PEUGEOT 3008 2014 Owners Manual

Manufacturer: PEUGEOT, Model Year: 2014, Model line: 3008, Model: PEUGEOT 3008 2014Pages: 389, PDF Size: 22.92 MB

Page 201 of 389

10

Checks199

Checks

Unless otherwise indicated, check these components in accordance with the warranty and maintenance record and according to your engine. Other wise, have them checked by a PEUGEOT dealer or a qualified workshop.

Replace the oil filter each time the engine oil is changed. Refer to the warranty and maintenance record for details of the replacement interval for this component.

Oil filter

Refer to the warranty and maintenance record for details of the replacement intervals for these components. Depending on the environment (e.g. dusty atmosphere) and the use of the vehicle (e.g. city driving), replace them twice as often if necessary . if necessary . if necessary A clogged passenger compartment filter may have an adverse effect on the per formance of the air conditioning system and generate undesirable odours.

Air filter and passenger compartment filter

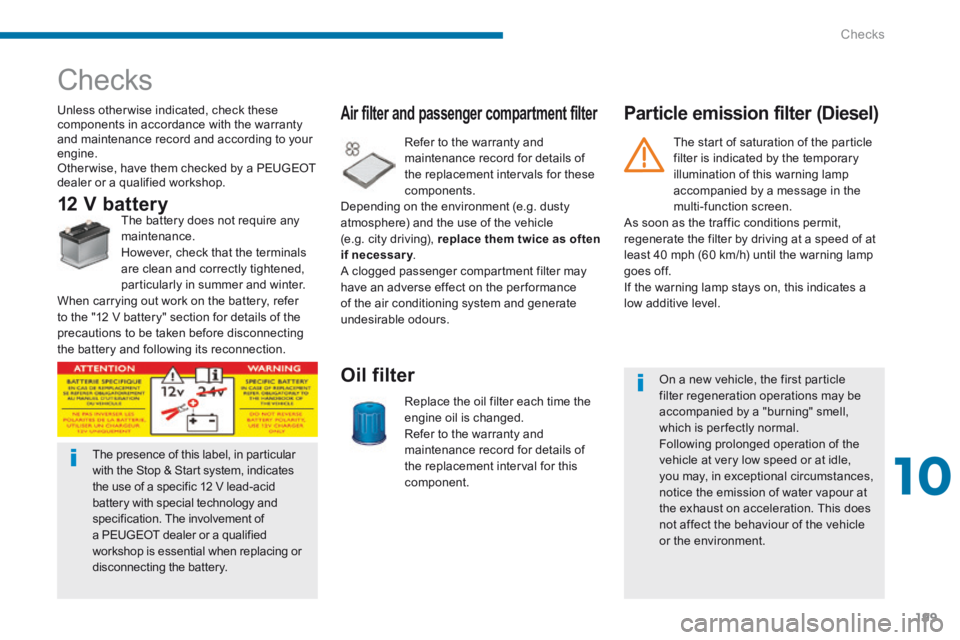

12 V battery The battery does not require any

maintenance. However, check that the terminals are clean and correctly tightened, particularly in summer and winter. When carrying out work on the battery, refer to the "12 V battery" section for details of the precautions to be taken before disconnecting the battery and following its reconnection.

Particle emission filter (Diesel)

On a new vehicle, the first particle filter regeneration operations may be accompanied by a "burning" smell, which is per fectly normal.

Following prolonged operation of the vehicle at very low speed or at idle, you may, in exceptional circumstances, notice the emission of water vapour at the exhaust on acceleration. This does not affect the behaviour of the vehicle or the environment.

The presence of this label, in particular with the Stop & Start system, indicates the use of a specific 12 V lead-acid battery with special technology and specification. The involvement of a PEUGEOT dealer or a qualified workshop is essential when replacing or disconnecting the battery.

The start of saturation of the particle filter is indicated by the temporary illumination of this warning lamp accompanied by a message in the multi-function screen. As soon as the traffic conditions permit, regenerate the filter by driving at a speed of at least 40 mph (60 km/h) until the warning lamp goes off. If the warning lamp stays on, this indicates a low additive level.

Page 202 of 389

Checks

200

Brake disc wear

Brake pads

Brake wear depends on the style of driving, particularly in the case of vehicles used in town, over short distances. It may be necessary to have the condition of the brakes checked, even between vehicle services. Unless there is a leak in the circuit, a drop in the brake fluid level indicates that the brake pads are worn.

For information on checking brake disc wear, contact a PEUGEOT dealer or a qualified workshop.

Manual gearbox

The gearbox does not require any maintenance (no oil change). Refer to the warranty and maintenance record for the details of the level checking interval for this component.

Electronic gearbox

The gearbox does not require any maintenance (no oil change). Refer to the warranty and maintenance record for details of the checking interval for this component.

Automatic gearbox

The gearbox does not require any maintenance (no oil change). Refer to the warranty and maintenance record for details of the level checking interval for this component.

This system does not require any routine servicing. However, in the event of a problem, have the system checked by a PEUGEOT dealer or a qualified workshop.

Electric parking brake

Only use products recommended by PEUGEOT or products of equivalent quality and specification. In order to optimise the operation of units as important as those in the braking system, PEUGEOT selects and offers very specific products. After washing the vehicle, dampness, or in wintry conditions, ice can form on the brake discs and pads: braking efficiency may be reduced. Make light brake applications to dry and defrost the brakes.

For more information, refer to the "Electric parking brake - Operating faults" section.

Page 203 of 389

11

Practical information201

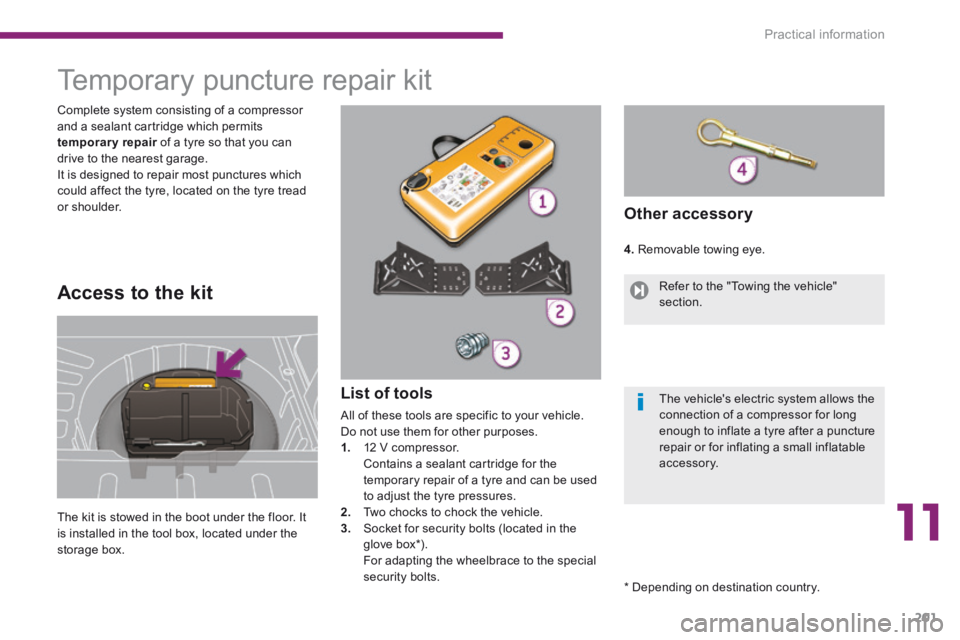

Temporary puncture repair kit

The kit is stowed in the boot under the floor. It is installed in the tool box, located under the storage box.

Complete system consisting of a compressor and a sealant cartridge which permits temporary repair of a tyre so that you can temporary repair of a tyre so that you can temporary repairdrive to the nearest garage. It is designed to repair most punctures which could affect the tyre, located on the tyre tread or shoulder.

List of tools

All of these tools are specific to your vehicle.

Do not use them for other purposes. 1. 12 V compressor. Contains a sealant cartridge for the temporary repair of a tyre and can be used to adjust the tyre pressures. 2. Two chocks to chock the vehicle. 3. Socket for security bolts (located in the glove box*) . For adapting the wheelbrace to the special security bolts.

4. Removable towing eye.

Access to the kit

Other accessory

Refer to the "Towing the vehicle" section.

The vehicle's electric system allows the connection of a compressor for long enough to inflate a tyre after a puncture repair or for inflating a small inflatable accessory.

* Depending on destination country.

Page 204 of 389

Practical information

202

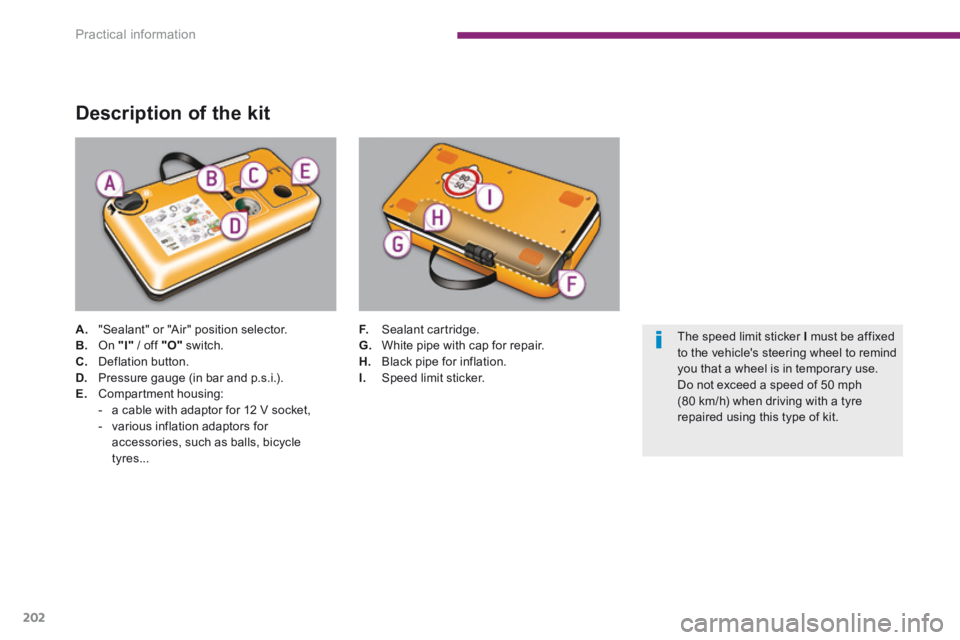

Description of the kit

A. "Sealant" or "Air" position selector. B. On "I" / off "O" switch. C. Deflation button. D. Pressure gauge (in bar and p.s.i.). E. Compartment housing: - a cable with adaptor for 12 V socket, - various inflation adaptors for

accessories, such as balls, bicycle tyres...

F. Sealant cartridge. G. White pipe with cap for repair. H. Black pipe for inflation. I. Speed limit sticker.

The speed limit sticker I must be affixed to the vehicle's steering wheel to remind you that a wheel is in temporary use. Do not exceed a speed of 50 mph (80 km/h) when driving with a tyre repaired using this type of kit.

Page 205 of 389

11

Practical information203

Repair procedure

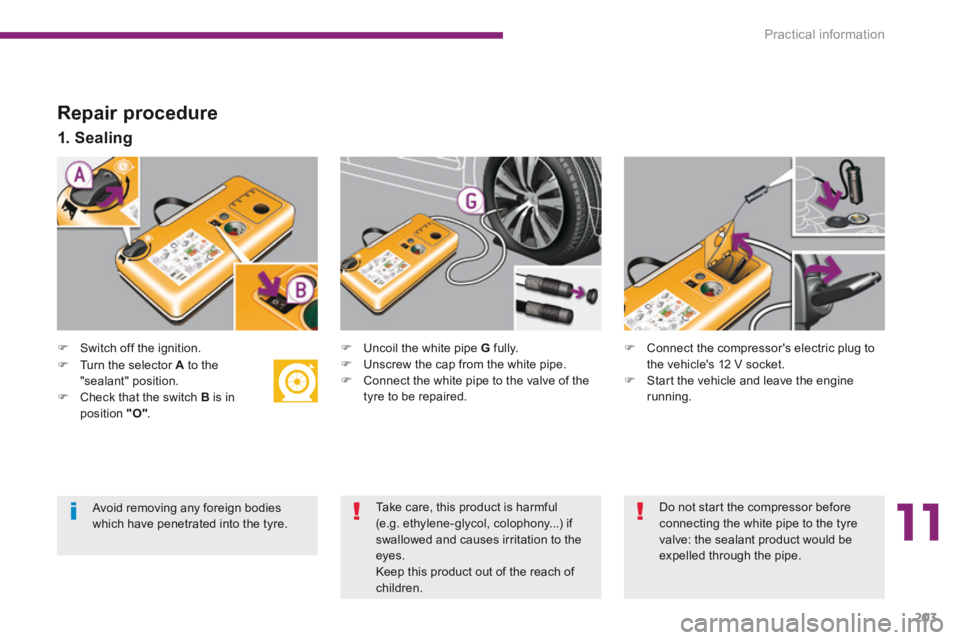

Switch off the ignition.

1. Sealing

Uncoil the white pipe G fully. Unscrew the cap from the white pipe. Connect the white pipe to the valve of the tyre to be repaired.

Connect the compressor's electric plug to the vehicle's 12 V socket. Start the vehicle and leave the engine running.

Turn the selector A to the "sealant" position. Check that the switch B is in position "O" .

Take care, this product is harmful (e.g. ethylene-glycol, colophony...) if swallowed and causes irritation to the eyes. Keep this product out of the reach of children.

Avoid removing any foreign bodies which have penetrated into the tyre.

Do not start the compressor before connecting the white pipe to the tyre valve: the sealant product would be expelled through the pipe.

Page 206 of 389

Practical information

204

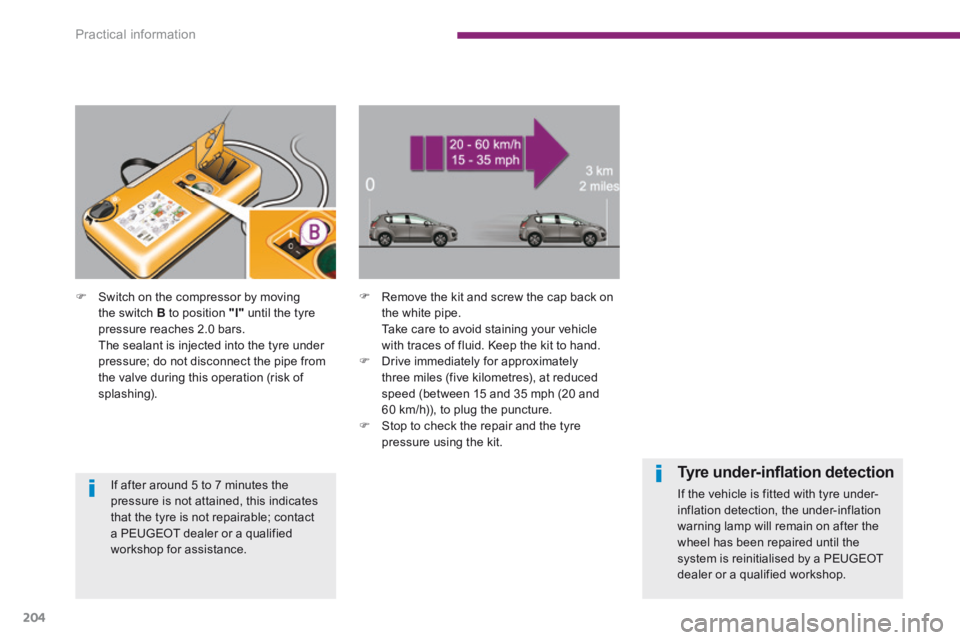

Remove the kit and screw the cap back on the white pipe. Take care to avoid staining your vehicle with traces of fluid. Keep the kit to hand. Drive immediately for approximately three miles (five kilometres), at reduced speed (between 15 and 35 mph (20 and 60 km/h)), to plug the puncture. Stop to check the repair and the tyre pressure using the kit.

Switch on the compressor by moving the switch B to position "I" until the tyre pressure reaches 2.0 bars. The sealant is injected into the tyre under pressure; do not disconnect the pipe from the valve during this operation (risk of splashing).

If after around 5 to 7 minutes the pressure is not attained, this indicates that the tyre is not repairable; contact a PEUGEOT dealer or a qualified workshop for assistance.

Tyre under-infl ation detection

If the vehicle is fitted with tyre under-inflation detection, the under-inflation warning lamp will remain on after the

wheel has been repaired until the system is reinitialised by a PEUGEOT dealer or a qualified workshop.

Page 207 of 389

11

Practical information205

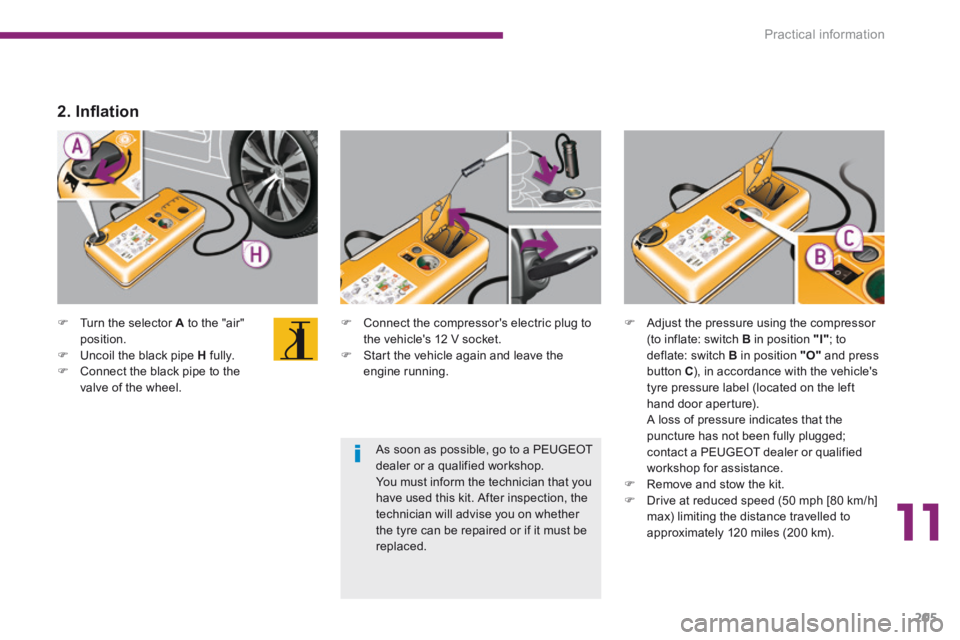

Turn the selector A to the "air" position. Uncoil the black pipe H fully. Connect the black pipe to the valve of the wheel.

Connect the compressor's electric plug to the vehicle's 12 V socket. Start the vehicle again and leave the engine running.

Adjust the pressure using the compressor (to inflate: switch B in position "I" ; to deflate: switch B in position "O" and press button C ), in accordance with the vehicle's tyre pressure label (located on the left hand door aperture). A loss of pressure indicates that the puncture has not been fully plugged; contact a PEUGEOT dealer or qualified workshop for assistance. Remove and stow the kit. Drive at reduced speed (50 mph [80 km/h] max) limiting the distance travelled to approximately 120 miles (200 km).

2 . I n fl a t i o n

As soon as possible, go to a PEUGEOT dealer or a qualified workshop. You must inform the technician that you have used this kit. After inspection, the technician will advise you on whether the tyre can be repaired or if it must be replaced.

Page 208 of 389

Practical information

206

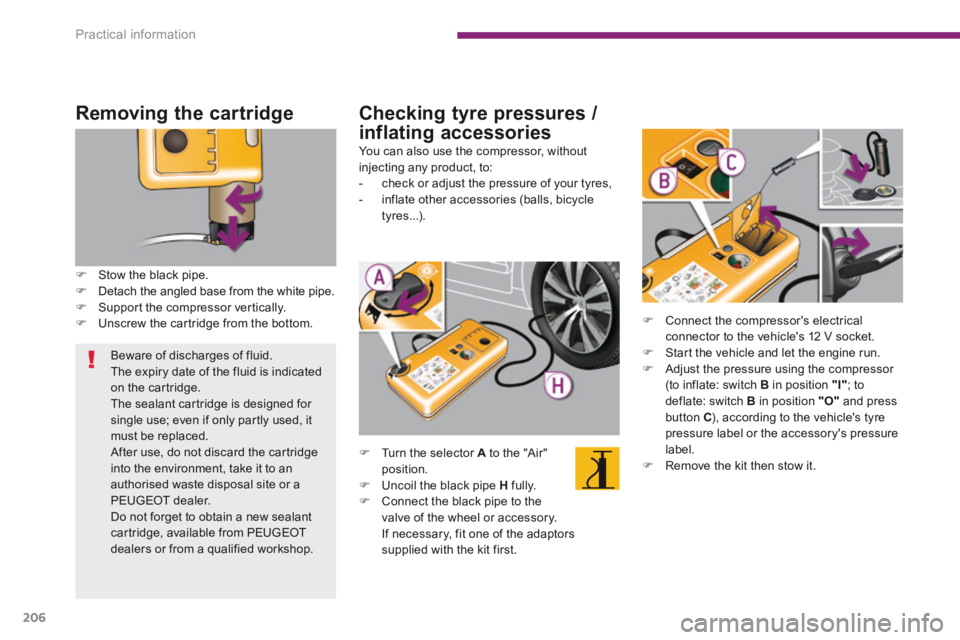

Removing the cartridge

Stow the black pipe. Detach the angled base from the white pipe. Support the compressor vertically. Unscrew the cartridge from the bottom.

Checking tyre pressures /

inflating accessories

Turn the selector A to the "Air" position. Uncoil the black pipe H fully. Connect the black pipe to the valve of the wheel or accessory. If necessary, fit one of the adaptors supplied with the kit first.

You can also use the compressor, without injecting any product, to: - check or adjust the pressure of your tyres, - inflate other accessories (balls, bicycle tyres...).

Connect the compressor's electrical connector to the vehicle's 12 V socket. Start the vehicle and let the engine run. Adjust the pressure using the compressor (to inflate: switch B in position "I" ; to deflate: switch B in position "O" and press button C ), according to the vehicle's tyre

pressure label or the accessory's pressure label. Remove the kit then stow it.

Beware of discharges of fluid. The expiry date of the fluid is indicated on the cartridge. The sealant cartridge is designed for single use; even if only partly used, it

must be replaced. After use, do not discard the cartridge into the environment, take it to an authorised waste disposal site or a PEUGEOT dealer. Do not forget to obtain a new sealant cartridge, available from PEUGEOT dealers or from a qualified workshop.

Page 209 of 389

11

Practical information207

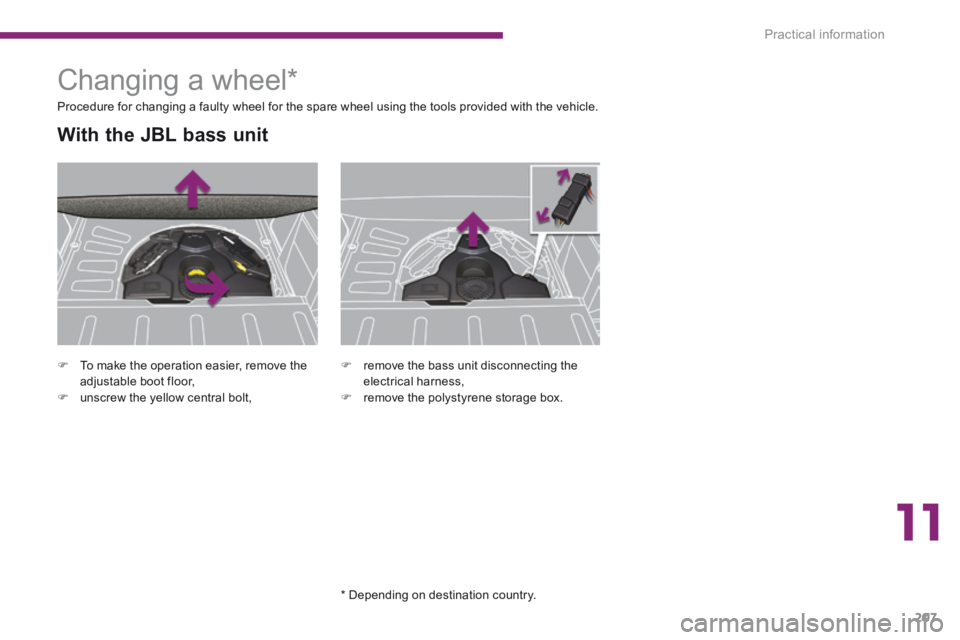

To make the operation easier, remove the adjustable boot floor, unscrew the yellow central bolt,

With the JBL bass unit

remove the bass unit disconnecting the electrical harness, remove the polystyrene storage box.

Changing a wheel *

Procedure for changing a faulty wheel for the spare wheel using the tools provided with the vehicle.

* Depending on destination country.

Page 210 of 389

Practical information

208

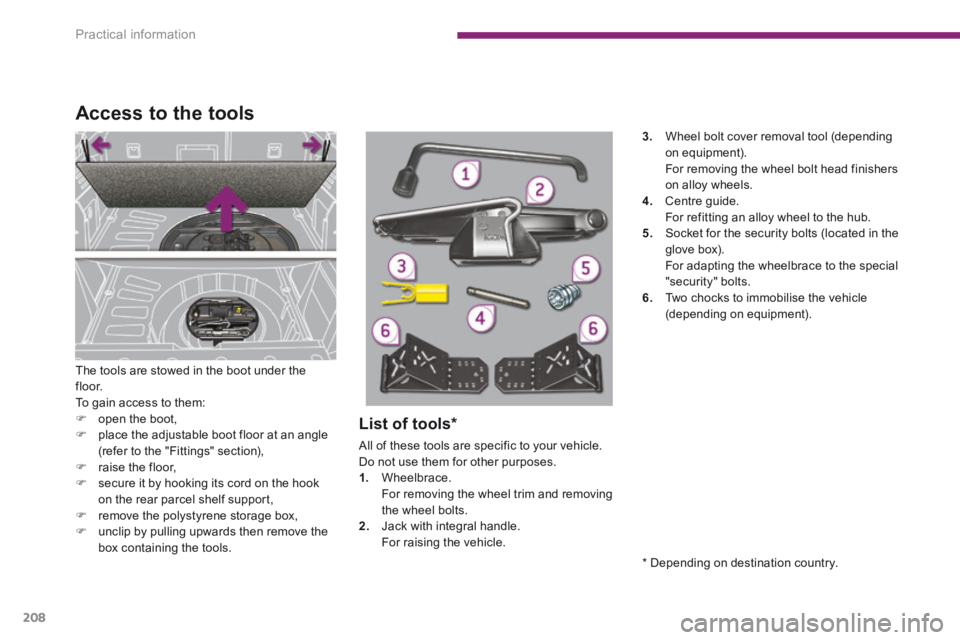

The tools are stowed in the boot under the f l o o r. To gain access to them: open the boot, place the adjustable boot floor at an angle (refer to the "Fittings" section), raise the floor, secure it by hooking its cord on the hook on the rear parcel shelf support, remove the polystyrene storage box, unclip by pulling upwards then remove the box containing the tools.

Access to the tools

* Depending on destination country.

List of tools *

All of these tools are specific to your vehicle. Do not use them for other purposes. 1. Wheelbrace. For removing the wheel trim and removing the wheel bolts. 2. Jack with integral handle. For raising the vehicle.

3. Wheel bolt cover removal tool (depending on equipment). For removing the wheel bolt head finishers on alloy wheels. 4. Centre guide. For refitting an alloy wheel to the hub.

5. Socket for the security bolts (located in the glove box). For adapting the wheelbrace to the special "security" bolts. 6. Two chocks to immobilise the vehicle (depending on equipment).