RAM CHASSIS CAB 2021 Owners Manual

Manufacturer: RAM, Model Year: 2021, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2021Pages: 463, PDF Size: 21.5 MB

Page 391 of 463

SERVICING AND MAINTENANCE389

7. Remove the dipstick again and note the

fluid level on both sides. The fluid level

reading is only valid if there is a solid

coating of oil on both sides of the dipstick.

Note that the holes in the dipstick will be full

of fluid if the actual level is at or above the

hole. The fluid level should be between the

“HOT” (upper) reference holes on the

dipstick at normal operating temperature.

If the fluid level is low, add fluid through the

dipstick tube to bring it to the proper level.

Do not overfill. Use ONLY the specified fluid

Ú page 444. After adding any quantity of oil

through the dipstick tube, wait a minimum

of two minutes for the oil to fully drain into

the transmission before rechecking the

fluid level.

NOTE:

If it is necessary to check the transmission below

the operating temperature, the fluid level should be

between the two “COLD” (lower) holes on the

dipstick with the fluid at 60-70°F / 16-21°C. Only

use the COLD region of the dipstick as a rough refer -

ence when setting the fluid level after a transmis -sion service or fluid change. Re-check the fluid level,

and adjust as required, once the transmission

reaches normal operating temperature.

8. Reinsert the dipstick. Check for leaks.

Release the parking brake.

NOTE:

If it is necessary to check the transmission below

the operating temperature, the fluid level should be

between the two COLD (lower) holes on the dipstick

with the fluid at 68-86°F / 20-30°C. Only use the

COLD region of the dipstick as a rough reference

when setting the fluid level after a transmission

service or fluid change. Re-check the fluid level, and

adjust as required, once the transmission reaches

normal operating temperature.

Fluid And Filter Changes — Eight-Speed

Transmission

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not required.

However, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Fluid And Filter Changes — Six Speed

Transmission

For the proper maintenance intervals

Ú page 354.

In addition, change the fluid and filters if the

fluid becomes contaminated (with water, etc.),

or if the transmission is disassembled for any

reason.

CAUTION!

If the fluid temperature is below 50°F (10°C)

it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough

to produce an accurate reading. Run the

engine at idle, in PARK, to warm the fluid.

CAUTION!

If the fluid temperature is below 50°F (10°C)

it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough

to produce an accurate reading. Run the

engine at idle, in PARK, to warm the fluid.

8

21_DPF_OM_EN_USC_t.book Page 389

Page 392 of 463

390SERVICING AND MAINTENANCE

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer’s specified transmission fluid

Ú

page 444. It is important to maintain the

transmission fluid at the correct level using the

recommended fluid. No chemical flushes should

be used in any transmission; only the approved

lubricant should be used.

REAR AXLE AND 4X4 FRONT DRIVING

A

XLE FLUID LEVEL

For models with 9.25 in Front Axles and 11.5 in

Rear Axles Ú page 444. For normal service,

periodic fluid level checks are not required.

When the vehicle is serviced for other reasons,

the exterior surfaces of the axle assembly

should be inspected.

When checking the fluid level, the vehicle

should be in a level position. The fluid level at

room temperature should be as follows:

3500 Front Axle: ¼ inch ± ¼ inch (6.4 mm ±

6.4 mm) below the bottom of the fill hole.

3500 Rear Axle: ¼ inch ± ¼ inch (6.4 mm ±

6.4 mm) below the bottom of the fill hole.

4500/5500 Front Axle: ¼ inch +/- ¼ inch

(6.4 mm ± 6.4 mm) below the bottom of the fill

hole.

4500/5500 Rear Axle: 1/8 inch +/- 1/8 inch

(3.2 mm +/- 3.2 mm) below the bottom of the

fill hole.

Drain And Refill

On 4500/5500 vehicles, remove the lower bolt

to drain the axle fluid.

4500/5500 Rear Axle Plugs

For the proper maintenance intervals

Ú page 354.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder, and (for six-speed

transmissions) will require more frequent fluid

and filter changes

Ú

page 444.

1 — 4500/5500 Rear Axle Fluid Fill Plug

2 — 4500/5500 Rear Axle Fluid Drain Plug

21_DPF_OM_EN_USC_t.book Page 390

Page 393 of 463

SERVICING AND MAINTENANCE391

Lubricant Selection

For further information Úpage 444.

NOTE:

The presence of water in the gear lubricant will

result in corrosion and possible failure of differ -

ential components. Operation of the vehicle in

water, as may be encountered in some

off-highway types of service, will require draining

and refilling the axle to avoid damage.

Limited-Slip Differentials DO REQUIRE limited

slip oil additive (friction modifiers).

NOTE:

Slight noise and mild shuddering may be

evident while turning a vehicle with limited

slip differential on concrete or dry pavement.

These conditions should be considered normal

operation of the limited slip differential.

TRANSFER CASE

Fluid Level Check

This fluid level can be checked by removing the

filler plug. The fluid level should be to the

bottom edge of the filler plug hole with the

vehicle in a level position.

Drain And Refill

For the proper maintenance intervals

Ú page 354.

Selection Of Lubricant

Use only the manufacturer's recommended

fluid Ú page 444.

NOISE CONTROL SYSTEM REQUIRED

M

AINTENANCE & WARRANTY

All vehicles built over 10,000 lbs. (4,535 kg) Gross

Vehicle Weight Rating and manufactured for sale

and use in the United States are required to comply

with the Federal Government's Exterior Noise

Regulations. These vehicles can be identified by

the Noise Emission Control Label located in the

operator's compartment.

Required Maintenance For Noise Control

Systems

The following maintenance services must be

performed every six months or 7,500 miles

(12,000 km) whichever comes first, to ensure

proper operation of the noise control systems.

In addition, inspection and service should be

performed anytime a malfunction is observed or

suspected. Proper maintenance of the entire

vehicle will help the effectiveness of the noise

control systems.

Exhaust System

Inspect the entire exhaust system for leaks and

damaged parts. Devices such as hangers,

clamps, and U-bolts should be tight and in good

condition. Damaged components, burned or

blown out mufflers, burned or rusted out

exhaust pipes should be replaced according to

the procedures and specifications outlined in

the appropriate service manual.

8

21_DPF_OM_EN_USC_t.book Page 391

Page 394 of 463

392SERVICING AND MAINTENANCE

Air Cleaner Assembly

Inspect air cleaner housing for proper assembly

and fit. Make certain that the air cleaner is

properly positioned and that the cover is tight.

Check all hoses leading to the air cleaner for

tightness. The air filter element must also be

clean and serviced according to the instructions

outlined in the Scheduled Maintenance section

of this manual.

Tampering With Noise Control System

Prohibited

Federal law prohibits the following acts or the

causing thereof: (1) the removal or rendering

inoperative by any person, other than for purposes

of maintenance, repair, or replacement, of any

device or element of design incorporated into any

new vehicle for the purpose of noise control prior to

its sale or delivery to the ultimate purchaser or while

it is in use, or (2) the use of the vehicle after such

device or element of design has been removed or

rendered inoperative by any person.

Among those acts presumed to constitute

tampering are the acts listed below. AIR CLEANER

Removal of the air cleaner.

Removal of the air cleaner filter element from

the air cleaner housing.

Removal of the air ducting.

EXHAUST SYSTEM

Removal or rendering inoperative exhaust

system components including the muffler or

tailpipe.

ENGINE COOLING SYSTEM

Removal or rendering inoperative the fan

clutch.

Removal of the fan shroud.

Noise Emission Warranty

The manufacturer warrants that this vehicle as

manufactured by the manufacturer, was

designed, built and equipped to conform at the

time it left the manufacturer's control with all

applicable U.S. EPA Noise Control Regulations.

This warranty covers this vehicle as designed,

built and equipped by the manufacturer, and is

not limited to any particular part, component or

system of the vehicle manufactured by the

manufacturer. Defects in design, assembly or in

any part, component or system of the vehicle as

manufactured by the manufacturer, which, at

the time it left the manufacturer's control,

caused noise emissions to exceed Federal

standards, are covered by this warranty for the

life of the vehicle.

21_DPF_OM_EN_USC_t.book Page 392

Page 395 of 463

SERVICING AND MAINTENANCE393

Maintenance Log and Service Chart (Diesel Engines)

Noise Systems Maintenance Chart and Service Log — Insert Month, Day, Year under column mileage closest to the mileage at which

service was performed.

MILES7,500 15,000 22,500 30,000 37,500 45,000 52,500 60,000

KILOMETERS 12,000 24 ,000 36,000 48,000 60,000 72,000 84,000 96,000

Exhaust

system-inspect

Air cleaner

assembly-inspect

ODOMETER

READING

PERFORMED BY

PERFORMED AT

MILES 67,500 75,000 82,500 90,000 97,500 105,000 112,500 120,000

KILOMETERS 108,000 120,000 132,000 144,000 156,000 168,000 180,000 192,000

Exhaust

system-inspect

Air cleaner

assembly-inspect

ODOMETER

READING

8

21_DPF_OM_EN_USC_t.book Page 393

Page 396 of 463

394SERVICING AND MAINTENANCE

(Continued)

FUSES

General Information The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery

discharge.

Blade Fuses

PERFORMED BY

PERFORMED AT

Noise Systems Maintenance Chart and Service Log — Insert Month, Day, Year under column mileage closest to the mileage at which

service was performed.

WARNING!

When replacing a blown fuse, always use

an appropriate replacement fuse with the

same amp rating as the original fuse. Never

replace a fuse with another fuse of higher

amp rating. Never replace a blown fuse with

metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity

or vice versa. Failure to use proper fuses

may result in serious personal injury, fire

and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system, trans

-

mission system) or steering system blows,

contact an authorized dealer.

WARNING! (Continued)

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse

element

3 — Blade fuse with a bad/not functional fuse

element (blown fuse)

21_DPF_OM_EN_USC_t.book Page 394

Page 397 of 463

SERVICING AND MAINTENANCE395

Power Distribution Center

The Power Distribution Center is located in the

engine compartment near the battery. This

center contains cartridge fuses, micro fuses,

relays, and circuit breakers. A description of

each fuse and component may be stamped on

the inside cover, otherwise the cavity number of

each fuse is stamped on the inside cover that

corresponds to the following chart.

Power Distribution Center Location

Cavity Cartridge FuseMicro Fuse Description

F01– –Spare

F02 60 Amp Yellow –ABS Pump Motor (HD Only)

F03 60 Amp Yellow –Rad Fan – If Equipped

F04 50 Amp Red 400W Inverter – If Equipped

F05 40 Amp Green –Compressor For Air Suspension – If Equipped

F06 40 Amp Green –Steering Torque Overlay Module (STOM)

F07 40 Amp Green –Starter Solenoid

F08 20 Amp Blue –NOX Sensor – If Equipped

F09 40 Amp Green –Diesel / Fuel Heater – If Equipped

F09 30 Amp Pink –Gas / Brake Vacuum Pump – If Equipped

F10 40 Amp Green –CBC #2 / Ext Lights

F11 40 Amp Green –Brake System Module (ECU and Valves)

8

21_DPF_OM_EN_USC_t.book Page 395

Page 398 of 463

396SERVICING AND MAINTENANCE

F1240 Amp Green –CBC #3 / Pwr Locks

F13 40 Amp Green –Blower Motor

F14 40 Amp Green –CBC #4 / Ext Lights

F15 30 Amp Pink –Power Side Steps — If Equipped

F16 30 Amp Pink –Smart-Bar Module – If Equipped

F17 30 Amp Pink –Winch Control Module – If Equipped

F19 30 Amp Pink –Diesel SCR Feed– If Equipped

F20 30 Amp Pink –Passenger Door Module

F21 30 Amp Pink –Drive Train Control Module

F22 20 Amp Blue –Gas / ECM– If Equipped

F22 25 Amp White –Diesel PCM – If Equipped

F23 30 Amp Pink –CBC #1 / Int Light

F24 30 Amp Pink –Driver Door Module

F25 30 Amp Pink –Front Wiper

F26 — –Spare

F27 — –Spare

F28 20 Amp Blue –Trailer Tow Backup Lights – If Equipped

F29 20 Amp Blue –Trailer Tow Parking Lights – If Equipped

F30 30 Amp Pink –Trailer Tow Receptacle / Trailer Tow (Separate E-Brake) / Trailer Tow

F31 – –Spare

Cavity Cartridge Fuse Micro Fuse Description

21_DPF_OM_EN_USC_t.book Page 396

Page 399 of 463

SERVICING AND MAINTENANCE397

F32– –Spare

F33 20 Amp Blue –Trans Control Module – If Equipped

F34 30 Amp Pink –Vehicle System Interface Module #2 – If Equipped

F35 30 Amp Pink –Sunroof – If Equipped

F36 30 Amp Pink –Electric Back Light – If Equipped

F37 30 Amp Pink –Diesel Frame / Fuel Heater #2– If Equipped

F38 30 Amp Pink –Integrated Trailer Brake Module – If Equipped

F39 – –Spare

F40 –10 Amp Red Ventilated Seats – If Equipped

F41 –10 Amp Red Active Grille Shutter / Active Air Dam – If Equipped

F42 –20 Amp Yellow Horn

F43 –15 Amp Blue Heated Steering Wheel – If Equipped

F44 –10 Amp Red Diagnostic Port

F46 –10 Amp Red Upfitters Relay Coil – If Equipped

F47 – –Spare

F48 – –Spare

F49 –10 Amp Red IP Cluster / CSG

F50 –20 Amp Yellow Air Suspension Control Module – If Equipped

F51 –10 Amp RedIgnition Node Module / Keyless Ignition Node Module, Radio Frequency

Hub Module / Electric Steering Column Lock - If Equipped

F52 –5 Amp Tan Battery Sensor

Cavity Cartridge Fuse Micro Fuse Description

8

21_DPF_OM_EN_USC_t.book Page 397

Page 400 of 463

398SERVICING AND MAINTENANCE

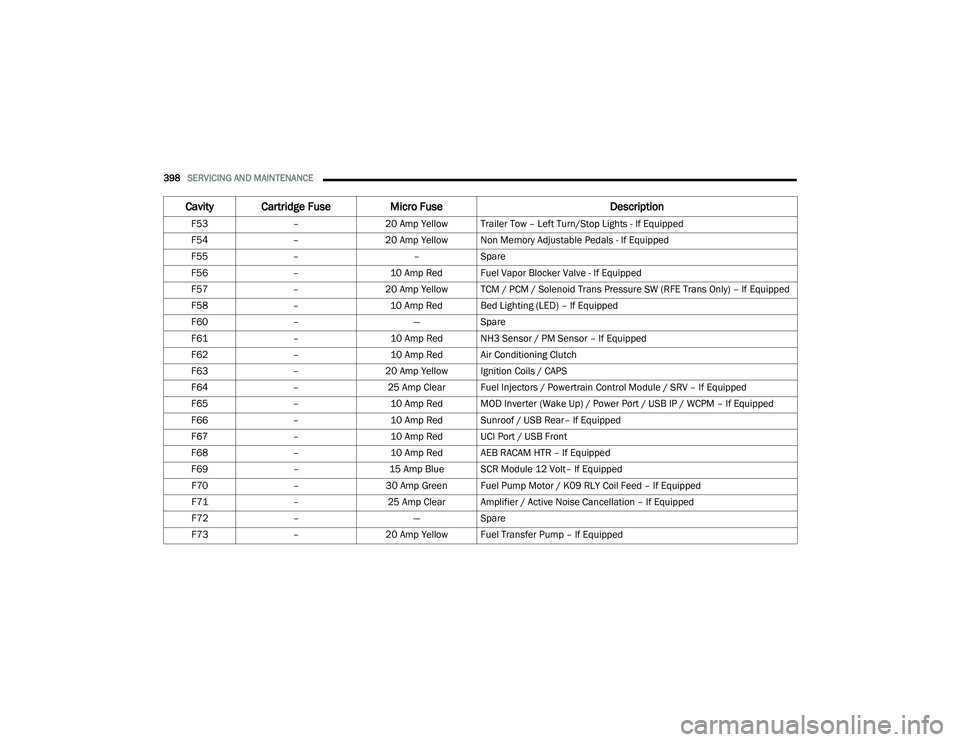

F53–20 Amp Yellow Trailer Tow – Left Turn/Stop Lights - If Equipped

F54 –20 Amp Yellow Non Memory Adjustable Pedals - If Equipped

F55 – –Spare

F56 –10 Amp Red Fuel Vapor Blocker Valve - If Equipped

F57 –20 Amp Yellow TCM / PCM / Solenoid Trans Pressure SW (RFE Trans Only) – If Equipped

F58 –10 Amp Red Bed Lighting (LED) – If Equipped

F60 – —Spare

F61 –10 Amp Red NH3 Sensor / PM Sensor – If Equipped

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils / CAPS

F64 –25 Amp Clear Fuel Injectors / Powertrain Control Module / SRV – If Equipped

F65 –10 Amp Red MOD Inverter (Wake Up) / Power Port / USB IP / WCPM – If Equipped

F66 –10 Amp Red Sunroof / USB Rear– If Equipped

F67 –10 Amp Red UCI Port / USB Front

F68 –10 Amp Red AEB RACAM HTR – If Equipped

F69 –15 Amp Blue SCR Module 12 Volt– If Equipped

F70 –30 Amp Green Fuel Pump Motor / K09 RLY Coil Feed – If Equipped

F71 –25 Amp Clear Amplifier / Active Noise Cancellation – If Equipped

F72 – —Spare

F73 –20 Amp Yellow Fuel Transfer Pump – If Equipped

Cavity Cartridge Fuse Micro Fuse Description

21_DPF_OM_EN_USC_t.book Page 398