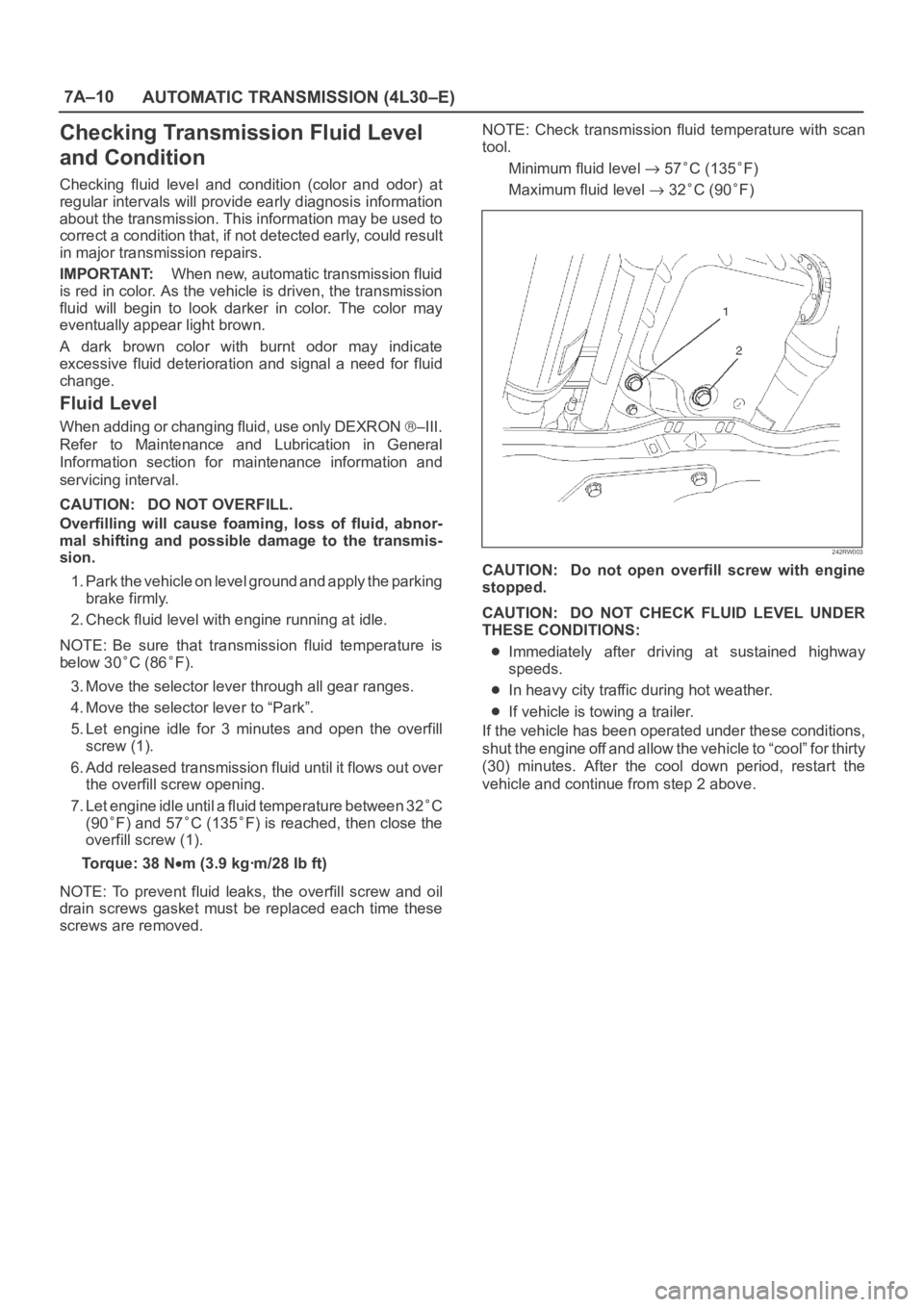

Checking Transmission Fluid Level

and Condition

Checking fluid level and condition (color and odor) at

regular intervals will provide early diagnosis information

about the transmission. This information may be used to

correct a condition that, if not detected early, could result

in major transmission repairs.

IMPORTANT:When new, automatic transmission fluid

is red in color. As the vehicle is driven, the transmission

fluid will begin to look darker in color. The color may

eventually appear light brown.

A dark brown color with burnt odor may indicate

excessive fluid deterioration and signal a need for fluid

change.

Fluid Level

When adding or changing fluid, use only DEXRON –III.

Refer to Maintenance and Lubrication in General

Information section for maintenance information and

servicing interval.

CAUTION: DO NOT OVERFILL.

Overfilling will cause foaming, loss of fluid, abnor-

mal shifting and possible damage to the transmis-

sion.

1. Park the vehicle on level ground and apply the parking

brake firmly.

2. Check fluid level with engine running at idle.

NOTE: Be sure that transmission fluid temperature is

below 30

C (86F).

3. Move the selector lever through all gear ranges.

4. Move the selector lever to “Park”.

5. Let engine idle for 3 minutes and open the overfill

screw (1).

6. Add released transmission fluid until it flows out over

the overfill screw opening.

7. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached, then close the

overfill screw (1).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.NOTE: Check transmission fluid temperature with scan

tool.

Minimum fluid level

57C (135F)

Maximum fluid level

32C (90F)

242RW003

CAUTION: Do not open overfill screw with engine

stopped.

CAUTION: DO NOT CHECK FLUID LEVEL UNDER

THESE CONDITIONS:

Immediately after driving at sustained highway

speeds.

In heavy city traffic during hot weather.

If vehicle is towing a trailer.

If the vehicle has been operated under these conditions,

shut the engine off and allow the vehicle to “cool” for thirty

(30) minutes. After the cool down period, restart the

vehicle and continue from step 2 above.

Page 2181 of 6000

7A–27 AUTOMATIC TRANSMISSION (4L30–E)

Changing Transmission Fluid

There is no need to change the transmission fluid unless

the transmission is used under one or more of the

following heavy duty conditions.

A. Repeated short trips

B. Driving on rough roads

C. Driving on dusty roads

D. Towing a trailer

If the vehicle is used under these conditions, change the

fluid every 20,000 miles (32,000 km.)

More over, the remaining life percentage of ATF can be

estimated by using Tech 2 as an auxiliary tool to judge the

right time for ATF replacement.

The remaining life percentage is calculated from ATF’S

heat history. When it is close to 0%, ATF replacement is

recommended.

1. Place a large drain pan under the oil pan.

2. Remove the transmission oil drain screw (2) and drain

fluid.

3. Tighten drain screw (2).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

4. Remove the transmission overfill screw (1) and fill

transmission through overfill screw opening, using

DEXRON

–III ATF.

NOTE: Add transmission fluid until it flows out over the

overfill screw opening.

5. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached.6. Add transmission fluid until it flows out over the overfill

screw opening, then close the overfill screw (1).

To r q u e : 3 8 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.

NOTE: Check transmission fluid temperature with

service scan tool.

242RW003

Selector Lever

Inspection

1. Make sure that when the shifter control lever is shifted

from “P” to “L”, a “clicking” can be felt at each shift

position. Make sure that the gear corresponds to that

of the position plate indicator.

2. Check to see if the shifter lever can be shifted as

shown in illustration.

C07RW009

Page 2270 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–25

DTC P0218 Transmission Fluid Over Temperature

D07RW029

Circuit Description

The Transmission Fluid Temperature (TFT) sensor is a

thermister that controls the signal voltage to the PCM.

The PCM supplies a 5–volt reference to the sensor on

circuit RED/BLK–GRN/RED. When the transmission fluid

is cold, the sensor resistance is high and the PCM will

sense high signal voltage. As the fluid temperature

warms to a normal transmission operating temperature of

100

C (212F), the sensor resistance becomes less and

the voltage decreases to 1.5 to 2.0 volts.

This DTC detects a high transmission temperature for a

long period of time. This is a type “D” DTC.

Conditions For Setting The DTC

No TFT DTCs P0712 or P0713.

TFT is greater than 135C (275F).

All conditions met for 21 seconds.

Action Taken When The DTC Sets

Hot mode TCC Shift Pattern.

The PCM will not illuminate the CHECK TRANS

Lamp.

ATF Lamp ON. (TFT is greater than 145C (293F).)

Disable E–side TCC OFF request.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warm–up cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Inspect the wiring for poor electrical connections at

the PCM and at the transmission 16–way connector.

Look for possible bent, backed out, deformed, or

damaged terminals. Check for weak terminal tension

as well.

Also check for a chafed wire that could short to bare

metal or other wiring. Inspect for a broken wire inside

the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Check harness routing for a potential short to ground

in circuit RED/BLK–GRN/RED.

Scan tool TFT sensor temperature should rise

steadily to about 100

C (212F), then stabilize.

Check for a “skewed” (mis–scaled) sensor by

comparing the TFT sensor temperature to the

ambient temperature after a vehicle cold soak. A

“skewed” sensor can cause delayed garage shifts or

TCC complaints.

Check for a possible torque converter stator problem.

Verify customer driving habits, trailer towing, etc.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart.

3. This test checks for a “skewed” sensor or shorted

circuit.

4. This test simulates a TFT DTC P0713.

Page 2281 of 6000

7A1–36

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0712 Transmission Fluid Temperature (TFT) Sensor Circuit Low Input

D07RW029

Circuit Description

The TFT sensor is a thermister that controls the signal

voltage to the PCM. The PCM supplies a 5–volt reference

signal to the sensor on circuit RED/BLK–GRN/RED.

When the transmission fluid is cold, the sensor resistance

is high. The PCM detects high signal voltage. As the

transmission fluid temperature increases to the normal

operating temperature of 100

C (212F), the sensor

resistance becomes less and the voltage decreases to

1.5 to 2 volts. With transmission fluid over temperature

and DTC P0218 also set, check the transmission cooling

system.

This DTC detects a continuous short to ground in the TFT

signal circuit or the TFT sensor. This is a type “D” DTC.

Conditions For Setting The DTC

Battery voltage is between 10 and 16 volts.

Ignition is “on”.

TFT sensor indicating a voltage less than 0.4 volts.

All conditions met for 20 seconds.

Action Taken When The DTC Sets

Transmission default temperature will be:

80

C (176F) if engine temperature code is set.

100

C (212F) if engine temperature is warm.

80

C (176F) if engine run time is greater than 5

minutes.

21

C (69.8F) if engine run time is less than 5

minutes.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Check harness routing for a potential short to ground

in circuit RED/BLK–GRN/RED. Scan tool TFT

display should rise steadily to about 100

C (212F),

then stabilize.

Inspect the wiring for poor electrical connection at the

PCM and at the transmission 16–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as we ll. A lso ch eck fo r a ch af e d w ire th at cou l d s ho r t

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

The temperature to resistance value scale may be

used to test the TFT sensor at the various

temperature levels to evaluate the possibility of a

“skewed” (mis–scaled) sensor.

A “skewed” sensor could result in delayed garage

shifts or TCC complaints.

Verify customer driving habits, trailer towing, etc.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

3. This test checks for a short to ground or a “skewed”

sensor.

4. This test checks for an internal fault within the

transmission by creating an open.

Page 2284 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–39

DTC P0713 Transmission Fluid Temperature (TFT) Sensor Circuit High Input

D07RW029

Circuit Description

The TFT sensor is a thermistor that controls the signal

voltage to the PCM. The PCM supplies a 5–volt reference

signal to the sensor on circuit RED/BLK–GRN/RED.

When the transmission fluid is cold, the sensor resistance

is high and the PCM will sense high signal voltage. As the

transmission fluid temperature warms to the normal

operating temperature of 100

C (212F), the sensor

resistance becomes less and the voltage decreases to

about 1.5 to 2 volts.

This DTC detects a continuous open or short to power in

the TFT signal circuit or the TFT sensor. This is a type “D”

DTC.

Conditions For Setting The DTC

Battery voltage is between 10 and 16 volts.

Ignition is “on”.

TFT sensor indicating a voltage greater than 4.86

volts.

All conditions met for 20 seconds.

Action Taken When The DTC Sets

Transmission default temperature will be:

80

C (176F) if engine temperature code is set.

100

C (212F) if engine temperature is warm.

80

C (176F) if engine run time is greater than 5

minutes.

21

C (69.8F) if engine run time is less than 5

minutes.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Inspect the wiring for poor electrical connection at the

PCM and at the transmission 16–way connector.

Look for possible bent, backed out, deformed or

damaged terminals. Check for weak terminal tension

as we ll. A lso ch eck fo r a ch af e d w ire th at cou l d s ho r t

to bare metal or other wiring. Inspect for a broken wire

inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Scan tool displays transmission fluid temperature in

degrees. After transmission is operating, the

temperature should rise steadily to about 100

C

(212

F), then stabilize.

The temperature to resistance value scale may be

used to check the TFT sensor at the various

temperature levels to evaluate the possibility of a

“skewed” (mis–scaled) sensor.

A “skewed” sensor could result in hard shifts or TCC

complaints.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

3. This check verifies problem in the TFT sensor circuit.

4. This test simulates a TFT sensor DTC P0712. If the

PCM recognizes the low signal voltage (high

temperature), and the scan tool displays 146

C

(295

F) or greater, the PCM and wiring are OK.

Page 2287 of 6000

7A1–42

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0719 TCC Brake Switch Circuit High (Stuck On)

D07RW032

Circuit Description

The TCC brake switch is used to indicate brake pedal

status. The normally opened brake switch signal voltage

circuit is opened.

Brake switch supplies a B+ signal on circuit GRN/YEL to

the PCM when the brakes are applied. The PCM uses

this signal to deenergize the TCC solenoid when the

brakes are applied.

This DTC detects a closed brake switch during

accelerations. This is a type “D” DTC.

Conditions For Setting The DTC

No OSS DTCs P0722 or P0723.

The PCM detects a closed brake switch/circuit (12

volts) for 2 seconds, and the following events occur

seven consecutive times: vehicle speed is less than 8

km/h (5 mph); then vehicle speed is between 8 and 32

km/h (5 and 20 mph) for 4 seconds; then vehicle

speed is greater than 32 km/h (20 mph) for 4 seconds.

Action Taken When The DTC Sets

If throttle opening is greater than 10% and vehicle

speed is greater than 45 km/h (28 mph), then

disregard brake switch contingency for TCC off

mode.

The PCM will not illuminate the CHECK TRANS

Lamp.

Conditions For Clearing The DTC

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

Inspect the wiring for poor electrical connections at

the PCM and TCC brake switch. Look for possible

bent, backed out, deformed or damaged terminals.

Check for weak terminal tension as well. Also check

for a chafed wire that could short to bare metal or

other wiring. Inspect for a broken wire inside the

insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Check customer driving habits and/or unusual driving

conditions (i.e. stop and go, highway).

Check brake switch for proper mounting and

adjustment.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

3. This test checks for voltage at the brake switch.

6. This test checks the brake switch.

9. This test checks circuit GRN/YEL at the PCM.

Page 2293 of 6000

7A1–48

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P0723 Transmission Output Speed Sensor (OSS) Intermittent

D07RW006

Circuit Description

Output speed information is provided to the PCM by the

OSS, which is a permanent magnet (PM) generator. The

PM generator produces a pulsing AC voltage. The AC

voltage level and number of pulses increases as the

speed of the vehicle increases. The PCM then converts

the pulsing voltage to output speed, which is used for

calculations. The vehicle speed can be displayed with a

scan tool.

This DTC detects a low output speed when there is a high

engine speed in a drive gear range. This is a type “C”

DTC.

Conditions For Setting The DTC

In Park or Neutral:

Transmission output speed change is greater than

10,000 rpm.

Conditions met for 6 seconds.

Engine running time is greater than 2 seconds.

Not in Park or Neutral:

Transmission output speed change is greater than

512 rpm.

Conditions met for 0.075 seconds

Engine running time is greater than 2 seconds.

Engine vacuum is less than 70 kPa.

Output speed is greater than 1,380 rpm for 1 second.

NORAW–NOLAST < 60 rpm for 6 seconds.

NORAW: Latest raw data of output shaft speed.

NOLAST: Filtered pervious data of output speed.

Action Taken When The DTC Sets

Fixed to 4th gear.

Maximum line pressure.

Inhibit TCC engagement.

The PCM will illuminate the CHECK TRANS Lamp.

Conditions For Clearing The MIL/DTC

The PCM will turn off the CHECK TRANS Lamp after

three consecutive ignition cycles without a failure

reported.

The DTC can be cleared from the PCM history by

using a scan tool.

The DTC will be cleared from history when the vehicle

has achieved 40 warmup cycles without a failure

reported.

The PCM will cancel the DTC default actions when

the fault no longer exists and the ignition is cycled “off”

long enough to power down the PCM.

Diagnostic Aids

A OSS DTC P0723 will set when output speed has

been detected and is lost.

Inspect the wiring for poor electrical connection at the

PCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring. Inspect for a

broken wire inside the insulation.

When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Test Description

The numbers below refer to the step numbers on the

diagnostic chart:

5. This test checks the OSS circuit.

6. This test checks the integrity of the OSS.

8. This test checks the 5–volt and ground circuit of the

PCM.