torque RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 74 of 208

FUEL MIXTURE

Inlet manifold

12D7F engine

TIGHTENING TORQUES (in daN.m)

There are no special notes for removal - refitting

TIGHTENING TORQUES (in daN.m)

Injector gallery mounting bolt on manifold 1

Manifold mounting nut on cylinder head 1.7

Manifold mounting stud on cylinder head 1

12-9

Page 75 of 208

FUEL MIXTURE

Inlet manifold

12

Inlet manifold bolt and nut 2

TIGHTENING TORQUES (in daN.m)

REMOVAL

Remove:

- the air filter,

- the injector gallery (see section 13).

Lift the vehicle.

Remove the strut (1) (to gain access to the bolt

fixing the strut on the right-hand side of the vehi-

cle, remove the mudguard and the right-hand

wheel).

E7J engine

13339R2

Disconnect the accelerator cable and the electrical

connectors (2) connected to the throttle body.

Remove the bolts and nuts (3) securing the mani-

fold. Lower the vehicle.

Remove the air intake pipe (A) connecting the

throttle body to the air filter.

13335-1R

13130R

12-10

Page 77 of 208

FUEL MIXTURE

Exhaust manifold

12D7F engine

Manifold mounting nut 2.5

Manifold mounting stud 1

Exhaust downpipe mounting bolt 2.2

TIGHTENING TORQUES (in daN.m)

There are no special notes for the removal - refitting.

12-12

Page 78 of 208

FUEL MIXTURE

Exhaust manifold

12

Manifold mounting bolt 2

TIGHTENING TORQUES (in daN.m)

REMOVAL

Remove the multifunction support (1) (see section

10).

Disconnect the exhaust manifold / exhaust link

(2).

Remove the heat shield (3).

Remove the exhaust manifold. E7J engine

13239R2

REFITTING

Replace the manifold gasket.

Refitting is then the reverse of removal.

12-13

Page 79 of 208

FUEL MIXTURE

Inlet/Exhaust manifolds

12F8Q engine

Manifold mounting studs on cylinder head 1

Manifold mounting nuts on cylinder head 2.7

Inlet manifold strut mounting bolt 2.5

Cylinder block strut mounting bolt 2.5

TIGHTENING TORQUES (in daN.m)

REMOVAL

Remove the air filter (two mounting bolts at the

top, two mounting nuts at the bottom (1)).

Remove, from above, the two nuts fixing the ex-

haust downpipe to the manifold.

Slacken, without removing it, the nut on the

clamp connecting the downpipe to the exhaust

pipe.

Tilt the exhaust downpipe towards the gearbox.

Remove the nuts securing the manifolds:

- nuts (A) from above,

- nuts (B) from below.

PRO12.1

Special note

To remove nut (C) located above the starter mo-

tor, use a small ratchet (6.35 mm square) and a

universal joint.

13047-1R1

13047R

12-14

Page 82 of 208

FUEL SUPPLY

Injector gallery

13

IMPORTANT: during the opening of the fuel cir-

cuit , be sure to use a cloth to avoid possible pro-

jections of fuel due to the residual pressure.

REMOVAL

Disconnect :

- the battery,

- the pressure measurement pipe (1) of the

pressure regulator,

- the fuel return pipe (2),

- the electrical connector of the injectors (3)

99937R3

SPECIAL TOOLING REQUIRED

Mot. 1311-06 Tool for removing the fuel

supply unions

Bolt mounting injector gallery on manifold 1

TIGHTENING TORQUES (in daN.m)

D7F Engine

13-2

Page 95 of 208

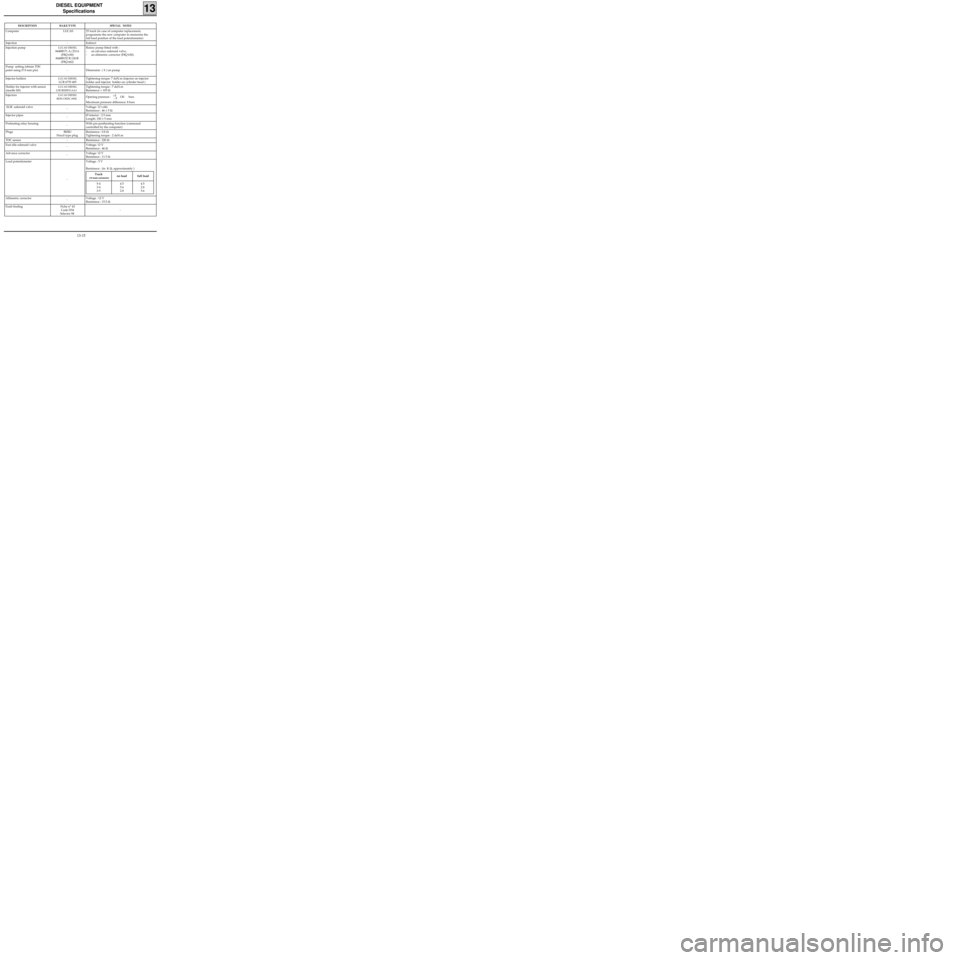

DIESEL EQUIPMENT

Specifications

13

DESCRIPTIONMAKE/TYPESPECIAL NOTES

Computer LUCAS 25 track (in case of computer replacement,

programme the new computer to memorise the

full load position of the load potentiometer)

Injection - Indirect

Injection pump

LUCAS DIESEL

8448B171 A/231A

(F8Q 630)

8448B152 B/241B

(F8Q 662)Rotary pump fitted with :

- an advance solenoid valve,

- an altimetric corrector (F8Q 630).

Pump setting (obtain TDC

point using ∅ 8 mm pin) - Dimension ( X ) on pump

Injector holders

LUCAS DIESEL

LCR 6735 405Tightening torque: 7 daN.m (injector on injector

holder and injector holder on cylinder head )

Holder for injector with sensor

(needle lift)

LUCAS DIESEL

LDCR020011AA1Tightening torque : 7 daN.m

Resistance ≈ 105 Ω

Injectors

LUCAS DIESEL

RDN OSDC 6902Opening pressure : 130 bars

Maximum pressure difference: 8 bars

EGR solenoid valve

-Voltage: 12 volts

Resistance : 46 ± 5 Ω

Injector pipes

-Ø interior : 2.5 mm

Length: 330 ± 5 mm

Preheating relay housing

-With pre-postheating function (command

controlled by the computer)

Plugs BERU

Pencil type plugResistance : 0.8 Ω

Tightening torque : 2 daN.m

TDC sensor - Resistance : 220 Ω

Fast idle solenoid valve

-Voltage: 12 V

Resistance : 46 Ω

Advance corrector

-Voltage: 12 V

Resistance : 11.5 Ω

Load potentiometer

-Voltage : 5 V

Resistance : (in K Ω, approximately )

Altimetric corrector

-Voltage : 12 V

Resistance : 15.5 Ω

Fault finding Fiche n° 43

Code D34

Selector S8-+5

- 5

Track

(10 track connector)no load full load

5-4

3-4

3-54.5

5.6

2.84.5

2.8

5.6

13-15

Page 99 of 208

DIESEL EQUIPMENT

Advance solenoid valve (1)

13

10314-1R

SPECIAL TOOLING REQUIRED

Mot. 997-01 Tool for removing injector and

advance solenoid valve

Advance solenoid valve 3

TIGHTENING TORQUES (in daN.m)

REMOVAL

Disconnect the electrical connector from the

pump.

Remove the two terminal connectors for the ad-

vance solenoid from the 10 track pump connec-

tor.

13-19

Page 101 of 208

DIESEL EQUIPMENT

Advance solenoid valve

13

ITB191917

REFITTING

It is VITAL to remove the small filter (3) situated at

the bottom of the system, using a pair of thin-

nose pliers, and replace with a new filter.

The outer part serves as a seal and locks on

tightening the actuator.

Replace, in the following order : the seal at (4) of

the "banjo" return connection (5) ; the new

activator (1) fitted with an external filter, along

with the the two seals at (6) and (7).

Tighten the actuator to a torque of 3 daN.m

using socket Mot. 997-01.

Place the new protective cover (2)on the actuator.

Reconnect the two terminals to the connector.

Reconnect the connector itself.

Replace the protective sheath on the wiring,

along with the retaining clip.Bleed the diesel circuit using the priming pump

before starting the engine.

It is IMPERATIVE to erase the computer memory

by pressing G0**.

It is vital to road test the vehicle after the

operation.

13127R

13-21

Page 102 of 208

DIESEL EQUIPMENT

Altimetric corrector

13

13129R

SPECIAL TOOLING REQUIRED

Mot. 997-01 Tool for removing injector

Mot. 1140 Tool for removing altimetric

corrector

Altimetric corrector 3

TIGHTENING TORQUES (in daN.m)

REMOVAL

Remove the high pressure pipes.

Remove the injector with sensor(cylinder n° 3),

using tool Mot. 997-01.

Remove the electrical connector from the pump.

Remove the two terminals for the altimetric cor-

rector from the 10 track pump connector. F8Q 662

13-22