PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1321 of 1825

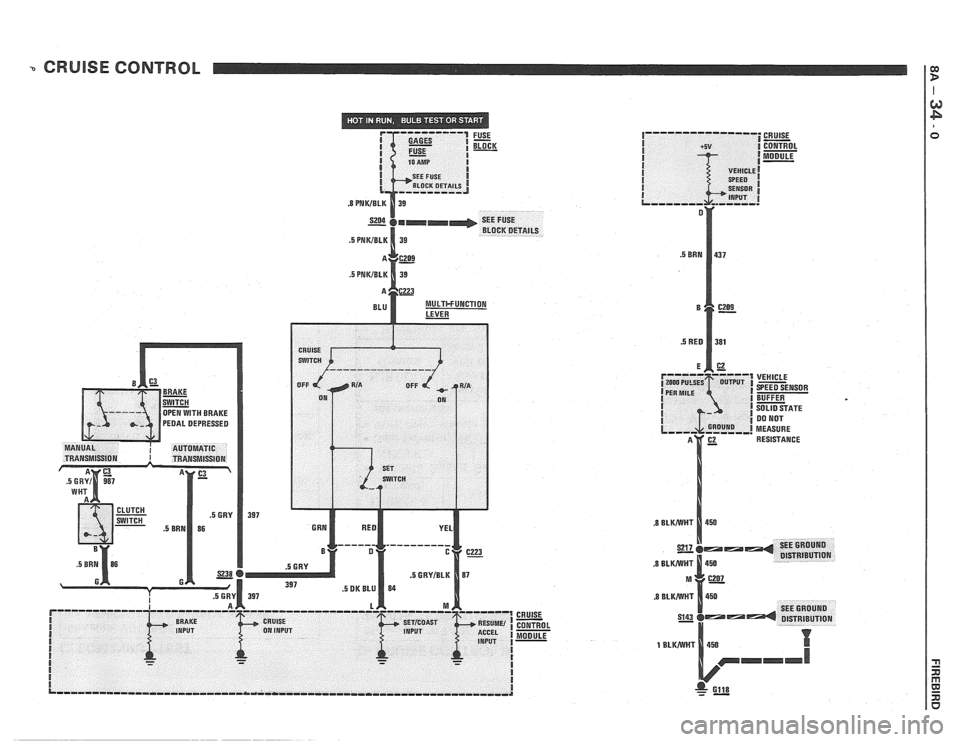

3 CRUISE CONTROL

.8 PNKIBLK 39

DO NOT

MEASURE RESISTANCE

Page 1322 of 1825

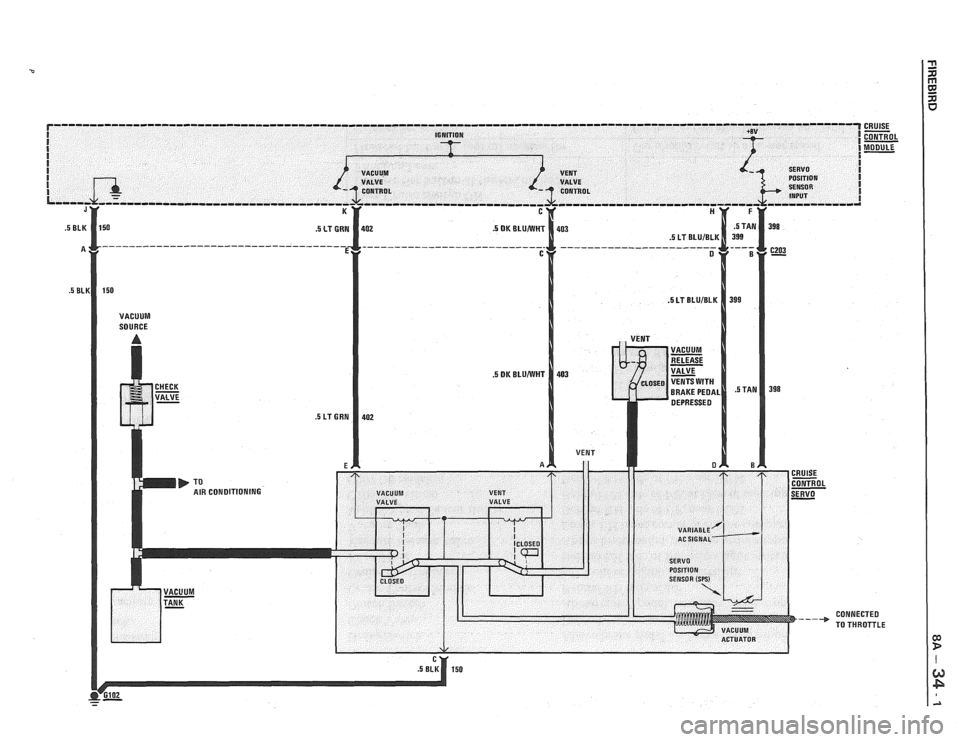

r--------------------------------------------------------------------------------------------------------------- I I IGNITION

I I I I SERVO I VACUUM I

I POSITION I

I SENSOR I INPUT I

CONNECTED

TO THROTTLE

Page 1323 of 1825

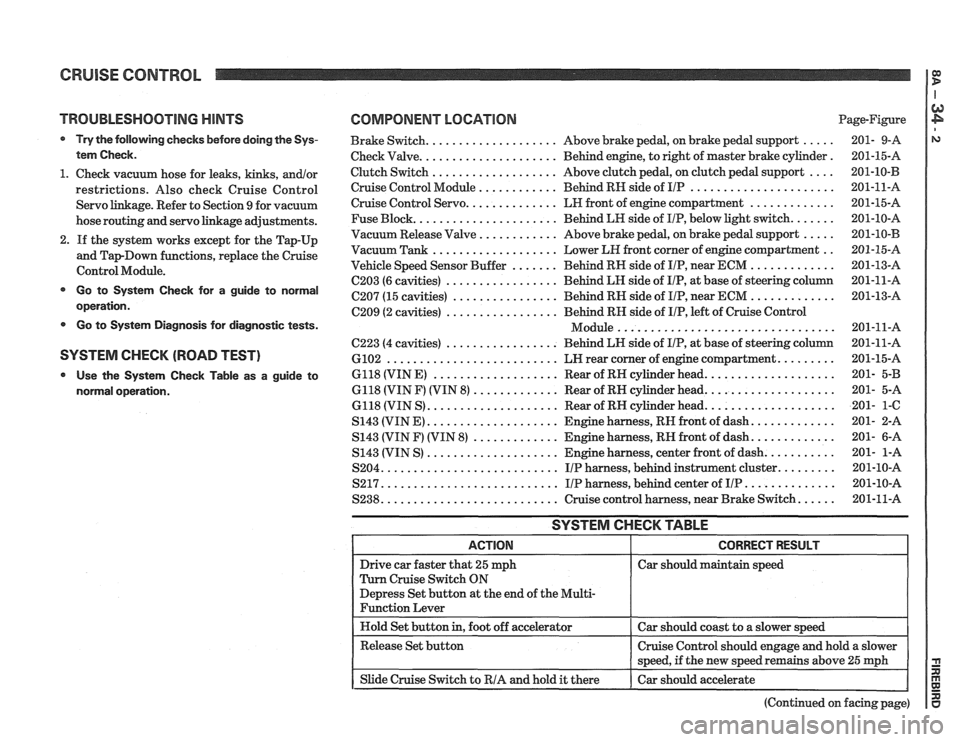

CRUISE CONTROL

TROUBLESHOOTING HINTS

Try the following checks before doing the Sys-

tem Check

.

1 . Check vacuum hose for leaks. kinks. andlor

restrictions . Also check Cruise Control

Servo linkage

. Refer to Section 9 for vacuum

hose routing and servo linkage adjustments

.

2 . If the system works except for the Tap-Up

and

TapDown functions. replace the Cruise

Control Module

.

Go to System Check for a guide to normal

operation

.

Go to System Diagnosis for diagnostic tests .

SYSTEM CHECK (ROAD TEST)

Use the System Check Table as a guide to

normal operation

.

COMPONENT LOCATION Page-Figure

Brake Switch

.................... Above brake pedal. on brake pedal support ..... 201- 9-A

Check Valve

..................... Behind engine. to right of master brake cylinder . 201-15-A

Clutch Switch

................... Above clutch pedal. on clutch pedal support .... 201-10-B

Cruise Control Module

............ Behind RH side of IIP ...................... 201-11-A

Cruise Control Servo .............. LH front of engine compartment ............. 201-15-A

Fuse Block

...................... Behind LH side of IIP. below light switch ....... 201-10-A

Vacuum Release Valve

............ Above brake pedal. on brake pedal support ..... 201-10-B

Vacuum Tank ................... Lower LH front corner of engine compartment .. 201-15-A

Vehicle Speed Sensor Buffer

....... Behind RH side of IIP. near ECM ............. 201-13-A

C203 (6 cavities) ................. Behind LH side of IIP. at base of steering column 201-11-A

C207 (15 cavities) ................ Behind RH side of IIP. near ECM ............. 201-13-A

C209 (2 cavities) ................. Behind RH side of IIP. left of Cruise Control

................................. Module 201-11-A

C223 (4 cavities) ................. Behind LH side of IIP. at base of steering column 201-11-A

6102 .......................... LN rear corner of engine compartment ......... 201-15-A

6118 (VIN E)

................... Rear of RH cylinder head .................... 201- 5-B

6118 (VIN F) (VIN 8)

............. Rear of RN cylinder head .................... 201- 5-A

6118 (VIN S)

.................... Rear of RN cylinder head .................... 201- 1-C

S143 (VIN E) .................... Engine harness. RH front of dash ............. 201- 2-A

S143 (VIN

F) (VIN 8) ............. Engine harness. RN front of dash ............. 201- 6-A

S143 (VIN S)

.................... Engine harness. center front of dash ........... 201- 1-A

S204

........................... IIP harness. behind instrument cluster ......... 201-10-A

S217

........................... IIP harness. behind center of IIP .............. 201-10-A

S238

........................... Cruise control harness. near Brake Switch ...... 201-11-A

SYSTEM CHECK TABLE

Car should maintain speed

(Continued on facing page)

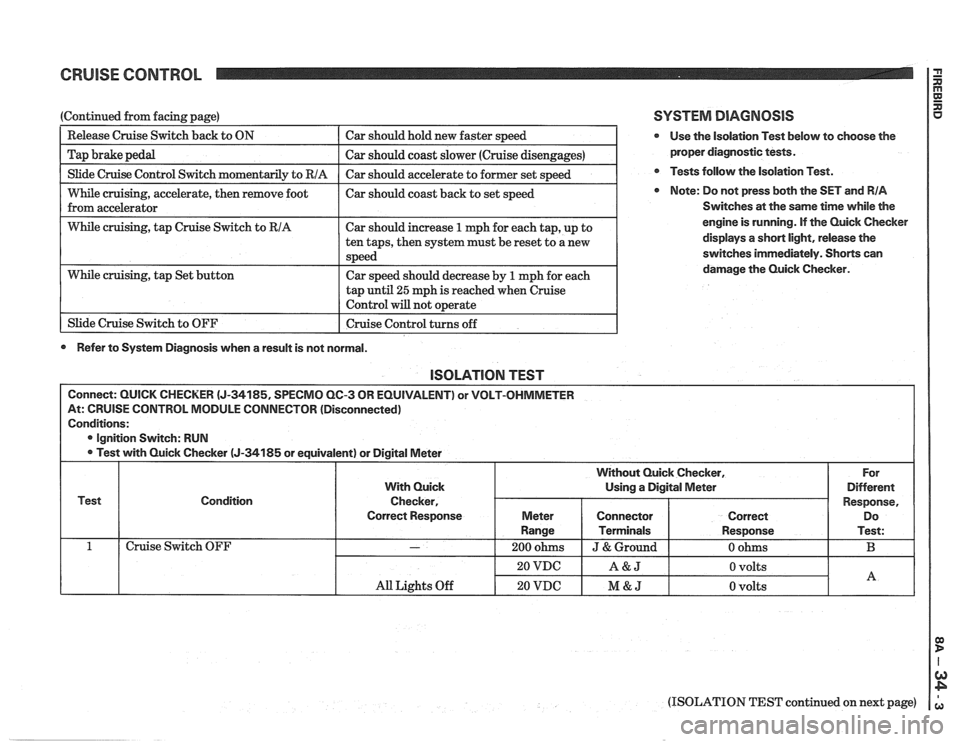

Page 1324 of 1825

CRUISE CONTROL 2

I Slide Cruise Control Switch momentaril~ to RIA I Car should accelerate to former set s~eed I

(Continued from facing page)

--

While cruising, accelerate, then remove foot I car should coast back to set speed

from accelerator

Release Cruise Switch

back to ON

Tap brake pedal

I While cruising, tap Cruise Switch to RIA I Car should increase 1 mph for each tap, up to I

Car should hold new faster speed

Car should coast slower (Cruise disengages)

tap

until 25 mph is reached when cruise

Control will not o~erate I

While cruising, tap Set button

1 Slide Cruise Switch to OFF ten

taps, then system must be reset to a new

speed

Car speed should decrease by

1 mph for each

I Cruise Control turns off 1

0 Refer to System Diagnosis when a result is not normal.

SYSTEM DIAGNOSIS

@ Use the isolation Test below to choose the

proper diagnostic tests.

@ Tests follow the Isolation Test.

Note: Do not press both the SET and RIA

Switches at the same time while the

engine is running. If the Quick Checker

displays

a short light, release the

switches immediately. Shorts can

damage the Quick Checker.

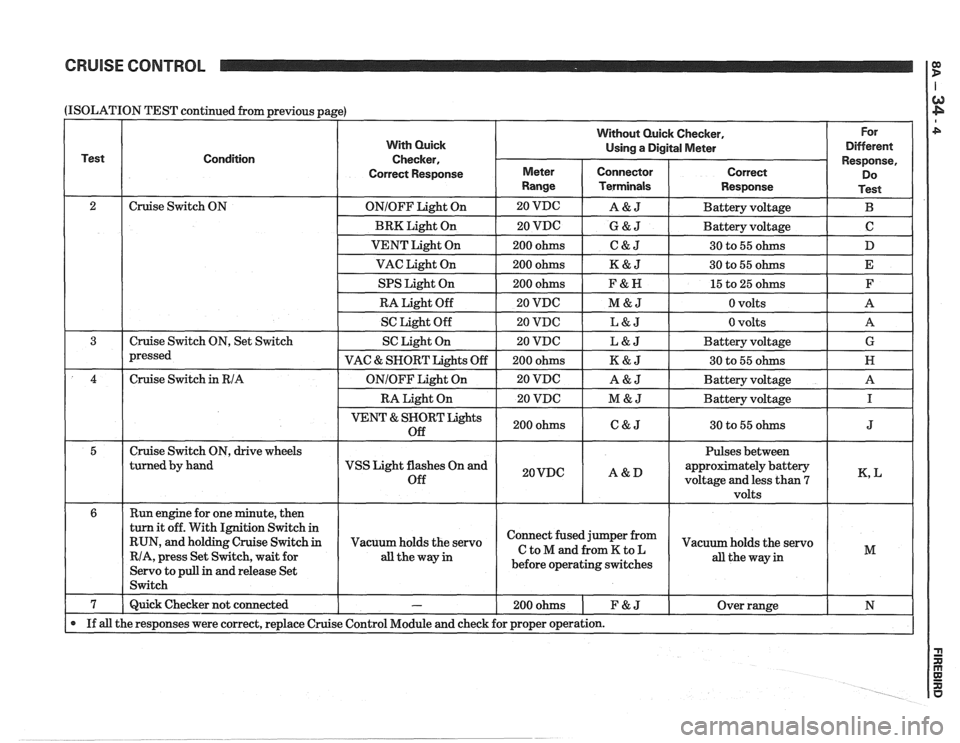

lSOLATlON TEST

Connect: QUICK CHECKER (J-34185, SPECMO QC-3 OR EQUIVALENT) or VOLT-OHMMETER

At: CRUISE CONTROL MODULE CONNECTOR (Disconnected)

Conditions:

@ Ignition Switch: RUN

Test with Quick Checker

(J-34185 or equivalent) or Digital Meter

Test Condition

Cruise Switch OFF

(ISOLATION TEST continued on next page)

All Lights Off

With Quick

Checker,

Correct Response

-

20 VDC

20 VDC

For

Different

Response, Do

Test:

B

Without Quick Checker,

Using a Digital Meter

A&J

M&J

Meter

Range

200 ohms

0 volts

0 volts

Connector

Terminals

J & Ground

A

Correct

Response

0 ohms

Page 1325 of 1825

CRUISE CONTROL

(ISOLATION

Test

2 3

4

5

6

7

If all

TEST continued from previous page)

Condition

Cruise Switch ON

Cruise Switch ON, Set Switch

pressed

Cruise Switch

in RIA

Cruise Switch ON, drive wheels

turned by hand

Run engine for one minute, then

turn it off. With Ignition Switch in

RUN, and holding Cruise Switch

in

RIA, press Set Switch, wait for

Servo to pull

in and release Set

Switch

Quick Checker not connected

the responses were correct, replace Cruise

With Quick

Checker,

Correct Response

ONIOFF Light On

BRK Light On

VENT Light On

VAC Light On

SPS Light On

RA Light Off

SC Light Off

SC Light On

VAC

& SNORT Lights Off

ONIOFF Light On

RA Light On

VENT & SNORT Lights

Off

VSS Light flashes On and

Off

Vacuum holds the servo

all theway in

-

Control Module and check

Without Quick Checker, For

Using

a Digital Meter Different

Meter

Range

20 VDG

20 VDC

200 ohms

200 ohms

200 ohms

20 VDC

20 VDC

20 VDC

200 ohms

20 VDC

20 VDC

200 ohms

20VDC

Connector Terminals

A&J

G&J

C&J

K&J

F&N

M&J

L&J

L&J

K&J

A&J

M&J

C&J

A&D

Response,

Correct Do

Response Test

Battery voltage B

Battery voltage C

30 to 55 ohms D

30 to 55 ohms E

15 to 25 ohms F

0 volts A

0 volts

A

Battery voltage G

30 to 55 ohms N

Battery voltage A

Battery voltage

I

30 to 55 ohms J

Pulses between

approximately battery

voltage and less than

7 K, L

volts

Connect fused jumper from

CtoMandfromKtoL

before operating switches

200ohms 1 F&J

for proper operation.

Vacuum holds the servo

all the way in M

Over range N

Page 1326 of 1825

CRUISE CONTROL 13 rn E

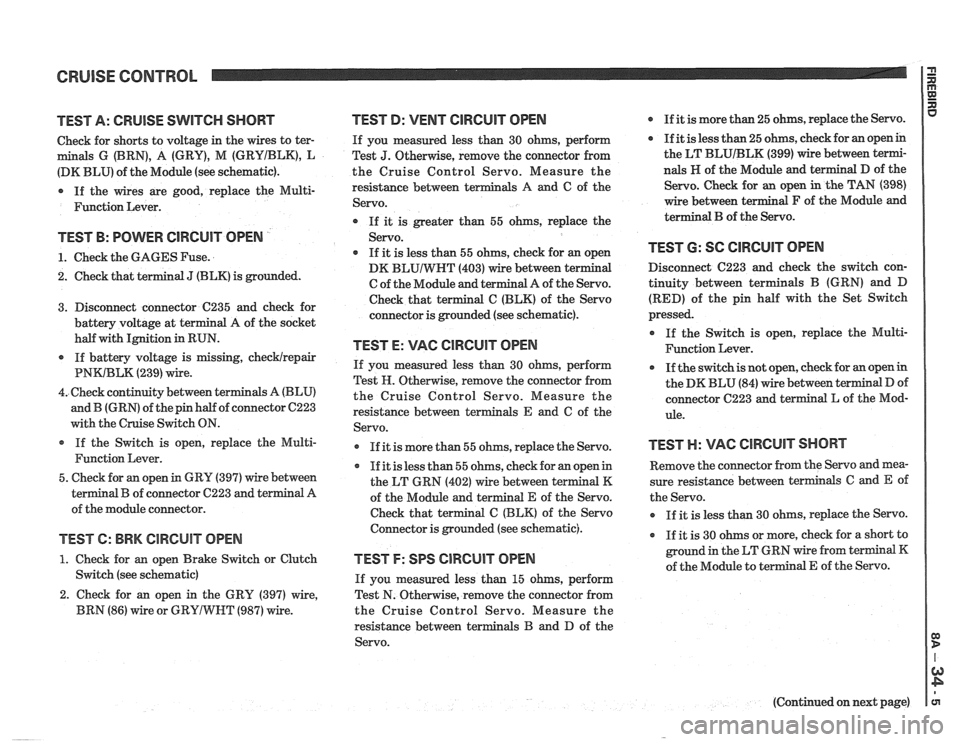

TEST A: CRUISE SWITCH SHORT

Check for shorts to voltage in the wires to ter-

m als G (BRN), A (GRY), M (GRYIBLK), L

(DK BLU) of the Module (see schematic).

* If the wires are good, replace the Multi-

Function Lever.

TEST B: POWER ClRCUlT OPEN

1. Check the GAGES Fuse.

2. Check that terminal

J (BLK) is grounded.

3. Disconnect connector

C235 and check for

battery voltage at terminal A of the socket

half with Ignition

in RUN.

* If battery voltage is missing, checklrepair

PNWBLK (239) wire.

4. Check continuity between t

and B (GRN) of the pin half of connector C223

with the Cruise Switch ON.

If the Switch is open, replace the Multi-

Function Lever.

5. Check for an open in GRY (397) wire between

al

B of connector C223 and terminal A

of the module connector.

TEST 6: BRK CIRCUIT OPEN

1. Check for an open Brake Switch or Clutch

Switch (see schematic)

2. Check for an open in the

GRY (397) wire,

BRN

(86) wire or GRYIWNT (987) wire.

TEST D: VENT ClRCUlT OPEN

If you measured less than 30 ohms, perform

Test

J. Otherwise, remove the connector from

the Cruise Control Servo. Measure the

resistance between

terminals A and C of the

Servo.

If

it is greater than 55 ohms, replace the

Servo.

* If it is less than 55 ohms, check for an open

DK

BLUIWHT (403) wire between te

C of the Module and

t

Check that terminal C (BLK) of the Servo

connector is grounded (see schematic).

TEST E: VAC ClRCUlT OPEN

If you measured less than 30 ohms, perform

Test

IF. Otherwise, remove the connector from

the Cruise Control Servo. Measure the

resistance between

t als E and C of the

Servo.

If it is more than 55 ohms, replace the Servo.

If it is less than 55 ohms, check for an open in

the LT GRN (402) wire between t

of the Module and terminal E of the Servo.

Check that terminal C (BLK) of the Servo

Connector is grounded (see schematic).

TEST F: SPS CIRCUIT OPEN

If you measured less than 15 ohms, perform

Test N. Otherwise, remove the connector from

the Cruise Control Servo. Measure the

resistance between terminals

B and D of the

Servo.

r If it is more than 25 ohms, replace the Servo.

* If it is less than 25 ohms, check for an open in

the LT

BLUIBLK (399) wire between termi-

nals

H of the Module and

Servo. Check for an open

wire between

t al F of the Module and

terminal B of the Servo.

TEST 6: SC ClRGUlT OPEN

Disconnect C223 and check the switch con-

tinuity between terminals B (GRN) and D

(RED) of the pin half with the Set Switch

pressed.

* If the Switch is open, replace the Multi-

Function Lever.

If the switch is not open, check for an open in

the DK BLU (84) wire between terminal

D of

connector C223 and te al

L of the

Mod-

ule.

TEST H: VAC CIRCUIT SHORT

Remove the connector from the Servo and mea-

sure resistance between terminals

C and E of

the Servo.

r If it is less than 30 ohms, replace the Servo.

If it is 30 ohms or more, check for a short to

ground in the LT GRN wire from terminal K

of the Module to terminal

E of the Servo.

(Continued on next page)

Page 1327 of 1825

CRUISE CONTROL

(Continued from previous page)

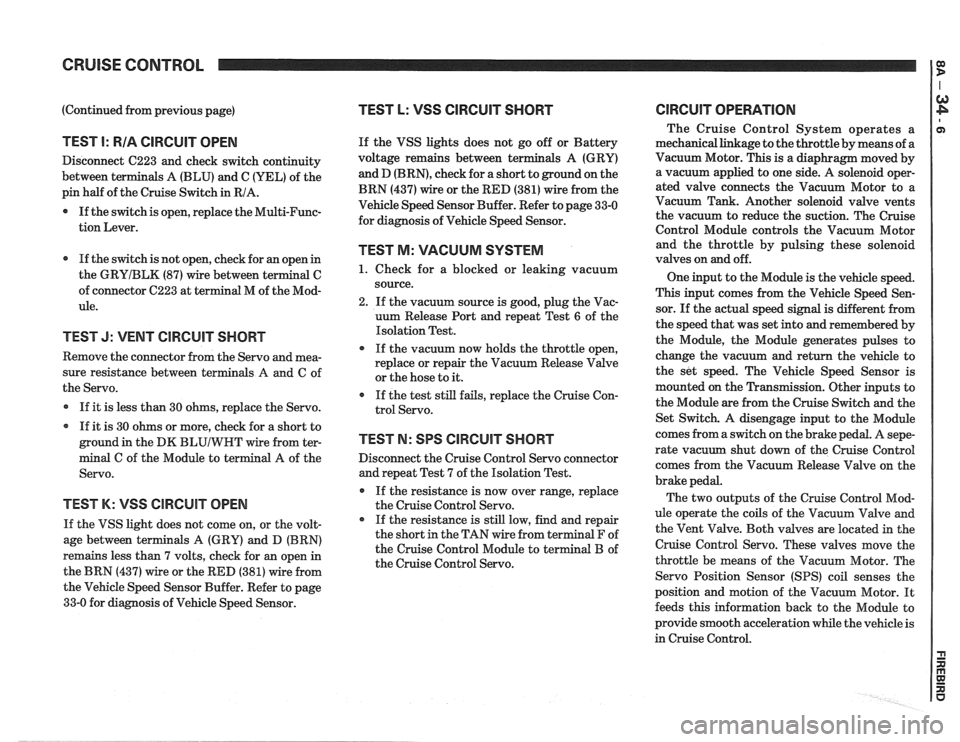

TEST I: RIA CIRCUIT OPEN

Disconnect C223 and check switch continuity

between terminals A (BLU) and C (YEL) of the

pin half of the Cruise Switch in RIA.

0 If the switch is open, replace the Multi-Func-

tion Lever.

If the switch is not open, check for an open in

the

GRYIBLK (87) wire between terminal C

of connector C223 at terminal M of the Mod-

ule.

TEST J: VENT CIRCUIT SHORT

Remove the connector from the Servo and mea-

sure resistance between terminals

A and C of

the Servo.

If it is less than 30 ohms, replace the Servo.

If it is 30 ohms or more, check for a short to

ground in the DK

BLUIWHT wire from ter-

minal C of the Module to terminal A of the

Servo.

TEST K: VSS ClRCUlT OPEN

If the VSS light does not come on, or the volt-

age between terminals A (GRY) and D (BRN)

remains less than 7 volts, check for an open in

the BRN (437) wire or the RED (381) wire from

the Vehicle Speed Sensor Buffer. Refer to page

33-0 for diagnosis of Vehicle Speed Sensor.

TEST L: VSS CIRCUIT SHORT

If the VSS lights does not go off or Battery

voltage remains between ter

and D

(BRN), check for a short to ground on the

BRN (437) wire or the RED (381) wire from the

Vehicle Speed Sensor Buffer. Refer to page 33-0

for diagnosis of Vehicle Speed Sensor.

TEST M: VACUUM SYSTEM

1. Check for a blocked or leaking vacuum

source.

2. If the vacuum source is good, plug the Vac-

uum Release Port and repeat Test

6 of the

Isolation Test.

If the vacuum now holds the throttle open,

replace or repair the Vacuum Release Valve

or the hose to it.

If the test still fails, replace the Cruise Con-

trol Servo.

TEST N: SPS CIRCUIT SHORT

Disconnect the Cruise Control Servo connector

and repeat Test 7 of the Isolation Test.

If the resistance is now over range, replace

the Cruise Control Servo.

If the resistance is still low, find and repair

the short in the TAN wire from terminal F of

the Cruise Control Module to terminal B of

the Cruise Control Servo.

ClRCUlT OPERATION

The Cruise Control System operates a

mechanical linkage to the throttle by means of a

Vacuum Motor. This is a diaphragm moved by

a vacuum applied to one side. A solenoid oper-

ated valve connects the Vacuum Motor to a

Vacuum Tank. Another solenoid valve vents

the vacuum to reduce the suction. The Cruise

Control Module controls the Vacuum Motor

and the throttle by pulsing these solenoid

valves on and off.

One input to the Module is the vehicle speed.

This input comes from the Vehicle Speed Sen-

sor. If the actual speed signal is different from

the speed that was set into and remembered by

the Module, the Module generates pulses to

change the vacuum and return the vehicle to

the set speed. The Vehicle Speed Sensor is

mounted on the Transmission. Other inputs to

the Module are from the Cruise Switch and the

Set Switch. A disengage input to the Module

comes from a switch on the brake pedal. A

sepe-

rate vacuum shut down of the Cruise Control

comes from the Vacuum Release Valve on the

brake pedal.

The two outputs of the Cruise Control Mod-

ule operate the coils of the Vacuum Valve and

the Vent Valve. Both valves are located in the

Cruise Control Servo. These valves move the

throttle be means of the Vacuum Motor. The

Servo Position Sensor

(SPS) coil senses the

position and motion of the Vacuum Motor. It

feeds this information back to the Module to

provide smooth acceleration while the vehicle is

in Cruise Control.

Page 1328 of 1825

Page 1329 of 1825

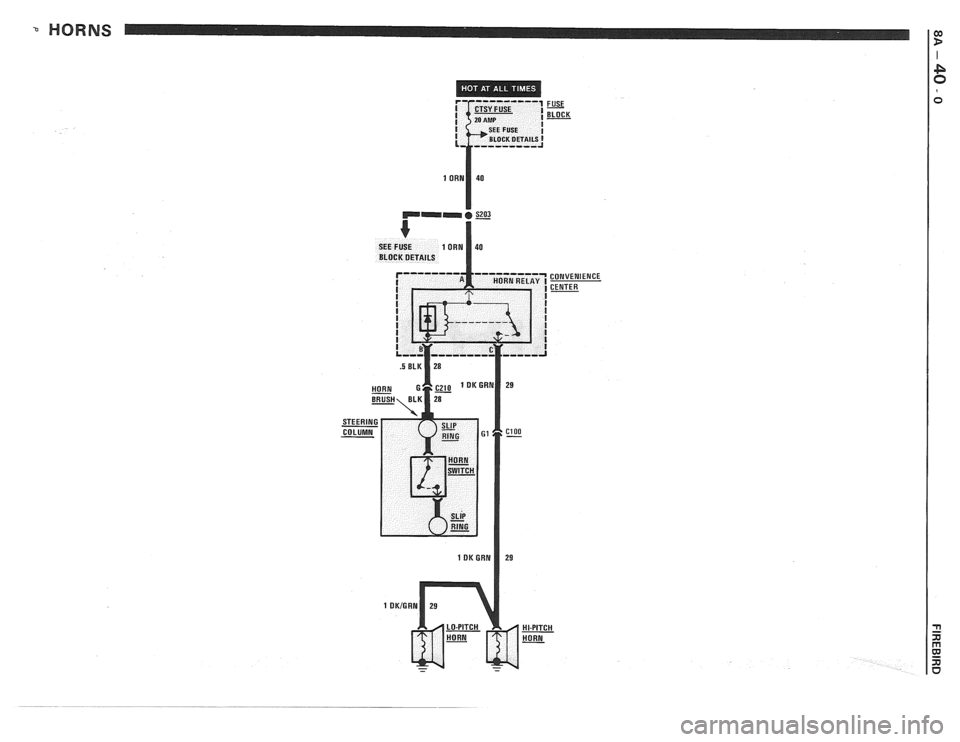

HORNS I $

FUSE - BLOCK -

CONVENIENCE CENTER

Page 1330 of 1825

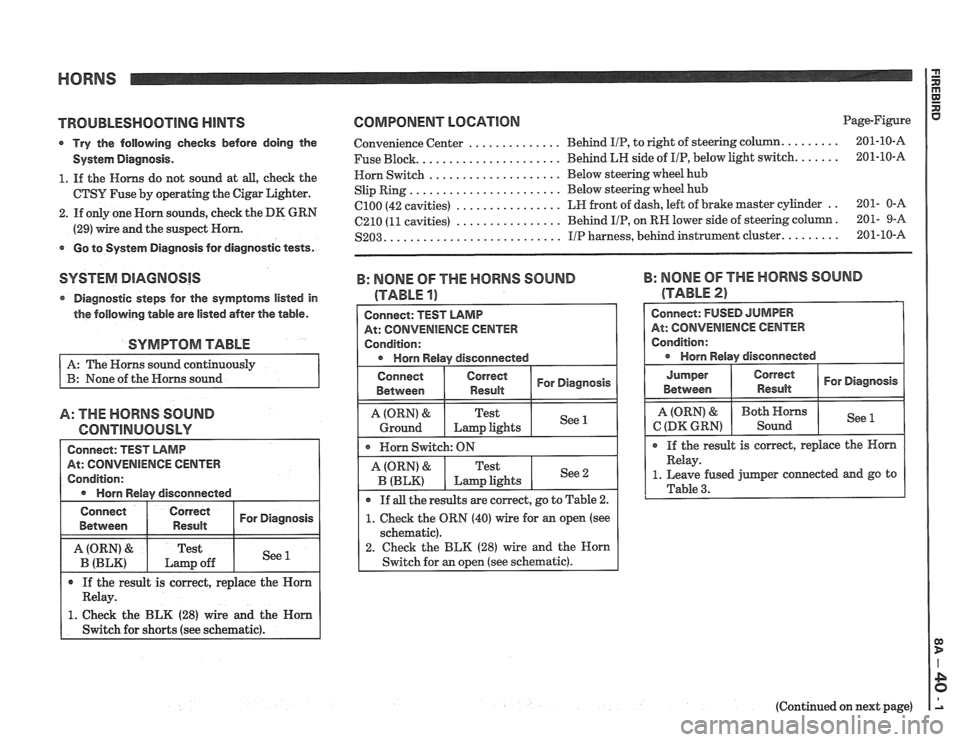

HORNS

TROUBEESHOOTlNG HINTS

Try the following checks before doing the

System Diagnosis.

1. If the Horns do not sound at all, check the

CTSY Fuse by operating the Cigar Lighter.

2. If only one Worn sounds, check the DK GRN

(29) wire and the suspect Horn.

Go to System Diagnosis for diagnostic tests.

SYSTEM DIAGNOSIS

Diagnostic steps for the symptoms listed in

the following table are listed after the table.

SYMPTOM TABLE

A: The Horns sound continuously

B: None of the Horns sound

A: THE HORNS SOUND

GONTlNUOUSLY

COMPONENT LOCATION Page-Figure

.............. Convenience Center Behind IIP, to

right of steering column. ........ 201-10-A

..................... ...... Fuse Block. Behind LH side

of I/P, belour light switch. 201-10-A

.................... Horn Switch Below

steering wheel hub

....................... Slip Ring Below

steering wheel hub

................ el00 (42 cavities) LH front of dash, left of brake master cylinder .. 201- 0-A

................ C210 (11 cavities) Behind IIP, on

RW lower side of steering column. 201- 9-A

.......................... S203. IIP harness, behind instrument cluster. ........ 201-10-8

B: NONE OF THE MORNS SOUND

(TABLE a,

Connect: TEST LAMB

IiENcE CENTER

I Condition:

a Horn Relay disconnected

Connect

Between I ","d::r I For Diagnosis

A (ORN) &

Ground

B: NOME OF THE HORNS SOUND

(TABLE 21

Horn Switch: ON

Jumper

Between

Test

Lamp lights

(Continued on next page)

See 1

See 2 A (ORN) &

B (BLK)

If all the results

are correct, go to Table 2.

1. Cheek the ORN (40) wire for an open (see

schematic).

2. Check the BLK (28) wire and the Horn

Switch for an open (see schematic).

Test

Lmp lights