fuel Ram 4500 Chassis Cab 2018 Owner's Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2018, Model line: 4500 Chassis Cab, Model: Ram 4500 Chassis Cab 2018Pages: 298, PDF Size: 5.88 MB

Page 180 of 298

Heavy Duty Use Of The Vehicle

Change engine oil at 4,000 miles (6,500 km)

or 350 hours of engine run time if the vehicle

is operated in a dusty and off road environ-

ment or is operated predominately at idle or

only very low engine RPM’s. This type of

vehicle use is considered Severe Duty.

SCHEDULED MAINTENANCE — 6.7L

CUMMINS DIESEL ENGINE

CAUTION!

Failure to perform the required mainte-

nance items may result in damage to the

vehicle.

At Each Stop For Fuel

Check the engine oil level at least 30 minutes

after a fully warmed engine is shut off.

Checking the oil level while the vehicle is on

level ground will improve the accuracy of the

oil level reading. Add oil only when the level

is at or below the ADD or MIN mark. Once A Month

• Inspect the batteries, and clean and

tighten the terminals as required.

• Check the fluid levels of the coolant reser- voir, brake master cylinder, and automatic

transmission (if equipped), and add as

needed.

At Each Oil Change

• Change the engine oil filter.

• Inspect the exhaust system.

• Inspect engine air filter.

• Check the coolant level, hoses, and clamps.

• Inspect front end, and lubricate — If equipped with serviceable fittings.

• Lube the front drive shaft fitting (4X4 mod- els only).

Inspection and service should also be per-

formed anytime a malfunction is observed or

suspected. Retain all receipts.

Oil Change Indicator System —

Cummins Diesel

Your vehicle is equipped with an engine oil

change indicator system. This system will

alert you when it is time to change your

engine oil by displaying the words “Oil

Change Due” in your instrument cluster dis-

play. The oil change reminder will remind the

owner to change the engine oil every

15,000 miles or 500 hours, whichever

comes first, except for the Chassis Cab mod-

els and Pickup models configured with op-

tional B20 capability that are using B20 bio-

diesel, which are 12,500 miles or 400 hours,

whichever comes first. Failure to change the

engine oil per the maintenance schedule can

result in internal engine damage.

Replace the engine oil and oil filter every

15,000 miles (24,000 km) or six months, or

sooner if prompted by the oil change indicator

system. Under no circumstances should oil

change intervals exceed 15,000 miles

(24,000 km) or six months, whichever comes

first.

SERVICING AND MAINTENANCE

178

Page 181 of 298

NOTE:

• Under no circumstances should oil changeintervals exceed 15,000 miles

(24,000 km) or six months or 500 Hours,

whichever comes first.

• Replace the engine oil and oil filter every 12,500 miles (20 000 km) when running

B20 fuel (Chassis Cab Only).

If Chassis Cab models and Pickup models

configured with optional B20 capability are

operated with greater than 5% levels of bio-

diesel, the oil change interval must not ex-

ceed 12,500 miles (20 000 km) under any

circumstances. See the Fuel Requirements

section for more information regarding opera-

tion of Chassis Cab models and Pickup mod-

els configured for use with biodiesel blend

(B6-B20) fuel meeting ASTM specification

D-7467.Perform Service Indicator —

Cummins Diesel

Your vehicle will require emissions mainte-

nance at a set interval. To help remind you

when this maintenance is due, the instru-

ment cluster will display “Perform Service”.

When the “Perform Service” message is dis-

played on the instrument cluster it is neces-

sary to have the emissions maintenance per-

formed. Emissions maintenance may include

replacing the Closed Crankcase Ventilation

(CCV) filter element. The procedure for clear-

ing and resetting the “Perform Service” indi-

cator message is located in the appropriate

Service Information.

179

Page 183 of 298

Mileage or time passed (whichever comes first):7,500

15,000

22,500

30,000

37,500

45,000

52,500

60,000

67,500

75,000

82,500

90,000

97,500

105,000

112,500

120,000

127,500

135,000

142,500

150,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

Or Kilometers:

12,000

24,000

36,000

48,000

60,000

72,000

84,000

96,000

108,000

120,000

132,000

144,000

156,000

168,000

180,000

192,000

204,000

216,000

228,000

240,000

Inspect wheel bearings. XX XX X

Additional Maintenance

Replace cabin air filter. XXX XX X

Replace engine fuel filter element. X X X X X X X X X X

Replace chassis mounted fuel filter element. X X X X X X X X X X

Inspect the front and rear axle surfaces. If

gear oil leakage is suspected, check the fluid

level. If using your vehicle for police, taxi,

fleet, off-road or frequent trailer towing

change the axle fluid. *

Inspect the transfer case fluid (4x4), change

for any of the following: police, taxi, fleet, or

frequent trailer towing. XX XX X

Change the transfer case fluid (4x4). XX

Change automatic transmission fluid

(AS69RC transmission only). XX XX X

Change the automatic transmission fluid and

sump filter (AS69RC transmission only). XX

Change automatic transmission fluid and fil-

ter(s) if using your vehicle for any of the fol-

lowing: police, fleet, or frequent trailer towing

(68RFE transmission only). XX

181

Page 189 of 298

If the vehicle experiences a sudden loss of

engine power while being driven in heavy

snow or rain, or when plowing snow, and/or

the “SERVICE AIR FILTER” message is dis-

played on the instrument cluster along with a

chime that repeats every 60 seconds, visually

inspect the air filter for snow/ice build up or

extreme water saturation. If the air filter is

not damaged, remove all snow/ice and rein-

stall air filter. If the air filter is damaged,

replace filter element.

NOTE:

The air filter housing contains a Mass Air

Flow sensor. This sensor is critical to proper

engine operation and component longevity.

Any damage or modification to this sensor

could result in major engine and/or exhaust

aftertreatment damage. We recommend you

use Mopar brand parts.

Even though your vehicle is equipped with an

Air Filter Monitor, a visual inspection of the

air cleaner filter element is recommended

every 15,000 miles (24,000km) or

12 months – whichever occurs first.Under nocircumstances should the air cleaner filter ele-

ment exceed 30,000 miles (48,000 km) or

24 months, whichever comes first.

CAUTION!

Many aftermarket performance air filter

elements do not adequately filter the air

entering the engine. Use of such filters can

severely damage your engine.

Draining Fuel/Water Separator

Filter

There are two fuel filter assemblies. One is

located on the driver's side of the engine. The

best access to this water drain valve is from

under the hood. The second one is on the

under body, located in front of the rear axle

above the drive shaft on pick-up models. The

Chassis Cab models second filter location is

on the frame behind the front axle. The best

access to this water drain valve is from under

the vehicle.

CAUTION!

• Do not drain the fuel/water separator

filter when the engine is running.

• Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

If water is detected in the water separator

while the engine is running, or while the

ignition switch is in the ON position, the

“Water In Fuel Indicator Light” will illumi-

nate and an audible chime will be heard five

times. At this point you should stop the

engine and drain the water from both of the

filters.

CAUTION!

If the “Water In Fuel Indicator Light” re-

mains on, DO NOT START the engine be-

fore you drain water from the fuel filters to

avoid engine damage.

If the “Water In Fuel Indicator Light” comes

on and a single chime is heard while you are

driving, or with the ignition switch in the ON

187

Page 190 of 298

position, there may be a problem with your

water separator wiring or sensor. See your

authorized dealer for service.

Upon proper draining of the water from both

fuel filters, the “Water In Fuel Indicator

Light” will remain illuminated for approxi-

mately 10 seconds. If the water was drained

while the engine was running, the “Water In

Fuel Indicator Light” may remain on for ap-

proximately three minutes.

NOTE:

Care should be taken in disposing of used

fluids from your vehicle. Used fluids, indis-

criminately discarded, can present a problem

to the environment. Contact an authorized

dealer, service station, or government agency

for advice on recycling programs and for

where used fluids and filters can be properly

disposed of in your area.

Drain the fuel/water separator filters when

the “Water In Fuel Indicator Light” is ON.

Within 10 minutes of vehicle shutdown, turn

the engine mounted filter drain valve (located

on the side of the filter assembly) counter-

clockwise 1/4 turn, and turn the under body

mounted filter drain valve (located on thebottom of the filter assembly) counterclock

wise 1 full turn. Then turn the ignition switch

to the ON position, and allow any accumu-

lated water to drain. Leave the drain valve

open until all water and contaminants have

been removed. When clean fuel is visible,

close the drain valves by turning them fully

clockwise, and turn the ignition switch to

OFF.

If more than a couple ounces/milliliters of

fuel have been drained, follow the directions

for “Priming If The Engine Has Run Out Of

Fuel.”

Engine Mounted Fuel Filter

Replacement

NOTE:

• Using a fuel filter that does not meet the

manufacturer's filtration and water separat-

ing requirements can severely impact fuel

system life and reliability.

• The engine mounted filter housing is equipped with a No-Filter-No-Run (NFNR)

feature. Engine will not run if:

1. No filter is installed. 2. Inferior/Non-approved filter is used.

Use of OEM filter is required to ensure

vehicle will run.

CAUTION!

• Diesel fuel will damage blacktop pavingsurfaces. Drain the filter into an appro-

priate container.

• Do not prefill the fuel filter when install-

ing a new fuel filter. There is a possibility

debris could be introduced into the fuel

filter during this action. It is best to

install the filter dry and allow the in-tank

lift pump to prime the fuel system.

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain hose.

3. Open the water drain valve 1/4 turn coun- terclockwise and completely drain fuel

and water into the approved container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for re-

moval. Remove used o-ring and discard it.

SERVICING AND MAINTENANCE

188

Page 191 of 298

6. Remove the used filter cartridge from thehousing and dispose of according to your

local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

9. Remove new filter cartridge from plastic bag and install into housing.

NOTE:

Do not remove cartridge from bag until

you reach this step in order to keep car-

tridge clean.

10. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter

housing with fuel.

11. Install lid onto housing and tighten to 22.5 ft lbs (30.5 N.m). Do not over-

tighten the lid.

12. Prime the engine using the procedure in “Priming If The Engine Has Run Out Of

Fuel.” Then start the engine and confirm

there are no leaks.Underbody Mounted Fuel Filter

Replacement

NOTE:

• Using a fuel filter that does not meet themanufacturer's filtration and water separat-

ing requirements can severely impact fuel

system life and reliability.

• The underbody mounted filter housing will cause the engine not to run if:

1. No filter is installed.

CAUTION!

• Diesel fuel will damage blacktop paving surfaces. Drain the filter into an appro-

priate container.

• Do not prefill the fuel filter when install-

ing a new fuel filter. There is a possibility

debris could be introduced into the fuel

filter during this action. It is best to

install the filter dry and allow the in-tank

lift pump to prime the fuel system.

1. Ensure engine is turned off. 2. Place drain pan under the fuel filter drain

hose.

3. Open the water drain valve 1 full turn counterclockwise and completely drain

fuel and water into the approved

container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for re-

moval. Remove used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your

local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

NOTE:

WIF sensor is re-usable. Service kit comes

with new o-ring for filter canister and WIF

sensor.

189

Page 192 of 298

Priming If The Engine Has Run

Out Of Fuel

WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure

fuel spray can cause serious injury or

death.

1. Add a substantial amount of fuel to the tank, approximately 2 to 5 gal (8L to

19L).

2. Turn ignition switch to the start position to engage starter for one second, return ig-

nition switch to run position. This will

activate in tank fuel pump for approxi-

mately 15 seconds. Repeat this process

twice.

3. Start the engine using the “Normal Start- ing” procedure. Refer to “Starting Proce-

dures” in “Starting and Operating” for

further information.

CAUTION!

Do not engage the starter motor for more

than 15 seconds at a time. Allow two

minutes between the cranking intervals.

NOTE:

The engine may run rough until the air is

forced from all the fuel lines.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable un-

der certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system. NOTE:

• A maximum blend of 5% biodiesel, meet-

ing ASTM specification D-975 may be used

with your Cummins diesel engine. (Chassis

Cab models not configured with B20 capa-

bility.)

• A maximum blend of 20% biodiesel, meet- ing ASTM specification D-7467 may be

used with your Cummins diesel engine.

(Pickup models and Chassis Cab models

configured with B20 capability.)

• Use of biodiesel mixture in excess of 20% can negatively impact the fuel filter's abil-

ity to separate water from the fuel, resulting

in high pressure fuel system corrosion or

damage.

• Ethanol blends are not recommended or approved for use with your Cummins diesel

engine.

• In addition, commercially available fuel ad- ditives are not necessary for the proper

operation of your Cummins diesel engine.

SERVICING AND MAINTENANCE

190

Page 201 of 298

WARNING!

Overloading of your tires is dangerous.

Overloading can cause tire failure, affect

vehicle handling, and increase your stop-

ping distance. Use tires of the recom-

mended load capacity for your vehicle.

Never overload them.

Tires — General Information

Tire Pressure

Proper tire inflation pressure is essential to

the safe and satisfactory operation of your

vehicle. Four primary areas are affected by

improper tire pressure:

• Safety and Vehicle Stability

• Economy

• Tread Wear

• Ride ComfortSafety

WARNING!

• Improperly inflated tires are dangerous

and can cause collisions.

• Underinflation increases tire flexing and

can result in overheating and tire failure.

• Overinflation reduces a tire's ability to cushion shock. Objects on the road and

chuckholes can cause damage that re-

sult in tire failure.

• Overinflated or underinflated tires can

affect vehicle handling and can fail sud-

denly, resulting in loss of vehicle control.

• Unequal tire pressures can cause steer-

ing problems. You could lose control of

your vehicle.

• Unequal tire pressures from one side of

the vehicle to the other can cause the

vehicle to drift to the right or left.

• Always drive with each tire inflated to

the recommended cold tire inflation

pressure. Both under-inflation and over-inflation affect

the stability of the vehicle and can produce a

feeling of sluggish response or over respon-

siveness in the steering.

NOTE:

• Unequal tire pressures from side to side

may cause erratic and unpredictable steer-

ing response.

• Unequal tire pressure from side to side may cause the vehicle to drift left or right.

Fuel Economy

Underinflated tires will increase tire rolling

resistance resulting in higher fuel consump-

tion.

Tread Wear

Improper cold tire inflation pressures can

cause abnormal wear patterns and reduced

tread life, resulting in the need for earlier tire

replacement.

Ride Comfort And Vehicle Stability

Proper tire inflation contributes to a comfort-

able ride. Over-inflation produces a jarring

and uncomfortable ride.

199

Page 215 of 298

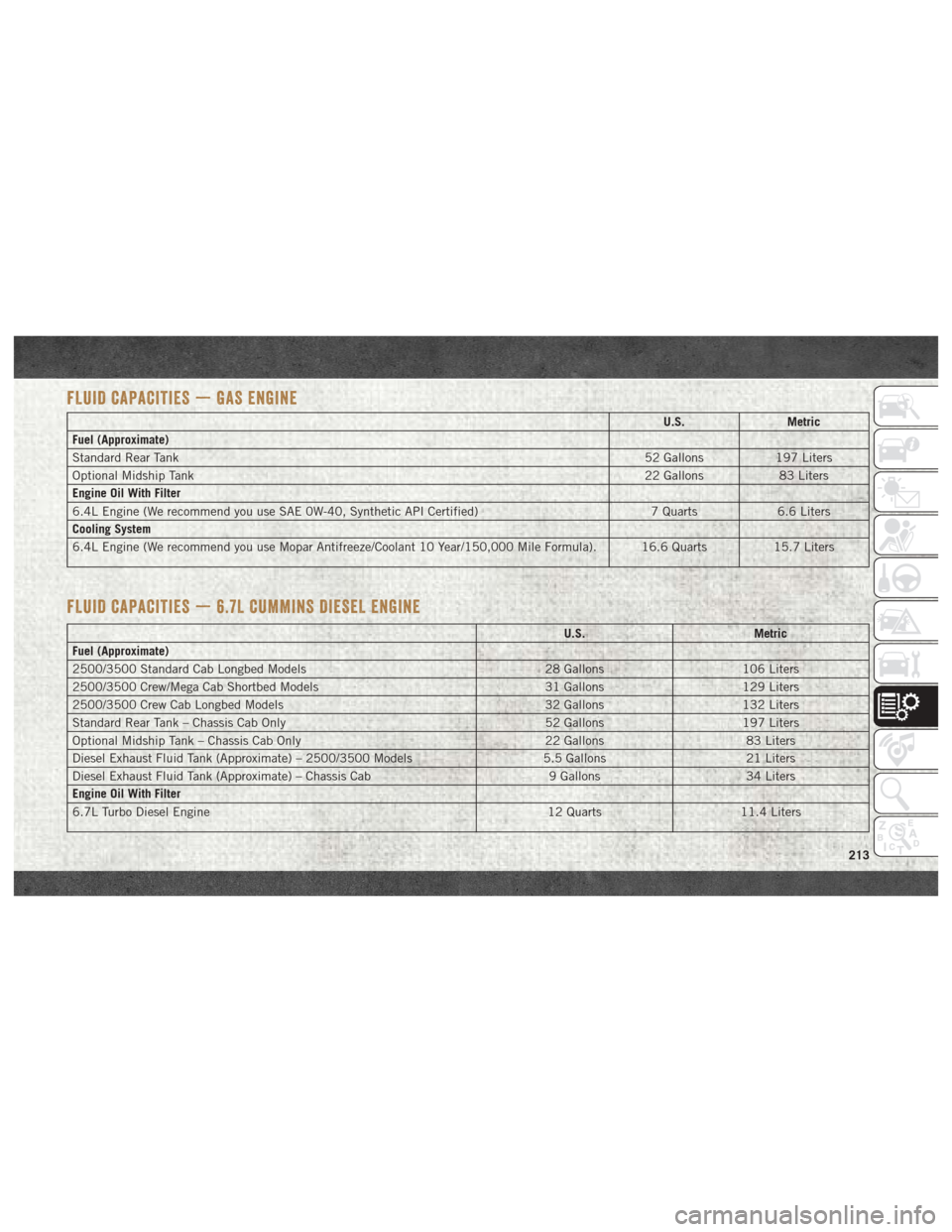

FLUID CAPACITIES — GAS ENGINE

U.S.Metric

Fuel (Approximate)

Standard Rear Tank 52 Gallons197 Liters

Optional Midship Tank 22 Gallons83 Liters

Engine Oil With Filter

6.4L Engine (We recommend you use SAE 0W-40, Synthetic API Certified) 7 Quarts6.6 Liters

Cooling System

6.4L Engine (We recommend you use Mopar Antifreeze/Coolant 10 Year/150,000 Mile Formula). 16.6 Quarts 15.7 Liters

FLUID CAPACITIES — 6.7L CUMMINS DIESEL ENGINE

U.S.Metric

Fuel (Approximate)

2500/3500 Standard Cab Longbed Models 28 Gallons106 Liters

2500/3500 Crew/Mega Cab Shortbed Models 31 Gallons129 Liters

2500/3500 Crew Cab Longbed Models 32 Gallons132 Liters

Standard Rear Tank – Chassis Cab Only 52 Gallons197 Liters

Optional Midship Tank – Chassis Cab Only 22 Gallons83 Liters

Diesel Exhaust Fluid Tank (Approximate) – 2500/3500 Models 5.5 Gallons21 Liters

Diesel Exhaust Fluid Tank (Approximate) – Chassis Cab 9 Gallons34 Liters

Engine Oil With Filter

6.7L Turbo Diesel Engine 12 Quarts11.4 Liters

213

Page 216 of 298

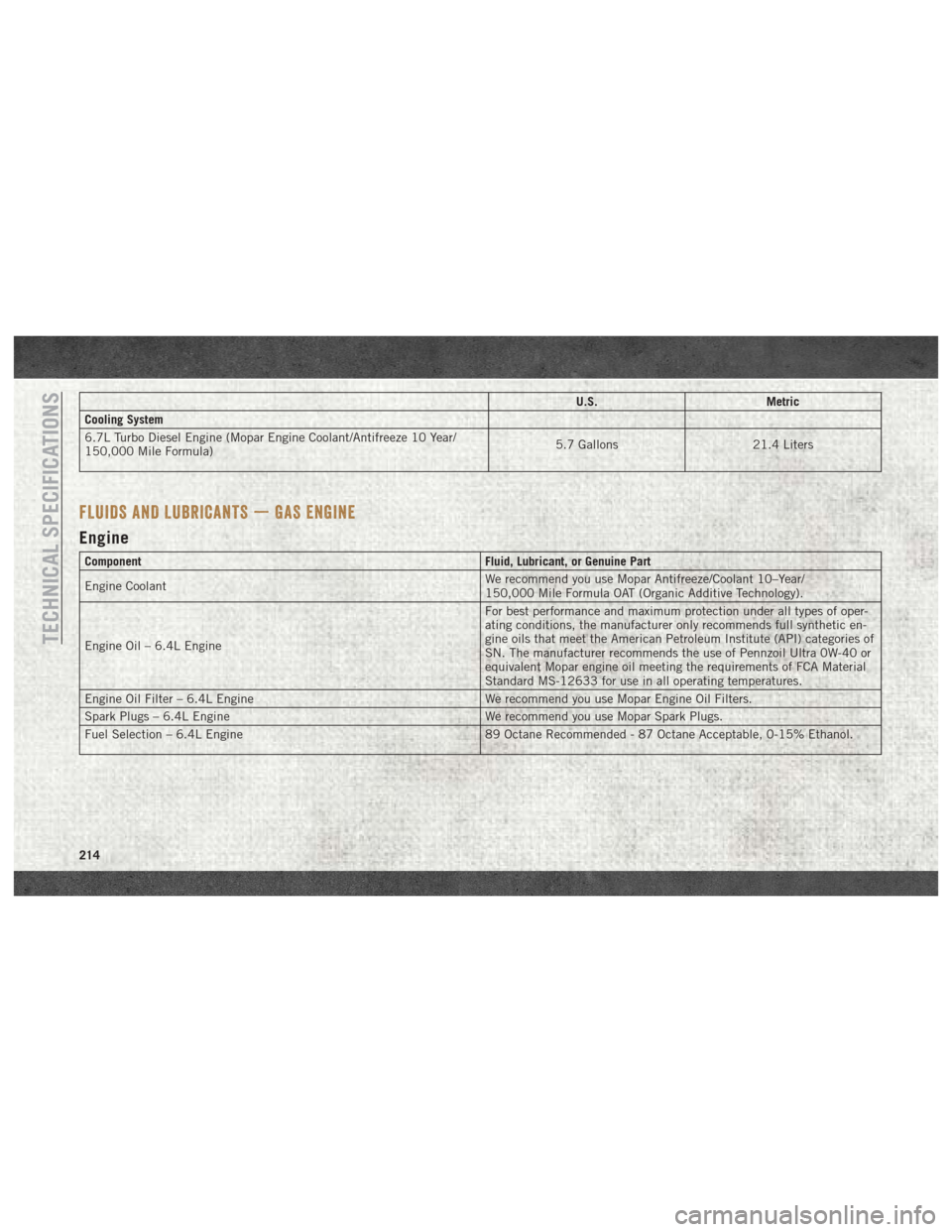

U.S.Metric

Cooling System

6.7L Turbo Diesel Engine (Mopar Engine Coolant/Antifreeze 10 Year/

150,000 Mile Formula) 5.7 Gallons

21.4 Liters

FLUIDS AND LUBRICANTS — GAS ENGINE

Engine

Component Fluid, Lubricant, or Genuine Part

Engine Coolant We recommend you use Mopar Antifreeze/Coolant 10–Year/

150,000 Mile Formula OAT (Organic Additive Technology).

Engine Oil – 6.4L Engine For best performance and maximum protection under all types of oper-

ating conditions, the manufacturer only recommends full synthetic en-

gine oils that meet the American Petroleum Institute (API) categories of

SN. The manufacturer recommends the use of Pennzoil Ultra 0W-40 or

equivalent Mopar engine oil meeting the requirements of FCA Material

Standard MS-12633 for use in all operating temperatures.

Engine Oil Filter – 6.4L Engine We recommend you use Mopar Engine Oil Filters.

Spark Plugs – 6.4L Engine We recommend you use Mopar Spark Plugs.

Fuel Selection – 6.4L Engine 89 Octane Recommended - 87 Octane Acceptable, 0-15% Ethanol.

TECHNICAL SPECIFICATIONS

214