fuel pressure RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 3 of 208

Contents

Consumables

Identification

Oil consumption

Oil pressure

Engine - Gearbox

Engine and transmission assembly

Sump

Crankshaft seal, timing end

Oil pump10-1

10-1

10-2

10-3

10-4

10-9

10-25

10-29

10-30

TOP AND FRONT OF ENGINE

Timing belt

Cylinder head gasket

Replacement of valve adjustersPage Page

11

Engine and

peripherals

11-1

11-11

11-29 ENGINE AND PERIPHERALS

10FUEL SUPPLY -

DIESEL EQUIPMENT

Fuel supply

Fuel cut off in case of an impact

Injector gallery

Fuel filter

Pump flow

Fuel pressure

Antipercolation device

Diesel equipment

General

Specifications

Location of components

Advance solenoid valve

Altimetric corrector

Fast idle LDA

Coded solenoid valve

Load potentiometer

Computer configuration

Injector with sensor (needle

lift)

Injection warning light

Pre-postheating control

Fast idle control

Injection/air conditioning

programming

Computer

Defect modes

Pump

Pump -Timing

Idle speed settings13-1

13-2

13-6

13-7

13-8

13-12

13-13

13-14

13-16

13-19

13-22

13-25

13-26

13-28

13-29

13-31

13-32

13-33

13-35

13-36

13-36

13-37

13-38

13-39

13-41

13-4613

FUEL MIXTURE

Specifications

Throttle body

Inlet manifold

Exhaust manifold

Inlet-exhaust manifolds12-1

12-7

12-15

12-18

12-2012

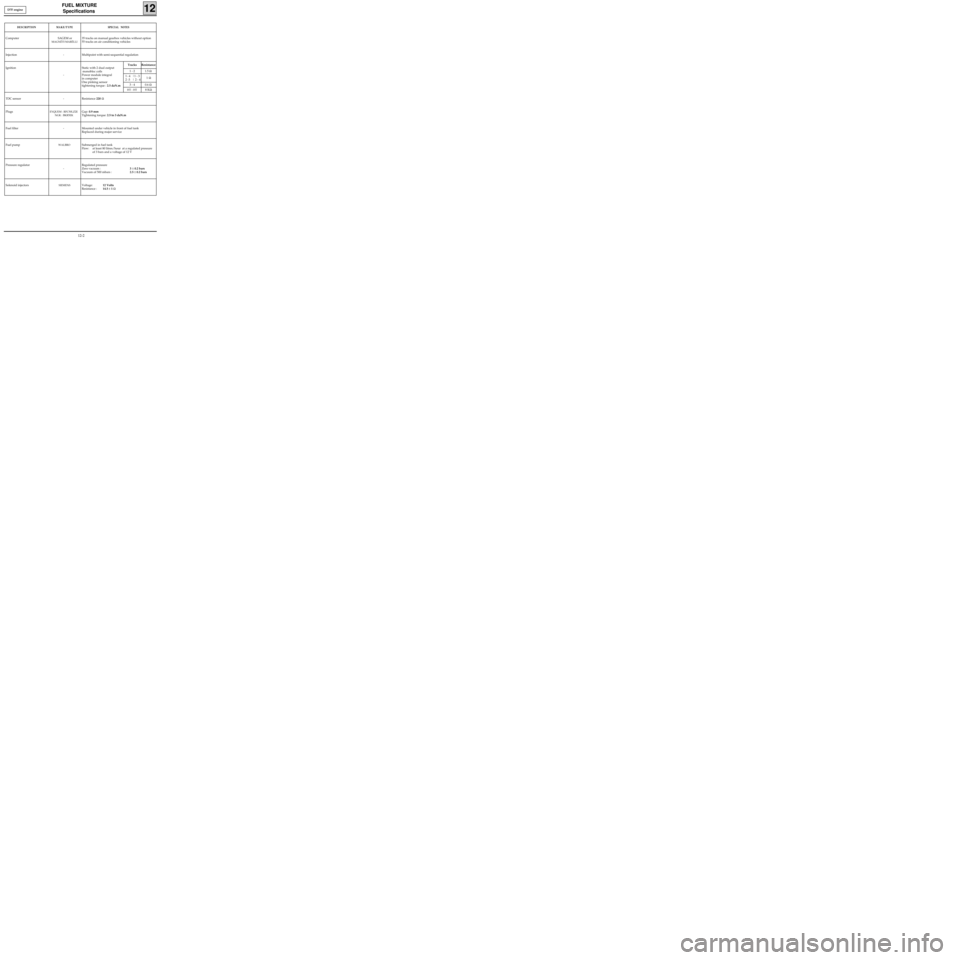

Page 67 of 208

FUEL MIXTURE

Specifications

12

DESCRIPTIONMAKE/TYPESPECIAL NOTES

Computer SAGEM or

MAGNÉTI MARÉLLI

35 tracks on manual gearbox vehicles without option

55 tracks on air conditioning vehicles

Injection - Multipoint with semi-sequential regulation

Ignition

-Static with 2 dual output

monobloc coils

Power module integral

in computer

One pinking sensor

tightening torque : 2.5 daN.m

TDC sensor - Resistance 220 Ω

Plugs

EYQUEM : RFC50LZ2E

NGK : BKR5EKGap: 0.9 mm

Tightening torque: 2.5 to 3 daN.m

Fuel filter - Mounted under vehicle in front of fuel tank

Replaced during major service

Fuel pump

WALBROSubmerged in fuel tank

Flow: at least 80 litres/hour at a regulated pressure

of 3 bars and a voltage of 12 V

Pressure regulator

-Regulated pressure

Zero vacuum :3 ± 0.2 bars

Vacuum of 500 mbars :2.5 ± 0.2 bars

Solenoid injectors

SIEMENSVoltage:12 Volts

Resistance :14.5 ± 1 Ω

Tracks Resistance

1 - 2 1.5 Ω

1

- 4 |1 - 3

2 -3 | 2 - 41 Ω

3 - 4 0.6 Ω

HT - HT8 KΩ

D7F engine

12-2

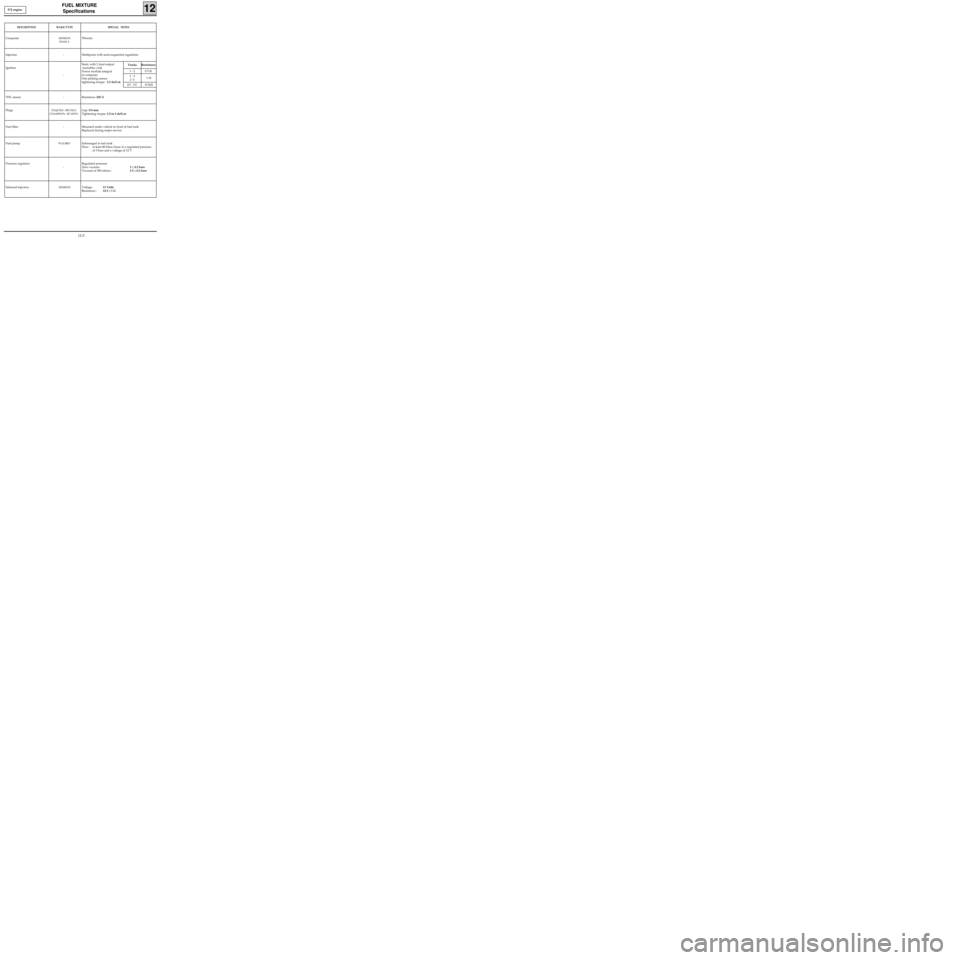

Page 70 of 208

FUEL MIXTURE

Specifications

12

DESCRIPTIONMAKE/TYPESPECIAL NOTES

ComputerSIEMENS

FENIX 555tracks

Injection - Multipoint with semi-sequential regulation

Ignition

-Static with 2 dual output

monobloc coils

Power module integral

in computer

One pinking sensor

tightening torque : 2.5 daN.m

TDC sensor - Resistance 220 Ω

Plugs

EYQUEM : RFC52LS

CHAMPION

: RC10PYC

Gap: 0.9 mm

Tightening torque: 2.5 to 3 daN.m

Fuel filter - Mounted under vehicle in front of fuel tank

Replaced during major service

Fuel pump

WALBROSubmerged in fuel tank

Flow: at least 80 litres/hour at a regulated pressure

of 3 bars and a voltage of 12 V

Pressure regulator

-

Regulated pressure

Zero vacuum :3 ± 0.2 bars

Vacuum of 500 mbars :2.5 ± 0.2 bars

Solenoid injectors

SIEMENSVoltage:12 Volts

Resistance :14.5 ± 1 Ω

Tracks Resistance

1 - 2 0.5 Ω

1 - 3

2 -31 Ω

HT - HT10 KΩ

E7J engine

12-5

Page 81 of 208

FUEL SUPPLY

Fuel cut off in case of an impact

13

OBJECTIVE

The main function of this feature is to avoid any

fires that may result from the leakage of fuel du-

ring an accident. In order to achieve this, all

components pumping fuel from the fuel tank will

automatically stop functioning during and imme-

diately after the impact. They can then only be

made to operate again by a mechanical action car-

ried out by the driver or the repairer.

DESCRIPTION

The system consists simply of an inertia switch (1),

which:

- detects the impact,

- and thus cuts off the electrical circuit.

13051R

This is fitted:

• in petrol engines, between track 1 of the

pump relay (236) and the + 12 V supply ,

• in diesel engines, between the + supply and

the electrical solenoid (or the coded solenoid

valve if the vehicle is fitted with an engine im-

mobiliser).

OPERATING PRINCIPLE

During the impact, the ball of the inertia switch

moves up and interrupts the electrical connec-

tion.

In petrol engines, the + supply of the pump relay

control circuit (236) is cut. Neither the pump or

the injectors will receive any further supply of

electricity .

The fuel contained in the tank is actually isolated.

In diesel engines, the + supply of the electrical

solenoid or of the coded solenoid is cut off.

The pump can no longer take in fuel, and there is

no longer any high pressure. All risk of fire due to

the outlet of diesel fuel at high pressure onto the

engine is removed.

RESETTING AND OPERATING THE SWITCH

In order to reset the inertia switch, it is sufficient

to press it down in order to replace the ball bea-

ring in its original position .

IMPORTANT: for petrol engines, , having reset

the switch, it is

VITAL to erase the memory of the

computer, using the

XR25. The injection compu-

ter will memorise a pump relay fault once the

system has gone into operation .

13-1

Page 82 of 208

FUEL SUPPLY

Injector gallery

13

IMPORTANT: during the opening of the fuel cir-

cuit , be sure to use a cloth to avoid possible pro-

jections of fuel due to the residual pressure.

REMOVAL

Disconnect :

- the battery,

- the pressure measurement pipe (1) of the

pressure regulator,

- the fuel return pipe (2),

- the electrical connector of the injectors (3)

99937R3

SPECIAL TOOLING REQUIRED

Mot. 1311-06 Tool for removing the fuel

supply unions

Bolt mounting injector gallery on manifold 1

TIGHTENING TORQUES (in daN.m)

D7F Engine

13-2

Page 83 of 208

FUEL SUPPLY

Injector gallery

13

To disconnect the unions, slip tool Mot. 1311-06

between the two stems (A) and (B).

Press on the tool to lift the two retaining clips,

then pull on the union.

Remove the two bolts (5) mounting the injector

gallery on the manifold.

Slide the injector gallery, along with the injectors,

between the manifold and the cylinder head.

Extract the injector gallery from the right hand

side of the vehicle.

NOTES :The fuel pressure regulator (6) is clipped

to the injector gallery.

There is an intermediate connector (7) between

the injector connector (8) and the computer.

10046R

Disconnect the fuel supply pipe (4) using the tool

Mot. 1311-06 with the largest section (the fuel

supply pipe is equipped with a removal tool

which is attached to the connection incorporated

in the vehicle ).

99375R

99461R1

D7F Engine

13-3

Page 85 of 208

FUEL SUPPLY

Injector gallery

13

In order to remove an injector, remove the clips at

(8), then pull on the injector .

99373R

IMPORTANT: during the opening of the fuel cir-

cuit , be sure to use a cloth to avoid possible pro-

jections of fuel due to the residual pressure.

REMOVAL

Disconnect the battery.

Remove the air filter.

Remove:

- the fuel supply pipe (1)

- the fuel return pipe (2)

- the fuel pressure regulator pipe (3) .

Remove the three bolts (4) mounting the injector

gallery (5).

Remove the injector gallery.E7J Engine

13244R

REFITTING

Replace the O rings at the base of the injector (if

the injector has been removed, also replace the

seal which is level with the injector head).

To ensure that the fuel supply unions are correct-

ly fastened, it is necessary to hear a"click" sound

whilst fastening.

For all other operations, refitting is the reverse of

removal .

13-5

Page 86 of 208

FUEL SUPPLY

Fuel filter

13

LOCATION

The fuel filter is located under the vehicle, in

front of the fuel tank. Petrol

engines

99214R

SPECIAL TOOLING REQUIRED

Mot. 1265 Pliers for removing quick release

unions

REPLACEMENT

It is recommended to replace the fuel filter at

each vehicle major service.

IMPORTANT : during the opening of the fuel cir-

cuit , be sure to use a cloth to avoid possible pro-

jections of fuel due to the residual pressure.

REMOVAL

Before removing the filter take precautions to

catch fuel that will run out of the pipes (the pipes

should not be clamped as they would be dama-

ged).

Remove the clips (1).

Disconnect the pipes fitted with quick release

unions (2) using tool Mot. 1265.

96420R3

Remove bolt (3) and remove the fuel filter.

REFITTING

Observe the flow direction of the fuel (marked by

an arrow on the filter).

Reconnect the pipes by hand (tool Mot. 1265 is

not required ).

Ensure that the quick release unions are correctly

fastened .

Refit the safety clips (1).

13-6

Page 87 of 208

FUEL SUPPLY

Pump flow

13

Petrol

engines

96093R2

SPECIAL TOOLING REQUIRED

Mot. 1265 Pliers for removing quick release

unions

EQUIPMENT REQUIRED

2 000 ml measuring cylinder

It is advised to check the pump supply flow

through the fuel return pipe connected to the

pump-fuel sender unit assembly.

IMPORTANT

During this operation, it is essential :

• to refrain from smoking and handling incan-

descent objects close to the working area,

• to take precautions against possible fuel

projections which may occur due to the resi-

dual pressure in the supply pipes when they

are removed.

CHECKING THE PUMP FLOW

Disconnect the fuel return pipe (1) (Mot. 1265).

Connect a piece of pipe to the hose and place this

into a 0-2 000 ml graduated measuring cylinder.

Shunt terminals (3) and (5) of relay (K) on the DF7

engine, or for the

E7J engine shunt at (L) on the

fuel pump relay (which is located in the engine

fuse box ). In one minute, the pump flow must be

a minimum of 1.3 litres with a voltage of 12

volts.

If the fuel flow is low, check the pump feed vol-

tage (approximately 10 % reduction in flow for a

voltage drop of 1 Volt)

12839S

13-7

Page 88 of 208

FUEL SUPPLY

Fuel pressure

13

CHECKING THE FUEL PRESSURE

SPECIAL TOOLING REQUIRED

Mot. 1311-01 Fuel pressure test kit (with a pressure

gauge 0; + 10 bar tool kit)

Mot. 1311-05 Junction tool (for union K)

Mot. 1311-06 Tool for removing fuel supply unions

IMPORTANT : during the opening of the fuel cir-

cuit , be sure to use a cloth to avoid possible pro-

jections of fuel due to the residual pressure.

Disconnect the fuel supply pipe using the tool

Mot. 1311-06 with the largest section (see method

described in section 13 "Injector gallery").

Connect tool Mot. 1311-05 to the injector gallery,

then reconnect the fuel supply pipe to the tool

itself.

99375R

99934R1

99939S

DF7 Engine

13-8