torque RENAULT KANGOO 1997 KC / 1.G Electrical Equipment Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 83

Page 28 of 83

INSTRUMENT PANEL

Dashboard

REMOVAL

Disconnect the battery.

Removing the steering wheel (with AIRBAG)

83

PRB5702

12973S

Remove the two airbag cushion bolts behind the

steering wheel.

Disconnect the connectors (airbag, horn).

Remove:

- the airbag cushion,

- the steering wheel bolt (renew it on refitting,

pre-bonded bolt, tightening torque: 4.5

daN.m),

- the steering wheel after setting the wheels

straight.

Removing the steering wheel (without AIRBAG)

Remove:

- the central cushion,

- the steering wheel bolt (renew it on refitting,

pre-bonded bolt, tightening torque: 4.5

daN.m),

- the steering wheel after setting the wheels

straight.

83-1

Page 32 of 83

INSTRUMENT PANEL

Dashboard

83

- the loud speaker grilles,

- the dashboard mountings.

Gently pull the dashboard.

Release the wiring retaining clips.

Disconnect:

- the headlight remote adjustment control

connector and hazard warning light connector,

- the remaining connectors (example : decoder

unit).

Remove the dashboard.REFITTING

When refitting, it is important to ensure the va-

rious wires are correctly routed and have suffi-

cient space so that the dashboard can be correctly

centred.

SPECIAL NOTES FOR REFITTING THE STEERING

WHEEL WITH AIRBAG

Ensure the rotary switch under the steering wheel

is correctly positioned.

If there is any doubt that this switch is correctly

centred follow the method for centring described

in section 88 "driver’s airbag".

Renew the steering wheel bolt each time it is re-

moved (pre-bonded bolt) for a steering wheel

with airbag.

Observe the correct tightening torque (4.5

daN.m).

IMPORTANT

Before reconnecting the driver’s airbag cushion,

check to see if the system is operating correctly as

follows:

•check the airbag warning light on the

instrument panel is illuminated when the

ignition is on,

•connect a dummy ignition module to the

driver’s airbag connector and check that the

warning light extinguishes,

•switch the ignition off, connect the airbag

cushion in place of the dummy ignition module

and secure the cushion to the steering wheel,

•switch the ignition on. Check the warning light

illuminates for three seconds when the ignition

is switched on then extinguishes and remains

extinguished.

If the warning light does not operate exactly as

described above, refer to the fault finding section

and test the system using the XRBAG (Elé. 1288)

(see section 88).

12964R

83-5

Page 37 of 83

Mot. 1264

Mot. 1264-01

Mot. 1265

Mot. 1265-01Wrench for removing sender unit nut

Pliers for removing quick-release unions

INSTRUMENT PANEL

Fuel level sensor

83

97163R6

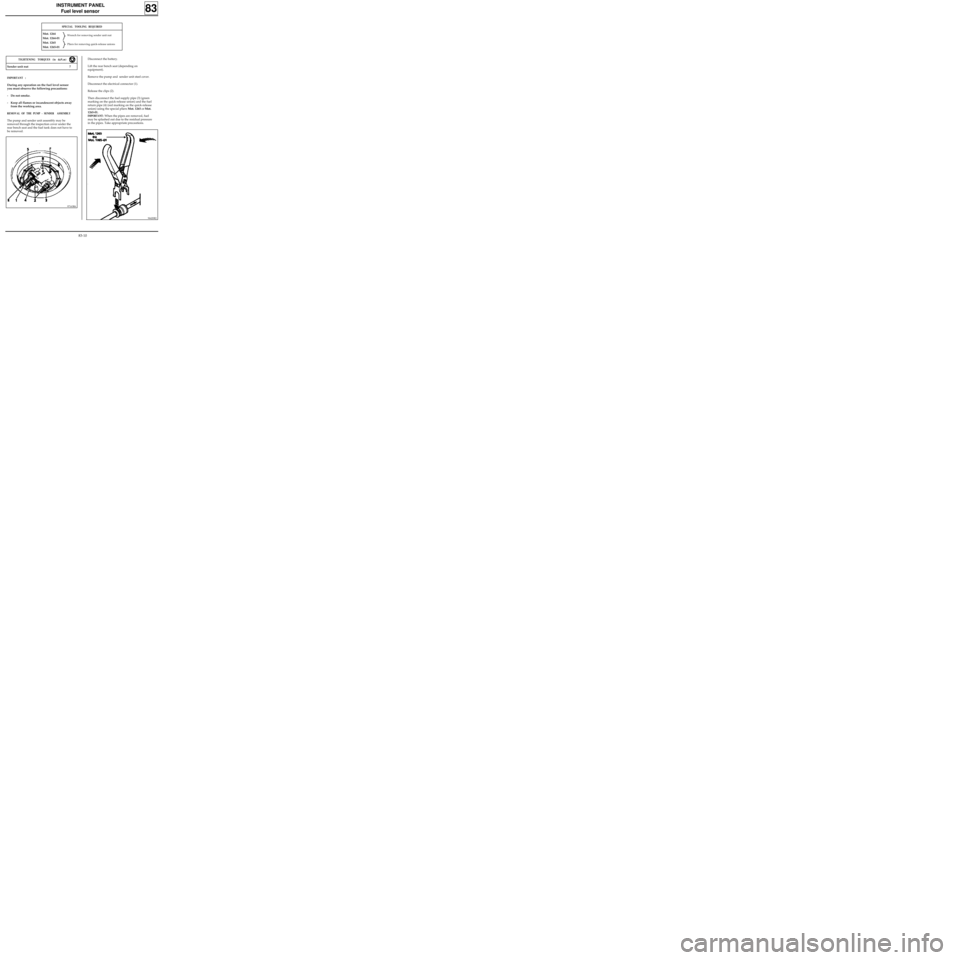

Disconnect the battery.

Lift the rear bench seat (depending on

equipment).

Remove the pump and sender unit steel cover.

Disconnect the electrical connector (1).

Release the clips (2).

Then disconnect the fuel supply pipe (3) (green

marking on the quick-release union) and the fuel

return pipe (4) (red marking on the quick-release

union) using the special pliers Mot. 1265 or Mot.

1265-01.

IMPORTANT: When the pipes are removed, fuel

may be splashed out due to the residual pressure

in the pipes. Take appropriate precautions.

IMPORTANT :

During any operation on the fuel level sensor

you must observe the following precautions:

- Do not smoke.

- Keep all flames or incandescent objects away

from the working area.

REMOVAL OF THE PUMP - SENDER ASSEMBLY

The pump and sender unit assembly may be

removed through the inspection cover under the

rear bench seat and the fuel tank does not have to

be removed.

96420R2

SPECIAL TOOLING REQUIRED

TIGHTENING TORQUES (in daN.m)

Sender unit nut 7

83-10

Page 38 of 83

INSTRUMENT PANEL

Fuel level sensor

83

97163R7

Tighten the mounting nut on the fuel and sender

unit assembly to a torque of 3.5 daN.m using the

tool Mot. 1264-01, holding the sender unit to pre-

vent it from rotating.

Make sure that the connector is firmly locked and

that the quick-release unions are securely clipped

on (with 2 O-ring seals)

Reconnect the battery.

CONNECTION

Disconnect the connector and the pipes on the

sender unit side.

Remove the mounting nut (5) of the pump and

sender unit using tool Mot. 1264-01.

Slacken the nut, remove the tool, unscrew the nut

by hand and remove it.

Remove the pump and sender unit assembly.

NOTE : If several hours may pass between

removing and refitting the pump and sender unit

assembly, refit the nut to the fuel tank to prevent

it from distorting.

REFITTING OF THE PUMP AND SENDER UNIT

ASSEMBLY

Special notes

Check that the seal is in good condition and re-

place it if necessary.

Fit the seal on the fuel tank first before fitting the

assembly.

Refit the pump and sender unit assembly in the

fuel tank by aligning it so that the indexing arrow

(F) is positioned in line with the longitudinal axis

of the vehicle, pointing towards the rear of the

vehicle.

DI8307

Track Allocation

A1 Earth

A2 Low fuel level warning light

B1 Sender unit information to instrument

panel

B2 Not used

C1 + pump

C2 - pump

Checking

IndicationValue between

terminals

A1 and B1 (in Ω)

4/4 7 maximum

3/4 54.5 ± 7

1/2 98 ± 10

1/4 155 ± 16

Low fuel 300 ± 20

97162S

83-11

Page 44 of 83

CONTROLS - SIGNALS

Rotary switch under steering wheel

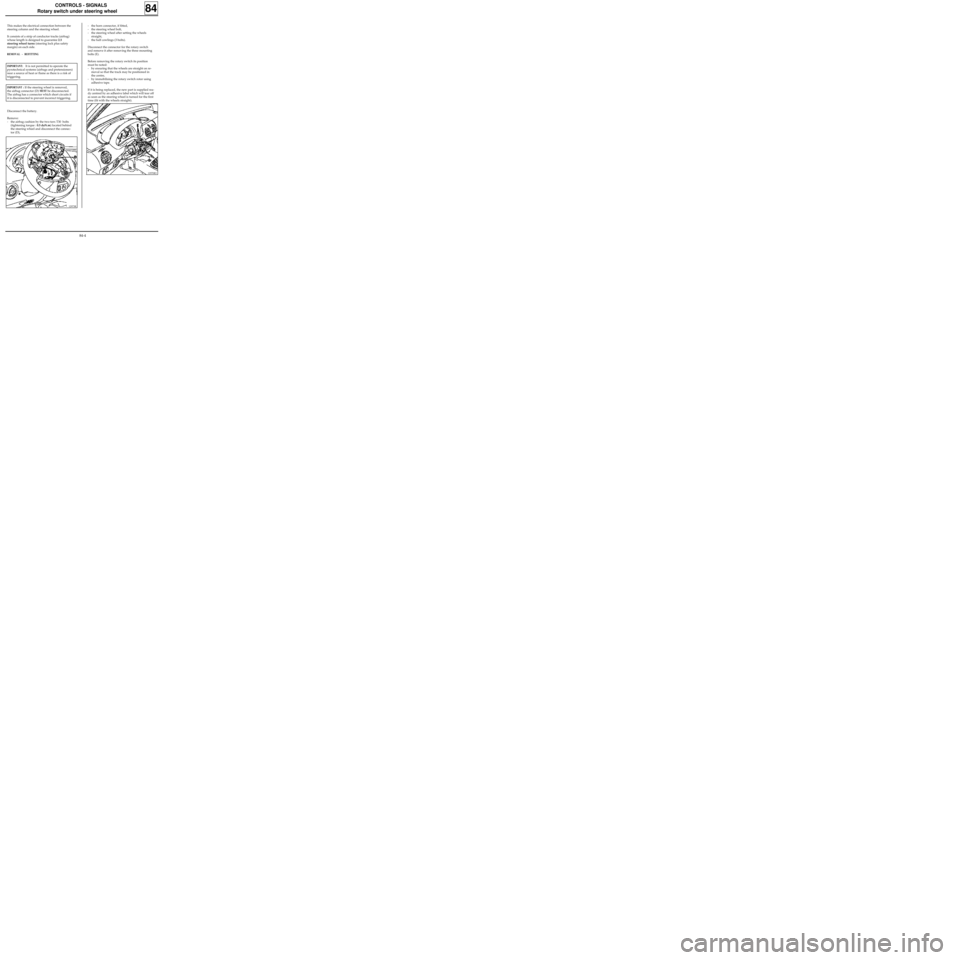

This makes the electrical connection between the

steering column and the steering wheel.

It consists of a strip of conductor tracks (airbag)

whose length is designed to guarantee 2.5

steering wheel turns (steering lock plus safety

margin) on each side.

REMOVAL - REFITTING

84

- the horn connector, if fitted,

- the steering wheel bolt,

- the steering wheel after setting the wheels

straight,

- the half cowlings (3 bolts).

Disconnect the connector for the rotary switch

and remove it after removing the three mounting

bolts (E).

Before removing the rotary switch its position

must be noted:

- by ensuring that the wheels are straight on re-

moval so that the track may be positioned in

the centre,

- by immobilising the rotary switch rotor using

adhesive tape.

If it is being replaced, the new part is supplied rea-

dy centred by an adhesive label which will tear off

as soon as the steering wheel is turned for the first

time (fit with the wheels straight).

12970R3

Disconnect the battery.

Remove:

- the airbag cushion by the two torx T30 bolts

(tightening torque : 0.5 daN.m) located behind

the steering wheel and disconnect the connec-

tor (D),

IMPORTANT: It is not permitted to operate the

pyrotechnical systems (airbags and pretensioners)

near a source of heat or flame as there is a risk of

triggering.

IMPORTANT : If the steering wheel is removed,

the airbag connector (D)

MUST be disconnected.

The airbag has a connector which short circuits if

it is disconnected to prevent incorrect triggering.

12973R

84-4

Page 45 of 83

CONTROLS - SIGNALS

Rotary switch under steering wheel

Special notes for refitting

Ensure the wheels are still straight.

Ensure the rotary switch under the steering wheel

is still immobilised before refitting.

If there is any doubt follow the method for cen-

tring described in section 88 "driver’s airbag".

Renew the steering wheel bolt each time it is re-

moved (pre-bonded bolt).

Observe the correct tightening torque (4.5

daN.m).

84

IMPORTANT

Before reconnecting the driver’s airbag cushion,

check to see if the system is operating correctly as

follows:

•check the airbag warning light on the

instrument panel is illuminated when the

ignition is on,

•connect a dummy ignition module to the

driver’s airbag connector and check that the

warning light extinguishes,

•switch the ignition off, connect the airbag

cushion in place of the dummy ignition module

and secure the cushion to the steering wheel,

•switch the ignition on. Check the warning light

illuminates for three seconds when the ignition

is switched on then extinguishes and remains

extinguished.

If the warning light does not operate exactly as

described above, refer to the fault finding section

and test the system using the XRBAG (Elé. 1288)

(see section 88).

IMPORTANT: if these instructions are not obser-

ved, the systems may not operate normally and

may be incorrectly triggered.

84-5

Page 47 of 83

WIPERS

Front windscreen wiper

REMOVAL OF THE WIPER MECHANISM WITH

MOTOR

Make sure that the wiper motor is in the park

position.

Disconnect the battery.

Note the position of the wiper arms.

Open the bonnet.

Remove:

- the wiper arms using tool Elé. 1294-01,

- the scuttle panel grille seal,

- the scuttle panel grille after removing the two

side covers and the two bolts and disconnecting

the washer pipe.

85

13069R

Remove the three mechanism mounting bolts (A).

Disconnect the motor and release the assembly.

SPECIAL TOOLING REQUIRED

Elé. 1294-01 Wiper arm removing tool

Special notes for refitting

Check that the motor is in the park position be-

fore refitting the wiper arms.

Clean the splines on the wiper arm pins using a

metal brush.

Refit the wiper arms, locating the blade on the

marks made on removal.

Fit new nuts and torque tighten to 1.8 daN.m (±

15 %) using a torque wrench.

85-1

Page 48 of 83

WIPERS

Front windscreen wiper

85

13069R1

Remove:

- the motor shaft nut (B) and release the linkage

after noting its position,

- the three motor mountings.

Release the motor after disconnecting it.

Special notes for refitting

Refit the linkage to the motor on the mark made

during removal.

Check that the motor is in the park position be-

fore refitting the wiper arms.

Clean the splines on the wiper arm pins using a

metal brush.

Refit the wiper arms, locating the blade on the

marks made on removal.

Fit new nuts and torque tighten to 1.8 daN.m (±

15 %) using a torque wrench.REMOVING THE MOTOR ALONE

Make sure that the wiper motor is in the park po-

sition.

Disconnect the battery.

Note the position of the wiper arms.

Open the bonnet.

Remove:

- the wiper arms using tool Elé. 1294-01,

- the scuttle panel grille seal,

- the scuttle panel grille after removing the two

side covers and the two bolts and disconnecting

the washer pipe.

85-2

Page 49 of 83

WIPERS

Rear screen wiper

85

Tailgate versionREMOVING THE MOTOR

Make sure that the wiper motor is in the park po-

sition.

Disconnect the battery.

Note the position of the wiper arms.

Remove:

- the wiper arm mounting nut,

- the wiper arm from its pin using special tool

Elé. 1294-01,

- the inner door handle on versions with swin-

ging doors (1 bolt),

- the tailgate trim (clipped).

Disconnect connector (A) for the wiper motor.

Remove the three bolts (B) mounting the motor

and release it.

Special notes for refitting

Check that the motor is in the park position be-

fore refitting the wiper arm.

Clean the splines on the wiper arm pin using a me-

tal brush.

Refit the wiper arm, locating the blade on the

marks made on removal.

Fit a new nut and torque tighten to 1.2 daN.m (±

20 %) using a torque wrench.

Version with swinging doors

13071R

13070R

85-3

Page 50 of 83

WIPERS

Electric washer pump

85

This vehicle is fitted with a bidirectional electric

pump (E) which feeds fluid from the same reser-

voir to both the front and rear screen washers ac-

cording to the electrical feed to the two track

connector (D).

Two cases may be considered:

13069R2

Track Feed

A + 12 Volts

B Earth

The pipes are fed via the white end piece (1)

whilst the front windscreen washer is in opera-

tion.

Track Feed

A Earth

B + 12 Volts

The pipes are fed via the black end piece (2) whilst

the rear screen washer is in operation.

DI8503

REMOVAL - REFITTING

To reach the washer pump it is necessary to re-

move:

- the wiper arms using tool Elé. 1294-01 after no-

ting their positions,

- the scuttle panel grille seal,

- the scuttle panel grille after removing the two

side covers and the two bolts and disconnecting

the front washer pipe.

When removing the washer pump (E), mark the

two pipes (1 and 2) before disconnecting them.

Special notes for refitting

Check that the motor is in the park position be-

fore refitting the wiper arms.

Clean the splines on the wiper arm pins using a

metal brush.

Refit the wiper arms, locating the blade on the

marks made on removal.

Fit new nuts and torque tighten to 1.8 daN.m (±

15 %) using a torque wrench.

85-4