sensor RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 170 of 208

OXYGEN SENSOR VOLTAGE (#05)

Reading #05 on the XR25 : the value read is the voltage sent to the computer by the oxygen sensor; it is ex-

pressed in volts (the value actually varies between 0 and 1 000 millivolts).

When the engine is in the loop phase, the voltage value should oscillate rapidly and should be between

50±50 mV (lean mixture) and 850 ± 50 mV (rich mixture) and vice versa.

The smaller the gap between the upper and lower values, the poorer the information from the sensor (the

gap is usually at least 500 mV).

RICHNESS CORRECTION (#35)

The value given under # 35 on the XR25 represents the average value of richness corrections made by the

computer depending on the richness of the burnt mixture as seen by the oxygen sensor (the oxygen sensor ac-

tually analyses the oxygen content of the exhaust gases directly from the richness of the burnt mixture).

The richness correction has a centre point of 128 with thresholds of 0 and 255 (experience has shown that un-

der normal operating conditions # 35 is located close to 128 with only a small amount of variation).

- Value less than 128 : request for mixture to be made leaner.

- Value greater than 128 : request for mixture to be made richer.

ENTRY INTO RICHNESS REGULATION MODE

Loop phase

Richness regulation begins after the timed starting period :

- for no load, if the coolant temperature has reached :

•46°C for the E7J engine ,

•30°C for the D7F engine.

- outside no load conditions if the coolant temperature is greater than :

•+ 20°C for the E7J, engine

•+ 20°C for the D7F engine.

The timed starting period is dependent on the coolant temperature :

- at 20°C it is a maximum of :

•3 minutes for the E7J engine,

•1 minute 20 seconds for the D7F engine,

- at 80°C it is a maximum of :

•1 minute 30 seconds for the E7J engine,

•35 seconds for the D7F engine,

If richness regulation has not yet started, #35 = 128

INJECTION

Richness regulation

17

17-20

Page 171 of 208

INJECTION

Richness regulation

17

Non-loop mode

When richness regulation is occurring, the operating phases when the computer ignores the voltage informa-

tion from the oxygen sensor are:

- Full load: #35 = variable and greater than 128

- Sharp acceleration: #35 = variable and greater than 128

- Deceleration with no load information (injection cut) : #35 = 128

- Oxygen sensor fault: #35 = 128

DEFECT MODE IN THE EVENT OF AN OXYGEN SENSOR FAULT

If the voltage from the oxygen sensor is incorrect (# 05 varies only slightly or not at all) during richness regu-

lation, the computer will only enter defect mode (# 35 = 128) if the fault has been present for 3 to 5 minutes.

The fault will be memorised in this case only.

If an oxygen sensor fault is present and recognised and if the fault has already been stored, the system enters

the open loop mode directly (# 35 = 128)

17-21

Page 202 of 208

FUEL TANK

Fuel tank

19

PURPOSE OF THE VALVES

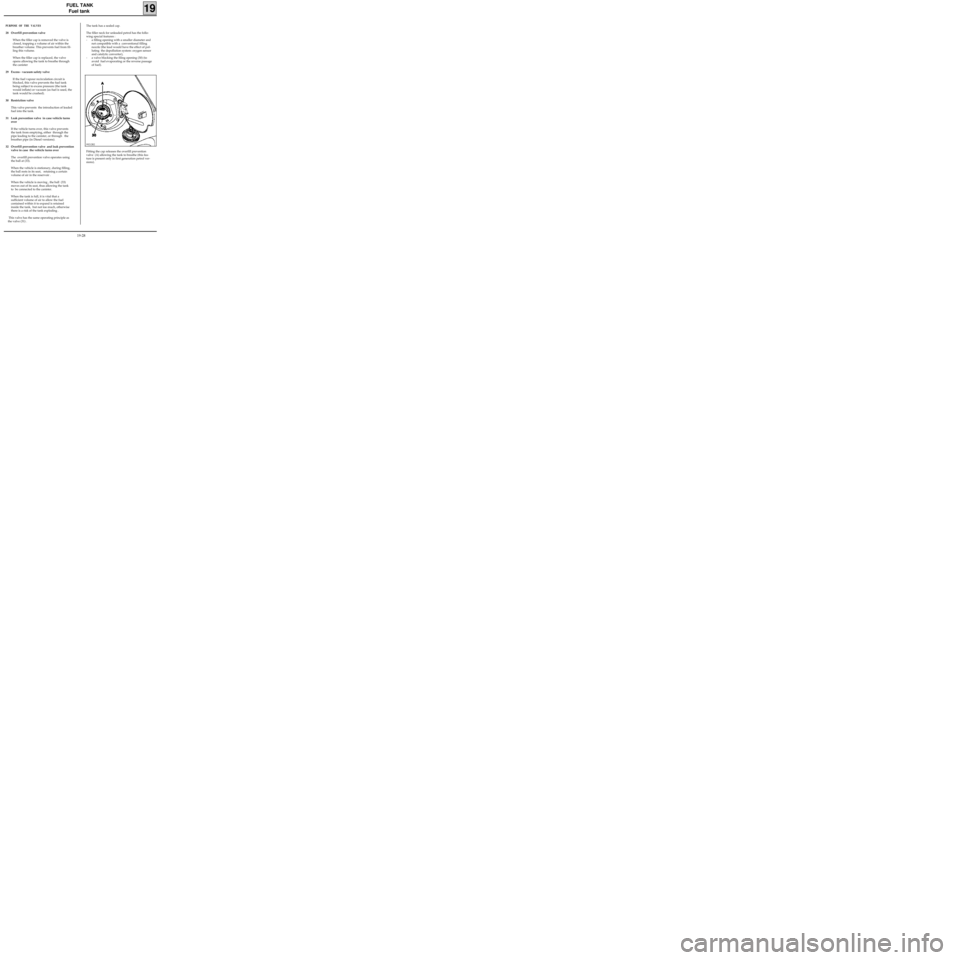

28 Overfill prevention valve

When the filler cap is removed the valve is

closed, trapping a volume of air within the

breather volume. This prevents fuel from fil-

ling this volume.

When the filler cap is replaced, the valve

opens allowing the tank to breathe through

the canister

29 Excess - vacuum safety valve

If the fuel vapour recirculation circuit is

blocked, this valve prevents the fuel tank

being subject to excess pressure (the tank

would inflate) or vacuum (as fuel is used, the

tank would be crushed).

30 Restriction valve

This valve prevents the introduction of leaded

fuel into the tank.

31 Leak prevention valve in case vehicle turns

over

If the vehicle turns over, this valve prevents

the tank from emptying, either through the

pipe leading to the canister, or through the

breather pipe (in Diesel versions).

32 Overfill prevention valve and leak prevention

valve in case the vehicle turns over

The overfill prevention valve operates using

the ball at (33).

When the vehicle is stationary, during filling,

the ball rests in its seat, retaining a certain

volume of air in the reservoir .

When the vehicle is moving , the ball (33)

moves out of its seat, thus allowing the tank

to be connected to the canister.

When the tank is full, it is vital that a

sufficient volume of air to allow the fuel

contained within it to expand is retained

inside the tank, but not too much, otherwise

there is a risk of the tank exploding .

This valve has the same operating principle as

the valve (31) .

The tank has a sealed cap.

The filler neck for unleaded petrol has the follo-

wing special features :

- a filling opening with a smaller diameter and

not compatible with a conventional filling

nozzle (the lead would have the effect of pol-

luting the depollution system: oxygen sensor

and catalytic converter),

- a valve blocking the filing opening (30) (to

avoid fuel evaporating or the reverse passage

of fuel).

Fitting the cap releases the overfill prevention

valve (A) allowing the tank to breathe (this fea-

ture is present only in first generation petrol ver-

sions).

99212R2

19-28