ABS RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 8 of 208

ENGINE AND ENGINE PERIPHERALS

Engine - Gearbox

10

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect:

- the battery,

- the electrical connectors from the engine

connection unit and its environment.

13034S

Drain:

- the cooling circuit (bottom hose of the

radiator),

- the gearbox oil,

- the engine oil if necessary.

Remove:

- the battery,

- the bonnet,

- the wheels,

- the air intake pipe,

- the expansion bottle and fix it to the engine. Brake caliper guide bolt 4

Shock absorber base bolts 18

Driveshaft gaiter mounting bolt 2.5

Wheel bolt 9

Left-hand suspended mounting bolt

on gearbox 6.2

Left-hand suspended mounting bolt

and nut on body 2.1

Right hand suspended

engine mounting bolt on engine 6.2

Right hand suspended

engine mounting bolt on body 6.2

TIGHTENING TORQUES (in daN.m)

D7F engine

SPECIAL TOOLING REQUIRED

B. Vi. 31-01 Set of three punches for roll

pins

Mot. 1202 Hose clip pliers

Mot. 1273 Tool for checking belt tension

Mot. 1311-06 Tool for removal of fuel pipe

Mot. 1379 Tool for retaining engine on

sub-frame

T. Av. 476 Ball joint extractor

EQUIPMENT REQUIRED

Load positioner

10-4

Page 9 of 208

ENGINE AND ENGINE PERIPHERALS

Engine - Gearbox

Left-hand side of the vehicle

Remove:

- the brake caliper mounting bolt, then fix it to

the shock absorber spring,

- the three driveshaft gaiter mounting bolts,

- the track rod end with the aid of tool

T.Av.476,

- the shock absorber base bolts.

Tilt the hub to disconnect the driveshaft from the

gearbox.

Right-hand side of the vehicle

Remove:

- the driveshaft roll pins with the punches

B.Vi.31-01,

- the brake caliper mounting bolt, then fix it to

the shock absorber spring,

- the track rod end with the aid of tool

T.Av.476,

- the shock absorber base bolts.

Tilt the hub to disconnect the driveshaft from the

gearbox.

Remove the earth strap mounting bolt (gearbox

side)

10D7F engine

10-5

Page 13 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect:

- the battery,

- the electrical connectors from the engine

connection unit and its environment.

13034S

Drain:

- the cooling circuit (disconnect the bottom

hose of the radiator),

- the gearbox oil if necessary,

- the engine oil if necessary.

Remove:

- the battery,

- the wheels,

- the air intake pipe,

- the upper radiator mountings,

- the expansion bottle and fix it to the engine,

- the power assisted steering fluid reservoir,

and secure it onto the engine. Shock absorber base bolts 18

Track rod end 3.7

Front sub-frame mounting bolt 6.2

Rear sub-frame mounting bolt 10.5

Driveshaft gaiter mounting bolt 2.5

Wheel bolt 9

Mounting nut for rubber engine mounting

pad on left suspended engine mounting 6.2

Mounting bolt for front right suspended

engine mounting on the engine 6.2

Mounting bolt for front right suspended

engine mounting on the body 6.2

Steering shaft yoke bolt 2.5

TIGHTENING TORQUES (in daN.m)

D7F engine

SPECIAL TOOLING REQUIRED

B. Vi. 31-01 Set of punches for roll pins

Mot. 1040-01 Dummy sub-frame for

removing and refitting engine

and transmission assembly

Mot. 1202 Hose clip pliers

Mot. 1311-06 Tool for removal of fuel pipe

Mot. 1379 Tool for retaining engine on

sub-frame

T. Av. 476 Ball joint extractor

T. Av. 1233-01 Tool for sub-frame and axle

assembly

10-9

Page 14 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

Disconnect:

- the accelerator cable,

- the canister pipe,

- the brake servo pipe,

- the heater hoses,

- the oxygen sensor connector,

- the fuel pipes.

Remove:

- the shock absorber base bolts,

- the steering shaft yoke bolt.

10

97390-1R

SPECIAL NOTES FOR VEHICLES FITTED WITH

DRIVER’S AIR BAG

WARNING

In order to avoid any risk of damage to the rotary

switch beneath the steering wheel, the following

instructions should be followed:

• Before disconnecting the steering column from

the rack, the steering wheel MUST be immobi-

lised with the wheels straight with the aid of a

"steering wheel lock" throughout the opera-

tion.

• If there is any doubt about the rotary switch

being properly centred, the steering wheel

must be removed in order to apply the centring

method described in the Technical Note cove-

ring the 2nd generation air bag.

REMINDER: this kind of work must only be carried

out by properly trained and qualified staff.

Remove:

- both the sub-frame reinforcements,

- the earth strap mounting bolt on the body

side,

- the exhaust downpipe nuts. D7F engine

10-10

Page 18 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

Front sub-frame mounting bolt 6.2

Rear sub-frame mounting bolt 10.5

Mounting bolt for front right suspended

engine mounting cover on engine 6.2

Mounting nut for front right suspended

engine mounting cover 4.4

Mounting nut for rubber engine mounting pad

on front left-hand side member support 6.2

Shock absorber base bolt 18

Brake caliper mounting bolt 4

Steering shaft yoke bolt 3

Wheel bolt 9

TIGHTENING TORQUES (in daN.m)

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Drain:

- the cooling circuit through the bottom hose

of the radiator,

- the gearbox and the engine if necessary.

Remove:

- the bonnet,

- the front wheels,

- the tie-rods between sub-frame and body,- the mounting bolts (1); pull away the brake

calipers as shown in the diagram below and

attach them to the suspension springs,

12994R1

- the shock absorber base bolts, E7J engine

SPECIAL TOOLING REQUIRED

Mot. 1040-01 Dummy sub-frame for removing

and refitting engine and

transmission assembly

Mot. 1159 Tool for maintaining engine on

sub-frame

Mot. 1202

Mot. 1448

Mot. 1311-06 Tool for removing fuel pipe

Hose clip pliers

10-14

Page 23 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

SPECIAL TOOLING REQUIRED

Mot. 1040-01 Dummy sub-frame for removing -

refitting the engine and

transmission assembly

Mot. 1159 Tool for maintaining engine on

sub-frame

Mot. 1202

Mot. 1448

Mot. 1311-06 Tool for removing fuel pipe

Front sub-frame mounting bolt 6.2

Rear sub-frame mounting bolt 10.5

Mounting bolt for front right suspended engine

mounting cover on engine 6.2

Mounting nut for front right suspended engine

mounting cover 4.4

Mounting nut for rubber engine mounting

pad on front left side member support 6.2

Shock absorber base bolt 18

Brake caliper mounting bolt 4

Steering shaft yoke bolt 3

Wheel bolt 9

TIGHTENING TORQUES (in daN.m)

REMOVAL

Put the vehicle on a 2 post lift.

Disconnect the battery.

Drain:

- the cooling circuit through the bottom hose

of the radiator,

- the gearbox and the engine if necessary.

Remove:

- the bonnet,

- the front wheels,

- the tie-rods between sub-frame and body,- the mounting bolts (1); pull away the brake

calipers as shown in the diagram below and

attach them to the suspension springs,

12994R1

- the shock absorber base bolts, F8Q engine

Hose clip pliers

10-19

Page 100 of 208

DIESEL EQUIPMENT

Advance solenoid valve

13

13342R

To remove the terminals from the pump

connector :

1) Pull the yellow guide to release the terminal

connectors, then press on the two tabs on

each side of the connector.

2) Extract the yellow guide.

3) Pull the wire to be removed.

4) The terminal connector is secured by two

tabs, one on each side ; using a screwdriver,

move one of these to one side (the action of

pulling on the wire prevents the tab from

going back into place).

5) Using a screwdriver, move the other tab to

one side.

The terminal connector can now be removed from

the connector.Remove the protective sheath grouping the pump

actuators.

Remove the protective cover from the solenoid

valve.

Remove the solenoid valve using tool Mot. 997-

01.

10579R1

APassage of connector

13-20

Page 103 of 208

DIESEL EQUIPMENT

Altimetric corrector

13

13342R

To remove the terminals for the pump

connector:

1) Pull the yellow guide to release it from the

terminals, then press the two tabs on either

side of the connector.

2) Extract the yellow guide.

3) Pull the wire to be removed.

4) The terminal is held in place by two small tabs,

one on each side; using a screwdriver, move

one of the tabs to one side (the action of

pulling on the wire prevents the tab from

going back into place.

5) Using a screwdriver move the other tab to one

side.

The terminal may now be removed from the

connector.Remove the protective sheath grouping the pump

actuators.

Remove the protective cover from the solenoid

valve.

Remove the altimetric corrector (1) using tool

Mot. 1440.

10579R2

AConnector passage

F8Q 662

13-23

Page 128 of 208

ANTIPOLLUTION

Fuel vapour rebreathing

14

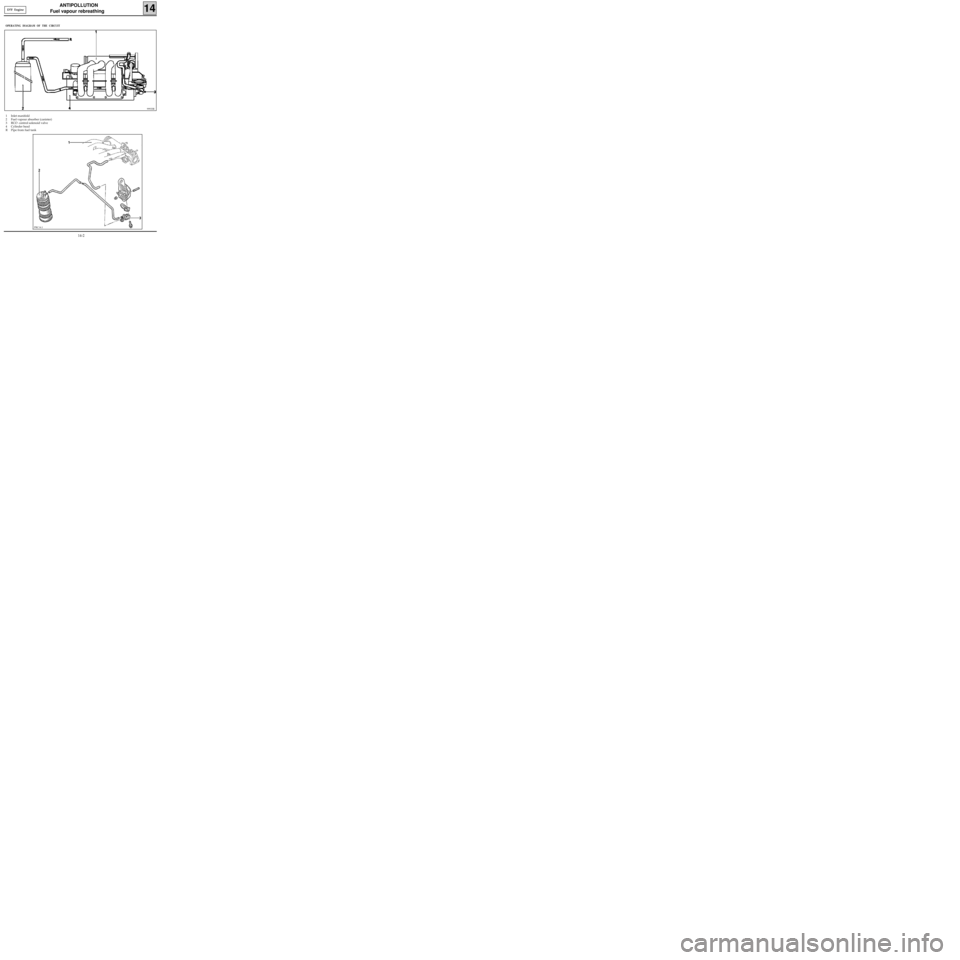

OPERATING DIAGRAM OF THE CIRCUIT

1 Inlet manifold

2 Fuel vapour absorber (canister)

3 RCO control solenoid valve

4 Cylinder head

R Pipe from fuel tank

99933R

PRC14.1

D7F Engine

14-2

Page 129 of 208

ANTIPOLLUTION

Fuel vapour rebreathing

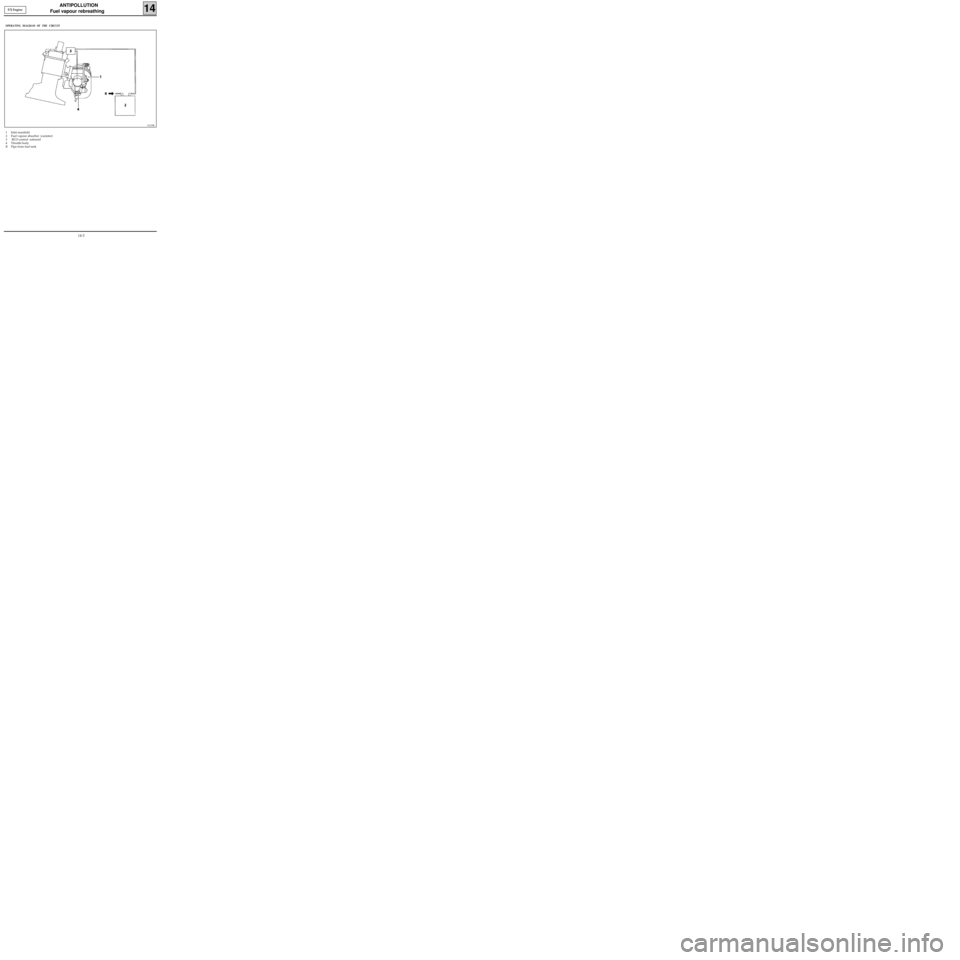

14E7J Engine

OPERATING DIAGRAM OF THE CIRCUIT

1 Inlet manifold

2 Fuel vapour absorber (canister)

3 RCO control solenoid

4 Throttle body

R Pipe from fuel tank

13123R

14-3