PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1291 of 1825

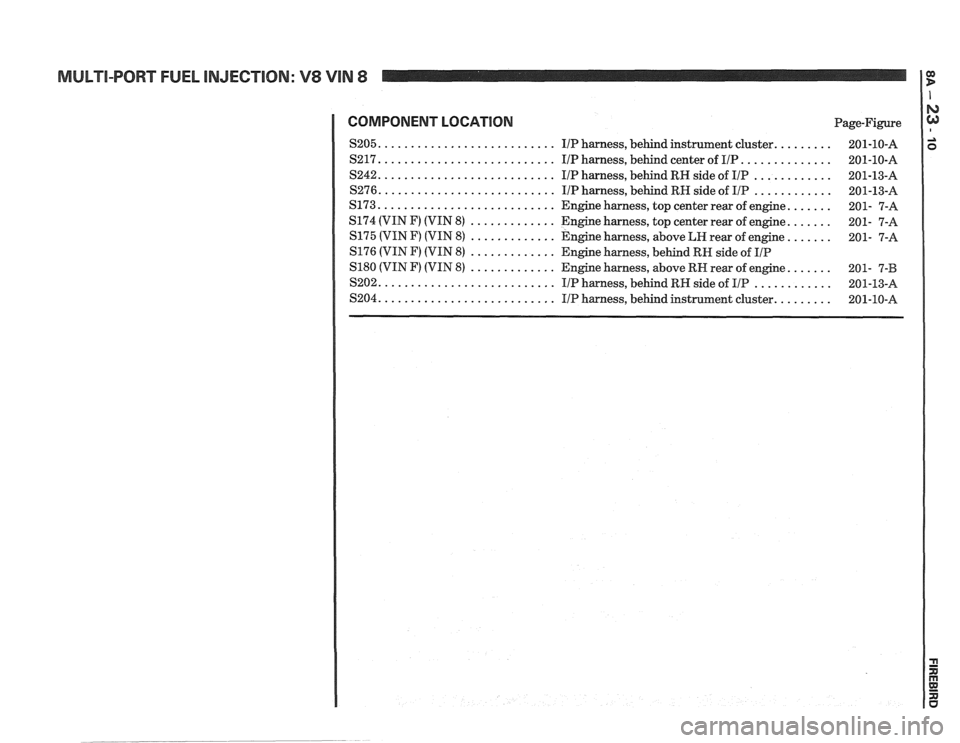

MULTI-PORT FUEL INJECTION: V8 VIN 8 1:

COMPONENT LOCATION Page-Figure

........ S205. .......................... IIP harness, behind instrument cluster.

.............. S217. .......................... IIP harness, behind center of IIP

S242. .......................... IIP harness, behind RH side of IIP ............

............ S276. .......................... I/P harness, behind RH side of IIP

S173. .......................... Engine harness, top center rear of engine. ......

S174 (VIN F) (VIN 8) ............. Engine harness, top center rear of engine. ......

S175 (VIN F) (VIN 8) ............. Engine harness, above LR rear of engine. ......

S176 (VIN F) (VIN 8) ............. Engine harness, behind RH side of IIP

S180 (VIN F) (VIN 8) ............. Engine harness, above RN rear of engine. ......

S202. .......................... IIP harness, behind RH side of IIP ............

S204. .......................... IIP harness, behind instrument cluster. ........

Page 1292 of 1825

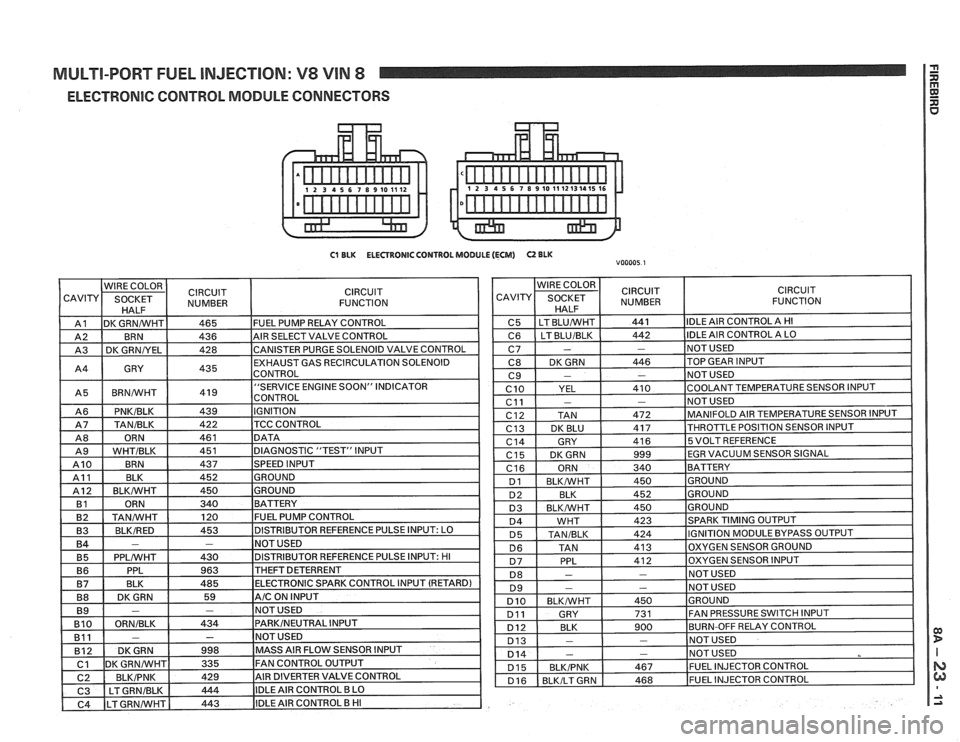

MULTI-PORT FUEL INJECTION: V8 VIN 8

ELECTRONIC CONTROL MODULE CONNECTORS

C1 ELK ELECTRONIC CONTROL MODULE (ECM) 0 BLK voooo5 1

Page 1293 of 1825

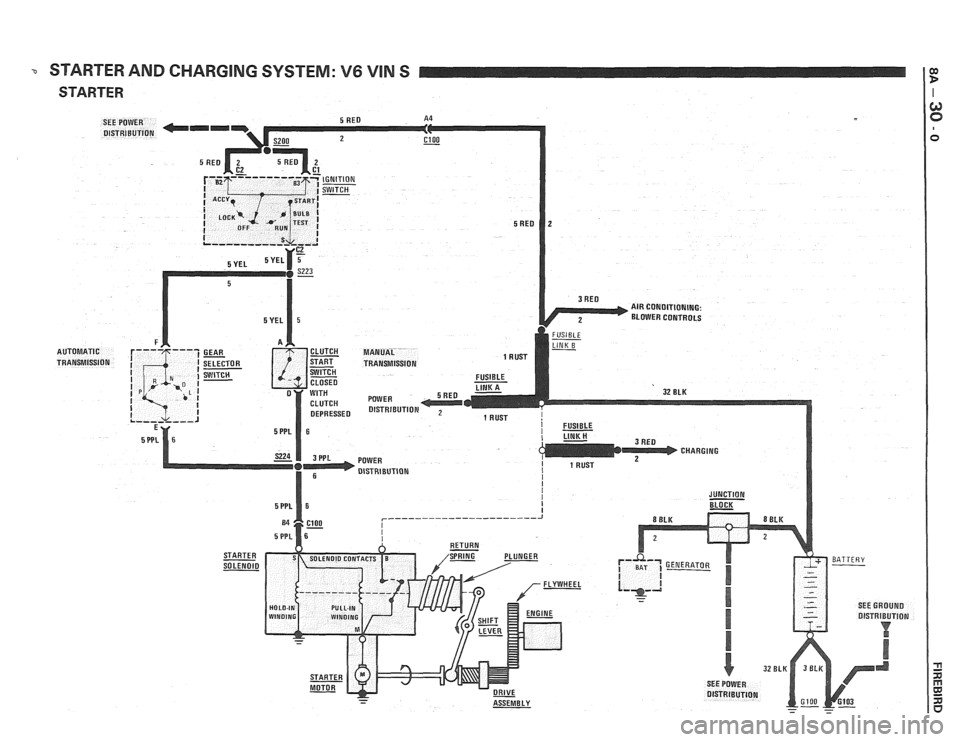

STARTER AND CHARGING SYSTEM: V6 VIN S :

STARTER I

Page 1294 of 1825

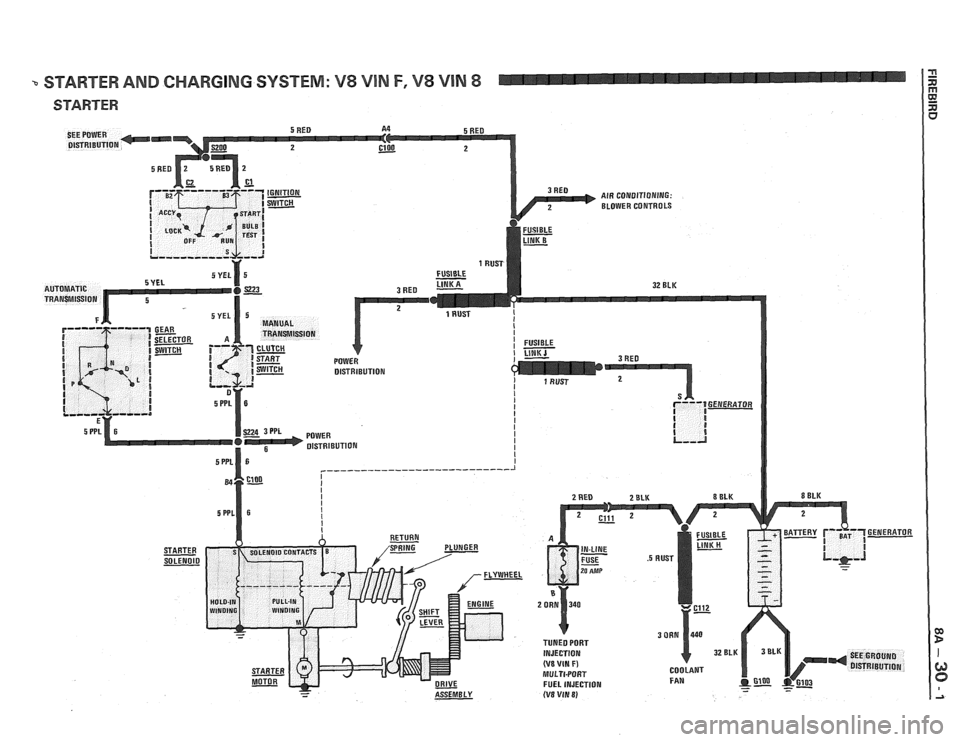

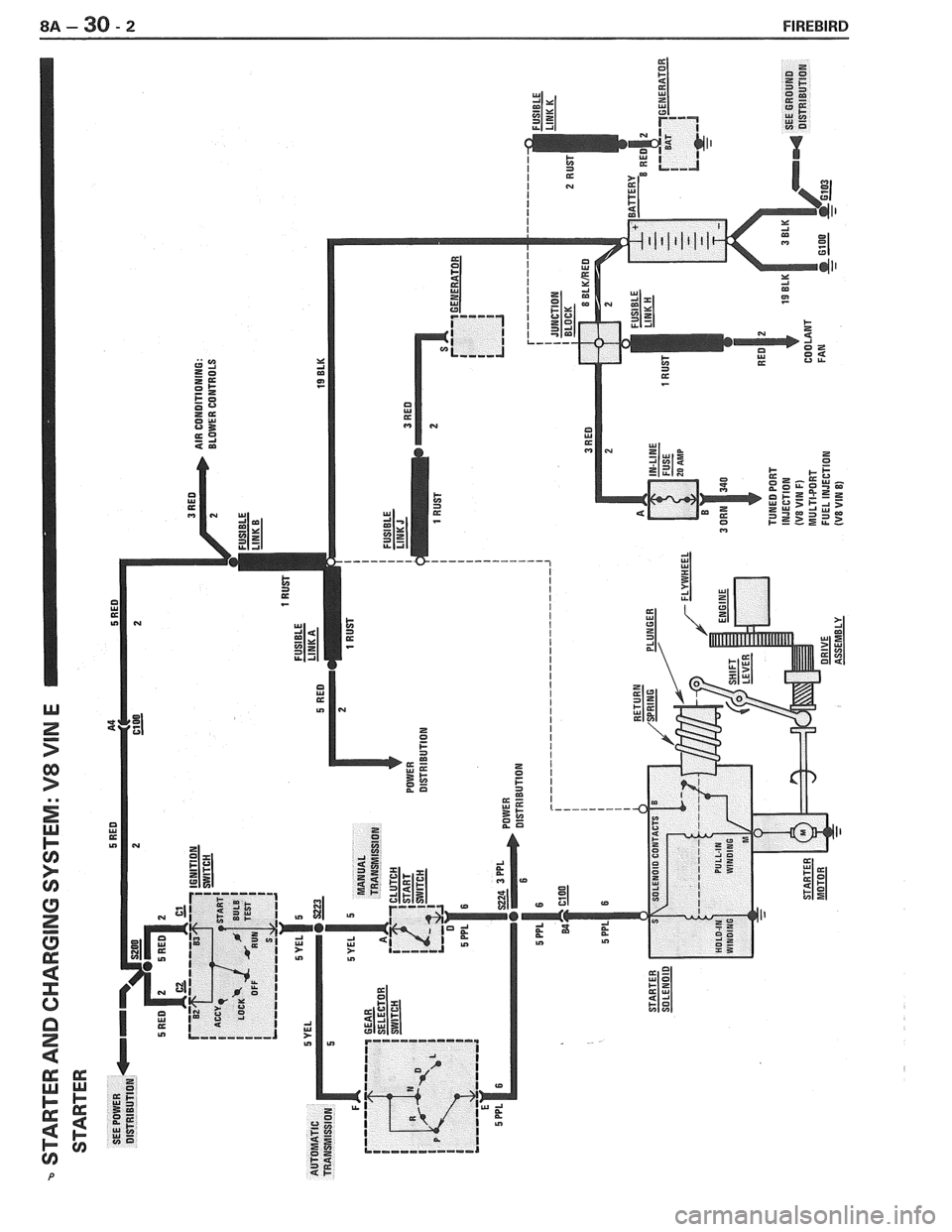

% STARTER AND CHARGING SYSTEM: V8 VIN F, V8 VIN 8 41 20 A E - kl STARTER a

Page 1295 of 1825

Page 1296 of 1825

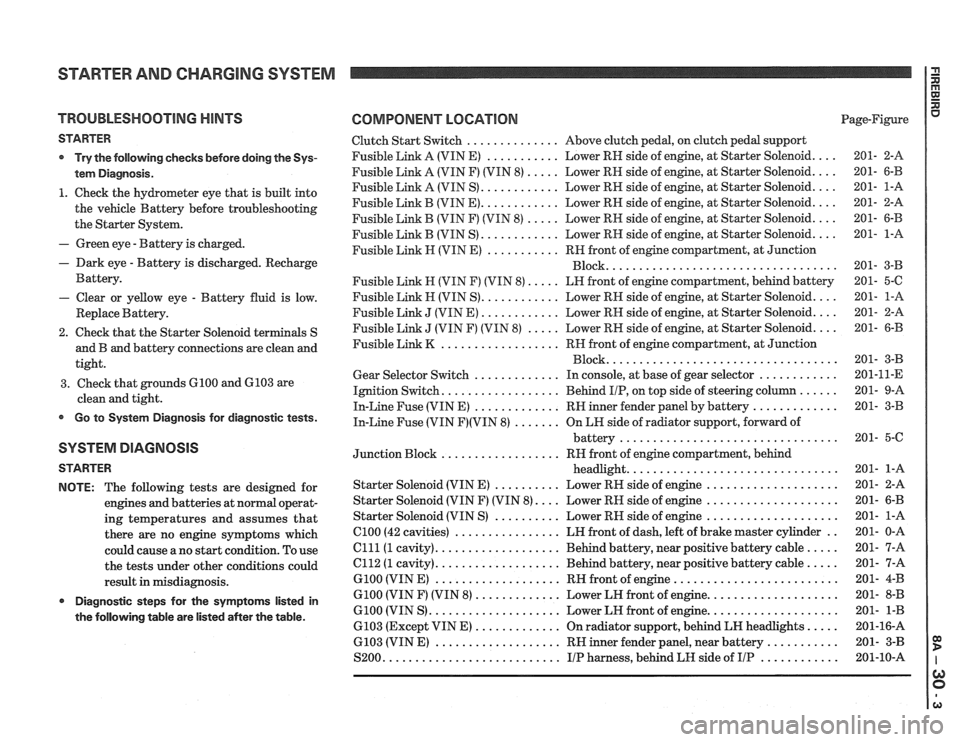

TROUBLESHOOTING HINTS

STARTER

Try the following checks before doing

the Sys-

tem Diagnosis

.

1 . Check the hydrometer eye that is built into

the vehicle Battery before troubleshooting

the Starter System

.

. Green eye . Battery is charged .

. Dark eye . Battery is discharged . Recharge

Battery

.

- Clear or yellow eye . Battery fluid is low .

Replace Battery .

2 . Check that the Starter Solenoid te

and B and battery

connections are clean and

tight

.

3 . Check that grounds 6100 and 6103 are

clean and tight

.

Go to System Diagnosis for diagnostic tests .

SYSTEM DIAGNOSIS

STARTER

NOTE:

The following tests are designed for

engines and batteries at normal operat-

ing temperatures and assumes that

there are no engine symptoms which

could cause a no start condition

. To use

the tests under other conditions could

result in misdiagnosis

.

Diagnostic steps for the symptorns listed in

the following table are listed after the table

.

COMPONENT LOCATION Page-Figure

Clutch Start Switch

.............. Above clutch pedal. on clutch pedal support

Fusible Link A (VIN E)

........... Lower RH side of engine. at Starter Solenoid .... 201- 2-A

Fusible Link A (VIN F) (VIN

8) ..... Lower RH side of engine. at Starter Solenoid .... 201- 6-B

Fusible Link A (VIN S)

............ Lower RH side of engine. at Starter Solenoid .... 201- 1-A

Fusible Link B (VIN

E) ............ Lower RH side of engine. at Starter Solenoid .... 201- 2-A

Fusible Link

B (VIN F) (VIN 8) ..... Lower RH side of engine. at Starter Solenoid .... 201- 6-B

Fusible Link B (VIN S)

............ Lower RH side of engine. at Starter Solenoid .... 201- 1-A

Fusible Link

H (VIN E) ........... RN front of engine compartment. at Junction

................................... Block 201- 3-B

Fusible Link

H (VIN F) (VIN 8) ..... LH front of engine compartment. behind battery 201- 5-C

Fusible

Link H (VIN S) ............ Lower RH side of engine. at Starter Solenoid .... 201- 1-A

Fusible Link

J (VIN E) ............ Lower RH side of engine. at Starter Solenoid .... 201- 2-A

Fusible Link

J (VIN F) (VIN 8) ..... Lower RH side of engine. at Starter Solenoid .... 201- 6-B

Fusible Link

K .................. RH front of engine compartment. at Junction

................................... Block 201- 3-B

Gear Selector Switch

............. In console. at base of gear selector ............ 201-11-E

Ignition Switch

.................. Behind IIP. on top side of steering column ...... 201- 9-A

In-Line Fuse (VIN E)

............. RH inner fender panel by battery ............. 201- 3-B

In-Line Fuse (VIN F)(VIN 8) ....... On LN side of radiator support. forward of

battery

................................. 201- 5-C

Junction Block

.................. RH front of engine compartment. behind

headlight

................................ 201- 1-A

Starter Solenoid (VIN

E) .......... Lower RH side of engine .................... 201- 2-A

Starter Solenoid (VIN F) (VIN

8) .... Lower RH side of engine .................... 201- 6-B

Starter Solenoid (VIN S)

.......... Lower RH side of engine .................... 201- 1-A

el00 (42 cavities) ................ LH front of dash. left of brake master cylinder .. 201- 0-A

Clll(1 cavity) ................... Behind battery. near positive battery cable ..... 201- 7-A

el12 (1 cavity) ................... Behind battery. near positive battery cable ..... 201- 7-A

G100 (VIN E) ................... RH front of engine ......................... 201- 4-B

G100 (VIN F) (VIN 8) ............. Lower LH front of engine .................... 201- 8-B

6100 (VIN S) .................... Lower LH front of engine .................... 201- 1-B

6103 (Except VIN

E) ............. On radiator support. behind LH headlights ..... 201-16-A

6103 (VIN

E) ................... RH inner fender panel. near battery ........... 201- 3-B

S200

........................... IIP harness. behind LH side of IIP ............ 201-10-A

Page 1297 of 1825

STARTER AND CHARGING SYSTEM

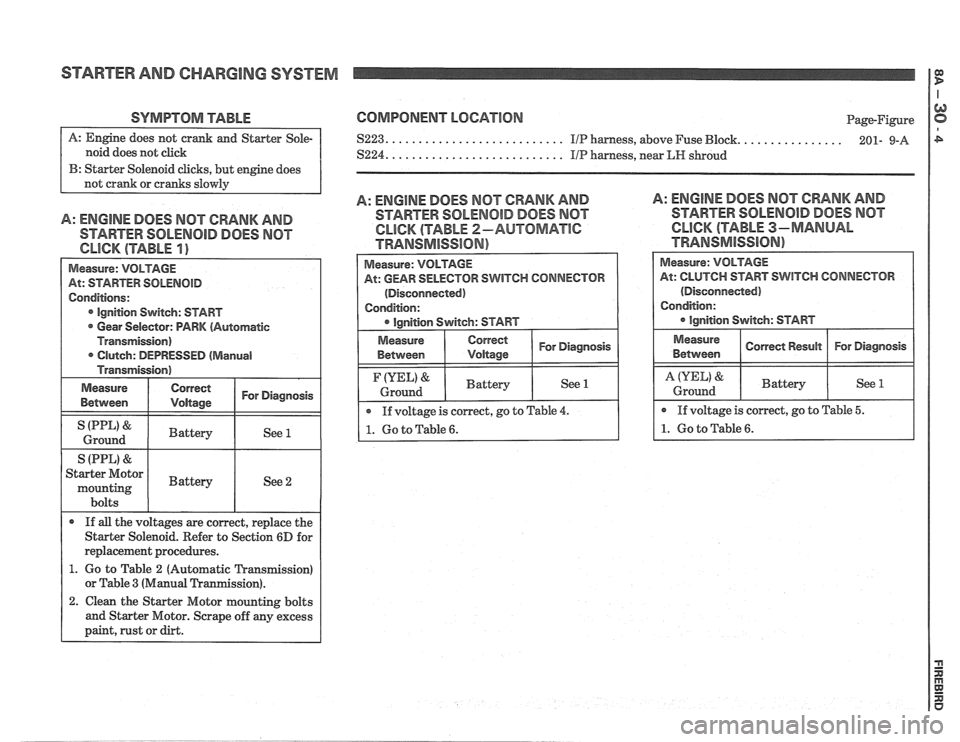

SYMPTOM TABLE

noid does not click

B: Starter Solenoid clicks, but engine does

A: ENGINE DOES MOT CRANK AND

STARTER SOLENOID DOES NOT

Measure: VOLTAGE

At: STARTER

SOLENOID

Conditions:

Ignition Switch: START

Gear Selector: PARK (Automatic

Transmission) Clutch: DEPRESSED

(Manual

Transmission)

Measure

Between

Correct I For Diagnosis I

I (PPL' & I Battery I See 1 I Ground

S (PPL)

& I I

Starter Motor

mounting I Battery I See 2

bolts

If

all the voltages are correct, replace the

Starter Solenoid. Refer to Section

6D for

replacement procedures.

1. Go to Table 2 (Automatic Transmission)

or Table

3 (Manual Tranmission).

2. Clean the Starter Motor mounting bolts

and Starter Motor. Scrape off any excess

paint, rust or dirt.

COMPONENT LOCATION

....... $223. .......................... IIP harness, above Fuse Bbck.

S224. .......................... IIP harness, near LIP shroud Page-Figure

........ 201- 9-A

A: ENGINE DOES MOT CRANK AND

STARTER SOLENOID DOES NOT

CLICK (TABLE 2-AUTOMATlC

TRANSMISSION)

A: ENGINE DOES MOT CRANK AND

STARTER SOLENOID DOES MOT

CLICK (TABLE 3-MANUAL

TRAMSMiSS16N)

Measure:

VOLTAGE

At: GEAR SELECTOR SWITCH CONNECTOR

(Disconnected)

Condition:

Correct 1 For Diagnosis I

If voltage is correct, go to Table 4.

1. Go to Table 6.

(YEL) &

Ground

At: CLUTCH START SWITCH CONNECTOR

(Disconnected)

Battery See 1

Page 1298 of 1825

STARTER AND CHARGING SYSTEM

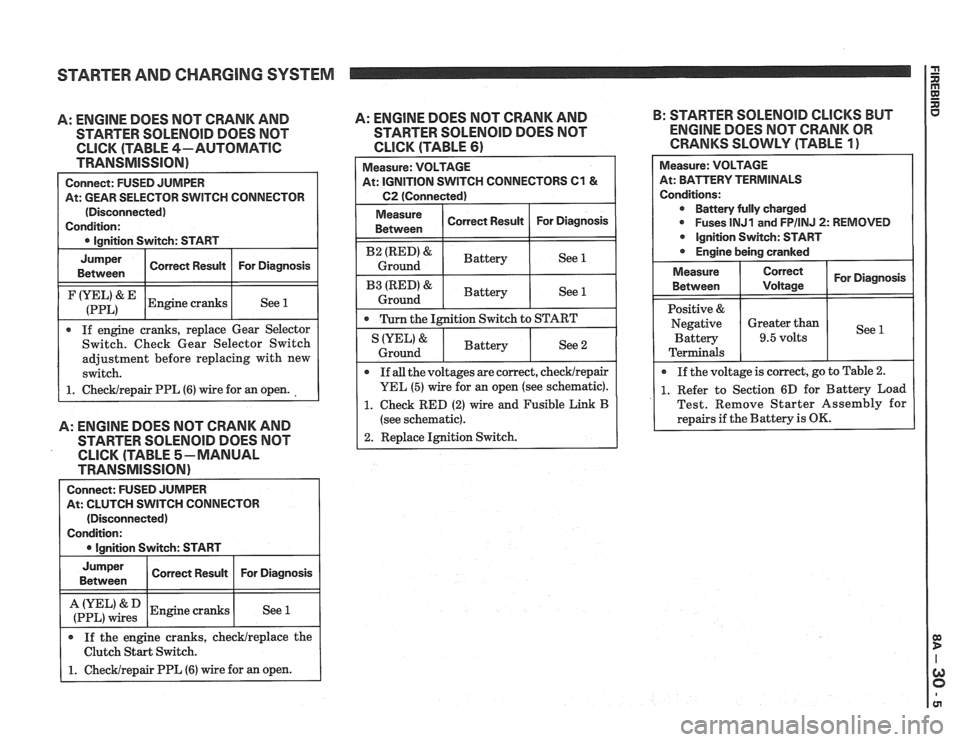

A: ENGINE DOES NOT CRANK AND

STARTER SOLENOID DOES NOT

CLICK (TABLE 4-AUTOMATIC

TRANSMISSION)

Connect: FUSED JUMPER

At: GEAR SELECTOR SWITCH CONNECTOR

(Disconnected)

Condition:

0 Ignition Switch: START

I

Jumper I Corren Resuk I For Diagnosis I Between

I (:::LI& IEngine cranks I See 1 1

If engine cranks, replace Gear Selector

Switch. Check Gear Selector Switch

adjustment before replacing with new

switch.

1. ChecWrepair PPL (6) wire for an open.

A: ENGINE DOES NOT CRANK AND

STARTER SOLENOlD DOES NOT

CLICK (TABLE 5-MANUAL

TRANSMISSION)

Connect: FUSED JUMPER

At: CLUTCH SWITCH CONNECTOR

(Disconnected)

Condition:

I 0 lanition Switch: START I

I :if,",":: 1 Engine cranks I See 1 I

Jumper

Between

If the engine cranks, checklreplace the

Clutch Start Switch.

1. Checklrepair PPL (6) wire for an open.

A: ENGINE DOES NOT CRANK AND B:

STARTER SOLENOID CLICKS BUT

STARTER

SOLENOID DOES NOT ENGINE DOES NOT CRANK OR

CLICK (TABLE 61 CRANKS SLOWLY (TABLE 1)

Correct Result Measure:

VOLTAGE

At: IGNITION SWITCH CONNECTORS

C1 &

C2 (Connected)

For Diagnosis

I Measure ( Correct Result I For Diagnosis 1 Between

I B2 (RED)& I Battery ( See 1 I Ground

I B3 IRED'& I Battery ( See 1 1 Ground

0 Turn the Ignition Switch to START

Measure: VOLTAGE

At: BPirTERV TERMINALS

Conditions: Battery fully charged

0 Fuses lNJ1 and FPIINJ 2: REMOVED

Ignition Switch: START

Engine being cranked

See 2 IYEL' &

Ground

For Diagnosis

See

Measure

Between

Positive &

Negative Battery

Terminals

If

all the voltages are correct, checklrepair

YEL (5) wire for an open (see schematic).

1. Check RED (2) wire and Fusible Link B

(see schematic).

2. Replace Ignition Switch.

Battery

0 If

the voltage is correct, go to Table 2.

1. Refer to Section 6D for Battery Load

Test. Remove Starter Assembly for

repairs if the Battery is

OK.

Correct

Voltage

Greater than

9.5 volts

Page 1299 of 1825

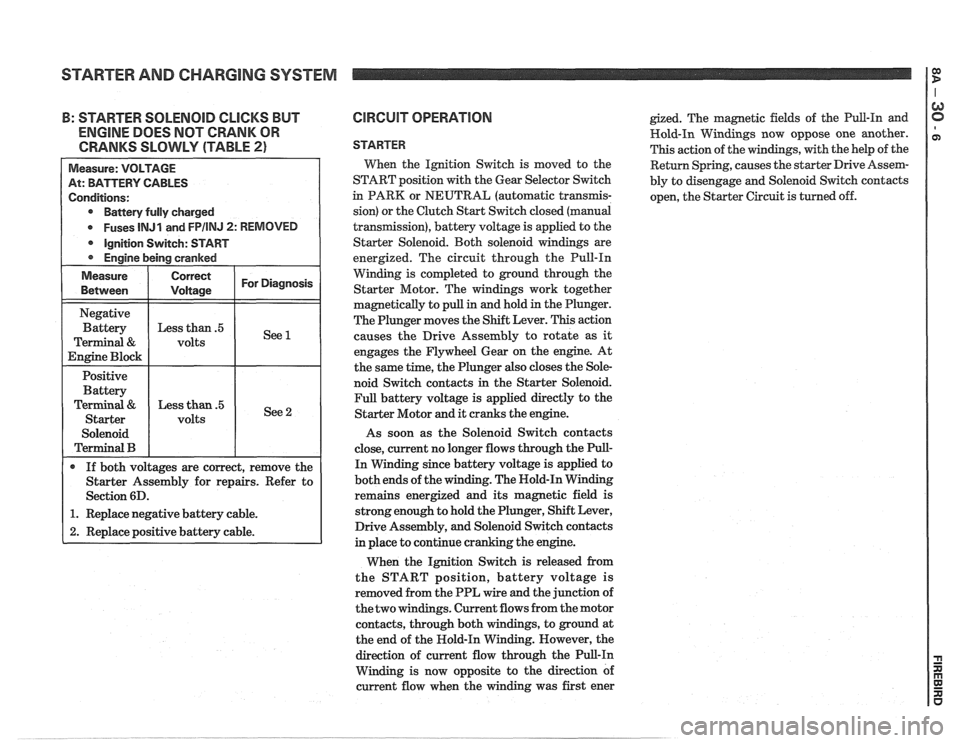

STARTER AND CHARGING SYSTEM

: STARTER SOLENOID CLICKS BUT

ENGINE DOES NOT CRANK OR

CRANKS SLOWLY (TABLE

2)

Battery fully charged

Fuses

lNJl and FPIINJ 2: REMOVED

Starter Assembly for repairs. Refer to

1. Replace negative battery cable.

2. Replace positive battery cable.

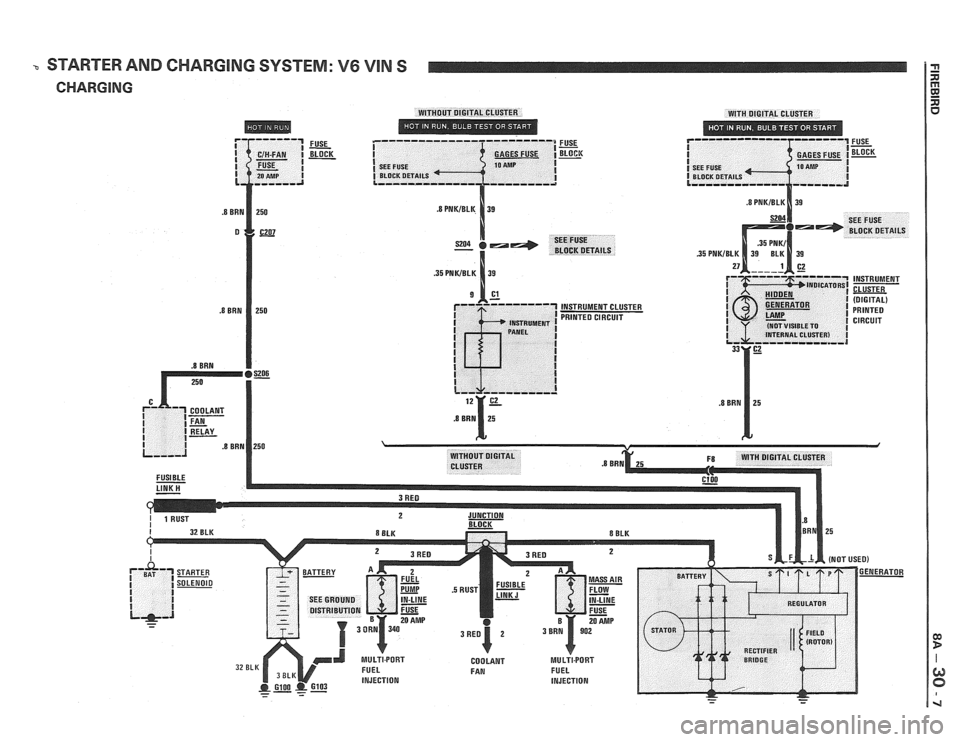

CIRCUIT OPERATION

STARTER

Wen the Ignition Switch is moved to the

START position with the Gear Selector Switch

in PARK or NEUTRAL (automatic

transrnis-

sion) or the Clutch Start Switch closed (manual

transmission), battery voltage is applied to the

Starter Solenoid. Both solenoid windings are

energized. The circuit through the Pull-In

Winding is completed to ground through the

Starter Motor. The windings work together

magnetically to pull in and hold in the Plunger.

The Plunger moves the Shift Lever. This action

causes the Drive Assembly to rotate as

it

engages the Flywheel Gear on the engine. At

the same time, the Plunger also closes the Sole-

noid Switch contacts in the Starter Solenoid.

Full battery voltage is applied directly to the

Starter Motor and it cranks the engine.

As soon as the Solenoid Switch contacts

close, current no longer flows through the Pull-

In Winding since battery voltage is applied to

both ends of the winding. The Nold-In Winding

remains energized and its magnetic field is

strong enough to hold the Plunger, Shift Lever,

Drive Assembly, and Solenoid Switch contacts

in place to continue cranking the engine.

When the Ignition Switch is released from

the START position, battery voltage is

removed from the PPL wire and the junction of

the two windings. Current flows from the motor

contacts, through both windings, to ground at

the end of the Hold-In Winding. However, the

direction of current flow through the Pull-In

Winding is now opposite to the direction of

current flow when the winding was first ener

gized. The magnetic fields of the Pull-In and

Hold-In Windings now oppose one another.

This action of the windings, with the help of the

Return Spring, causes the starter Drive Assem-

bly to disengage and Solenoid Switch contacts

open, the Starter Circuit is turned off.

Page 1300 of 1825

STARTER AND CHARGING SYSTEM: V6 VIN S