wheel RENAULT KANGOO 1997 KC / 1.G Chassis Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 105

Page 36 of 105

REAR AXLE

Half suspension arms, tubular rear axle

REFITTING

Ensure the bearing races or the needle bearings

are in perfect condition, otherwise replace them

(see section "Bushes, tubular rear axle").

The needle bearings are greased for life and do

not require further lubrication.

NOTE : new suspension arms are supplied by the

Parts Department fitted with bearing races or

needle bearings (depending on side).

Fit the two half suspension arms together until

dimension (B) is obtained.

NOTE : dimension (B) corresponds to the distance

between the same two mounting points for the

anti-roll bar on the suspension arms. It is therefore

possible to obtain this dimension by positioning

the anti-roll bar in its location and checking the

mounting bolts can be correctly positioned.

Ensure the fitting direction is observed.

Refitting is then the reverse of removal.

NOTE : if the half suspension arm is renewed,

bond the brake backing plate mounting bolts

with

Loctite FRENBLOC.

Bleed the brake circuit.

Adjust the handbrake control (see section 37).

33

TIGHTENING TORQUES (in daN.m)

Bearing mounting nut 11

Anti-roll bar mounting bolt 5.5

Wheel bolt 9

Shock absorber base bolt 8.5

REMOVAL

Put the vehicle on a two post lift, remove:

- the anti-roll bar,

- the lower shock absorber mounting,

- the secondary handbrake cable, disconnecting

at the central adjuster under the vehicle,

- the brake pipe,

- the two bearing mounting nuts (A).

Slacken the two nuts (A) on the other bearing so

the half suspension arm can be released from its

mountings.

Remove the half suspension arm, separating one

from the other.

13132R1

86320R

33-10

Page 37 of 105

Grind the bearing races on the male suspension

arm (right hand side) using a straight grinding

wheel, taking care not to mark the tube.

REAR AXLE

Bushes, tubular rear axle

SPECIAL TOOLING REQUIRED

T. Ar. 960-02 Bush + spacer extractor

T. Ar. 960-05 Tooling for replacing needle

bearings.

REMOVAL

Remove from the female suspension arm (left

hand side) :

- the outer bush (6) using tool T.Ar. 960,

- the inner bush (7) using the small socket of

tool T.Ar. 960.

This operation is carried out after removing the complete rear axle assembly and separating the two

suspension arms.

33

Split the bearing races using a chisel then remove

them.

Cut and remove the seal (5).

86182R

86180R

90864S

90863R

33-11

Page 41 of 105

REAR AXLE

Suspension bars, tubular rear axle

SPECIAL TOOLING REQUIRED

Emb. 880 Inertia extractor

TIGHTENING TORQUES (in daN.m)

Upper shock absorber mounting bolt 11.5

Lower shock absorber mounting bolt 8.5

REMOVAL

With the vehicle raised so its wheels hang free, re-

move the shock absorber on the side in question.

Remove the bar from the side, using tool

Emb. 880.

REFITTING

In order to position the suspension arm so that the

bar may be correctly positioned, a tool must be

locally made.

ANut, diameter 14 mm

BNut, diameter 12 mm

CThreaded rod, diameter 12 mm - length 660

mm

DBracket from flat sheet 30 x 5 mm

E 12 x 60 mm bolt, cut to a length of 20 mm

FWeld

33

75505R

Preset the tool to obtain dimension "X".

X = 402 mm

Fit the tool in place of the shock absorber.

88637R2

Coat the splines of the bar with MOLYKOTE BR2,

fit it into the bearing and the suspension arm, and

try, by rotating the rod, to find the position where

it fits freely into the splines of the suspension arm

and the bearing.

Remove the tool and refit the shock absorber.

Return the vehicle to its wheels and measure the

underbody heights (see section "Underbody

heights - Tubular rear axle").

Check and adjust if necessary:

- the braking compensator,

- the headlights.

33-15

Page 43 of 105

REAR AXLE

Four bar rear axle

SPECIAL TOOLING REQUIRED

Emb. 880 Inertia extractor

TIGHTENING TORQUES (in daN.m)

Upper shock absorber mounting 8.5

Lower shock absorber mounting 11.5

Wheel bolts 9

REMOVAL

Remove:

- the wheels,

- the shock absorbers,

- the suspension bar plugs.

Remove using tool Emb. 880 :

- the two suspension bars,

- the two anti-roll bars, retaining the central

shackle.

Clean and lubricate the bar splines using

MOLYKOTE BR2.

REFITTING

The anti-roll bars cannot be removed from the

vehicle when the shock absorber replacement tool

is in position. Because of this, and to make it

easier to refit the shackle, a wooden block must

be made according to the diagram below.

Fit:

- the shackle on the block (locally made) in the

centre of the rear axle assembly,

33

13135R

Dimensions in mm and degrees ( ° ).

33-17

Page 44 of 105

REAR AXLE

Four bar rear axle

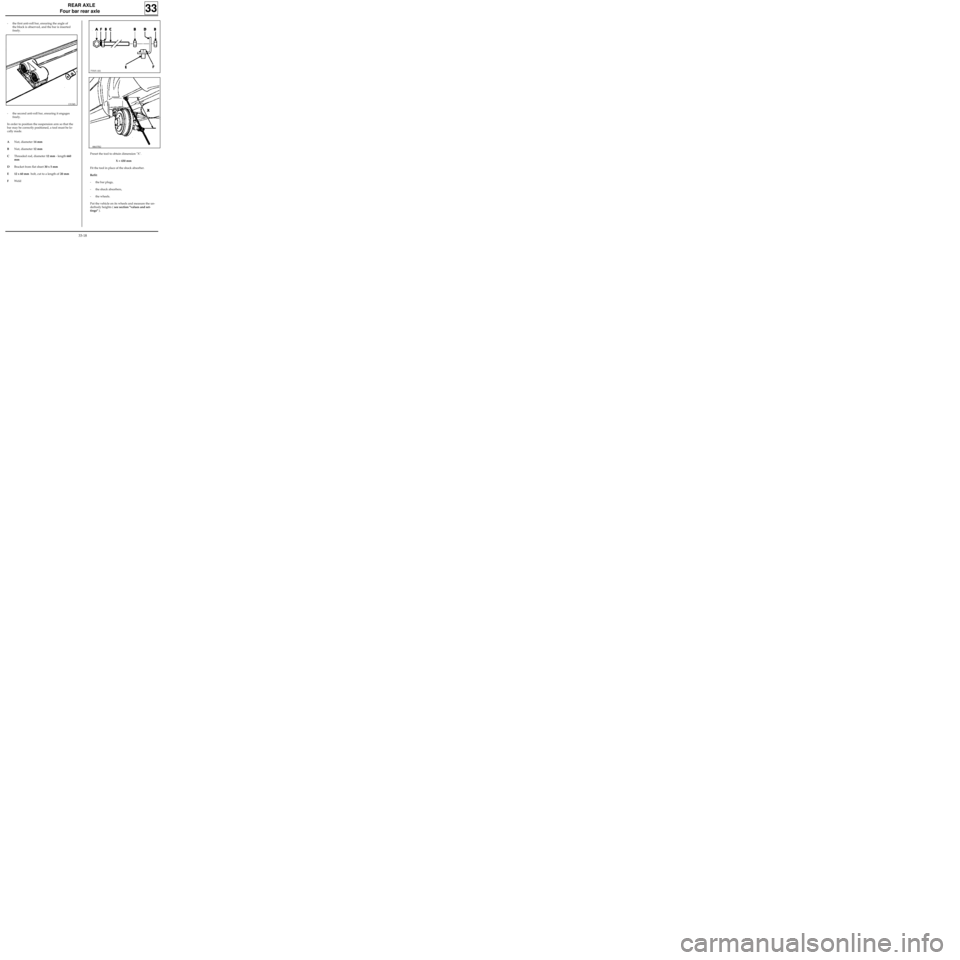

- the first anti-roll bar, ensuring the angle of

the block is observed, and the bar is inserted

freely.

33

13134S

- the second anti-roll bar, ensuring it engages

freely.

In order to position the suspension arm so that the

bar may be correctly positioned, a tool must be lo-

cally made.

ANut, diameter 14 mm

BNut, diameter 12 mm

CThreaded rod, diameter 12 mm - length 660

mm

DBracket from flat sheet 30 x 5 mm

E 12 x 60 mm bolt, cut to a length of 20 mm

FWeld

75505-1R1

88637R2

Preset the tool to obtain dimension "X".

X = 430 mm

Fit the tool in place of the shock absorber.

Refit:

- the bar plugs,

- the shock absorbers,

- the wheels.

Put the vehicle on its wheels and measure the un-

derbody heights ( see section "values and set-

tings" ).

33-18

Page 45 of 105

REAR AXLE

Four bar rear axle

33

Check and if necessary adjust:

- the braking compensator,

- the headlights.

REMINDER

When adjusting for a wheel height difference

between the right and left hand sides, always

make the adjustment on the anti-roll bars.

The adjustment for a difference in dimension " X"

between the right and left hand sides should

always be made on the suspension bars.

33-19

Page 49 of 105

Offset

(in mm)

DI3501

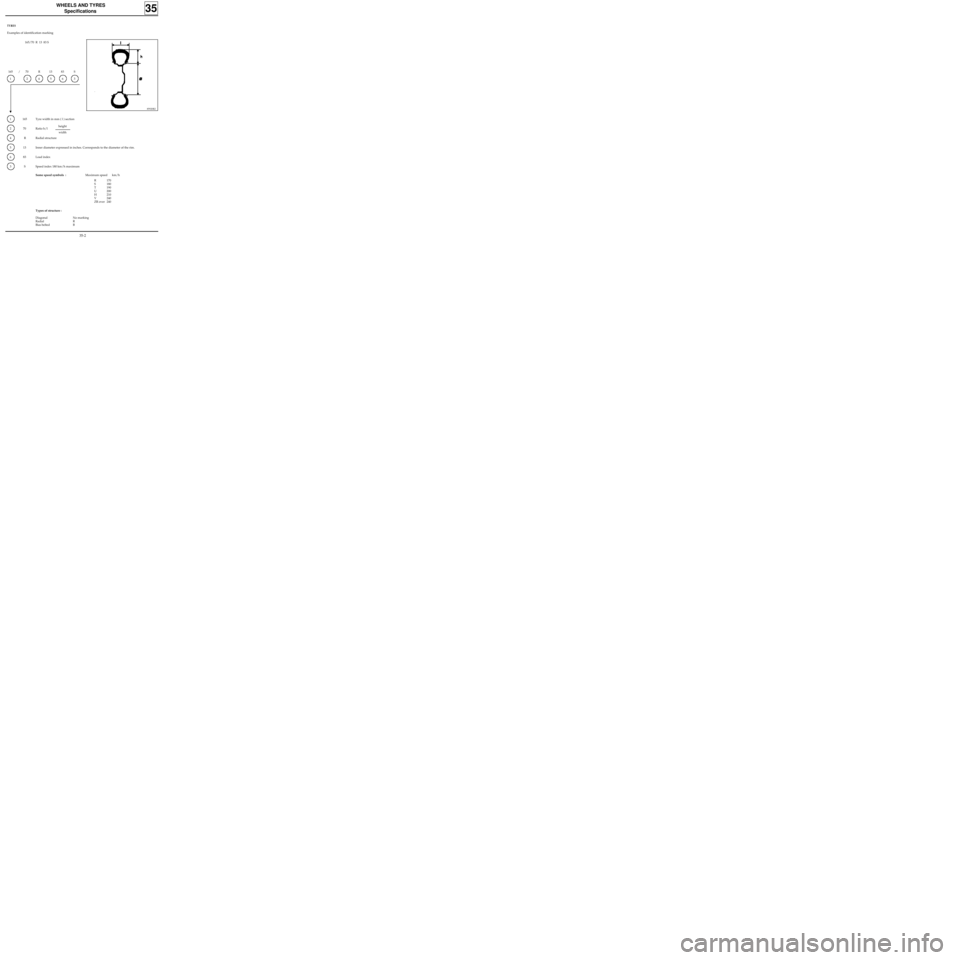

WHEELS AND TYRES

Specifications

WHEEL RIMS

There are two forms of wheel identification marking:

- engraved markings for steel rims,

- cast marking for alloy rims.

The marking gives the main dimensional specifications of the wheel.

The marking may be complete:

Example : 5 1/2 J 14 4 CH 36

or simplified

Example : 5 1/2 J 14

35

The four wheel bolts are over a diameter of 100

mm (4 mounting bolts).

Maximum run-out: 1.2 mm measured on the rim

edge (at G).

Maximum eccentricity: 0.8 mm measured on the

pressure face of the tyre beads.

FE

Number

of holes

DCB

WIDTH

(in inches)

5 1/2

A

TYPE

OF WHEEL

5 1/2 J 14

4 CH 36J144CH36

RIM

PROFILE

NOMINAL DIAMETER

(in inches). under tyre

beadTyre bead

profile

35-1

Page 50 of 105

85920R2

WHEELS AND TYRES

Specifications

Examples of identification marking

165/70SR1383

125463

165/70 R 13 83 S

TYRES

35

1165

702

3S

R

513

4

Tyre width in mm ( l ) section

Ratio h/lheight

width

Speed index 180 km/h maximum

Radial structure

Inner diameter expressed in inches. Corresponds to the diameter of the rim.

836Load index

Some speed symbols :Maximum speed km/h

R 170

S 180

T 190

U 200

H 210

V 240

ZR over 240

Types of structure :

Diagonal No marking

Radial R

Bias belted B

35-2

Page 51 of 105

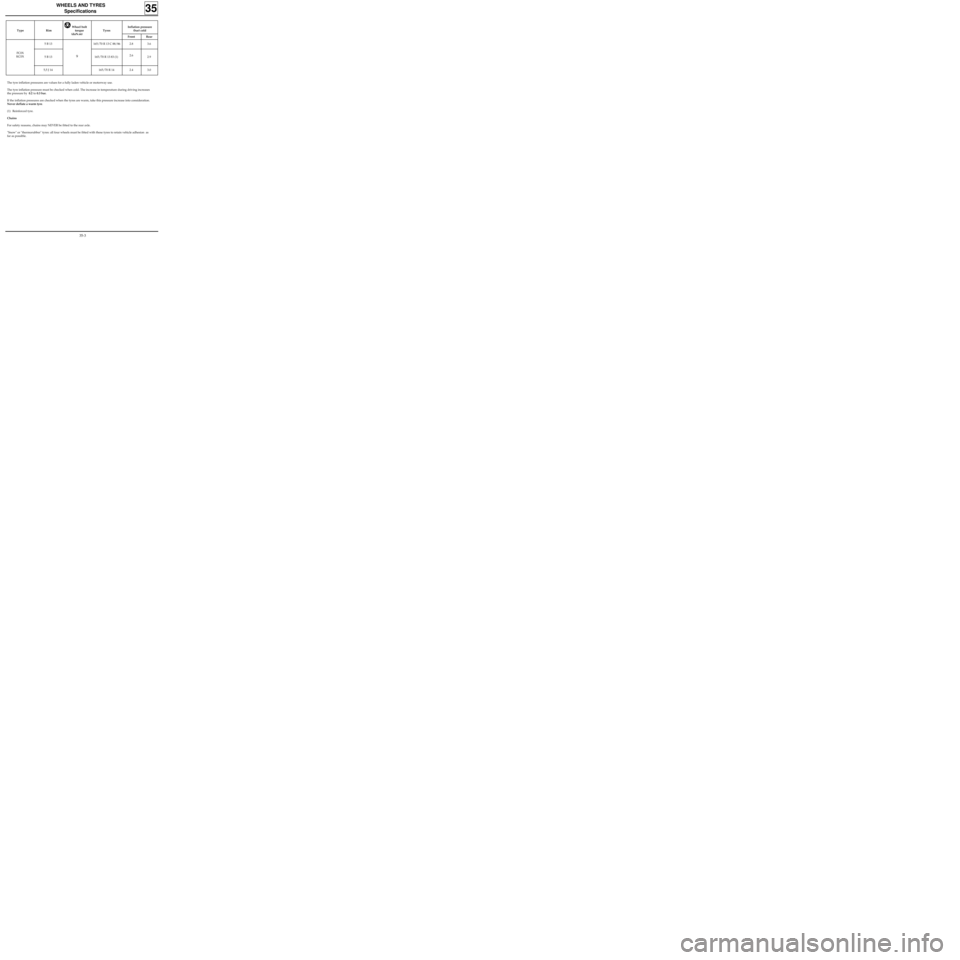

WHEELS AND TYRES

Specifications

The tyre inflation pressures are values for a fully laden vehicle or motorway use.

The tyre inflation pressure must be checked when cold. The increase in temperature during driving increases

the pressure by 0.2 to 0.3 bar.

If the inflation pressures are checked when the tyres are warm, take this pressure increase into consideration.

Never deflate a warm tyre.

(1) Reinforced tyre.

Chains

For safety reasons, chains may NEVER be fitted to the rear axle.

"Snow" or "thermorubber" tyres: all four wheels must be fitted with these tyres to retain vehicle adhesion as

far as possible.

35

TypeRim

Wheel bolt

torque

(daN.m)

Tyres

Inflation pressure

(bar) cold

FrontRear

FC0X

KC0X

5 B 13

5 B 13

5,5 J 14

9

2.8

2.6

2.4

3.6

2.9

3.0

165/70 R 13 C 88/86

165/70 R 13 83 (1)

165/70 R 14

35-3

Page 52 of 105

88659R

WHEELS AND TYRES

Wheel balancing

35

BALANCE WEIGHTS

Only use weights provided by the Parts

Department:

- fitted using hooks to steel wheels (hook is part

of the weight),

- fitted using hooks (flat hooks) or self adhesive

for alloy wheels.

A Steel wheel rim

B Alloy wheel rim

35-4