PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1511 of 1825

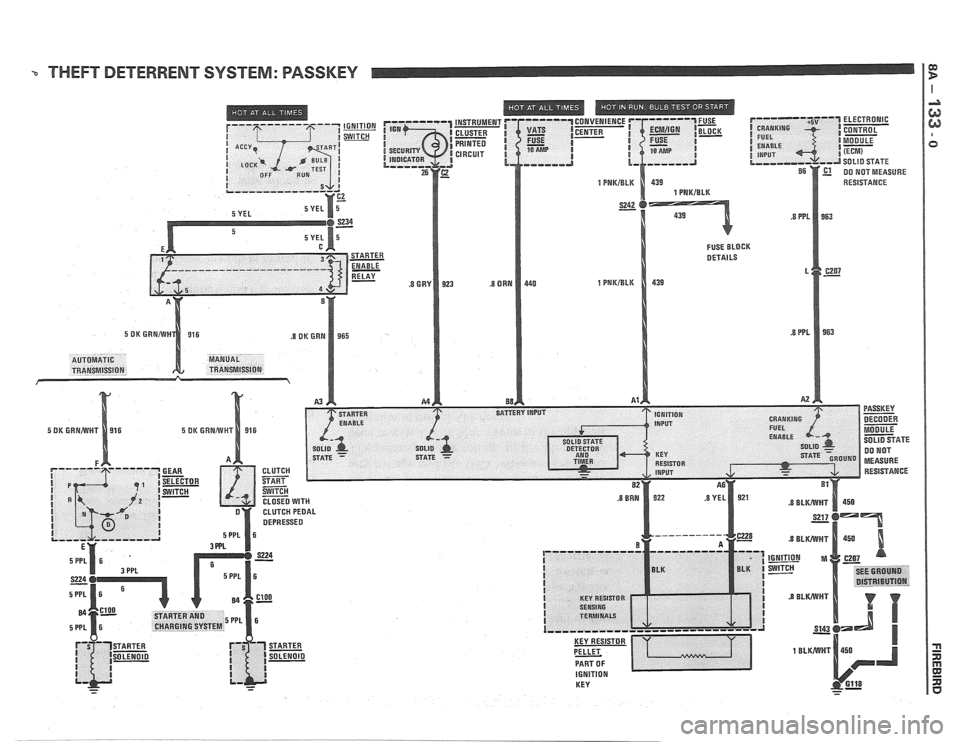

THEFT DETERRENT SYSTEM: PASSKEY !E

FUSE BLOCK

CLUTCH PEDAL

KEY

-

Page 1512 of 1825

THEFT DETERRENT SYSTEM: PASSKEY I a

TROUBLESHOOTING HINTS COMPONENT LOCATION

Try the following checks before doing the Sys-

tem Check.

1. Check the key pellet sensing contacts in the

Ignition Lock Cylinder by looking into the

key opening. If the contacts are damaged,

replace the Lock Cylinder.

2. Check the VATS Fuse by visual inspection.

3. Check owner's ignition key using the 535628

VATS Interrogator or equivalent.

If the Key

Code window shows "E", replace the

owner's key.

4. Check the Security Indicator Bulb.

5. Check the

CIH Fuse by visual inspection.

Go to System Check for a guide to normal

operation.

Go to System Diagnosis for diagnostic tests.

SYSTEM CHECK

Use the System Check Table as a guide to

normal operation.

r Refer to System Diagnosis for a list of symp-

toms and diagnostic steps.

Clutch Start Switch .............. Above clutch pedal, on clutch pedal support

Convenience Center

.............. Behind IIP, to right of steering column. ........

Electronic Control Module (ECM) ... Behind RN side of IIP ......................

Fuse Block. ..................... Behind LH side of IIP, below light switch. ......

Gear Selector Switch ............. In console, at base of gear selector ............

Ignition Switch. ................. Behind IIP, on top side of steering column ......

Starter Enable Relay ............. Behind LH side of IIP, left of steering column

Starter Solenoid (VIN E)

.......... Lower RH side of engine ....................

Starter Solenoid (VIN F) (VIN 8). ... Lower RH side of engine ....................

Starter Solenoid (VIN S) .......... Lower RN side of engine ....................

VATS Decoder Module. ........... Behind LH side of IIP, above steering column

Cl00 (42 cavities) ................ LH front of dash, left of brake master cylinder ..

C207 (15 cavities) ................ Behind RN side of IIP, near ECM .............

6228. .......................... Behind IIP, on upper RH side of steering column

6118 (VIN

E) ................... Rear of RN cylinder head. ...................

6118 (VIN F) (VIN 8) ............. Rear of RH cylinder head. ...................

6118 (VIN S) .................... Rear of RN cylinder head. ...................

S143 (VIN E) .................... Engine harness, RR front of dash. ............

S143 (VIN F) (VIN 8) ............. Engine harness, RN front of dash. ............

S143 (VIN S) .................... Engine harness, center front of dash. ..........

S217. .......................... IIP harness, behind center of IIP. .............

S224. .......................... IIP harness, near LH shroud

S234. .......................... I/P harness, above Fuse Block. ...............

S242. .......................... IIP harness, behind RH side of IIP ............

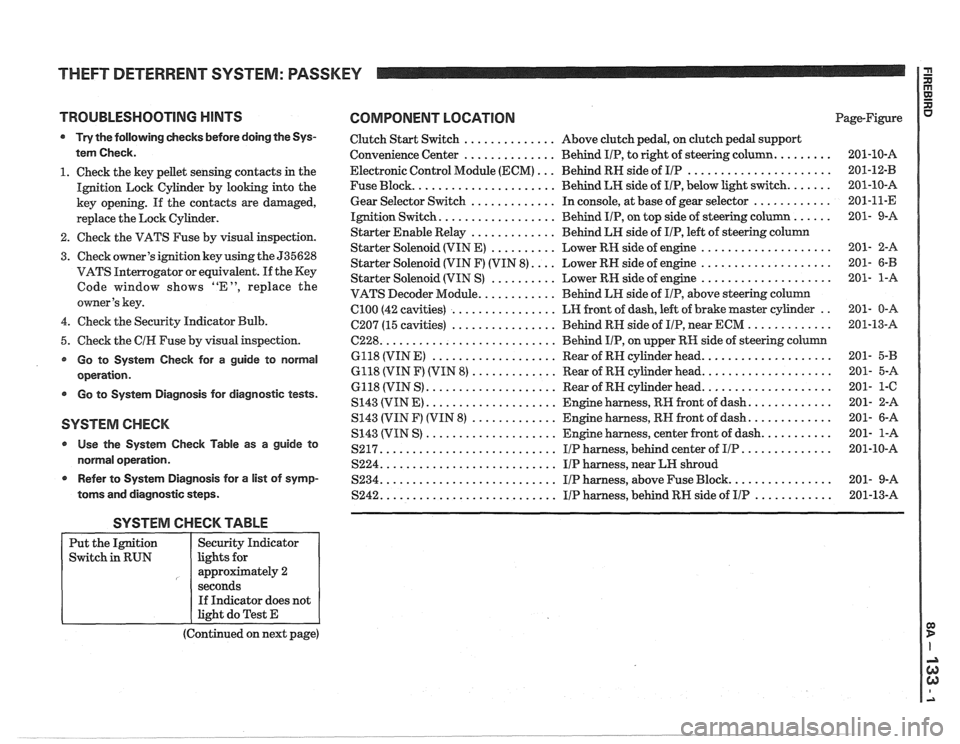

SYSTEM CHECK TABLE

(Continued on next page)

Put

the Ignition

Switch in RUN

R aJ XI

Page-Figure u

Security Indicator

lights for

approximately 2

seconds If Indicator does not

light do Test E

Page 1513 of 1825

THEFT DETERRENT SYSTEM: PASSKEY

(Continued from previous page)

If engine does not

Remove hush panel

disconnect C228

( Two-cavity

connector at base of

steering column)

Attempt to

start Engine should not

engine

Reconnect C228 and

attempt to start

engine again (must

be done within two

minutes of first

attempt)

Turn Ignition

Switch to

OFF

Wait four minutes

and turn Ignition

Switch to START crank

If engine cranks, do

Starter Enable

Relay Test

in

System Diagnosis

Engine should not

crank If engine cranks,

replace PASSKEY

I Decoder Module

I Replace hush panel 1 I

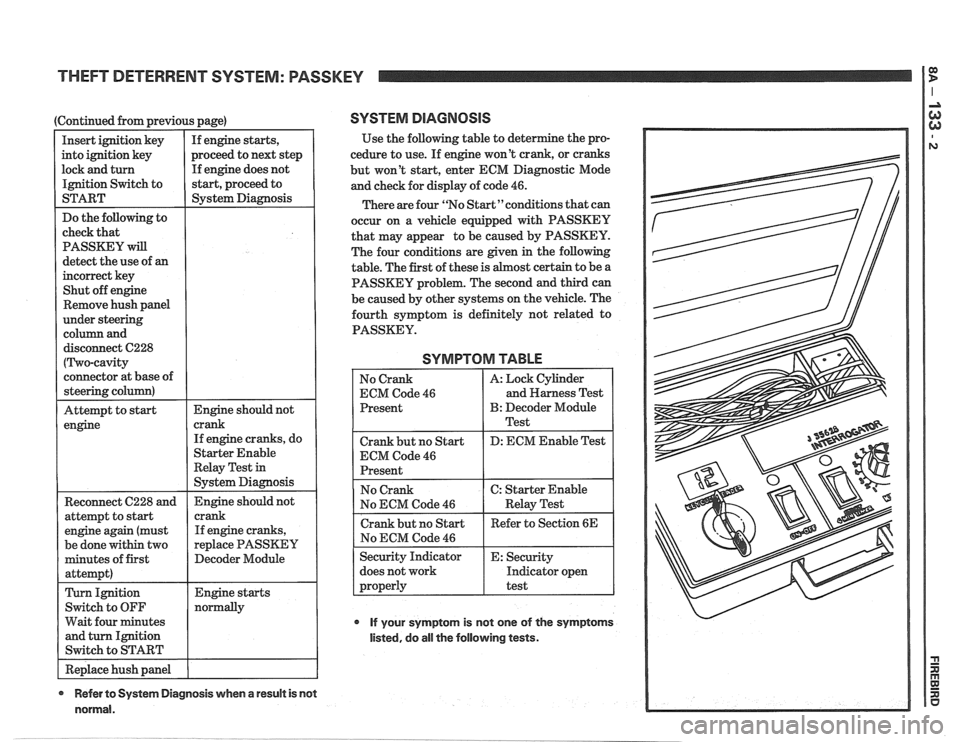

SYSTEM DIAGNOSIS

Use the following table to deter

cedure to use. If engine won't crank, or cranks

but won't start, enter ECM Diagnostic Mode

and check for display of code

46.

There are four "No Start"conditions that can

occur on a vehicle equipped with PASSKEY

that may appear to be caused by PASSKEY.

The four conditions are given in the following

table. The first of these is

host certain to be a

PASSKEY problem. The second and third can

be caused by other systems on the vehicle. The

fourth symptom is definitely not related to

PASSKEY.

SYMPTOM TABLE

No Crank

ECM Code

46

Present

Crank but no Start

ECM Code

46

Present A:

Lock Cylinder

and Harness Test

B: Decoder Module

Test

D: ECM Enable Test

No ECM Code

46

does not work Indicator open

If your symptom is not one of the symptoms

listed, do all the following tests.

* Refer to System Diagnosis when a result is not

normal.

Page 1514 of 1825

THEFT DETERRENT SYSTEM: PASSKEY I i

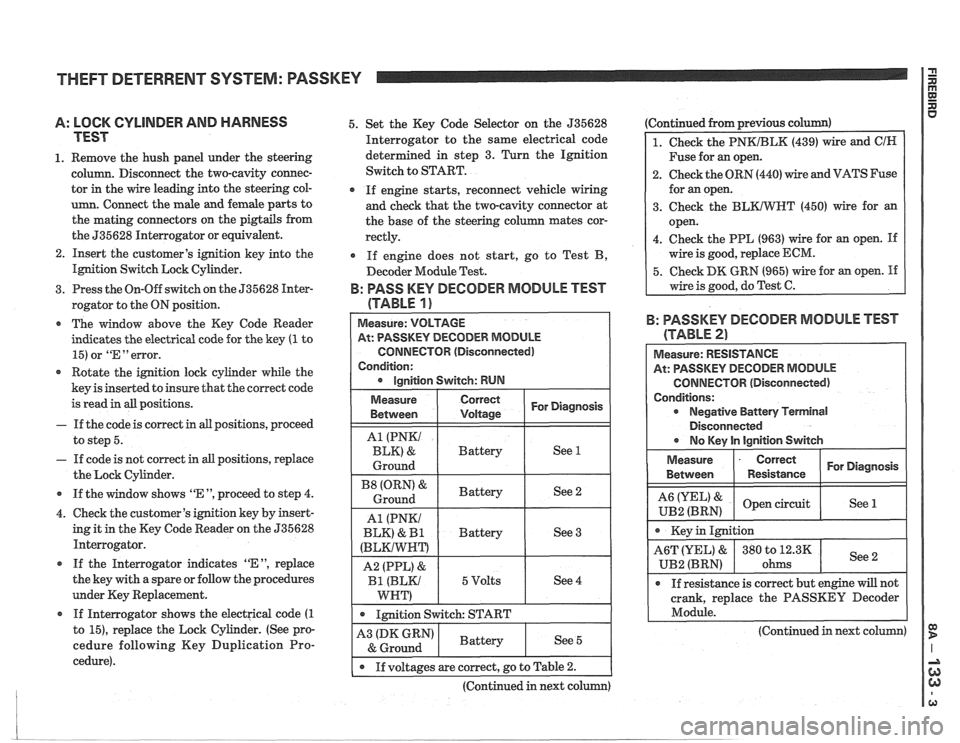

A: LOCK CYLINDER AND HARNESS

TEST

1. Remove the hush panel under the steering

column. Disconnect the two-cavity connec-

tor in the wire leading into the steering col-

umn. Connect the male and female parts to

the mating connectors on the pigtails from

the 535628 Interrogator or equivalent.

2. Insert the customer's ignition key into the

Ignition Switch Lock Cylinder.

3. Press the On-Off switch on the 535628 Inter-

rogator to the ON position.

* The window above the Key Code Reader

indicates the electrical code for the key

(1 to

15) or

"En error.

Rotate the ignition lock cylinder while the

key is inserted to insure that the correct code

is read in all positions.

- If the code is correct in all positions, proceed

to step 5.

- If code is not correct in all positions, replace

the Lock Cylinder.

* If the window shows "E ", proceed to step 4.

4. Check the customer's ignition key by insert-

ing it in the Key Code Reader on the 535628

Interrogator.

If the Interrogator indicates

"EM, replace

the key with a spare or follow the procedures

under Key Replacement.

If Interrogator shows the electrical code

(1

to 15), replace the Lock Cylinder. (See pro-

cedure following Key Duplication Pro-

cedure). 5.

Set the Key Code Selector on the 535628

Interrogator to the same electrical code

determined in step 3. Turn the Ignition

Switch to START.

If engine starts, reconnect vehicle wiring

and check that the two-cavity connector at

the base of the steering column mates cor-

rectly.

If engine does not start, go to Test B,

Decoder Module Test.

B: PASS KEY DECODER MODULE TEST

(TABLE

1 )

At: PASSKEY DECODER MODULE

CONNECTOR (Disconnected)

Condition:

1 . 1mition switch: START I

Ignition Switch: RUN

Continued from previous c

1. Check the PNKIBLK (439) wire and ClN

Fuse for an open.

2. Check the ORN (440) wire and VATS Fuse

for an open.

3. Check the

BLKIWT (450) wire for an

open.

4. Check the PPL (963) wire for an open.

If

wire is good, replace ECM.

5. Check DK GRN (965) wire for an open. If

wire is good, do Test C.

For Diagnosis

See 1

See 2

See 3

See 4

Measure

Between

A1 (PNKI

BLK) &

Ground

(ORN' &

Ground

A1 (PNKI

BLK)

& I31

(BLKIWNT)

A2 (PPL) &

Bl (BLKI

WNT)

B: PASSKEY DECODER MODULE TEST

Correct

Voltage

Battery

Battery

Battery

5 Volts

(TABLE 2)

Measure: RESISTANCE

At: PASSKEY DECODER MODULE

CONNECTOR (Disconnected)

Conditions: Negative Battery Terminal

Disconnected

r No lCev ln lainition Switch

Measure

- Correct For Diagnosis

Between Resistance

& open circuit

UB2 (BRN) See 1

crank,

replace the PASSKEY Decoder

Module.

-

(Continued in next column) A3 (DK GRN)

& Ground

I . If voltages are correct, go to Table 2.

(Continued in next column)

Battery See 5

Page 1515 of 1825

Continued from previous page)

Note: VVhen the PASSKEY Decoder Module

is replaced, the new key code may not

match the code in the owner's existing

keys. If it does not match, then new

keys must be made. Use the key

duplication procedure.

1. Check YEL (921) and BRN (922) wires for

shorts to ground or between the two

wires.

2. Check

UEL (921) and BRN (922) wires for

an open. If

engine does not crank, go to page 30-0 for

diagnosis of Starter and Charging Circuits.

C3. Reconnect the Starter Enable Relay and

connect a fused jumper from terminal A3

(DK GRN) wire of the PASSKEY Decoder

Module to ground. Ignition Switch to

START.

0 If engine cranks, replace the PASSKEY

Decoder Module.

If engine does not crank, check the DK

GRN (965) wire for

an open. If wire is OK,

replace the Starter Enable Relay.

6: STARTER ENABLE RELAY TEST

D: ECM ENABLE SIGNAL TEST

C2. Connect a fused jumper between terminals

Measure: VOLTAGE

At: STARTER ENABLE RELAY CONNECTOR

(Disconnected)

Condition:

0 Ignition Switch: START Measure:

VOLTAGE

At: PASSKEY DECODER MODULE

CONNECTOR (Connected)

Condition: 0 Ignition Switch: RUN

Measure

Between

&

Ground

&

Ground

Measure

Between I I For Diagnosis ( Voltage

1 I 5Volts I See 1 1

If voltages are correct, go to C2.

1. Check YEL (5) wire for an open. If wire is

good but voltage is not present, go to

8A-30 for diagnosis of Starter and Charg-

ing Circuits.

Correct

Voltage

Battery

Battery

I I

Ignition Switch: START

For Diagnosis

See 1

See 1

0 wait four minutes from last time Ignition

Switch was turned to OFF to

allow PAS-

SKEY Internal timer to reset.

I A2 IPPL)& ) 2 to3Volts I See2 i Ground

If voltages are correct, cranking Fuel

Enable signal is operating normally,

return to Symptom Table.

E (YEL) Vfire and A (DK GR wire 1 1. Check PPL (963) wire for an open. A of the Starter Enable Relay Connector. I I

(Continued in next column)

Ignition Switch to START.

If engine cranks proceed to

63.

Continued from previous column)

2. Replace PASSKEY Decoder Module.

Note: When the PASSKEY Decoder Module

is replaced, the key code

it is set for

may not match the code in the owner's

keys. If

it does not, then new keys

must be made. Use the procedure

under

Duplicgti~n of-Keys2

E: SECURITY INDICATOR OPEN TEST

CONNECTOR (Disconnected)

Condition:

KEY DUPLICATION PROCEDURE

Key Replacement (Spare Key Available)

The 535628 Interrogator or equivalent must

be used to det e

the proper electrical code

of the key.

1. Insert the customer's spare ignition key into

the Key Code Reader on the 535628 Inter-

rogator.

2. Press the On-Off rocker switch to the ON

position.

Page 1516 of 1825

THEFT DETERRENT SYSTEM: PASSKEY

3. A number from 1 to 15 will appear in the

window designating the electrical code of

the key.

4. Cut a new key having the electrical code

ed from the 535628 Interrogator.

5. Start the engine using the new key to insure

that the key is correct both mechanically

and electrically.

Key Replacement (No Spare Key Available)

1. If the Ignition Key is lost and there is no

spare key, determine the mechanical code

from the code on the Ignition Key Lock

CyE

inder. The code may also be det

the dealer invoice for the car, or from the

Chewolet Zone Office.

2. Cut anew key to this mechanical code. Use a

blank PASSKEY test key which has no

resistance pellet. This key will be used to

operate the Ignition Switch for the remain-

ing steps.

3. Remove the hush panel under the steering

column and disconnect

C281 (two-cavity

connector leading into the steering column).

4. Insert the male half of the connector into the

female

pigtail connector from the 535628

Interrogator.

5. Set the Key Code Selector on the

Hnter-

rogator (535628 or equivalent) to "1 ".

6. Attempt to start engine using the key made

in step 2.

r If engine starts, the Key Code Selector is set

to the correct electrical code. Cut a new key

having this electrical code. The new key will

be customer's replacement key.

If engine does not start, turn Ignition

Switch to OFF, then turn the Key Code

Selector to the next higher position. Wait

four minutes and attempt to start the engine

using the new electrical code. Use the 4-min-

ute Timer on the 535628 Interrogator to

indicate the 4-minute interval. Start the

Timer by depressing the "Start" rocker

switch. The red indicator

will turn off at the

end of a four minute interval.

CIRCUIT OPERATION

Resistor senshg contacts are located in the

Ignition Key Lock Cylinder. These contact the

Key Resistor Pellet on the key when it is

inserted. When the lock is rotated, battery is

applied through the

CIH Fuse to the PASSKEY

Decoder Module. The Pellet resistance is then

colnpared against a fixed resistance in the Mod-

ule.

If the Key Pellet is the proper resistance, ter-

minal A3 is grounded, energizing the Starter

Enable Relay. At the

same time, a signal is

appfied at terminal A2 to enable the Electronic

Control Module

(ECM). When this signal is

received by the Electronic Control Module

(ECM), it allows fuel injector pulses to begin.

If the Key Resistor Pellet is the wrong

value,

the PASSKEY Decoder Module will shut down

tes. During this interval there

will be no output at terminals A3 or

A2.

If the Ignition Switch is turned on again dur-

ing this interval, the Timer will begin over

again and the PASSKEY Decoder Module

will

remain shut down for another 2 to 4 minutes.

The PASSKEY Decoder Module will continue

this process even if a key with the correct pellet

is used to turn the ignition back on. The Timer

is restarted by the ignition voltage at

t

A1 when Ignition Switch is turned to RUN.

Once the Timer has completed its

2 to 4 min-

ute cycle with the ignition off, the PASSKEY

Decoder Module and Timer are reset. A key

having the correct code can then be used to

start the engine.

The Security Indicator is controlled directly

by the PASSKEY Decoder Module. If there is a

PASSKEY Failure this indicator will be

grounded by the PASSKEY

Decoder Module

with the ignition in RUN,

BULB TEST or

START. When the Ignition Switch is first

placed in

RUN, BULB TEST or START the

Indicator lights for about 2 seconds as a bulb

check.

Page 1517 of 1825

" THEFT DETERRENT SYSTEM: PASSKEY

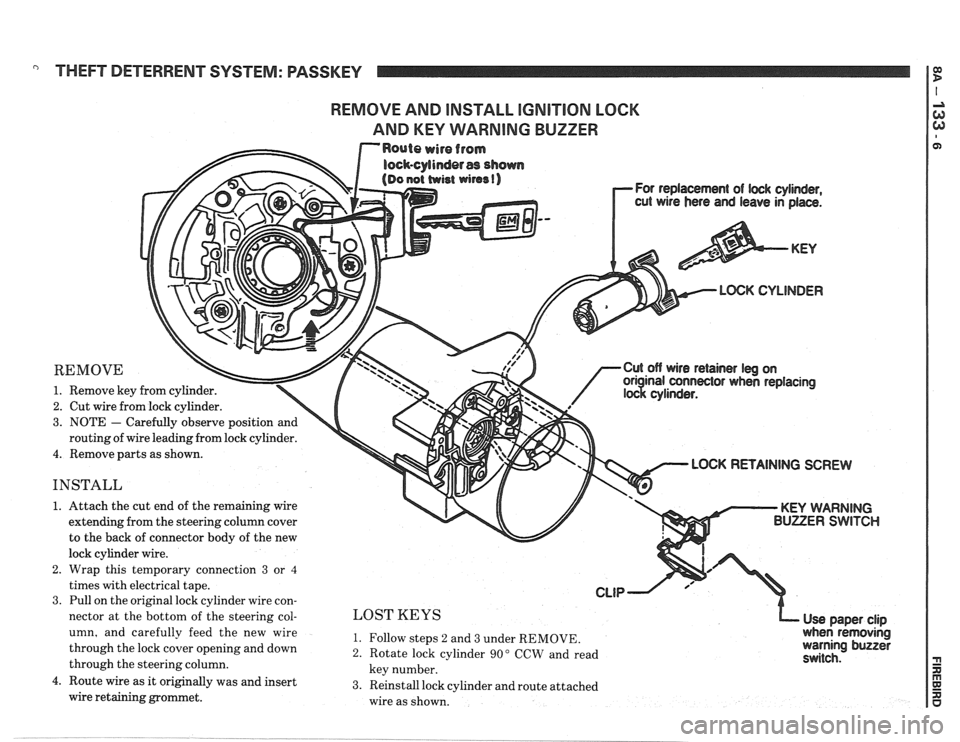

REMOVE AND INSTALL IGNITION LOCK

AND

KEY WARNING BUZZER

For replacement of lwk cylinder,

cut wire hers and leave in place.

LOGK CYLINDER

REMOVE

1. Remove key from cylinder.

2. Cut wire from lock cylinder.

3. NOTE - Carefully observe position an

routing of wire leading from lock cylinder.

4. Remove parts as shown. LOCK RETAINING SCREW

INSTALL

1. Attach the cut end of the remaining wire

extending from the steering column cover

to the back of connector body of the new

lock cylinder wire.

2. Wrap this temporary connection 3 or 4

times with electrical tape.

3. Pull on the original lock cylinder wire con-

nector at the bottom of the steering

col- LOST KEYS Use DaDer cli~ umn, and carefully feed the new wire 1. Follow steps 2 and 3 under REMOVE. wheh removihg

through the lock cover opening and down warning buzzer 2. Rotate lock cylinder 90" CCW and read

through the steering column. switch. key number. 4. Route wire as it originally was and insert 3. Reinstall lock cylinder and route attached

wire retaining grommet.

wire as shown.

Page 1518 of 1825

Page 1519 of 1825

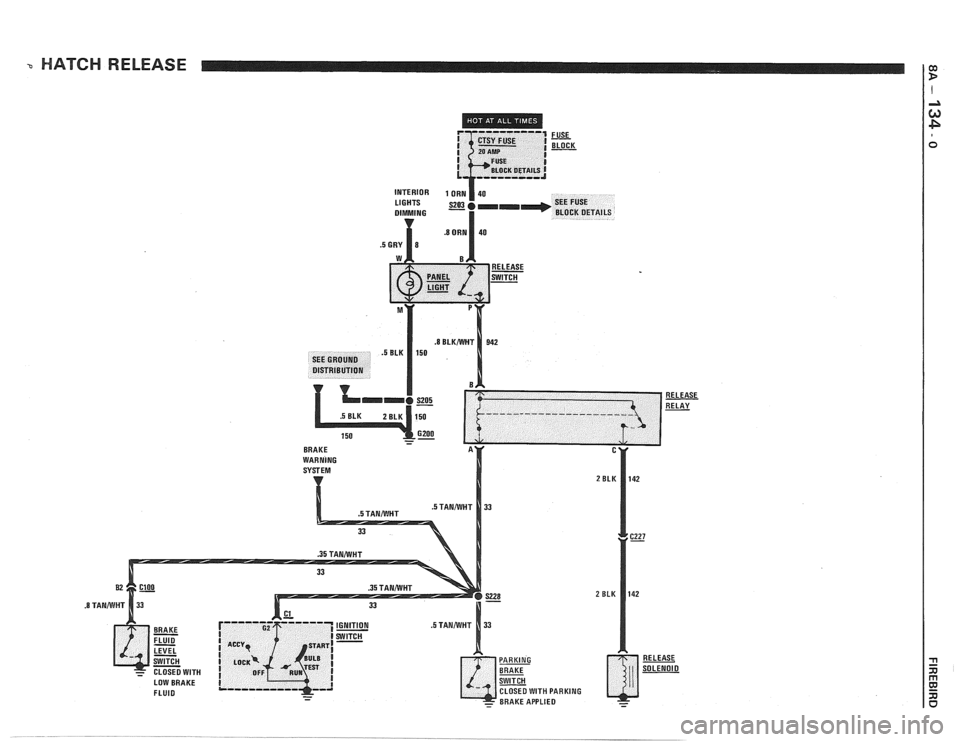

a HATCH RELEASE

RELEASE

RELAY

BRAKE

WARNING SYSTEM

I

CLOSED WITH PARKING - BRAKE APPLIED -

Page 1520 of 1825

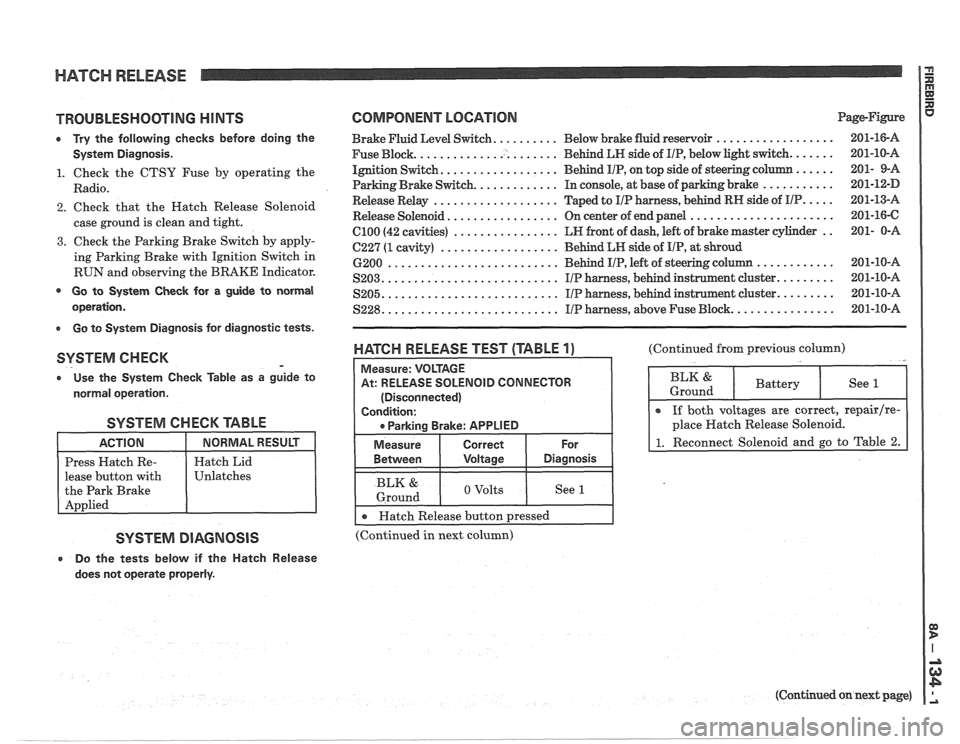

HATCH RELEASE P

E

TROUBLESHOOTING H lNTS

0 Try the following checks before doing the

System Diagnosis.

1. Check the CTSY Fuse by operating the

Radio.

2. Check that the Hatch Release Solenoid

case ground is clean and tight.

3. Check the Parking Brake Switch by apply-

ing Parking Brake with Ignition Switch in

RUN and observing the BRAKE Indicator.

@ Go to System Check for a guide to normal

operation.

Go to System Diagnosis for diagnostic tests.

SYSTEM CHECK -

o Use the System Check fable as a guide to

normal operation.

SYSTEM CHECK TABLE

lease button with

SYSTEM DIAGNOSIS

e Do the tests below if the Hatch Release

does not operate properly.

COMPONENT LOCATION Page-Figure

Brake Fluid Level Switch. ......... Below brake fluid reservoir ..................

Fuse Block. ..................... Behind LN side of IIP, below light switch. ......

Ignition Switch. ................. Behind IIP, on top side of steering column ......

Parking Brake Switch. ............ In console, at base of parking brake ...........

Release Relay ................... Taped to IIP harness, behind RN side of IIP. ....

Release Solenoid ................. On center of end panel ......................

el00 (42 cavities) ................ LN front of dash, left of brake master cylinder ..

C227 (1 cavity) .................. Behind LN side of IIP, at shroud

6200

.......................... Behind IIP, left of steering c

S203. .......................... IIP harness, behind instrunnent cluster. ........

.......................... ........ S205. IIP harness, behind instrument cluster.

S228. .......................... IIP harness, above Fuse Block. ...............

WATGH RELEASE TEST (TABLE 1)

At: RELEASE SOLENOID CONNECTOR

(Disconnected)

I 0 Parkina Brake: APPLIED I

I Measure I Correct I For

(Continued from previous column)

BLK & 1 o volts I See I 1 Ground

I r Hatch Release button pressed I --

(Continued in next column)

(Continued on next page)