lock OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 370 of 625

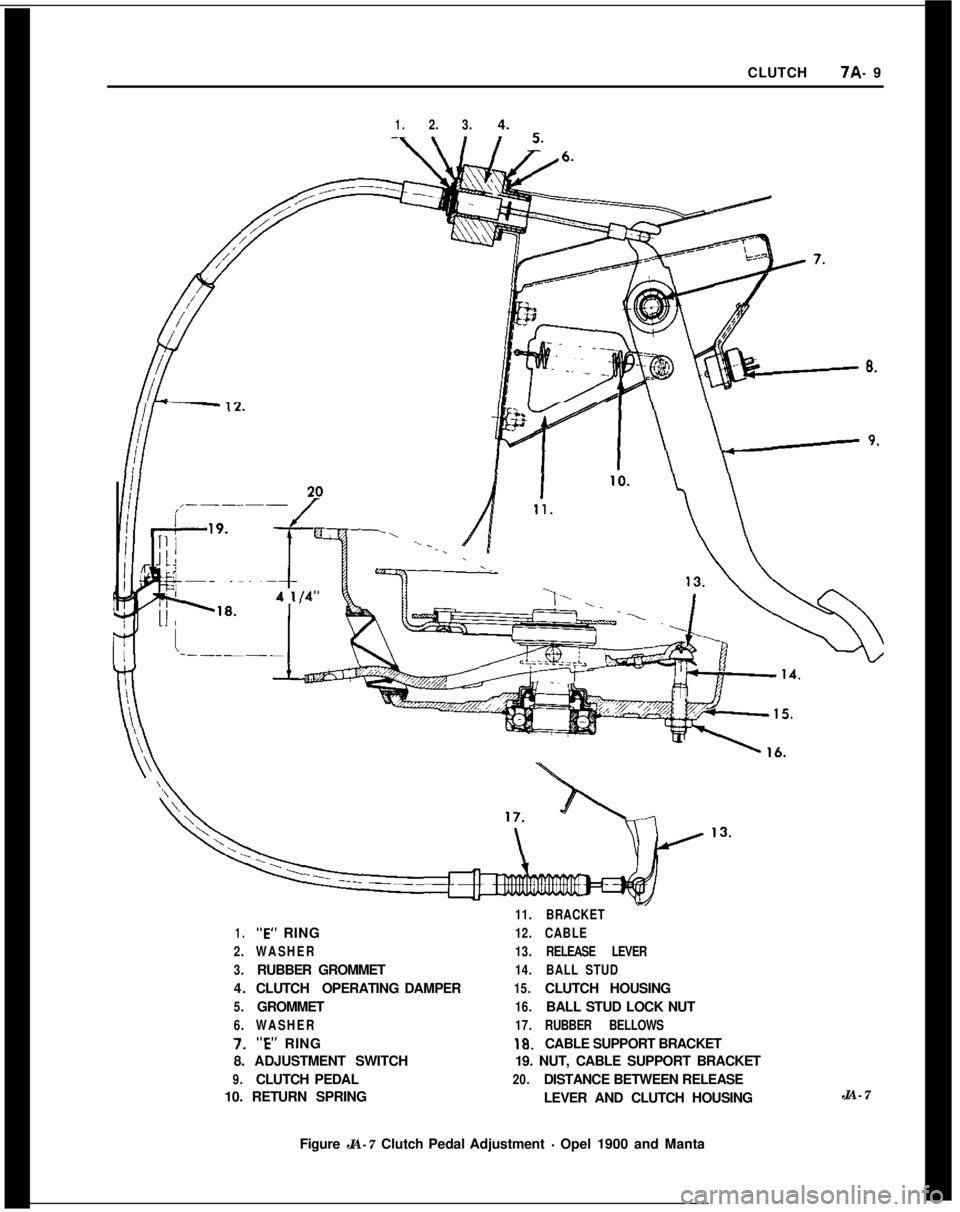

CLUTCHlA- 9

1.2.3.4.

8.

-9.

-11.BRACKET

1.“E” RING12.CABLE

2.WASHER13.RELEASE LEVER

3.RUBBER GROMMET

14.BALL STUD4.CLUTCH OPERATINGDAMPER

15.CLUTCH HOUSING

5.GROMMET16.BALL STUD LOCK NUT

6.WASHER17.RUBBER BELLOWS7.

“E” RING18.CABLE SUPPORT BRACKET

8. ADJUSTMENT SWITCH19. NUT, CABLE SUPPORT BRACKET

9.CLUTCH PEDAL20.DISTANCE BETWEEN RELEASE

10. RETURN SPRING

LEVER AND CLUTCH HOUSINGJA-7

Figure JA-7 Clutch Pedal Adjustment

- Opel 1900 and Manta

Page 371 of 625

7A- 101973 OPEL SERVICE MANUAL

Arrangement Of Clutch

1 Clutch release lever14 Clutch ossy. bolt, lockwasher

2 Slot in lever for control cable boll15 Hollow space under felt ring filled

endwith molybdenum disulfide paste

3Assembly marks

4Clutch assembly

5Flywheel

6 Flywheel ring gear

7Thrust pin

8Retaining spring

9Crankshaft

10 Clutch gear pilot bushing

11Oil seal

12Flywheel bolt

13Clutch housing

16 Felt ring

17 Clutch release bearing

18 Clutch gear ball beorirq

19 Clutch gear

20 Snap ring

21 Paper gasket

22 Clutch gear oil seal

23 Clutch release bearing sleeve

24 Clutch disc, long end of hub facing

forward.

?A-8Figure

7A-8 Arrangement of Clutch

Page 373 of 625

7B- 121973 OPEL SERVICE MANUAL

MANUAL TRANSMISSION

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Power

Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS:

Adjusting

ReverseGearshiftBlocker. . . . . . . . . . . . . . . . . . . . . . . . . .Shift Lever Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ServicingGearshift

Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAJOR REPAIR:

Transmission

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Installation

ofTransmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removing and Installing

Speed0 Driven Gear

(Transmission

Removed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ReplacingBushinginSelectorLever. . . . . . . . . . . . . . . . . . . . . . . . . .Transmission

Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Transmission

Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Specifications ..,....._....,......,.....,......,.,.....,,.,..,......,.,....,........

Page No.

78-12

7B-13

78-1978-l

9

7B-19

78-22

78-22

78-23

78-23

78-23

78-28

78-33

Page 375 of 625

7B- 141973 OPEL SERVICE MANUAL

POWER FLOW - 1st SPEED

MAIN DRIVE GEAR (INPUT)

COUNTERSHAFT GEAR UNIT 1st SPEED GEAR

1 st SPEED GEAR

1st AND 2nd GEAR SLIDING GEAR1st AND 2nd SPEED SLIDING GEAR GUIDE UNITCOUNTERSHAFT GEAR

UI‘!IT DRIVE GEAR1st SPEED GEAR1st AND 2nd GEAR SLIDING GEAR

,st AND 2nd SPEED SLIDING GEAR GUIDE UN1MAINSHAFT (OUTPUT)

70-2Figure 78.2

First SpeedAfter synchronizing the speeds of the mainshaft and

the 1st speed gear, the 1st and 2nd gear sliding gear

shifts to the rear of the transmission and locks the 1st

speed gear to the mainshaft through the 1st and 2nd

speed sliding gear guide unit. This 1st and 2nd speed

sliding gear guide unit is internally splined to the 1st

and 2nd gear sliding gear and is

exl~ernally splined to

the mainshaft. Both the 3rd speed gear and the 2nd

speed gear are idling. The reverse idler gear is not

engaged with any gear and, therefore, it is idle.

With a 1st speed gear ratio of

3.428:1, the main drive

gear (input) must turn 3.428 revolutions for every

one revolution of the main shaft (output).

IT

Page 376 of 625

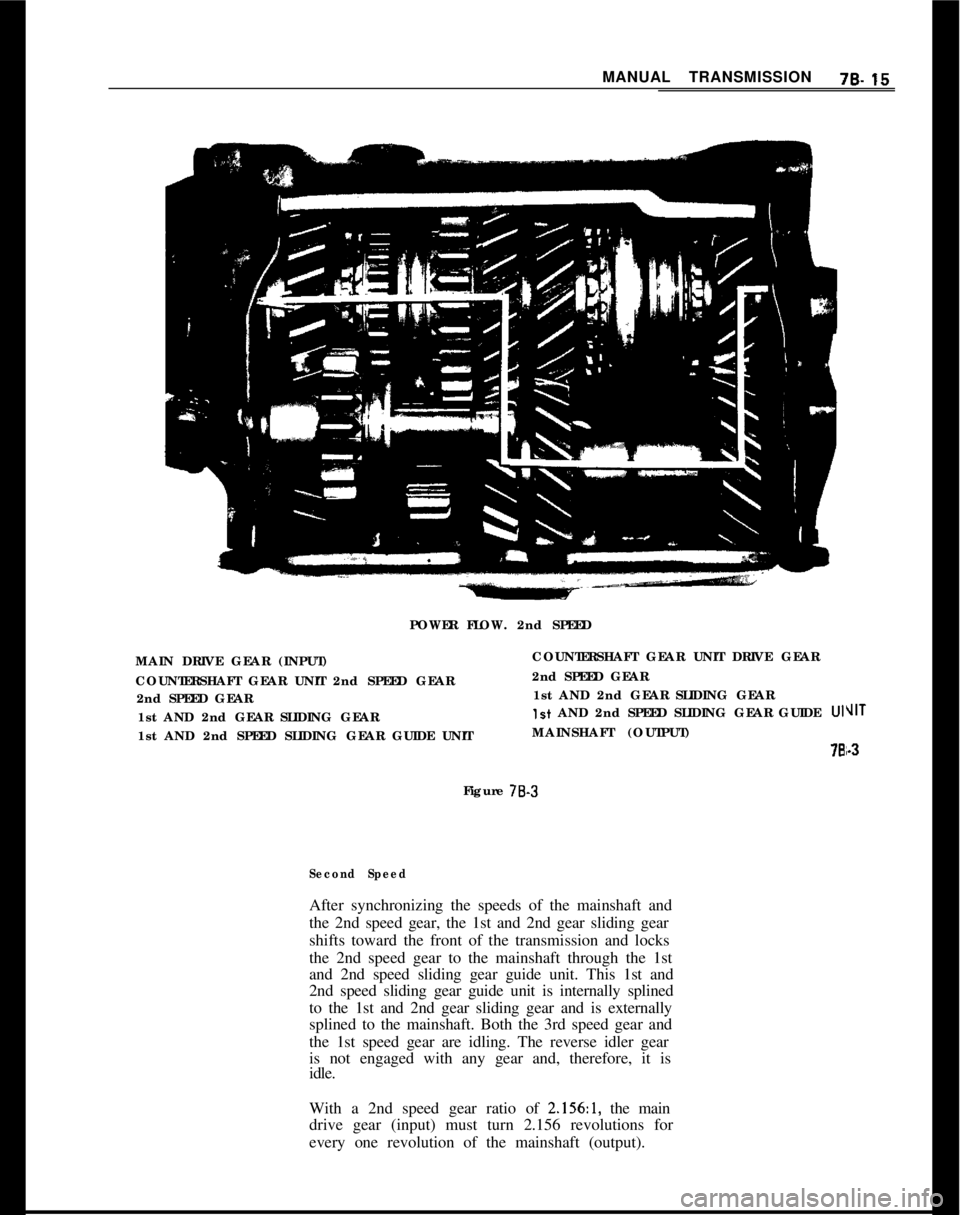

MANUAL TRANSMISSION76.15POWER FLOW. 2nd SPEED

MAIN DRIVE GEAR (INPUT)

COUNTERSHAFT GEAR UNIT 2nd SPEED GEAR

2nd SPEED GEAR

1st AND 2nd GEAR SLIDING GEAR

1st AND 2nd SPEED SLIDING GEAR GUIDE UNITCOUNTERSHAFT GEAR UNIT DRIVE GEAR

2nd SPEED GEAR

1st AND 2nd GEAR SLIDING GEAR

Ist AND 2nd SPEED SLIDING GEAR GUIDE UIMAINSHAFT (OUTPUT)

76Figure 78.3

Second SpeedAfter synchronizing the speeds of the mainshaft and

the 2nd speed gear, the 1st and 2nd gear sliding gear

shifts toward the front of the transmission and locks

the 2nd speed gear to the mainshaft through the 1st

and 2nd speed sliding gear guide unit. This 1st and

2nd speed sliding gear guide unit is internally splined

to the 1st and 2nd gear sliding gear and is externally

splined to the mainshaft. Both the 3rd speed gear and

the 1st speed gear are idling. The reverse idler gear

is not engaged with any gear and, therefore, it is

idle.

With a 2nd speed gear ratio of

2.156:1, the main

drive gear (input) must turn 2.156 revolutions for

every one revolution of the mainshaft (output).

VIT

i-3

Page 377 of 625

78. 161973 OPEL SERVICE MANUAL

POWER FLOW

- 3rd SPEED

MAIN DRIVE GEAR (INPUT)

COUNTERSHAFT GEAR UNIT 3rd SPEED GEAR

3rd SPEED GEAR

GEAR SHIFTER SLEEVE

GEAR SHIFTER SLEEVE CARRIERCOUNTERSHAFT GEAR UNIT GEAR DRIVE

3rd SPEED GEAR

GEAR SHIFTER SLEEVE

GEAR SHIFTER SLEEVE CARRIER

MAIN SHAFT (OUTPUT)

78-4

Figure 78.4

Third Speed

After synchronizing the speeds of the mainshaft and

the 3rd speed gear, the gear shifter sleeve shifts to the

rear of the transmission and locks the 3rd speed gear

to the mainshaft through the gear shifter sleeve car-

rier. This gear shifter sleeve carrier is internally

splined to the gear shifter sleeve and is externally

splined to the mainshaft. Both the 1st speed gear and

the 2nd speed gear are idling. The reverse idler gear

is

not engaged with any gear and, therefore, it is

idle.

With a 3rd speed gear ratio of

1.366:1, the main drive

gear (input) must turn 1.366 revolutions for every

one revolution of the mainshaft (output).

Page 378 of 625

MANUAL TRANSMISSION78.17POWER FLOW

- 4th SPEED

MAIN DRIVE GEAR (INPUT)

GEAR SHIFTER SLEEVE

GEAR SHIFTER SLEEVE CARRIERGEAR SHIFTER SLEEVE

GEAR SHIFTER SLEEVE CARRIER

MAIN SHAFT (OUTPUT)7E5

Figure 78.5

Fourth SpeedAfter synchronizing speeds of the main drive gear

and mainshaft, the gear shifter sleeve shifts forward

and locks the main drive gear to the mainshaft

through the gear shifter sleeve carrier. This carrier is

internally splined to the gear shifter sleeve and is

externally splined to the mainshaft. The 3rd speed

gear, 2nd speed gear, and the 1st speed gear are all

idling. The

reverse idler gear is not engaged with

any gear and, therefore, it is idle.

With a 4th speed gear ratio of 1.000: 1, the main drive

gear (input) must turn 1.000 revolutions for every

one revolution of the mainshaft (output).

Page 380 of 625

MANUAL TRANSMISSION76.19

DIAGNOSIS

MANUAL TRANSMISSION DIAGNOSIS

ConditionPossible CauseNoisy in Forward Speeds1) Low lubricant level.

2) Incorrect lubricant.

3) Transmission misaligned or loose.

4) Front main bearing worn or damaged.

5) Mainshaft bearing worn or damaged.

6) Countergear or bearings worn or damaged,

7) Main drive gear worn or damaged.

8) Synchronizers worn or damaged.

Noisy in “Reverse”1) Reverse sliding gear or shaft, worn or damaged

Hard Shifting1) Clutch improperly adjusted.

2) Shift shafts, or forks worn.

3) Incorrect lubricant.

4) Synchronizers worn or broken.

Jumping Out of Gear1) Partial engagement of gear.

2) Transmission misaligned or loose.

3) Worn pilot bearing.

4) End play in main drive gear (bearing retainer

loose or broken, loose or worn bearings on

main drive gear and mainshaft).

5) Worn clutch teeth on main drive gear and/or

worn clutch teeth on synchronizer sleeve.

6) Worn or broken blocking rings.

7) Bent mainshaft.

Sticking in Gear1) Clutch not releasing fully.

2) Low lubricant level.

3) Incorrect lubrication.

4) Defective (tight) main drive gear pilot

bearing.

5) Frozen blocking ring on main drive gear cone.

6) Burred or battered teeth on synchronizer

sleeve and/or main drive gear.

MAINTENANCE AND ADJUSTMENTS

ADJUSTING REVERSE GEARSHIFT BLOCKER1. Engage second speed.

2. Adjust selector ring (a) so that ball on lower end

of shift finger has an equal clearance on both sides

when seated into the transmission case extension bolt

hole. See Figure

7B-7.3. Back off selector ring an additional

l/4 of a turn

and tighten lock nut (B). See Figure

7B-7.SERVICING GEARSHIFT LEVER

Removal1. Unscrew console from floor panel, on small con-

sole remove three (3) attaching screws, on large con-

sole remove four (4) attaching screws. The fourth

screw is accessible after removal of the ash tray. See

Figure

7B-8.2. Remove rubber bellows from cover plate and from

below unbutton protective cap arranged around in-

termediate shift lever.

Page 381 of 625

76.201973 OPEL SERVICE MANUAL

GEARSHIF

INTERMEDIATE SHAFT,

.SHIFT

FINGER1SELECTOR LEVER

JT “B’

78-7Figure’7B.7 Reverse Gearshift Blocker Adjustment

Figure

78-B3. Unhook tension spring of gearshift lever and, after

removal of retaining washer, push pivot pin out of

intermediate shift lever. See Figure

7B-10.1. Prior to installation, grease support and spherical

end of shift finger with protective grease.

2. Replace lever, pivot pin, retaining washer, and

tension spring. Reposition protective cap and bel-

lows and button cap from below. Replace console.

3. In

Figuie 7B-11, distance A - 8.07”.Figure 7B-10

7&l 1Figure 78.1 1

4. After installation, check as to whether pull ring

can be lifted up approximately

.04 to .08”, whereby

the stop sleeve must still rest against intermediate

shift lever. Otherwise, loosen threaded pin forBowden control wire attachment. See Figure 7B- 12.

Adjust distance B

- free travel - by lifting up pull

ring, and retighten threaded pin. See Figure 7B- 13.

REPLACING BOWDEN CONTROL WIRE IN

GEARSHIFT LEVER

1. Remove gearshift lever.

Page 382 of 625

MANUAL TRANSMISSION78.2178-12

Figure 78-l 2

Figure

78.132. Knock off gearshift lever button and loosen

threaded pin for Bowden control wire attachment.

See Figure 7B-12.

3. Drive spiral pin and clamping sleeve out of shift

finger tube and stop sleeve. See Figure 7B-14.

4. Remove shift finger and pull Bowden control wire,

together with thrust spring, out of gearshift lever.

5. Oil sliding surface of stop sleeve on shift finger

tube with clutch oil.

6. After installation of thrust spring, attach newBowden control wire first with clamping sleeve.

When doing this, the cutout of stop sleeve in installa-

tion position shows to the left. The spiral pins must

not protrude on either side.

7. Clamp tight Bowden control wire with threaded

pin. Prior to tightening, pull ring must rest on gear-

shift lever tube and clamping block on pull ring.SPIRAL PINS7B-14

Figure 71-14

8. Heat up new gearshift lever knob in boiling water

to 176 degrees F. and push it onto lever tube. Ob-

serve distance A

- .3”, see Figure 7B-15. The gear-

shift lever tube end is provided with transverse

grooves for which reason the old button can no

longer be used.7515

Figure

78-l 5

9. Attach shift finger with spiral pin and install gear-

shift lever.

REPLACING GEARSHIFT LEVER BELLOWS

1. Remove gearshift lever.

2. Knock off gearshift lever button and pull off bel-

lows over pull ring.