low oil pressure RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 3 of 208

Contents

Consumables

Identification

Oil consumption

Oil pressure

Engine - Gearbox

Engine and transmission assembly

Sump

Crankshaft seal, timing end

Oil pump10-1

10-1

10-2

10-3

10-4

10-9

10-25

10-29

10-30

TOP AND FRONT OF ENGINE

Timing belt

Cylinder head gasket

Replacement of valve adjustersPage Page

11

Engine and

peripherals

11-1

11-11

11-29 ENGINE AND PERIPHERALS

10FUEL SUPPLY -

DIESEL EQUIPMENT

Fuel supply

Fuel cut off in case of an impact

Injector gallery

Fuel filter

Pump flow

Fuel pressure

Antipercolation device

Diesel equipment

General

Specifications

Location of components

Advance solenoid valve

Altimetric corrector

Fast idle LDA

Coded solenoid valve

Load potentiometer

Computer configuration

Injector with sensor (needle

lift)

Injection warning light

Pre-postheating control

Fast idle control

Injection/air conditioning

programming

Computer

Defect modes

Pump

Pump -Timing

Idle speed settings13-1

13-2

13-6

13-7

13-8

13-12

13-13

13-14

13-16

13-19

13-22

13-25

13-26

13-28

13-29

13-31

13-32

13-33

13-35

13-36

13-36

13-37

13-38

13-39

13-41

13-4613

FUEL MIXTURE

Specifications

Throttle body

Inlet manifold

Exhaust manifold

Inlet-exhaust manifolds12-1

12-7

12-15

12-18

12-2012

Page 49 of 208

TOP AND FRONT OF ENGINE

Cylinder head gasket

11

92076S

CLEANING

It is very important not to scratch the gasket faces

of the aluminium components.

Use the Décapjoint product to dissolve any part of

the gasket which remains attached.

Apply the product to the parts to be cleaned; wait

about ten minutes, then remove it using a

wooden spatula.

Wear gloves whilst carrying out this operation.

Care must be taken whilst carrying out this ope-

ration in order to avoid any foreign bodies ente-

ring the oilways supplying oil under pressure to

the camshaft (oilways are located both in the cy-

linder block and the cylinder head).

Failure to follow to this advice could lead to the

blocking of the jets and thus cause rapid deterio-

ration of the cams and tappets.

CHECKING THE GASKET FACE

Check for gasket face bow using a straight edge

and a set of shims .

Maximum deformation : 0.05 mm.

No regrinding of the cylinder head is permitted.

REFITTING

The cylinder head is centred by two dowels at the

rear of the engine.

REMINDER: in order to obtain the correct tighte-

ning of the bolts, use a syringe to remove any oil

which may have entered the cylinder head moun-

ting bolt holes .

Grease the threads and under the bolt heads with

engine oil.

Adjustment of the valve rockers and tightening

of the cylinder head should be carried out when

the engine is cold. D7F Engine

11-14

Page 55 of 208

TOP AND FRONT OF ENGINE

Cylinder head gasket

11

Unhook the wiring loom at (14).

Remove :

- the cylinder head bolts except for (F) which

must simply be loosened, then pivot the cylin-

der head around the bolt.

92106R

- the cylinder head .

Fit the cylinder liner retaining brackets, tool

Mot. 588.

92062R

- the mounting at (10),

- the bolt (11) of the strut and slacken the nut

at (12),

- the mounting bolt (13) of the dipstick guide

tube,

13336-1R1

E7J Engine

CLEANING

It is very important not to scratch the gasket faces

of the aluminium components.

Use the Décapjoint product to dissolve any part of

the gasket which remains attached.

Apply the product to the parts to be cleaned; wait

about ten minutes, then remove it using a

wooden spatula.

Wear gloves whilst carrying out this operation.

Care must be taken whilst carrying out this ope-

ration in order to avoid any foreign bodies ente-

ring the oilways supplying oil under pressure to

the camshaft (oilways are located both in the cy-

linder block and the cylinder head).

Failure to follow to this advice could lead to the

blocking of the jets and thus cause rapid deterio-

ration of the cams and tappets.

11-20

Page 67 of 208

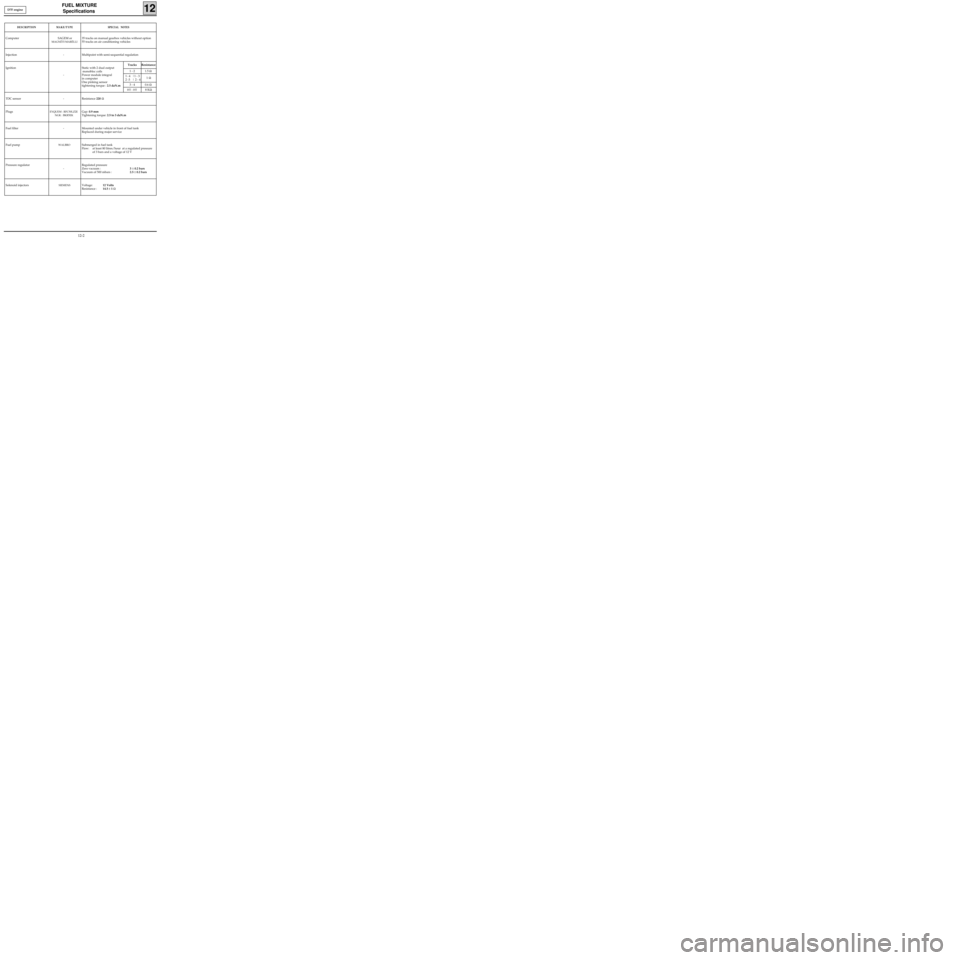

FUEL MIXTURE

Specifications

12

DESCRIPTIONMAKE/TYPESPECIAL NOTES

Computer SAGEM or

MAGNÉTI MARÉLLI

35 tracks on manual gearbox vehicles without option

55 tracks on air conditioning vehicles

Injection - Multipoint with semi-sequential regulation

Ignition

-Static with 2 dual output

monobloc coils

Power module integral

in computer

One pinking sensor

tightening torque : 2.5 daN.m

TDC sensor - Resistance 220 Ω

Plugs

EYQUEM : RFC50LZ2E

NGK : BKR5EKGap: 0.9 mm

Tightening torque: 2.5 to 3 daN.m

Fuel filter - Mounted under vehicle in front of fuel tank

Replaced during major service

Fuel pump

WALBROSubmerged in fuel tank

Flow: at least 80 litres/hour at a regulated pressure

of 3 bars and a voltage of 12 V

Pressure regulator

-Regulated pressure

Zero vacuum :3 ± 0.2 bars

Vacuum of 500 mbars :2.5 ± 0.2 bars

Solenoid injectors

SIEMENSVoltage:12 Volts

Resistance :14.5 ± 1 Ω

Tracks Resistance

1 - 2 1.5 Ω

1

- 4 |1 - 3

2 -3 | 2 - 41 Ω

3 - 4 0.6 Ω

HT - HT8 KΩ

D7F engine

12-2

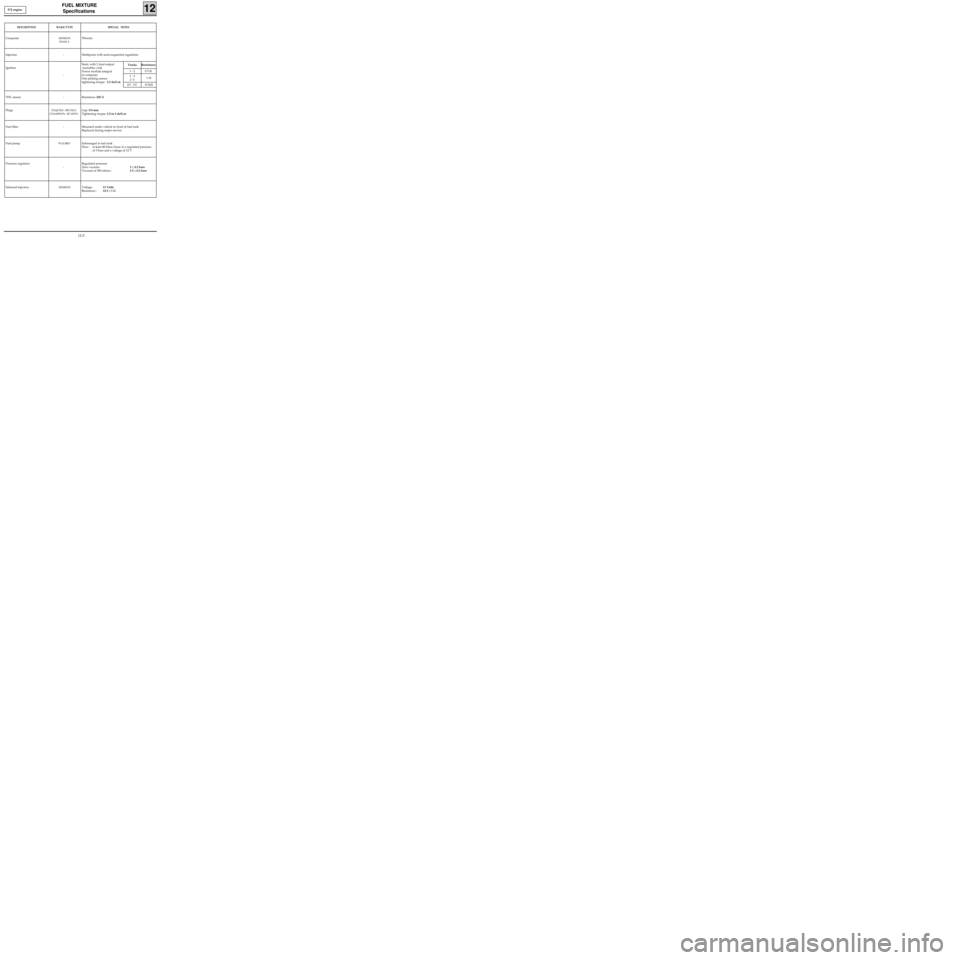

Page 70 of 208

FUEL MIXTURE

Specifications

12

DESCRIPTIONMAKE/TYPESPECIAL NOTES

ComputerSIEMENS

FENIX 555tracks

Injection - Multipoint with semi-sequential regulation

Ignition

-Static with 2 dual output

monobloc coils

Power module integral

in computer

One pinking sensor

tightening torque : 2.5 daN.m

TDC sensor - Resistance 220 Ω

Plugs

EYQUEM : RFC52LS

CHAMPION

: RC10PYC

Gap: 0.9 mm

Tightening torque: 2.5 to 3 daN.m

Fuel filter - Mounted under vehicle in front of fuel tank

Replaced during major service

Fuel pump

WALBROSubmerged in fuel tank

Flow: at least 80 litres/hour at a regulated pressure

of 3 bars and a voltage of 12 V

Pressure regulator

-

Regulated pressure

Zero vacuum :3 ± 0.2 bars

Vacuum of 500 mbars :2.5 ± 0.2 bars

Solenoid injectors

SIEMENSVoltage:12 Volts

Resistance :14.5 ± 1 Ω

Tracks Resistance

1 - 2 0.5 Ω

1 - 3

2 -31 Ω

HT - HT10 KΩ

E7J engine

12-5