torque OPEL GT-R 1973 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 233 of 625

4A- 21973 OPEL SERVICE MANUAL

PROPELLER SHAFT AND CENTRAL JOINT

CONTENTS

Subject

DESCRIPTION AND OPERATION:

PropellerShaftandCentralJoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

’Propeller Shaft Removal andInstallation

. . . . . . . ..-....Disassembly andAssembly of CentralJoint

. . . . . . . . . . . .SPECIFICATIONS:

Propeller Shaft and Central Joint Specifications . .

DESCRIPTION AND OPEqATlON

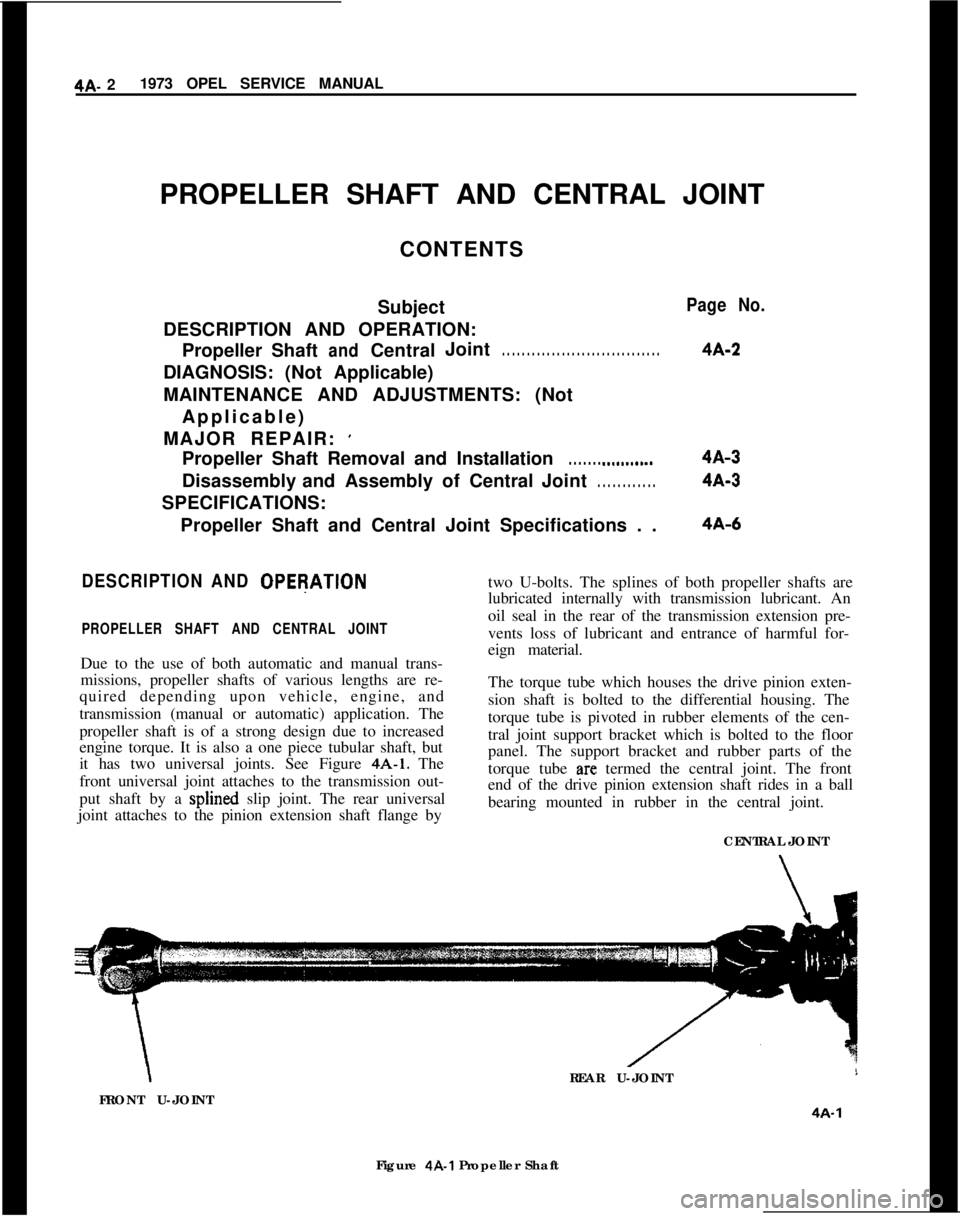

PROPELLER SHAFT AND CENTRAL JOINTDue to the use of both automatic and manual trans-

missions, propeller shafts of various lengths are re-

quired depending upon vehicle, engine, and

transmission (manual or automatic) application. The

propeller shaft is of a strong design due to increased

engine torque. It is also a one piece tubular shaft, but

it has two universal joints. See Figure 4A-1. The

front universal joint attaches to the transmission out-

put shaft by a splined slip joint. The rear universal

joint attaches to the pinion extension shaft flange by

Page No.

4A-2

4A-3

4A-3

4A-6two U-bolts. The splines of both propeller shafts are

lubricated internally with transmission lubricant. An

oil seal in the rear of the transmission extension pre-

vents loss of lubricant and entrance of harmful for-

eign material.

The torque tube which houses the drive pinion exten-

sion shaft is bolted to the differential housing. The

torque tube is pivoted in rubber elements of the cen-

tral joint support bracket which is bolted to the floor

panel. The support bracket and rubber parts of the

torque tube

arc termed the central joint. The front

end of the drive pinion extension shaft rides in a ball

bearing mounted in rubber in the central joint.

CENTRAL JOINT\REAR U-JOINT

FRONT U-JOINT

4A-1Figure 4R1 Propeller Shaft

Page 234 of 625

PROPELLER SHAFT AND CENTRAL JOINT4A- 3MAJOR REPAIR

PROPELLER SHAFT REMOVAL AND

INSTALLATION

Removal

1. Raise rear of car and support on jack stands at rear

jack brackets.

2. Disconnect parking brake cable equalizer from

rod.3. On the Opel

1900 and Manta, unhook parking

brake cable from floor panel.

4. On the Opel 1900 and Manta, unhook exhaust

system and let it down.

5. Mark the mating parts of the U-joint and the drive

pinion extension shaft flange.

6. Loosen bolt locks and remove bolts or nuts.

7. Work propeller shaft slightly forward, lower rear

end of shaft and slide assembly rearward. Remove

thrust spring from front of propeller shaft.

S. Install plug in transmission extension housing to

prevent loss of lubricant.

installation

CAUTION:

Fasteners in the foJlowing steps are impor-

tant attaching parts in that they could affect the

performance of

vital components and systems, and-

/or could

result in major repair expense. They must

be replaced with one of the

samepart number or with

an equivalent part

ifreplacement becomes oecessary.

Do not use a replacement part of lesser quality or

substitute design. Torque values must be used as

specirid during reassembly to assure proper reten-

tion of these parts.1. Remove plug from rear of transmission.

2. Slide thrust spring onto transmission output shaft

and slide propeller shaft through the oil seal and onto

the transmission output shaft. Make certain trans-

mission rear seal is not damaged.

3. Align rear universal joint and pinion flange locat-

ing marks and secure with respective bolts and lock

plates. Torque bolts to 11

lb.ft. Bend lock plate tangs

to secure bolts or nuts.

4. Connect parking brake cable equalizer to brake

rod and adjust to specifications.

5. On the Opel 1900 and Manta connect parking

brake cable to floor panel.DISASSEMBLY AND ASSEMBLY OF THE

CENTRAL JOINT

Disassembly of Central Joint1. Raise and support rear of car under axle tubes.

2. Release brake line bracket from rear of torque

tube.3. Disconnect parking brake cable equalizer and re-

turn spring from brake rod.

4. On the Opel 1900 and Manta, unhook exhaust

system and let it down.

5. Mark universal joint and flange. Disconnect pro-

peller shaft from flange and support it out of the way.

6. Support torque tube with floor jack using mini-

mum pressure.

7. Remove the central joint bracket to underbody

attaching bolts.

8. Allow floor jack to lower the torque tube.

9. Disconnect torque tube from differential carrier by

removing the attaching bolts.

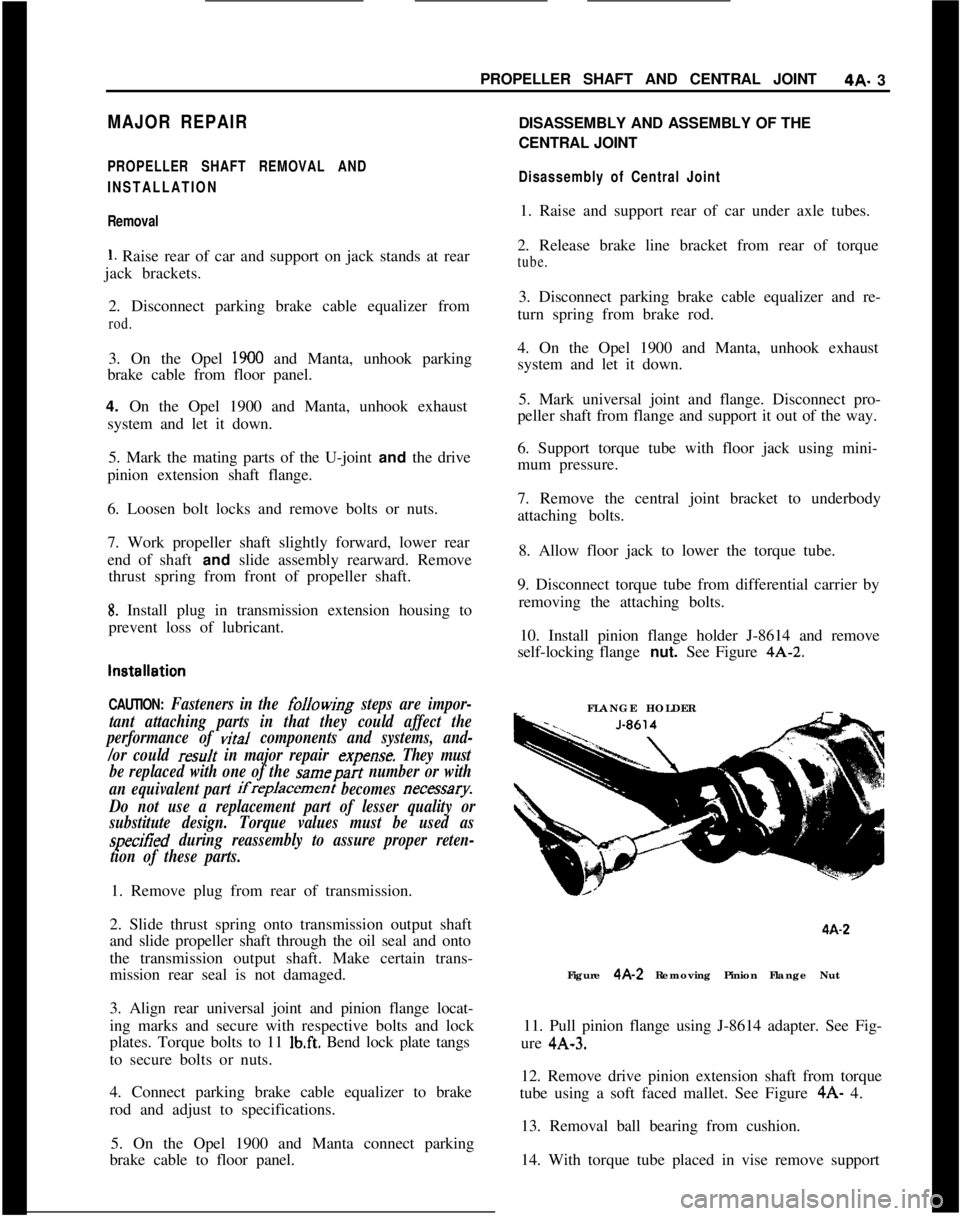

10. Install pinion flange holder J-8614 and remove

self-locking flange nut. See Figure 4A-2.

FLANGE HOLDER4A-2

Figure 4A-2 Removing Pinion Flange Nut

11. Pull pinion flange using J-8614 adapter. See Fig-

ure 4A-3.

12. Remove drive pinion extension shaft from torque

tube using a soft faced mallet. See Figure 4A- 4.

13. Removal ball bearing from cushion.

14. With torque tube placed in vise remove support

Page 235 of 625

4A- 41973 OPEL SERVICE MANUAL

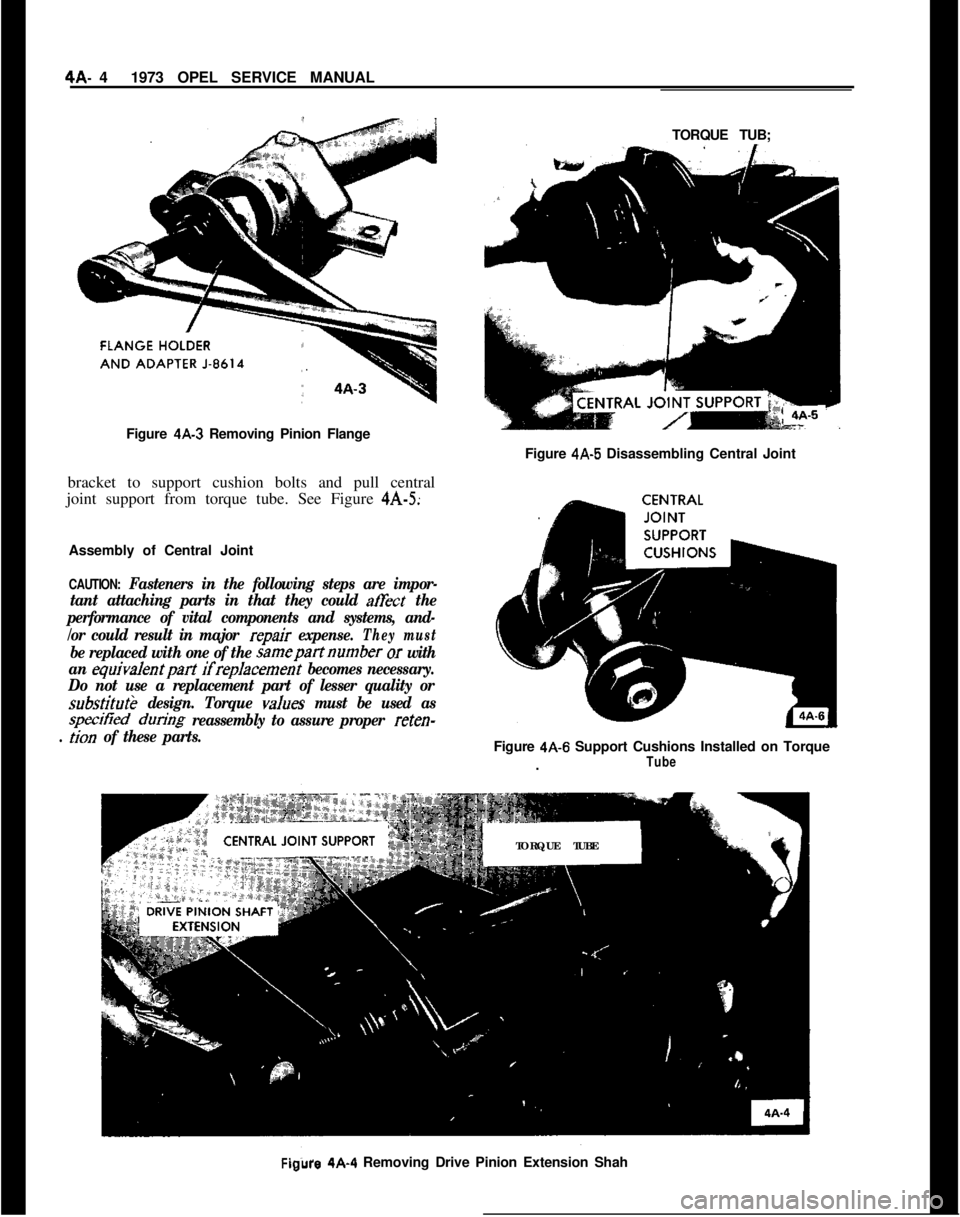

Figure 4A-3 Removing Pinion Flange

bracket to support cushion bolts and pull central

joint support from torque tube. See Figure 4A-5;

Assembly of Central Joint

CAUTION: Fasteners in the following steps are impor-

tant attaching parts in that they could

ah&t the

performance of vital components and systems, and-

/or could result in major

repair expense.They must

be replaced with one of the samepartnumber or with

an

equivalentpart ifreplacement becomes necessary.

Do not use a replacement part of lesser quality or

substitutk design. Torque vah~es must be used as

specitied dun’ng reassembly to assure proper reten-

. lion of these parts.TORQUE TUB;

Figure

4A-5 Disassembling Central Joint

Figure

4A-6 Support Cushions Installed on Torque

.TubeTORQUE TUBE

Figure 4A-4 Removing Drive Pinion Extension Shah

Page 236 of 625

PROPELLER SHAFT AND CENTRAL JOINT4A- 5

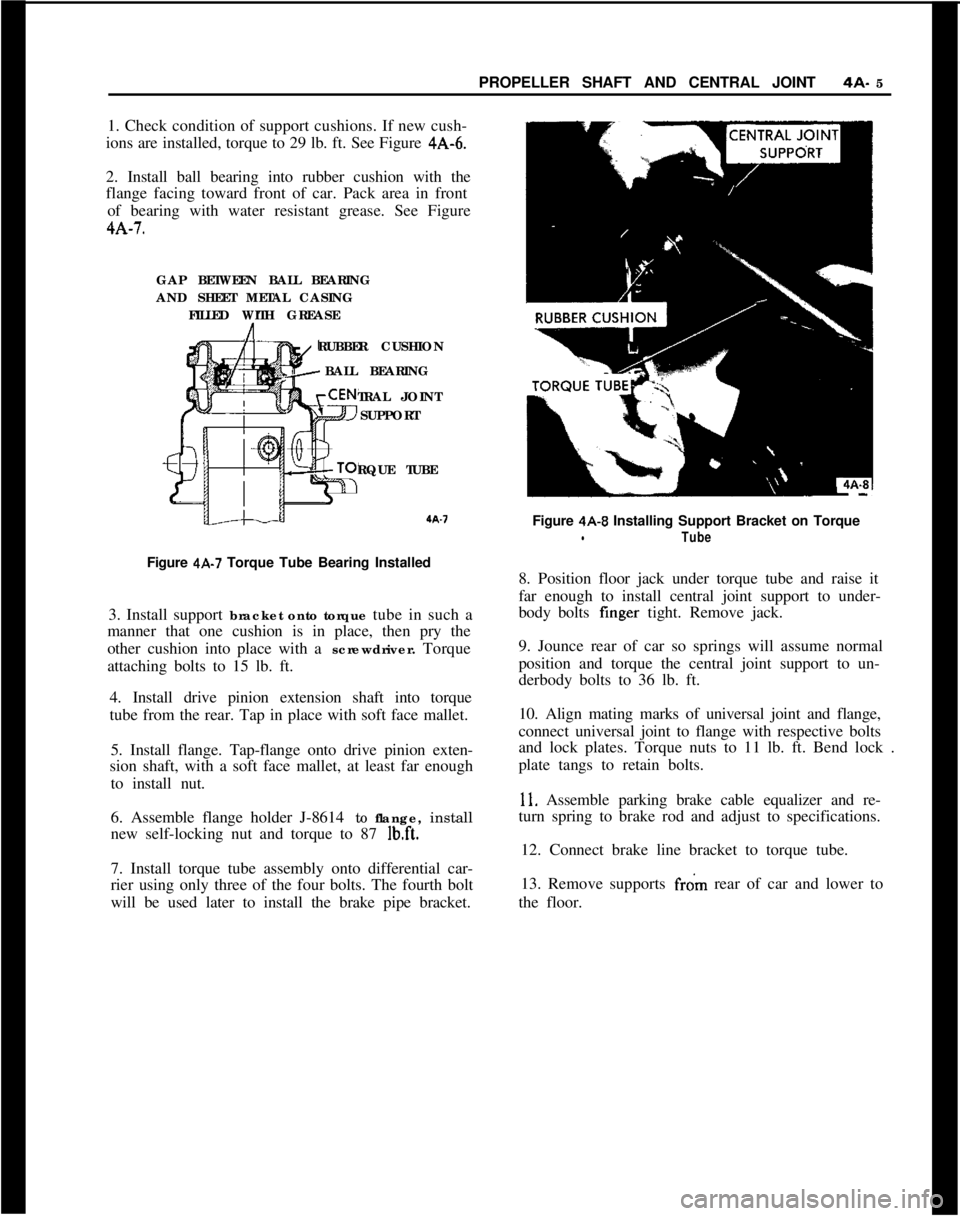

1. Check condition of support cushions. If new cush-

ions are installed, torque to 29 lb. ft. See Figure 4A-6.

2. Install ball bearing into rubber cushion with the

flange facing toward front of car. Pack area in front

of bearing with water resistant grease. See Figure4A-7.

GAP BETWEEN BALL BEARING

AND SHEET METAL CASING

FILLED WITH GREASE

RUBBER CUSHION

BALL BEARING

TRAL JOINT

SUPPORT

RQUE TUBEa.7

Figure 4A-7 Torque Tube Bearing Installed

3. Install support bracket onto torque tube in such a

manner that one cushion is in place, then pry the

other cushion into place with a screwdriver. Torque

attaching bolts to 15 lb. ft.

4. Install drive pinion extension shaft into torque

tube from the rear. Tap in place with soft face mallet.

5. Install flange. Tap-flange onto drive pinion exten-

sion shaft, with a soft face mallet, at least far enough

to install nut.

6. Assemble flange holder J-8614 to flange, install

new self-locking nut and torque to 87

lb.ft.7. Install torque tube assembly onto differential car-

rier using only three of the four bolts. The fourth bolt

will be used later to install the brake pipe bracket.Figure

4A-8 Installing Support Bracket on TorquelTube8. Position floor jack under torque tube and raise it

far enough to install central joint support to under-

body bolts finger tight. Remove jack.

9. Jounce rear of car so springs will assume normal

position and torque the central joint support to un-

derbody bolts to 36 lb. ft.

10. Align mating marks of universal joint and flange,

connect universal joint to flange with respective bolts

and lock plates. Torque nuts to 11 lb. ft. Bend lock .

plate tangs to retain bolts.

11. Assemble parking brake cable equalizer and re-

turn spring to brake rod and adjust to specifications.

12. Connect brake line bracket to torque tube.

13. Remove supports

f&n rear of car and lower to

the floor.

Page 237 of 625

4A- 61973 OPEL SERVICE MANUAL

SPECIFICATIONSPROPELLER SHAFT AND CENTRAL JOINT

SPECIFICATIONS

Tightening Specifications ~

Use a reliable to’rque wrench. Specifications are for clean and lightly-oiled

threads.

Part

Bolt

Bolt

BoltTorque

BoltLocation

Drive Pinion Extension Shaft Flange to Universal

Joint

.._.....................................................................Central Joint Support to Underbody

_.._....._........._..........CentralJointSupport toRubber Cushion

Tube Rubber Cushion to Torque Tube

._.........._...............Support

CushionTorque

Lb.Ft.

1136

15

Page 241 of 625

4B- 101973 OPEL SERVICE MANUAL

Figure 48-Z Removing Rear Axle Assemblyan equiva/entpart ifreplacement becomes necessary.

Do not use a replacement

part of lesser quality or

substitute design. Torque

values must be used as

specified

during reassembly to assure proper reten-

tion of these parts.1. Roll rear axle assembly under car on floor jack and

loosely attach lower control arms to rear axle hous-

ing.

2. Attach central joint support, to underbody with

bolts only finger tight.

3. Lower rear axle assembly, install lower damper

rings in spring seats, coil springs and upper damper

rings on springs. Make certain the damper rings and

springs are properly positioned.

4. Install track rod on axle housing.

5. On Opel 1900 and Manta, place a load of approxi-

mately 350

Ibs. in luggage conipartment or on the

GT, place a load of approximately 150 lbs. on drivers

seat and raise rear axle far enough for underbody to

clear jack stands.

6. Torque central joint support t$ underbody bolts to

36 lb.ft.

7. Torque lower control arm to

Axle housing bolts to

18

Ib.ft. on the GT and 22 lb.ft. dn the Opel 1900 and

Manta.

8. Torque track rod to rear axle attaching nut to

40lb.ft. on the GT and to 76

lb.ft. on the Opel 1900 and

Manta and remove added weight.

9. Install shock abosrbers and tighten nuts to 15

Ib.ft.on the GT and to 47

Ib.ft. on the Opel 1900 and

Manta.10. If car is equipped with stabilizer rod, connect

shackles to axle housing. Tighten to 25 lb. ft.

11. Connect brake hose to brake pipe and install

retaining clip.

12. Thread parking brake cable over exhaust system

and connect to lower control arm brackets, parking

brake actuating lever and brake backing plate. Install

brake drum.

13. Align mating marks and connect propeller shaft

to pinion flange. Tighten universal joint attaching

bolts to 11

Ib.ft. Bend respective lock plate tabs to

secure nuts or bolts.

14. Connect parking brake cable equalizer and return

spring to brake rod and adjust to specifications.

15. Bleed rear brake system and fill master cylinder.

16. Install wheel assemblies and tighten lug nuts to

65

lb.ft.17. Remove jack stands and lower car to the floor.

REMOVAL AND INSTALLATION OF AXLE SHAFT

ASSEMBLY

Removal1. Raise and support rear of car at jack brackets.

2. Remove wheel and brake drum as necessary.

3. Unscrew rear axle shaft retaining plate and with

axle shaft puller J-8805 coupled with slide hammer

J- 2619 on axle shaft flange, remove axle shaft.

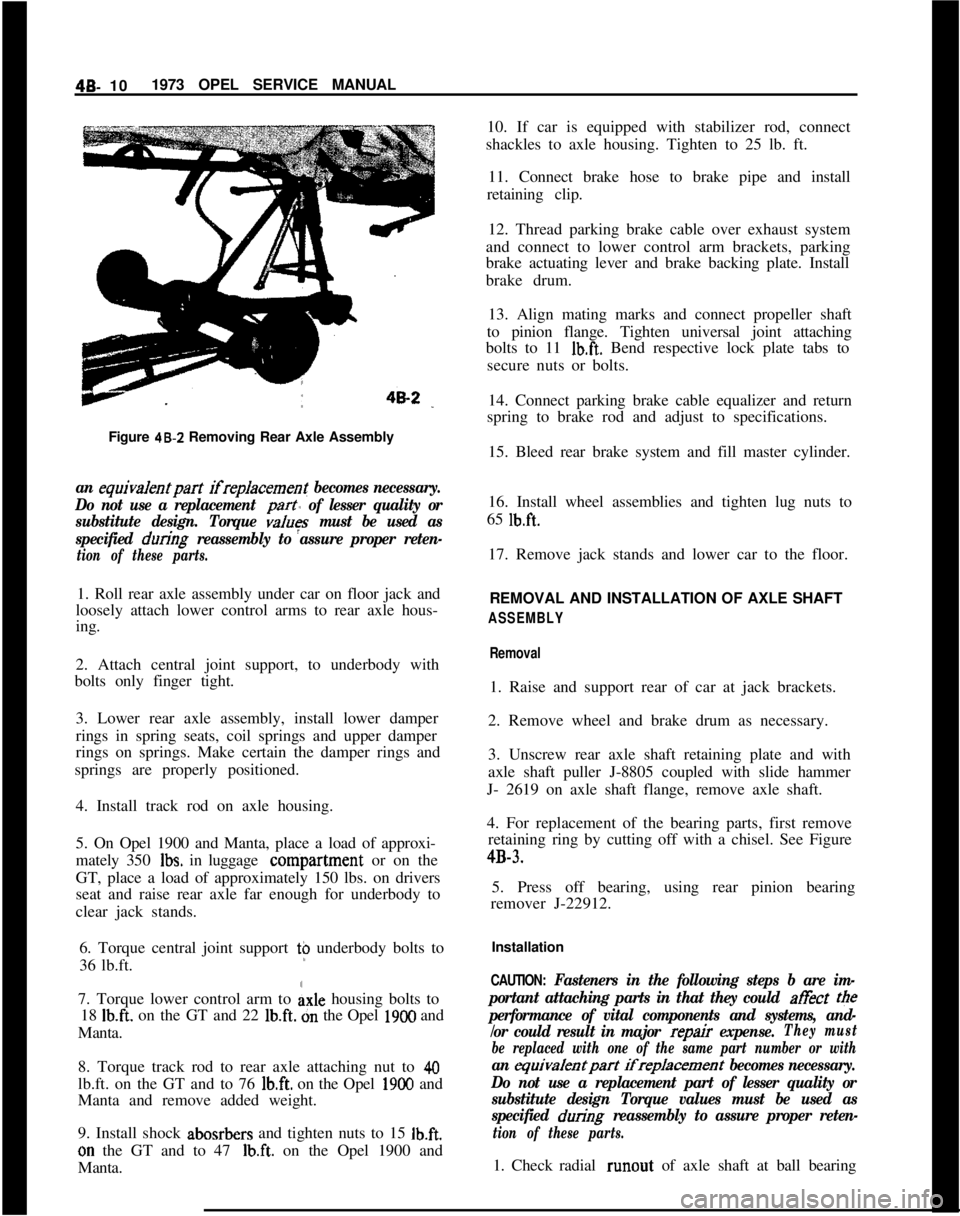

4. For replacement of the bearing parts, first remove

retaining ring by cutting off with a chisel. See Figure4B-3.

5. Press off bearing, using rear pinion bearing

remover J-22912.

Installation

CAUTION: Fasteners in the following steps b are im-

portant attaching parts in that they could at&t

tee

performance of vital components and systems, and-

/or could result in major

repair expense.They must

be replaced with one of the same part number or with

an equivalentpart ifreplacement becomes necessary.

Do not use a replacement part of lesser quality or

substitute design Torque values must be used as

specified

during reassembly to assure proper reten-

tion of these parts.1. Check radial runout of axle shaft at ball bearing

Page 242 of 625

REAR AXLE40- 11

Figure

48-3 Removing Axle Bearing Retaining Ring

seat and lateral runout of axle shaft flange near larg

est diameter.

Permissible radial runout is .002”, and permissible

“lateral runout is

.OO4”. An axle shaft which exceeds

these tolerances, or one which has been otherwise

damaged during removal, must be replaced.

2. Using installer ring J-21721-2, press on bearing so

that oil seal groove on bearing faces shaft splines.

3. Using installer ring J-21721-2, press on retainer

ring so that shoulder faces bearing.

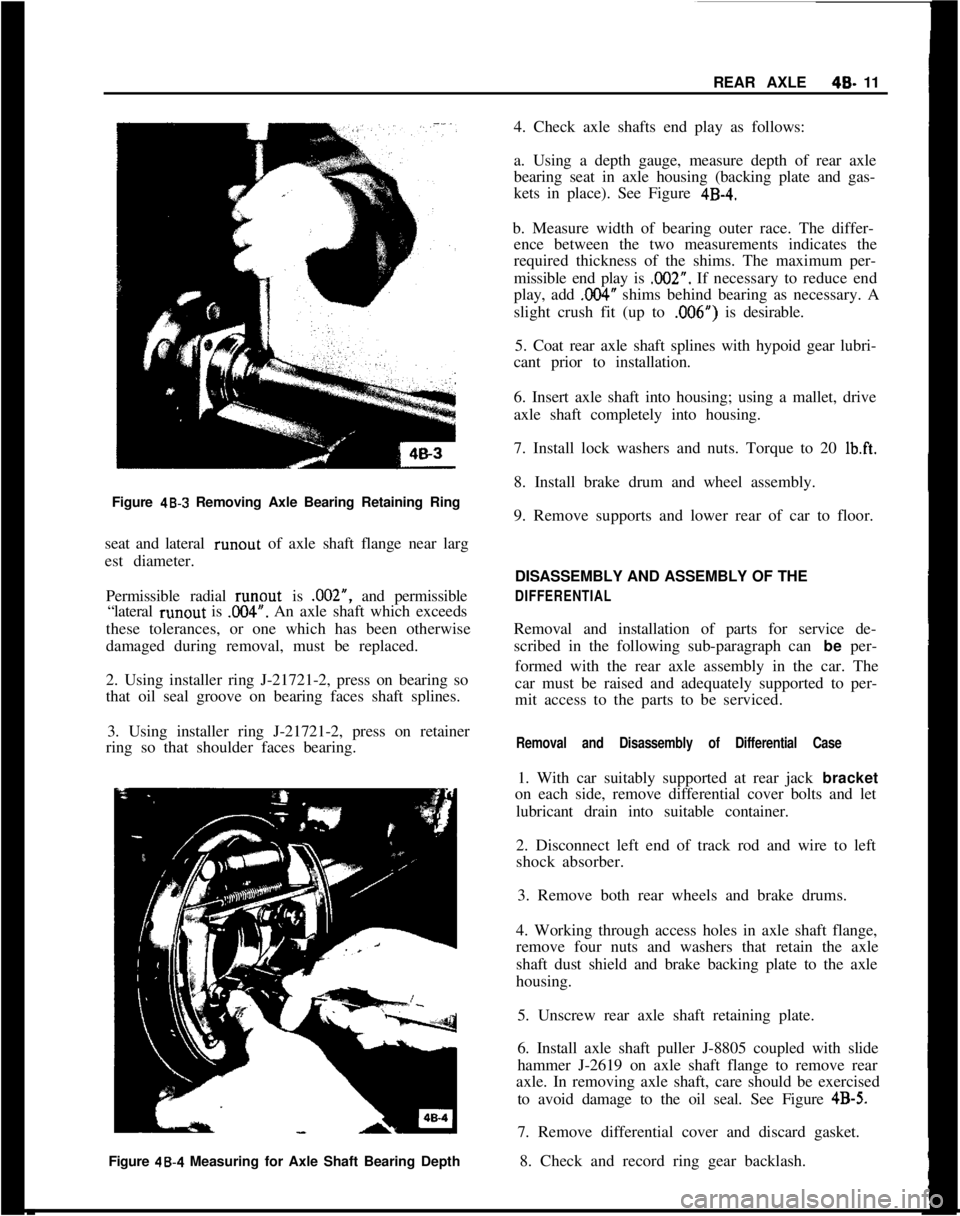

Figure 48.4 Measuring for Axle Shaft Bearing Depth4. Check axle shafts end play as follows:

a. Using a depth gauge, measure depth of rear axle

bearing seat in axle housing (backing plate and gas-

kets in place). See Figure

4B-4.b. Measure width of bearing outer race. The differ-

ence between the two measurements indicates the

required thickness of the shims. The maximum per-

missible end play is .002”. If necessary to reduce end

play, add

,004” shims behind bearing as necessary. A

slight crush fit (up to ,006”) is desirable.

5. Coat rear axle shaft splines with hypoid gear lubri-

cant prior to installation.

6. Insert axle shaft into housing; using a mallet, drive

axle shaft completely into housing.

7. Install lock washers and nuts. Torque to 20

Ib.ft.8. Install brake drum and wheel assembly.

9. Remove supports and lower rear of car to floor.

DISASSEMBLY AND ASSEMBLY OF THE

DIFFERENTIALRemoval and installation of parts for service de-

scribed in the following sub-paragraph can be per-

formed with the rear axle assembly in the car. The

car must be raised and adequately supported to per-

mit access to the parts to be serviced.

Removal and Disassembly of Differential Case1. With car suitably supported at rear jack bracket

on each side, remove differential cover bolts and let

lubricant drain into suitable container.

2. Disconnect left end of track rod and wire to left

shock absorber.

3. Remove both rear wheels and brake drums.

4. Working through access holes in axle shaft flange,

remove four nuts and washers that retain the axle

shaft dust shield and brake backing plate to the axle

housing.

5. Unscrew rear axle shaft retaining plate.

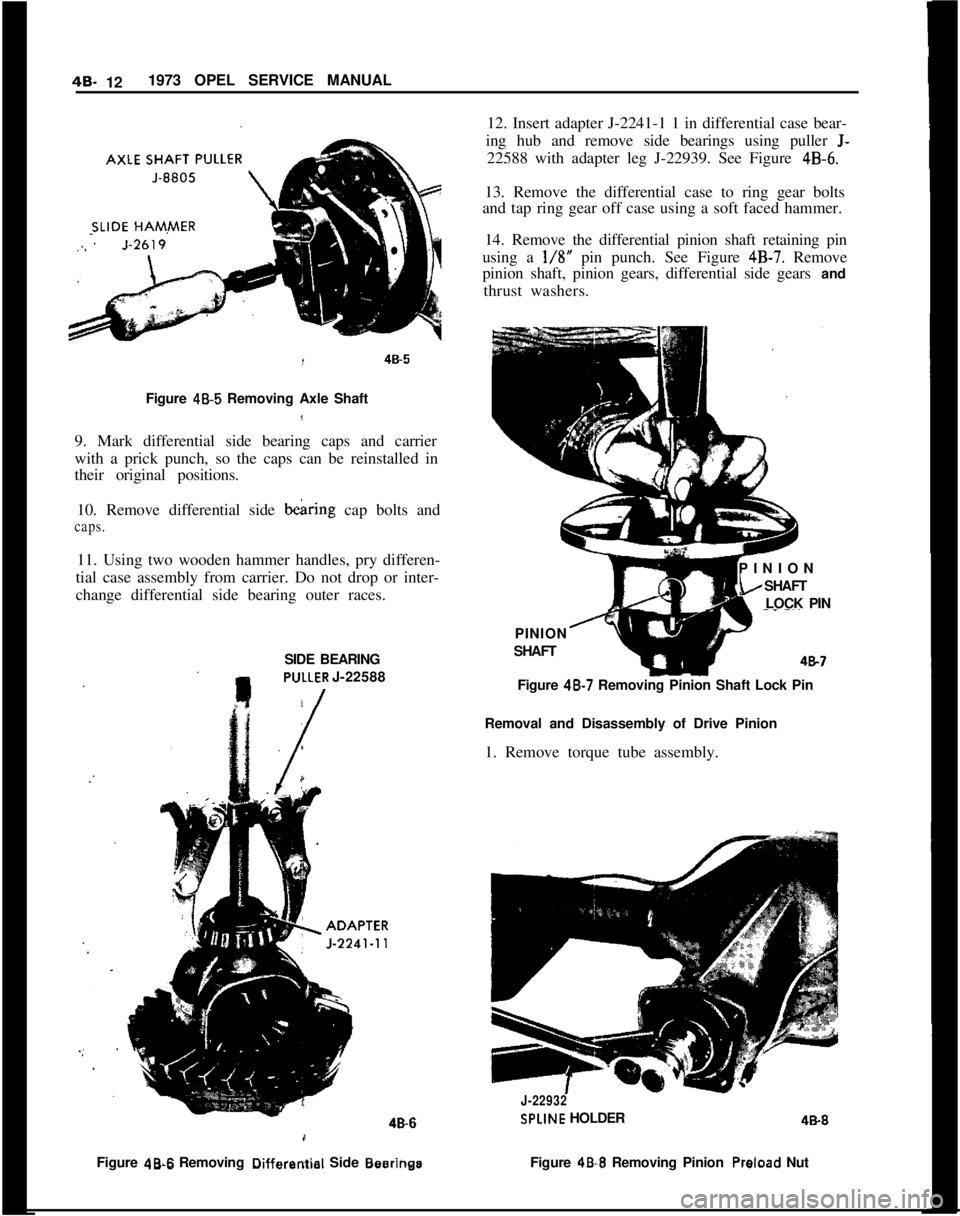

6. Install axle shaft puller J-8805 coupled with slide

hammer J-2619 on axle shaft flange to remove rear

axle. In removing axle shaft, care should be exercised

to avoid damage to the oil seal. See Figure

4B-5.7. Remove differential cover and discard gasket.

8. Check and record ring gear backlash.

Page 243 of 625

4S- 121973 OPEL SERVICE MANUAL

12. Insert adapter J-2241-1 1 in differential case bear-

ing hub and remove side bearings using puller J-22588 with adapter leg J-22939. See Figure

4B-6.13. Remove the differential case to ring gear bolts

and tap ring gear off case using a soft faced hammer.

14. Remove the differential pinion shaft retaining pin

using a

l/8” pin punch. See Figure 4B-7. Remove

pinion shaft, pinion gears, differential side gears and

thrust washers.

Figure 46.5 Removing Axle Shaft18

9. Mark differential side bearing caps and carrier

with a prick punch, so the caps can be reinstalled in

their original positions.

10. Remove differential side bearing cap bolts and

caps.11. Using two wooden hammer handles, pry differen-

tial case assembly from carrier. Do not drop or inter-

change differential side bearing outer races.

SIDE BEARING

PVLLER J-2258846.6

/NFigure

48-S Removing Differentiel Side BesrlngaPINION

SHAFTPINION

kSHAFT

LOCK PIN487

Figure 48-7 Removing Pinion Shaft Lock Pin

Removal and Disassembly of Drive Pinion

1. Remove torque tube assembly.

J-22932

SPLINE HOLDER4&8

Figure

48-E Removing Pinion Preload Nut

Page 245 of 625

46. 141973 OPEL SERVICE MANUAL

2. Install rear pinion bearing outer race (without

shims) using installer J-7818 and driver handle

J-8092. See Figure 4B-12.

3. To determine the correct pinion depth setting use

the following procedures:

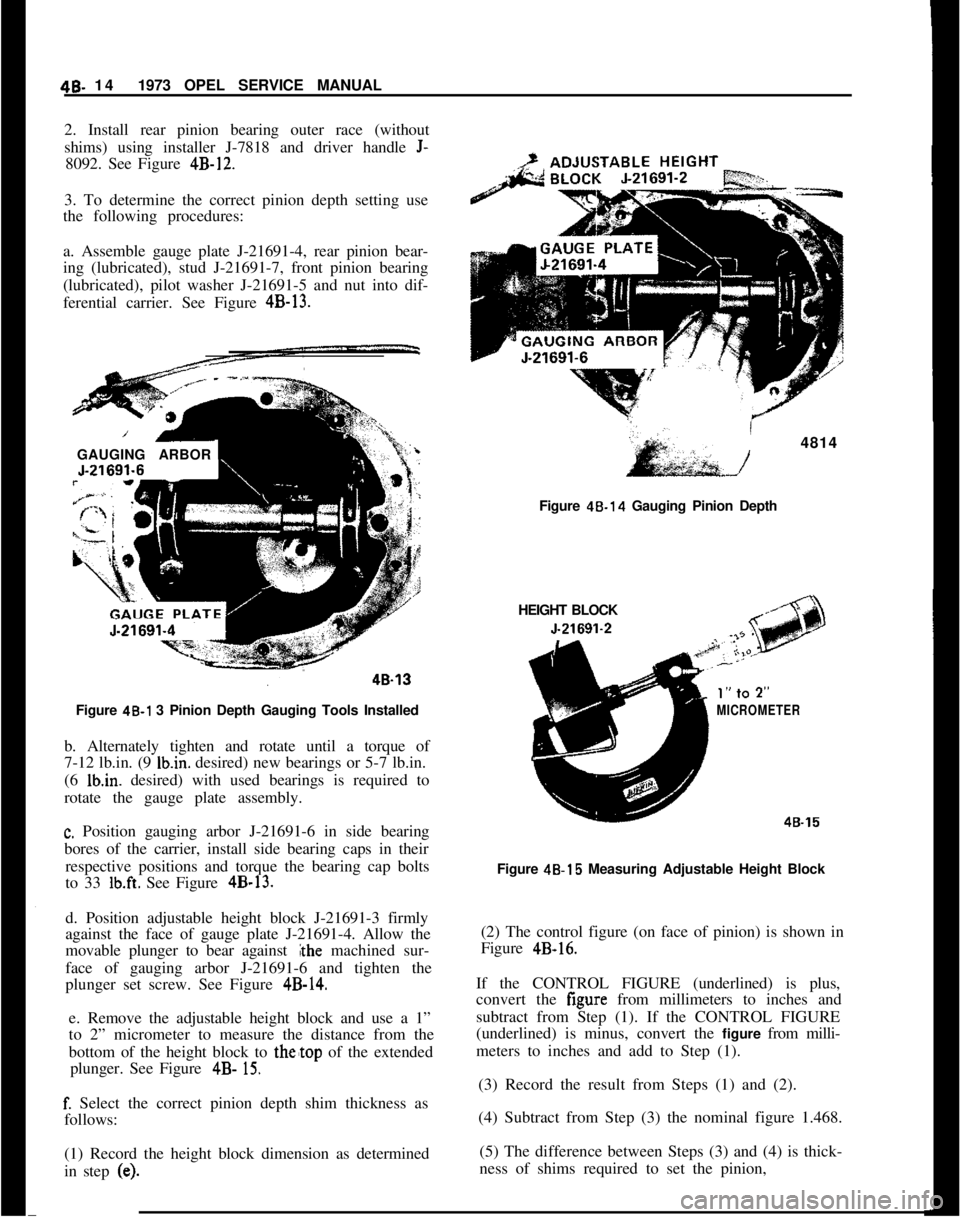

a. Assemble gauge plate J-21691-4, rear pinion bear-

ing (lubricated), stud J-21691-7, front pinion bearing

(lubricated), pilot washer J-21691-5 and nut into dif-

ferential carrier. See Figure 4B-13.

‘1GAUGING ARBOR

Figure 48-l 3 Pinion Depth Gauging Tools Installed

b. Alternately tighten and rotate until a torque of

7-12 lb.in. (9 Ibin. desired) new bearings or 5-7 lb.in.

(6 lb.in. desired) with used bearings is required to

rotate the gauge plate assembly.

c. Position gauging arbor J-21691-6 in side bearing

bores of the carrier, install side bearing caps in their

respective positions and torque the bearing cap bolts

to 33

lb.ft. See Figure 4B-13.

d. Position adjustable height block J-21691-3 firmly

against the face of gauge plate J-21691-4. Allow the

movable plunger to bear against

#the machined sur-

face of gauging arbor J-21691-6 and tighten the

plunger set screw. See Figure

4B-14.e. Remove the adjustable height block and use a 1”

to 2” micrometer to measure the distance from the

bottom of the height block to

thetop of the extended

plunger. See Figure

4B- 15.

f. Select the correct pinion depth shim thickness as

follows:

(1) Record the height block dimension as determined

in step

(e).

I4814

/Figure 48.14 Gauging Pinion Depth

HEIGHT BLOCK

MICROMETER

48-15Figure 4B-15 Measuring Adjustable Height Block

(2) The control figure (on face of pinion) is shown in

Figure

4B-16.If the CONTROL FIGURE (underlined) is plus,

convert the figure from millimeters to inches and

subtract from Step (1). If the CONTROL FIGURE

(underlined) is minus, convert the figure from milli-

meters to inches and add to Step (1).

(3) Record the result from Steps (1) and (2).

(4) Subtract from Step (3) the nominal figure 1.468.

(5) The difference between Steps (3) and (4) is thick-

ness of shims required to set the pinion,

Page 248 of 625

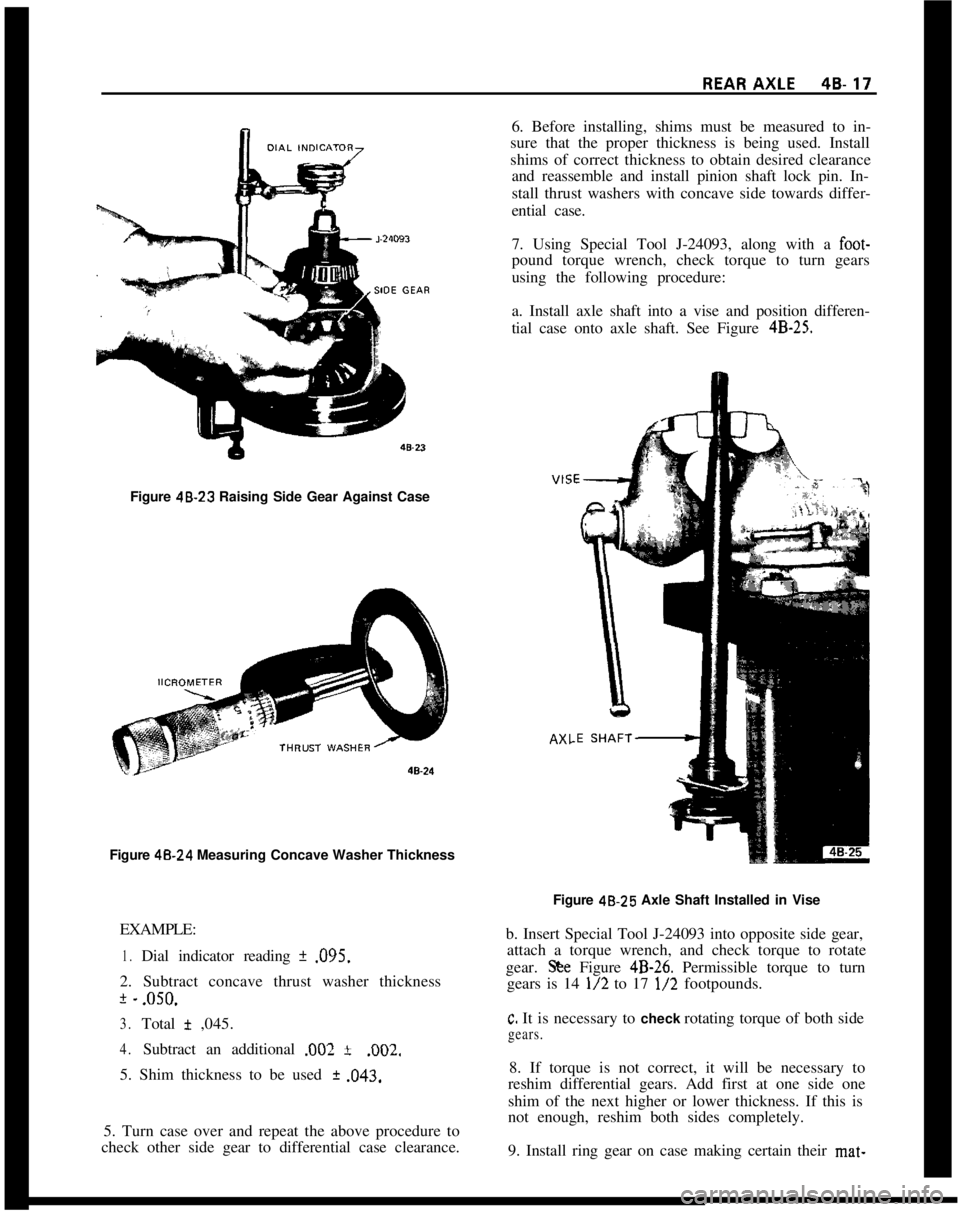

6. Before installing, shims must be measured to in-

sure that the proper thickness is being used. Install

shims of correct thickness to obtain desired clearance

and reassemble and install pinion shaft lock pin. In-

stall thrust washers with concave side towards differ-

ential case.

7. Using Special Tool J-24093, along with a foot-pound torque wrench, check torque to turn gears

using the following procedure:

a. Install axle shaft into a vise and position differen-

tial case onto axle shaft. See Figure

4B-25.Figure 48-23 Raising Side Gear Against Case

Figure 48.24 Measuring Concave Washer Thickness

AX,EXAMPLE:

1.Dial indicator reading * .095.

2. Subtract concave thrust washer thickness

+ -.oso.

3.Total + ,045.

4.Subtract an additional .002 *.002.

5. Shim thickness to be used

+ .043.

5. Turn case over and repeat the above procedure to

check other side gear to differential case clearance.Figure 48.25 Axle Shaft Installed in Vise

b. Insert Special Tool J-24093 into opposite side gear,

attach a torque wrench, and check torque to rotate

gear. S& Figure

4B-26. Permissible torque to turn

gears is 14

l/2 to 17 l/2 footpounds.

c. It is necessary to check rotating torque of both side

gears.8. If torque is not correct, it will be necessary to

reshim differential gears. Add first at one side one

shim of the next higher or lower thickness. If this is

not enough, reshim both sides completely.

9. Install ring gear on case making certain their mat-