air condition RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 3 of 208

Contents

Consumables

Identification

Oil consumption

Oil pressure

Engine - Gearbox

Engine and transmission assembly

Sump

Crankshaft seal, timing end

Oil pump10-1

10-1

10-2

10-3

10-4

10-9

10-25

10-29

10-30

TOP AND FRONT OF ENGINE

Timing belt

Cylinder head gasket

Replacement of valve adjustersPage Page

11

Engine and

peripherals

11-1

11-11

11-29 ENGINE AND PERIPHERALS

10FUEL SUPPLY -

DIESEL EQUIPMENT

Fuel supply

Fuel cut off in case of an impact

Injector gallery

Fuel filter

Pump flow

Fuel pressure

Antipercolation device

Diesel equipment

General

Specifications

Location of components

Advance solenoid valve

Altimetric corrector

Fast idle LDA

Coded solenoid valve

Load potentiometer

Computer configuration

Injector with sensor (needle

lift)

Injection warning light

Pre-postheating control

Fast idle control

Injection/air conditioning

programming

Computer

Defect modes

Pump

Pump -Timing

Idle speed settings13-1

13-2

13-6

13-7

13-8

13-12

13-13

13-14

13-16

13-19

13-22

13-25

13-26

13-28

13-29

13-31

13-32

13-33

13-35

13-36

13-36

13-37

13-38

13-39

13-41

13-4613

FUEL MIXTURE

Specifications

Throttle body

Inlet manifold

Exhaust manifold

Inlet-exhaust manifolds12-1

12-7

12-15

12-18

12-2012

Page 4 of 208

Page

Cooling

Specifications

Filling and bleeding

Testing

Diagram

Water pump

Exhaust

General

Exhaust pipe assembly

Fuel tank

Tank

Sender unit

Pump and sender unit assembly

Engine suspension

Suspended engine mountings19-1

19-2

19-3

19-4

19-7

19-12

19-15

19-17

19-29

19-30

19-32 COOLING - EXHAUST - FUEL TANK -

ENGINE SUSPENSION

19

16-1

16-7 STARTING - CHARGING

Alternator

Starter

16

IGNITION - INJECTION

Ignition

Static ignition

Plugs

Injection

General

Location of components

Centralised coolant temperature

management

Injection fault warning light

Immobiliser function

Computer configuration depending

on gearbox type17

14-1

14-2

14-7

14-11 ANTIPOLLUTION

Test for the presence of lead

Fuel vapour rebreathing

Oil vapour rebreathing

Exhaust gas recirculation

(EGR)

14

17-17

17-18

17-19

17-20

17-22 IGNITION - INJECTION

(continued)

Injection/air conditioning

programming

Idle speed correction

Adaptive idle speed

correction

Richness regulation

Adaptive richness correction

17

Page

17-1

17-3

17-4

17-8

17-13

17-14

17-15

17-16

Contents

Page 67 of 208

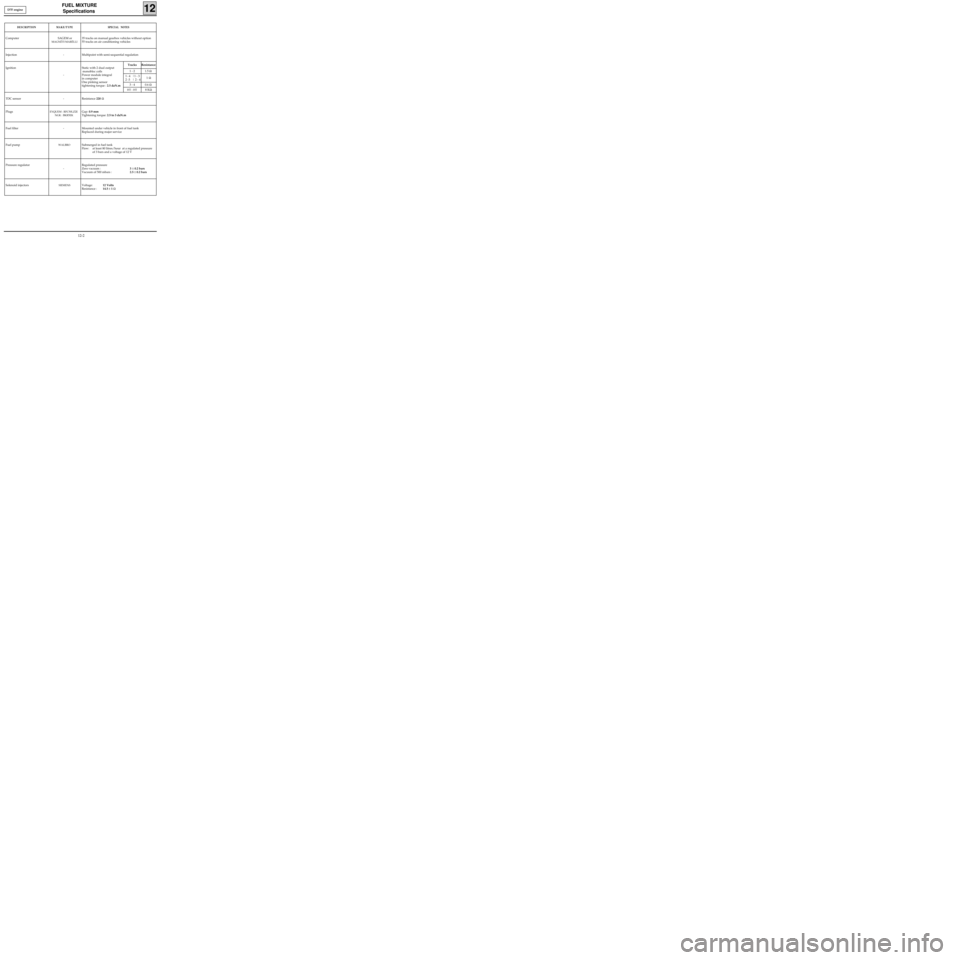

FUEL MIXTURE

Specifications

12

DESCRIPTIONMAKE/TYPESPECIAL NOTES

Computer SAGEM or

MAGNÉTI MARÉLLI

35 tracks on manual gearbox vehicles without option

55 tracks on air conditioning vehicles

Injection - Multipoint with semi-sequential regulation

Ignition

-Static with 2 dual output

monobloc coils

Power module integral

in computer

One pinking sensor

tightening torque : 2.5 daN.m

TDC sensor - Resistance 220 Ω

Plugs

EYQUEM : RFC50LZ2E

NGK : BKR5EKGap: 0.9 mm

Tightening torque: 2.5 to 3 daN.m

Fuel filter - Mounted under vehicle in front of fuel tank

Replaced during major service

Fuel pump

WALBROSubmerged in fuel tank

Flow: at least 80 litres/hour at a regulated pressure

of 3 bars and a voltage of 12 V

Pressure regulator

-Regulated pressure

Zero vacuum :3 ± 0.2 bars

Vacuum of 500 mbars :2.5 ± 0.2 bars

Solenoid injectors

SIEMENSVoltage:12 Volts

Resistance :14.5 ± 1 Ω

Tracks Resistance

1 - 2 1.5 Ω

1

- 4 |1 - 3

2 -3 | 2 - 41 Ω

3 - 4 0.6 Ω

HT - HT8 KΩ

D7F engine

12-2

Page 109 of 208

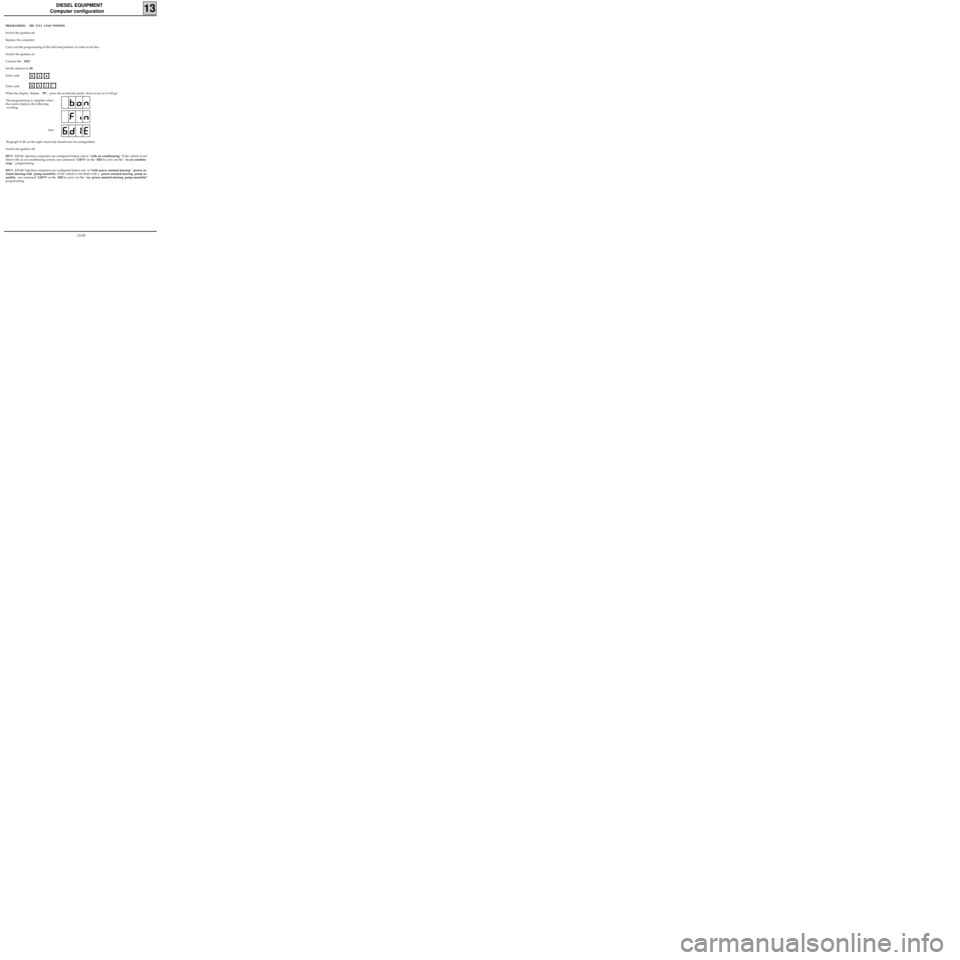

DIESEL EQUIPMENT

Computer configuration

13

PROGRAMMING THE FULL LOAD POSITION

Switch the ignition off.

Replace the computer.

Carry out the programming of the full load position; in order to do this :

Switch the ignition on.

Connect the

XR25.

Set the selector to S8.

Enter code

Enter code

When the display flashes "PF", press the accelerator pedal down as far as it will go.

The programming is complete when

the screen displays the following

wording: D

34

G31*

Bargraph N.12 on the right hand side should now be extinguished.

Switch the ignition off.

DPCN LUCAS injection computers are configured before sale to "with air conditioning". If the vehicle is not

fitted with an air conditioning system, use command G50*4* on the

XR25 to carry out the "no air conditio-

ning " programming.

DPCN LUCAS "injection computers are configured before sale to "with power assisted steering " (power as-

sisted steering with pump assembly). If the vehicle is not fitted with a power assisted steering pump as-

sembly, use command G50*9* on the

XR25 to carry out the "no power assisted steering pump assembly"

programming.then

13-29

Page 110 of 208

DIESEL EQUIPMENT

Computer configuration

13

COMPUTER CONFIGURATION IN RELATION TO AIR CONDITIONING.

For vehicles equipped with air conditioning , enter G50*3* on the XR25

For vehicles without air conditioning , enter G50*4* on the XR25 .

COMPUTER CONFIGURATION IN RELATION TO THE PAS (POWER ASSISTED STEERING PUMP ASSEMBLY)

The vehicle may have two types of PAS assembly :

-a

PAS assembly including a high pressure pump driven by a belt. In this case, the computer must be

configured without PAS : enter G50*9* on the

XR25,

-a

PAS assembly with a pump assembly which is driven electrically and controlled by the injection compu-

ter. ( this type of

PAS is fitted in all vehicles which are also equipped with AC). In this case, the computer

must be configured with PAS : enter G50*8* on the XR25.

IMPORTANT : according to the above explanations, only two types of combination are possible for the illumi-

nation of bargraphs 18 and 19.

Vehicle with AC

and PAS pump assemblyVehicle without AC and PAS pump assembly

(with conventional PAS)

18

19

18

19

DA CA

NOTE : if the computer has been replaced, remember to carry out the programming of the load potentio-

meter full load position (see "Load potentiometer " section ).

13-30

Page 116 of 208

DIESEL EQUIPMENT

Injection/air conditioning programming

13

CONNECTION BETWEEN AIR CONDITIONING ASSEMBLY AND INJECTION COMPUTER

The electrical connection :

- from the air conditioning computer to the diesel injection computer consists of one wire. This track only

carries the information that the AC is operating. From this, the diesel injection computer deduces the AC

selection information : track 11,

- from the diesel injection computer to the air conditioning computer consists of one wire. This track

carries all information regarding authorising and preventing operation of the compressor : track 19.

COMPRESSOR OPERATION PROGRAMMING

During certain stages of operation, the diesel injection computer stops the compressor from functioning.

Engine start programming

After the engine has started running, the compressor is prevented from functioning for 3 seconds.

Performance return programming

If the full load position is detected, the AC compressor is prevented from functioning for 8 seconds.

Stalling prevention programming

If the engine speed is lower than 650 rpm., the compressor is automatically cut off. It will only be allowed to

function again if the engine speed exceeds 775 rpm.

13-36

Page 130 of 208

ANTIPOLLUTION

Fuel vapour rebreathing

14

CONDITION FOR BLEEDING THE CANISTER ( D7F

engine)

• Coolant temperature greater than+ 15 °C

•Air temperature greater than +10 °C.

• No load position not recognised (if there is a

fault in the throttle potentiometer sensor, the

condition of no load position not recognised is

replaced by an engine speed condition

R > 1500 rpm.).

It is possible to visualise the cyclical opening ratio

for the canister bleed solenoid using the

XR25

and #23. The solenoid is closed if #23 = 0.7 %

CONDITION FOR BLEEDING THE CANISTER (E7J

engine)

During richness regulation

Coolant temperature greater than 50°C.

Air temperature greater than 15°C.

No load position not recognised (if there is a fault

in the throttle potentiometer sensor, the

condition of no load position not recognised is

replaced by an engine speed condition

R > 1500 rpm.).

Outside richness regulation

•Coolant temperature greater than 50°C.

•Air temperature greater than 15°C.

•Full load position recognised (function of

engine speed and manifold pressure).

If there is a fault in the oxygen sensor, bleeding is

permitted outside of no load conditions.

It is possible to visualise the cyclical opening ratio

for the canister bleed solenoid using the

XR25

and #23. The solenoid is closed if #23 = 0.7 %

(minimum value).

14-4

Page 131 of 208

ANTIPOLLUTION

Fuel vapour rebreathing

14

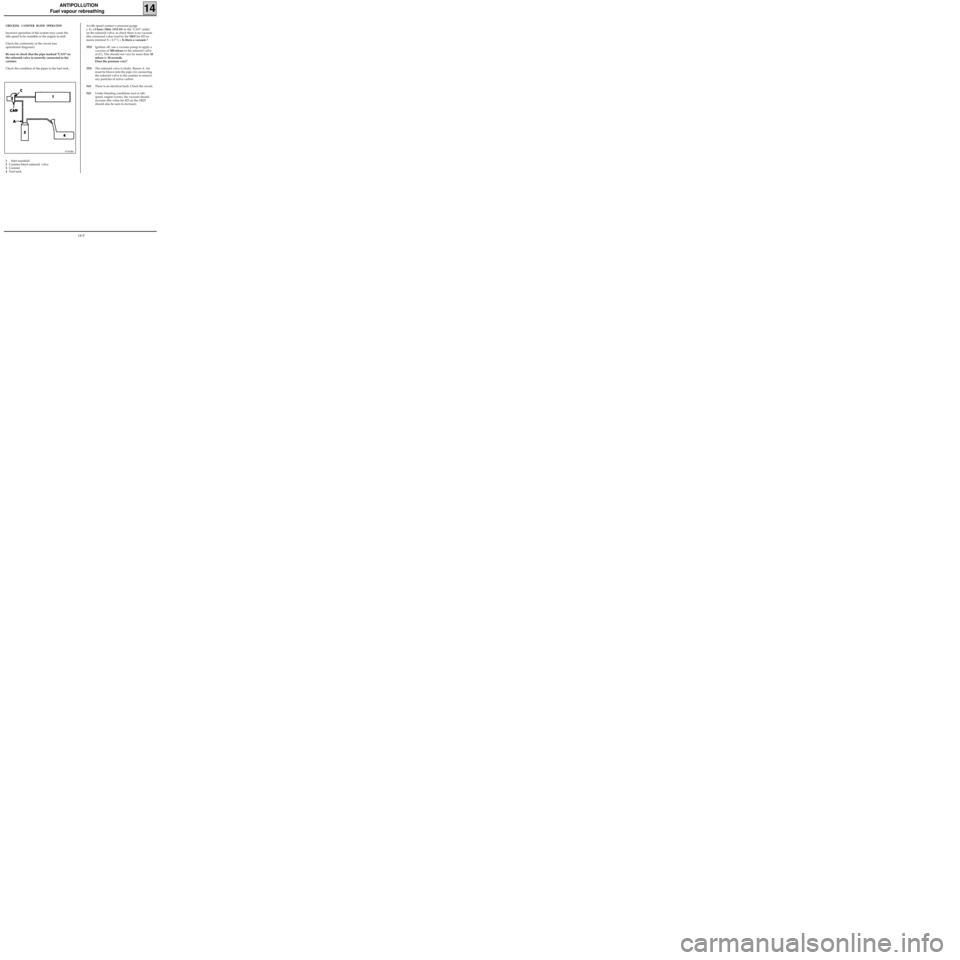

CHECKING CANISTER BLEED OPERATION

Incorrect operation of the system may cause the

idle speed to be unstable or the engine to stall.

Check the conformity of the circuit (see

operational diagrams)

Be sure to check that the pipe marked "CAN" on

the solenoid valve is correctly connected to the

canister.

Check the condition of the pipes to the fuel tank.

97393R6

1Inlet manifold

2Canister bleed solenoid valve

3Canister

4Fuel tankAt idle speed connect a pressure gauge

(- 3 ; +3 bars) (Mot. 1311-01) to the "CAN" outlet

on the solenoid valve, to check there is no vacuum

(the command value read by the

XR25 for #23 re-

mains minimal X = 0.7 % ). Is there a vacuum ?

YESIgnition off, use a vacuum pump to apply a

vacuum of 500 mbars to the solenoid valve

at (C). This should not vary by more than 10

mbars in 30 seconds.

Does the pressure vary?

YESThe solenoid valve is faulty. Renew it. Air

must be blown into the pipe (A) connecting

the solenoid valve to the canister to remove

any particles of active carbon.

NOThere is an electrical fault. Check the circuit.

NOUnder bleeding conditions (not at idle

speed, engine warm), the vacuum should

increase (the value for #23 on the XR25

should also be seen to increase).

14-5

Page 154 of 208

INJECTION

General

17

SPECIAL NOTES FOR MULTIPOINT INJECTION

• 35 track SAGEM or MAGNETI MARELLI computer for vehicles without options.

• 55 track SAGEM computer ,

SAFIR or MAGNETI MARELLI type for versions with air conditioning.

•Semi-sequential multipoint injection. Injectors controlled two by two (injectors for cylinders 1 and 4 fol-

lowed by injectors for cylinders 2 and 3).

•Semi-static ignition with dual single unit coils.

•Canister bleed solenoid valve controlled by RCO signal.

•Computer configuration depending on gearbox type (manual gearbox or automatic transmission).

•The maximum engine speed permitted is 6 200 rpm.

•Idle speed correction depending on :

- battery voltage,

- air conditioning

- power assisted steering pressostat.

•Injection warning light on instrument panel not operational.

•Use fault finding fiche n° 27. D7F Engine

FITTING A 2ND GENERATION ENGINE IMMOBILISER REQUIRES A SPECIAL PROCEDURE FOR REPLACING THE

COMPUTER.

17-4

Page 155 of 208

INJECTION

General

17

SPECIAL NOTES FOR MULTIPOINT INJECTION

• 55 track SIEMENS FENIX 5 computer.

•Semi-sequential multipoint injection. Injectors are controlled two by two (injectors for cylinders 1 and 4

followed by cylinders 2 and 3).

•Semi-static ignition with dual coils.

•Canister bleed solenoid controlled by RCO signal.

•Computer configuration depending on gearbox type (manual gearbox or automatic transmission)

•Idle speed correction depending on :

- air conditioning,

- power assisted steering pressostat,

- battery voltage.

•Injection warning light on instrument panel operational.

•Use fault finding fiche n° 27.

•Maximum speed :

-6 200 rpm if 1st , 2nd or 3rd gears

-6 000 rpm if 4th,or 5th gears. E7J Engine

FITTING A 2ND GENERATION ENGINE IMMOBILISER REQUIRES A SPECIAL PROCEDURE FOR REPLACING THE

COMPUTER.

17-5