Ram 3500 2020 Owner's Manual

Manufacturer: RAM, Model Year: 2020, Model line: 3500, Model: Ram 3500 2020Pages: 568

Page 321 of 568

STARTING AND OPERATING319

(Continued)

ENGINE RUNAWAY — DIESEL ENGINE

Diesel engine runaway is a rare condition

affecting diesel engines, where the engine

consumes its own lubrication oil and runs at

higher and higher RPM until it overspeeds to a

point where it destroys itself due to either

mechanical failure or engine seizure through

lack of lubrication.

REFUELING THE VEHICLE — GAS ENGINE

The fuel filler cap (gas cap) is located behind the

fuel filler door, on the left side of the vehicle.

Open the fuel door and remove the fuel filler cap

by turning it counter-clockwise.

Fuel Filler Cap

NOTE:

When removing the fuel filler cap, lay the cap

tether in the hook, located on the fuel filler door.

NOTE:

When the fuel nozzle “clicks” or shuts off, the

fuel tank is full.

WARNING!

In case of engine runaway due to flammable

fumes from fuel spills or turbocharger oil

leaks being sucked into the engine, do the

following to help avoid personal injury and/or

vehicle damage:

1. Turn the ignition switch to the OFF position.

2. Using a CO2 or dry chemical type fire

extinguisher, direct the spray from the fire

extinguisher into the grille on the driver side

so that the spray enters the engine air intake.

The inlet for the engine air intake is located

behind the drivers side headlamp and

receives air through the grille.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the gas cap is

removed or the tank is being filled.

Never add fuel to the vehicle when the

engine is running.

A fire may result if gasoline is pumped into

a portable container that is inside of a

vehicle. You could be burned. Always place

gas containers on the ground while filling.

CAUTION!

Damage to the fuel system or emissions

control system could result from using an

improper fuel tank filler tube cap.

A poorly fitting fuel filler cap could let impu-

rities into the fuel system.

A poorly fitting fuel filler cap may cause the

“Malfunction Indicator Light (MIL)” to turn

on.

To avoid fuel spillage and overfilling, do not

“top off” the fuel tank after filling. When the

fuel nozzle “clicks” or shuts off, the fuel

tank is full.

WARNING! (Continued)

5

20_DJD2_OM_EN_USC_t.book Page 319

Page 322 of 568

320STARTING AND OPERATING

Tighten the gas cap until you hear a “clicking”

sound. This is an indication that the gas cap

is tightened properly. The MIL in the instru -

ment cluster may turn on if the gas cap is not

secured properly. Make sure that the gas cap

is tightened each time the vehicle is refueled.

LOOSE FUEL FILLER CAP MESSAGE

If the vehicle diagnostic system

determines that the fuel filler cap is

loose, improperly installed, or

damaged, a loose gASCAP indicator

will display in the instrument cluster telltale

display area. Refer to “Instrument Cluster Display” in “Getting To Know Your Instrument

Panel” for further information. Tighten the fuel

filler cap properly and push the RIGHT button to

turn off the message. If the problem continues,

the message will appear the next time the

vehicle is started.

REFUELING THE VEHICLE — DIESEL ENGINE

1. Open the fuel filler door.

Fill Locations

NOTE:

There is no fuel filler cap. A flapper door inside

the filler pipe seals the system. 2. Insert the fuel nozzle fully into the filler pipe

– the nozzle opens and holds the flapper

door while refueling.

3. Fill the vehicle with fuel – when the fuel nozzle “clicks” or shuts off the fuel tank is

full.

4. Remove the fuel nozzle and close the fuel door.

Emergency Fuel Can Refueling

NOTE:

In the event that you run the vehicle out of fuel,

once refueled, place the ignition in the ON posi -

tion for 30 seconds, then turn the ignition OFF

and wait 30 seconds. Repeat this procedure

three times, prior to cranking the engine.

Most fuel cans will not open the flapper door.

A funnel is provided to open the flapper door to

allow emergency refueling with a fuel can.

1. Retrieve fuel funnel from the jack kit located under the front passenger seat.

2. Insert funnel into same filler pipe opening as the fuel nozzle.

WARNING!

Always place container on the ground

before filling.

Keep the pump nozzle in contact with the

container when you are filling it.

Use only approved containers for flam -

mable liquid.

Do not leave container unattended while

filling.

A static electric charge could cause a spark

and fire hazard.

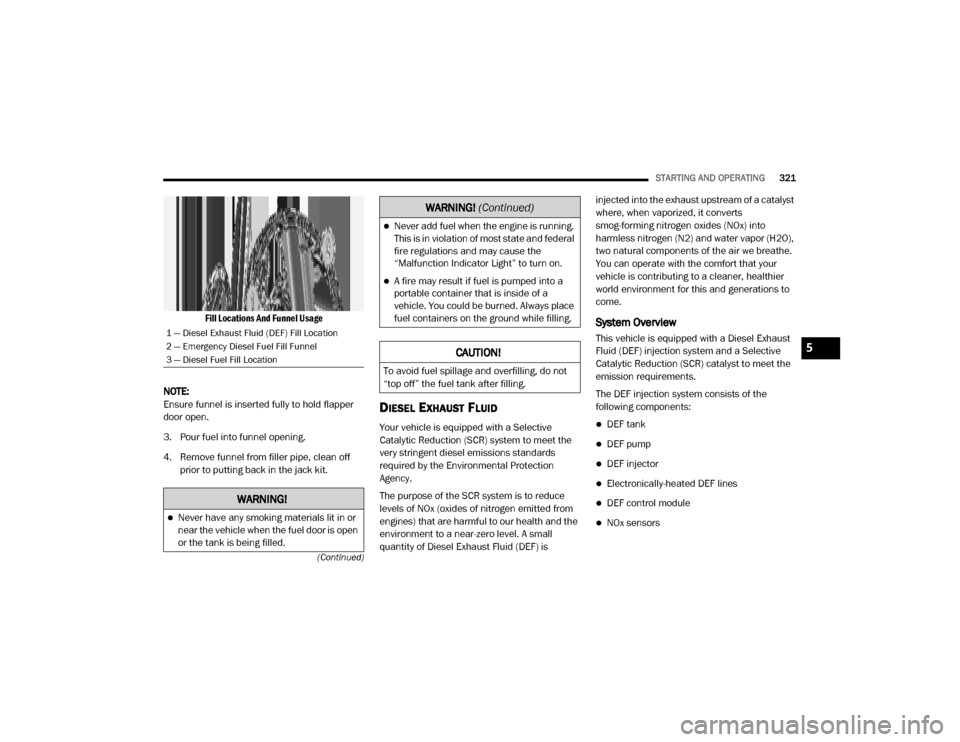

1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Diesel Fuel Fill Location

20_DJD2_OM_EN_USC_t.book Page 320

Page 323 of 568

STARTING AND OPERATING321

(Continued)

Fill Locations And Funnel Usage

NOTE:

Ensure funnel is inserted fully to hold flapper

door open.

3. Pour fuel into funnel opening.

4. Remove funnel from filler pipe, clean off prior to putting back in the jack kit.

DIESEL EXHAUST FLUID

Your vehicle is equipped with a Selective

Catalytic Reduction (SCR) system to meet the

very stringent diesel emissions standards

required by the Environmental Protection

Agency.

The purpose of the SCR system is to reduce

levels of NOx (oxides of nitrogen emitted from

engines) that are harmful to our health and the

environment to a near-zero level. A small

quantity of Diesel Exhaust Fluid (DEF) is injected into the exhaust upstream of a catalyst

where, when vaporized, it converts

smog-forming nitrogen oxides (NOx) into

harmless nitrogen (N2) and water vapor (H2O),

two natural components of the air we breathe.

You can operate with the comfort that your

vehicle is contributing to a cleaner, healthier

world environment for this and generations to

come.

System Overview

This vehicle is equipped with a Diesel Exhaust

Fluid (DEF) injection system and a Selective

Catalytic Reduction (SCR) catalyst to meet the

emission requirements.

The DEF injection system consists of the

following components:

DEF tank

DEF pump

DEF injector

Electronically-heated DEF lines

DEF control module

NOx sensors

1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Emergency Diesel Fuel Fill Funnel

3 — Diesel Fuel Fill Location

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open

or the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the

“Malfunction Indicator Light” to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always place

fuel containers on the ground while filling.

CAUTION!

To avoid fuel spillage and overfilling, do not

“top off” the fuel tank after filling.

WARNING!

(Continued)

5

20_DJD2_OM_EN_USC_t.book Page 321

Page 324 of 568

322STARTING AND OPERATING

Temperature sensors

SCR catalyst

UQS Sensor

Refer to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

system messages and warnings.

NOTE:

Your vehicle is equipped with a DEF injection

system. You may occasionally hear an audible

clicking noise. This is normal operation.

The DEF pump will run for a period of time

after engine shutdown to purge the DEF

system. This is normal operation.

Diesel Exhaust Fluid Storage

Diesel Exhaust Fluid (DEF) is considered a very

stable product with a long shelf life. If DEF is

kept in temperatures between 10°F and 90°F

(-12°C and 32°C), it will last a minimum of one

year.

DEF is subject to freezing at the lowest

temperatures. For example, DEF may freeze at

temperatures at or below 12°F (-11°C). The

system has been designed to operate in this

environment. NOTE:

When working with DEF, it is important to know

that:

Any containers or parts that come into

contact with DEF must be DEF compatible

(plastic or stainless steel). Copper, brass,

aluminum, iron or non-stainless steel should

be avoided as they are subject to corrosion

by DEF.

If DEF is spilled, it should be wiped up

completely.

Adding Diesel Exhaust Fluid

The DEF gauge (located on the instrument

cluster) will display the level of DEF remaining in

the tank. Refer to “Instrument Cluster” and

“Instrument Cluster Descriptions” in “Getting To

Know Your Instrument Panel” for further

information.

NOTE:

Driving conditions (altitude, vehicle speed,

load, etc.) will affect the amount of DEF that

is used in your vehicle.

Another factor is that outside temperature

can affect DEF consumption. In cold condi

-

tions, 12°F (-11°C) and below, the DEF gauge needle can stay on a fixed position and

may not move for extended periods of time.

This is a normal function of the system.

There is an electric heater inside the DEF

tank that automatically works when neces

-

sary. And if the DEF supply does freeze, the

truck will operate normally until it thaws.

DEF Fill Procedure

NOTE:

Refer to “Fluids And Lubricants” in “Technical

Specifications” for the correct fluid type.

1. Remove cap from DEF tank (located on driver’s side of the vehicle or in fuel door).

Fill Locations

1 — Diesel Exhaust Fluid (DEF) Fill Location

2 — Diesel Fuel Fill Location

20_DJD2_OM_EN_USC_t.book Page 322

Page 325 of 568

STARTING AND OPERATING323

(Continued)

2. Insert DEF fill adapter/nozzle into DEF tank filler neck.

NOTE:

The DEF gauge may take up to five

seconds to update after adding a gallon

or more of Diesel Exhaust Fluid (DEF) to

the DEF tank. If you have a fault related

to the DEF system, the gauge may not

update to the new level. See an autho -

rized dealer for service.

The DEF gauge may also not immediately

update after a refill if the temperature of

the DEF fluid is below 12°F (-11°C). The

DEF line heater will possibly warm up the

DEF fluid and allow the gauge to update

after a period of run time. Under very cold

conditions, it is possible that the gauge

may not reflect the new fill level for

several drives.

Excessive overfilling of the DEF tank can

result in a MIL lamp/fault code and inac-

curate level readings. 3. Stop filling the DEF tank immediately when

any of the following happen: DEF stops

flowing from the fill bottle into the DEF tank,

DEF splashes out the filler neck, or a DEF

pump nozzle automatically shuts off.

4. Reinstall cap onto DEF tank.

Filling The Def Tank In Cold Climates

Since DEF will begin to freeze at 12°F (-11°C),

your vehicle is equipped with an automatic DEF

heating system. This allows the DEF injection

CAUTION!

To avoid DEF spillage, and possible

damage to the DEF tank from overfilling, do

not “top off” the DEF tank after filling.

DO NOT OVERFILL. DEF will freeze below

12ºF (-11ºC). The DEF system is designed

to work in temperatures below the DEF

freezing point, however, if the tank is over -

filled and freezes, the system could be

damaged.

When DEF is spilled, clean the area imme -

diately with water and use an absorbent

material to soak up the spills on the ground.

Do not attempt to start your engine if DEF is

accidentally added to the diesel fuel tank

as it can result in severe damage to your

engine, including but not limited to failure

of the fuel pump and injectors.

Never add anything other than DEF to the

tank – especially any form of hydrocarbon

such as diesel fuel, fuel system additives,

gasoline, or any other petroleum-based

product. Even a very small amount of these,

less than 100 parts per million or less than

1 oz. per 78 Gallons (295 Liters) will

contaminate the entire DEF system and will

require replacement. If owners use a

container, funnel or nozzle when refilling

the tank, it should either be new or one that

is has only been used for adding DEF.

Mopar provides an attachable nozzle with

its DEF for this purpose.

CAUTION! (Continued)

5

20_DJD2_OM_EN_USC_t.book Page 323

Page 326 of 568

324STARTING AND OPERATING

system to operate properly at temperatures

below 12°F (-11°C). If your vehicle is not in

operation for an extended period of time with

temperatures below 12°F (-11°C), the DEF in

the tank may freeze. If the tank is overfilled and

freezes, it could be damaged. Therefore, do not

overfill the DEF tank.

Extra care should be taken when filling with

portable containers to avoid overfilling. Note the

level of the DEF gauge in your instrument

cluster. You may safely add a maximum of

2 Gallons (7.5 Liters) of DEF from portable

containers when your DEF gauge is reading

½ full.

VEHICLE LOADING

GROSS VEHICLE WEIGHT RATING

(GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear axle

systems (GAWR). Total load must be limited so

GVWR and front and rear GAWR are not

exceeded.

PAYLOAD

The payload of a vehicle is defined as the

allowable load weight a truck can carry,

including the weight of the driver, all

passengers, options and cargo.

GROSS AXLE WEIGHT RATING (GAWR)

The GAWR is the maximum permissible load on

the front and rear axles. The load must be

distributed in the cargo area so that the GAWR

of each axle is not exceeded.

Each axle GAWR is determined by the

components in the system with the lowest load

carrying capacity (axle, springs, tires or wheels).

Heavier axles or suspension components

sometimes specified by purchasers for

increased durability does not necessarily

increase the vehicle's GVWR.

TIRE SIZE

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

RIM SIZE

This is the rim size that is appropriate for the tire

size listed.

INFLATION PRESSURE

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full

GAWR.

CURB WEIGHT

The curb weight of a vehicle is defined as the

total weight of the vehicle with all fluids,

including vehicle fuel, at full capacity

conditions, and with no occupants or cargo

loaded into the vehicle. The front and rear curb

weight values are determined by weighing your

vehicle on a commercial scale before any

occupants or cargo are added.

LOADING

The actual total weight and the weight of the

front and rear of your vehicle at the ground can

best be determined by weighing it when it is

loaded and ready for operation.

20_DJD2_OM_EN_USC_t.book Page 324

Page 327 of 568

STARTING AND OPERATING325

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has

not been exceeded. The weight on the front and

rear of the vehicle should then be determined

separately to be sure that the load is properly

distributed over the front and rear axles.

Weighing the vehicle may show that the GAWR

of either the front or rear axle has been

exceeded but the total load is within the

specified GVWR. If so, weight must be shifted

from front to rear or rear to front as appropriate

until the specified weight limitations are met.

Store the heavier items down low and be sure

that the weight is distributed equally. Stow all

loose items securely before driving.

Improper weight distributions can have an

adverse effect on the way your vehicle steers

and handles and the way the brakes operate.TRAILER TOWING

In this section you will find safety tips and

information on limits to the type of towing you

can reasonably do with your vehicle. Before

towing a trailer, carefully review this information

to tow your load as efficiently and safely as

possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and

recommendations in this manual concerning

vehicles used for trailer towing.

COMMON TOWING DEFINITIONS

The following trailer towing-related definitions

will assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your

vehicle. This includes driver, passengers, cargo

and tongue weight. The total load must be

limited so that you do not exceed the GVWR.

Refer to “Vehicle Loading/Vehicle Certification

Label” in “Starting And Operating” for further

information.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the

weight of all cargo, consumables and

equipment (permanent or temporary) loaded in

or on the trailer in its "loaded and ready for

operation" condition.

The recommended way to measure GTW is to

put your fully loaded trailer on a vehicle scale.

The entire weight of the trailer must be

supported by the scale.

Gross Combination Weight Rating (GCWR)

The GCWR is the total allowable weight of your

vehicle and trailer when weighed in

combination.

CAUTION!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR.

If you do, parts on your vehicle can break, or

it can change the way your vehicle handles.

This could cause you to lose control. Also

overloading can shorten the life of your

vehicle.

WARNING!

If the gross trailer weight is 5,000 lbs (2,267 kg)

or more, it is recommended to use a

weight-distributing hitch to ensure stable

handling of your vehicle. If you use a standard

weight-carrying hitch, you could lose control of

your vehicle and cause a collision.

5

20_DJD2_OM_EN_USC_t.book Page 325

Page 328 of 568

326STARTING AND OPERATING

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do

not exceed either front or rear GAWR. Refer to

“Vehicle Loading/Vehicle Certification Label” in

“Starting And Operating” for further

information.

Tongue Weight (TW)

The tongue weight is the downward force

exerted on the hitch ball by the trailer. You must

consider this as part of the load on your vehicle.

Trailer Frontal Area

The frontal area is the maximum height

multiplied by the maximum width of the front of

a trailer.

Trailer Sway Control

The trailer sway control can be a mechanical

telescoping link that can be installed between

the hitch receiver and the trailer tongue that

typically provides adjustable friction associated

with the telescoping motion to dampen any

unwanted trailer swaying motions while

traveling.

If equipped, the electronic Trailer Sway Control

(TSC) recognizes a swaying trailer and

automatically applies individual wheel brakes

and/or reduces engine power to attempt to

eliminate the trailer sway.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer

tongue weight, just as if it were luggage located

at a hitch ball or some other connecting point of

the vehicle. These kinds of hitches are the most

popular on the market today and they are

commonly used to tow small and medium sized

trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute

trailer tongue weight to the tow vehicle's front

axle and the trailer axle(s). When used in

accordance with the manufacturer's directions,

it provides for a more level ride, offering more

consistent steering and brake control, thereby

enhancing towing safety. The addition of a

friction/hydraulic sway control also dampens

sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer

stability. Trailer Sway Control (TSC) and a weight

distributing (load equalizing) hitch are

recommended for heavier Tongue Weights (TW)

and may be required depending on vehicle and

trailer configuration/loading to comply with

GAWR requirements.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the

vehicle and have a collision.

20_DJD2_OM_EN_USC_t.book Page 326

Page 329 of 568

STARTING AND OPERATING327

With Weight-Distributing Hitch (Correct) Without Weight-Distributing Hitch (Incorrect)

Improper Adjustment Of Weight-Distributing Hitch (Incorrect)

Recommended Distribution Hitch Adjustment

Towing With 2500/3500 Air Suspension

1. Position the truck to be ready to connect to

the trailer (do not connect the trailer).

NOTE:

Normal Ride Height (NRH) or Alternate Trailer

Height (ATH) can be used. The vehicle must

remain in the engine running position while

attaching a trailer for proper leveling of the air

suspension system. It may not be possible to

enter Alternate Trailer Height (ATH) while lightly

loaded.

2. Measure the height of the top of the front wheel opening on the fender to ground, this

is height H1.

3. Attach the trailer to the vehicle without the weight distribution bars connected.

4. Measure the height of the top of the front wheel opening on the fender to ground, this

is height H2.

WARNING!

An improperly adjusted weight distributing

hitch system may reduce handling, stability

and braking performance and could result

in a collision.

Weight distributing systems may not be

compatible with surge brake couplers.

Consult with your hitch and trailer manufac -

turer or a reputable Recreational Vehicle

dealer for additional information.

5

20_DJD2_OM_EN_USC_t.book Page 327

Page 330 of 568

328STARTING AND OPERATING

5. Install and adjust the tension in the weight

distributing bars per the manufacturers’

recommendations so that the height of the

front fender is approximately (H2-H1)/

2+H1 (about 1/2 the difference between

H2 and H1 above normal ride height [H1]).

6. Perform a visual inspection of the trailer and weight distributing hitch to confirm

manufacturers’ recommendations have

been met.

NOTE:

For all towing conditions, we recommend towing

with TOW/HAUL mode engaged. Towing With All Other 2500/3500 (Non-Air

Suspension)

1. Position the truck to be ready to connect to

the trailer (do not connect the trailer).

2. Measure the height of the top of the front wheel opening on the fender to ground, this

is height H1.

3. Attach the trailer to the vehicle without the weight distribution bars connected.

4. Measure the height of the top of the front wheel opening on the fender to ground, this

is height H2.

5. Install and adjust the tension in the weight distributing bars per the manufacturers’

recommendations so that the height of the

front fender is approximately (H2-H1)/

2+H1 (about 1/2 the difference between

H2 and H1 above normal ride height [H1]).

6. Perform a visual inspection of the trailer and weight distributing hitch to confirm

manufacturers’ recommendations have

been met. NOTE:

For all towing conditions, we recommend towing

with TOW/HAUL mode engaged.

Fifth-Wheel Hitch

The fifth-wheel hitch is a special high platform with

a coupling that mounts over the rear axle of the

tow vehicle in the truck bed. It connects a vehicle

and fifth-wheel trailer with a coupling king pin.

Your truck may be equipped with a fifth wheel

hitch option. Refer to the separately provided

fifth wheel hitch safety, care, assembly, and

operating instructions.

Gooseneck Hitch

The gooseneck hitch employs a pivoted

coupling arm which attaches to a ball mounted

in the bed of a pickup truck. The coupling arm

connects to the hitch mounted over the rear

axle in the truck bed.

Measurement

Example Example 2500/

3500 Height (mm)

H1 1030

H2 1058

H2-H1 28

(H2-H1)/2 14

(H2-H1)/2 + H1 1044

Measurement

Example Example 2500/

3500 Height (mm)

H1 1030

H2 1058

H2-H1 28

(H2-H1)/2 14

(H2-H1)/2 + H1 1044

20_DJD2_OM_EN_USC_t.book Page 328