warning RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 3 of 208

Contents

Consumables

Identification

Oil consumption

Oil pressure

Engine - Gearbox

Engine and transmission assembly

Sump

Crankshaft seal, timing end

Oil pump10-1

10-1

10-2

10-3

10-4

10-9

10-25

10-29

10-30

TOP AND FRONT OF ENGINE

Timing belt

Cylinder head gasket

Replacement of valve adjustersPage Page

11

Engine and

peripherals

11-1

11-11

11-29 ENGINE AND PERIPHERALS

10FUEL SUPPLY -

DIESEL EQUIPMENT

Fuel supply

Fuel cut off in case of an impact

Injector gallery

Fuel filter

Pump flow

Fuel pressure

Antipercolation device

Diesel equipment

General

Specifications

Location of components

Advance solenoid valve

Altimetric corrector

Fast idle LDA

Coded solenoid valve

Load potentiometer

Computer configuration

Injector with sensor (needle

lift)

Injection warning light

Pre-postheating control

Fast idle control

Injection/air conditioning

programming

Computer

Defect modes

Pump

Pump -Timing

Idle speed settings13-1

13-2

13-6

13-7

13-8

13-12

13-13

13-14

13-16

13-19

13-22

13-25

13-26

13-28

13-29

13-31

13-32

13-33

13-35

13-36

13-36

13-37

13-38

13-39

13-41

13-4613

FUEL MIXTURE

Specifications

Throttle body

Inlet manifold

Exhaust manifold

Inlet-exhaust manifolds12-1

12-7

12-15

12-18

12-2012

Page 4 of 208

Page

Cooling

Specifications

Filling and bleeding

Testing

Diagram

Water pump

Exhaust

General

Exhaust pipe assembly

Fuel tank

Tank

Sender unit

Pump and sender unit assembly

Engine suspension

Suspended engine mountings19-1

19-2

19-3

19-4

19-7

19-12

19-15

19-17

19-29

19-30

19-32 COOLING - EXHAUST - FUEL TANK -

ENGINE SUSPENSION

19

16-1

16-7 STARTING - CHARGING

Alternator

Starter

16

IGNITION - INJECTION

Ignition

Static ignition

Plugs

Injection

General

Location of components

Centralised coolant temperature

management

Injection fault warning light

Immobiliser function

Computer configuration depending

on gearbox type17

14-1

14-2

14-7

14-11 ANTIPOLLUTION

Test for the presence of lead

Fuel vapour rebreathing

Oil vapour rebreathing

Exhaust gas recirculation

(EGR)

14

17-17

17-18

17-19

17-20

17-22 IGNITION - INJECTION

(continued)

Injection/air conditioning

programming

Idle speed correction

Adaptive idle speed

correction

Richness regulation

Adaptive richness correction

17

Page

17-1

17-3

17-4

17-8

17-13

17-14

17-15

17-16

Contents

Page 14 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

Disconnect:

- the accelerator cable,

- the canister pipe,

- the brake servo pipe,

- the heater hoses,

- the oxygen sensor connector,

- the fuel pipes.

Remove:

- the shock absorber base bolts,

- the steering shaft yoke bolt.

10

97390-1R

SPECIAL NOTES FOR VEHICLES FITTED WITH

DRIVER’S AIR BAG

WARNING

In order to avoid any risk of damage to the rotary

switch beneath the steering wheel, the following

instructions should be followed:

• Before disconnecting the steering column from

the rack, the steering wheel MUST be immobi-

lised with the wheels straight with the aid of a

"steering wheel lock" throughout the opera-

tion.

• If there is any doubt about the rotary switch

being properly centred, the steering wheel

must be removed in order to apply the centring

method described in the Technical Note cove-

ring the 2nd generation air bag.

REMINDER: this kind of work must only be carried

out by properly trained and qualified staff.

Remove:

- both the sub-frame reinforcements,

- the earth strap mounting bolt on the body

side,

- the exhaust downpipe nuts. D7F engine

10-10

Page 20 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

- the relay plate (4), the connector (5) and the

fuse support (6) by removing the fuse holder

(7),

13034R

- the canister pipe,

- the fuel supply and return pipes with the aid

of tool Mot. 1311-06, after removing the co-

ver,

- the accelerator and clutch cables.

Unclip the power assisted steering reservoir and

place it on the engine.

Remove:

- the upper mountings of the radiator and at-

tach it to the engine,

- the nut and the eccentric bolt of the steering

shaft yoke, after pushing back the guard.

97390S1

SPECIAL NOTES FOR VEHICLES FITTED WITH

DRIVER’S AIR BAG

99024R2

WARNING

In order to prevent any risk of damage to the ro-

tary switch beneath the steering wheel, the follo-

wing instructions should be observed:

• Before disconnecting the steering column and

the rack, the steering wheel MUST be immobi-

lised with the wheels straight, using a "stee-

ring wheel lock", throughout the operation.

• If there is any doubt that the rotary switch is

properly centred, the steering wheel must be

removed in order to apply the centring method

described in section 88 "Air bag".

REMINDER: this kind of work must only be carried

out by properly trained and qualified staff.

Fit tool Mot. 1159 between the sub-frame and the

cylinder block. E7J engine

10-16

Page 26 of 208

ENGINE AND ENGINE PERIPHERALS

Engine and transmission assembly

10

Remove:

- the upper mountings of the radiator and at-

tach it to the engine,

- the nut and the eccentric bolt of the steering

shaft yoke, after pushing back the guard.

97390S1

SPECIAL NOTES FOR VEHICLES FITTED WITH

DRIVER’S AIR BAG

WARNING

In order to prevent any risk of damage to the ro-

tary switch beneath the steering wheel, the follo-

wing instructions should be observed:

• Before disconnecting the steering column and

the rack, the steering wheel MUST be immobi-

lised with the wheels straight, using a "stee-

ring wheel lock", throughout the operation.

• If there is any doubt that the rotary switch is

properly centred, the steering wheel must be

removed in order to apply the centring method

described in section 88 "Air bag".

REMINDER: this kind of work must only be carried

out by properly trained and qualified staff.

F8Q engine

13084R

13034R

- the relay plate (4), the connector (5) and the

fuse support (6) by removing the fuse holders

(7),

- the accelerator and clutch cables.

Unclip the power assisted steering reservoir and

place it on the engine.

10-22

Page 93 of 208

DIESEL EQUIPMENT

General

13

The use of electronic injection in Diesel engines has allowed the operational power of these engines to be

optimised, thus reducing the emission rate of pollutant gases.

The system consists of a computer, which receives information from:

- the coolant temperature sensor,

- the air temperature sensor,

- the engine speed sensor,

- the vehicle speed sensor,

- the load potentiometer,

- the injection start sensor, which forms part of the injector of cylinder n° 3 (injector with sensor).

It controls :

- the injection pump :

• the altimetric corrector (F8Q 630) via a relay

• the advance solenoid valve.

- the cold engine starting system (heater plugs and pre-postheating unit),

- the exhaust gas recycling system (EGR),

- the diesel injection fault warning light,

- the preheating warning light,

- the solenoid valve controlling the fast idle speed LDA,

- the relay controlling the power assisted steering electric pump assembly (for vehicles with air conditio-

ning), the pump assembly is supplied once the engine speed exceeds 650 rpm.

It carries out a self diagnosis procedure which may be visualised through the

XR25.

SPECIAL FEATURES

On the injection pump it is possible to replace:

- the load potentiometer,

- the advance solenoid valve,

- the altimetric corrector,

- the electrical solenoid.

13-13

Page 98 of 208

DIESEL EQUIPMENT

Location of components

13

20 EGR valve

13047-1R

7Engine speed sensor

13048R

87970R

17Diesel injection fault warning light

18Preheating warning light

Warning light illuminates when ignition is

switched on during preheating phase.

12839S

C Power assisted steering pump assembly relay

HAltimetric corrector relay

LInjection locking relay

MDiesel heating relay

13-18

Page 112 of 208

DIESEL EQUIPMENT

Injection warning light

13

OPERATING PRINCIPLE OF THE DIESEL INJECTION WARNING LIGHT ON THE INSTRUMENT PANEL

On switching on the ignition, the diesel injection fault warning light is illuminated. It extinguishes as the en-

gine begins to run.

•Fault in a component of the injection assembly

Faults in the following components may cause the warning light to illuminate :

- injector with sensor

- advance solenoid valve,

- engine speed sensor ,

- load lever potentiometer,

- pre-postheating (according to version).

13-32

Page 113 of 208

DIESEL EQUIPMENT

Pre-postheating control

13

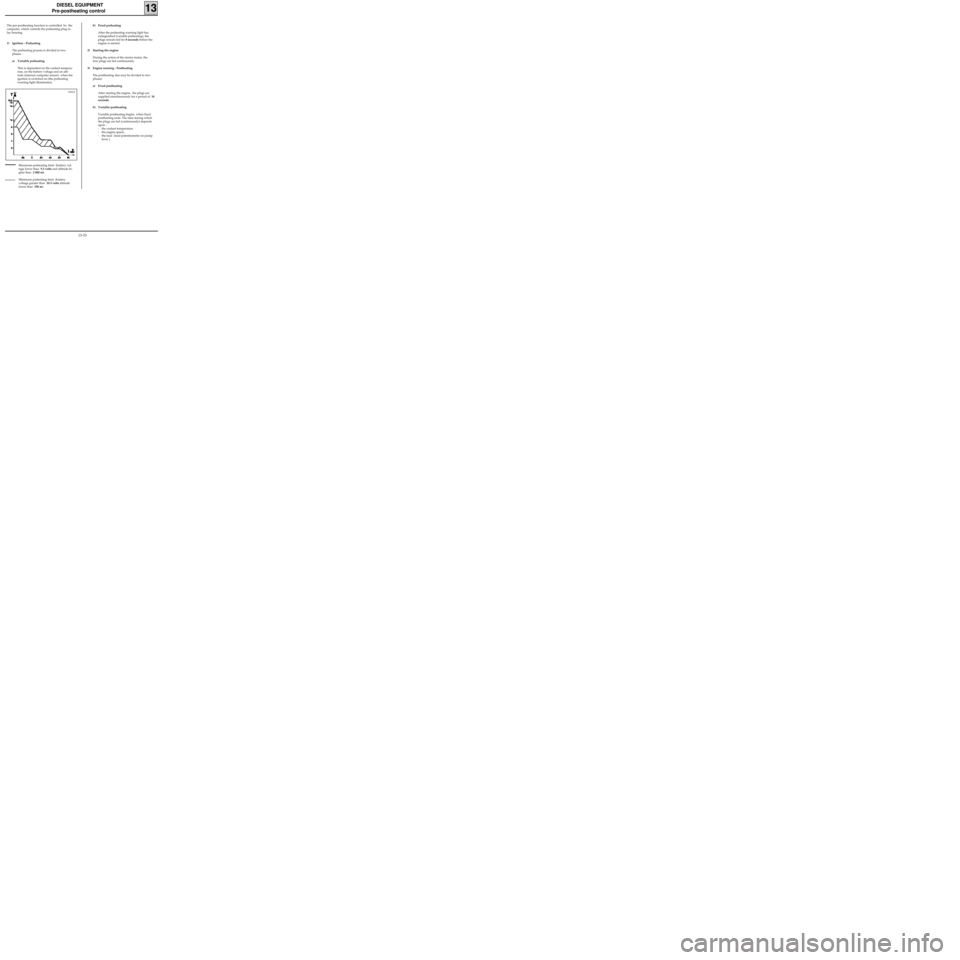

The pre-postheating function is controlled by the

computer, which controls the preheating plug re-

lay housing.

1) Ignition - Preheating

The preheating process is divided in two

phases :

a) Variable preheating

This is dependent on the coolant tempera-

ture, on the battery voltage and on alti-

tude (internal computer sensor) when the

ignition is switched on (the preheating

warning light illuminates).b) Fixed preheating

After the preheating warning light has

extinguished (variable preheating), the

plugs remain fed for 8 seconds before the

engine is started.

2) Starting the engine

During the action of the starter motor, the

four plugs are fed continuously.

3) Engine running - Postheating

The postheating also may be divided in two

phases:

a) Fixed postheating

After starting the engine, the plugs are

supplied simultaneously for a period of 10

seconds.

b) Variable postheating

Variable postheating begins when fixed

postheating ends. The time during which

the plugs are fed (continuously) depends

upon :

- the coolant temperature

- the engine speed ,

- the load (load potentiometer on pump

lever ).

Maximum preheating limit (battery vol-

tage lower than 9.3 volts and altitude hi-

gher than 2 000 m).

Minimum preheating limit (battery

voltage greater than 10.5 volts altitude

lower than 350 m).

13041S

13-33

Page 117 of 208

DIESEL EQUIPMENT

Computer

13

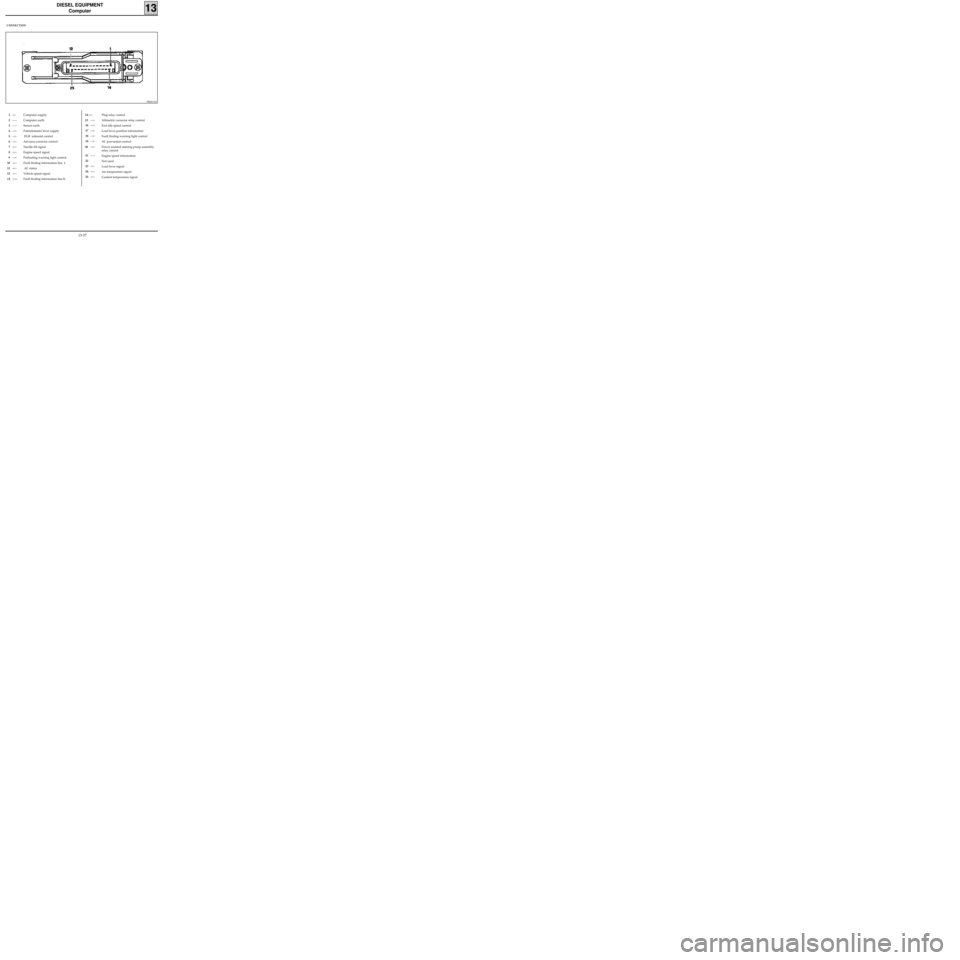

PRM1316

CONNECTION

1-<-

2-----

3-----

4-->-

5-->-

6-->-

7-<--

8-<--

9-->-

10-<--

11-<--

12-<--

13-><-Computer supply

Computer earth

Sensor earth

Potentiometer lever supply

EGR solenoid control

Advance corrector control

Needle lift signal

Engine speed signal

Preheating warning light control

Fault finding information line L

AC status

Vehicle speed signal

Fault finding information line KPlug relay control

Altimetric corrector relay control

Fast idle speed control

Load lever position information

Fault finding warning light control

AC prevention control

Power assisted steering pump assembly

relay control

Engine speed information

Not used

Load lever signal

Air temperature signal

Coolant temperature signal14-->-

15-->-

16-->-

17-->-

18-->-

19-->-

20 -->-

21-----

22

23-<--

24-<--

25-<--

13-37