engine RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 183 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

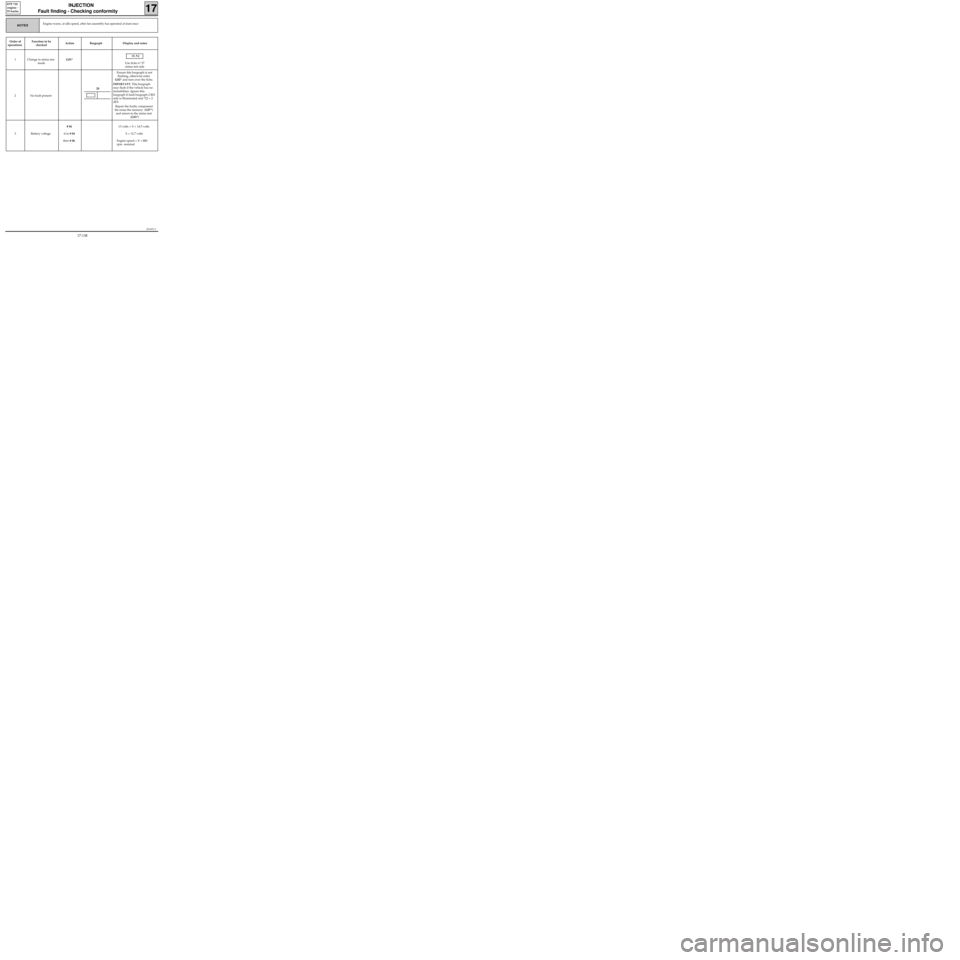

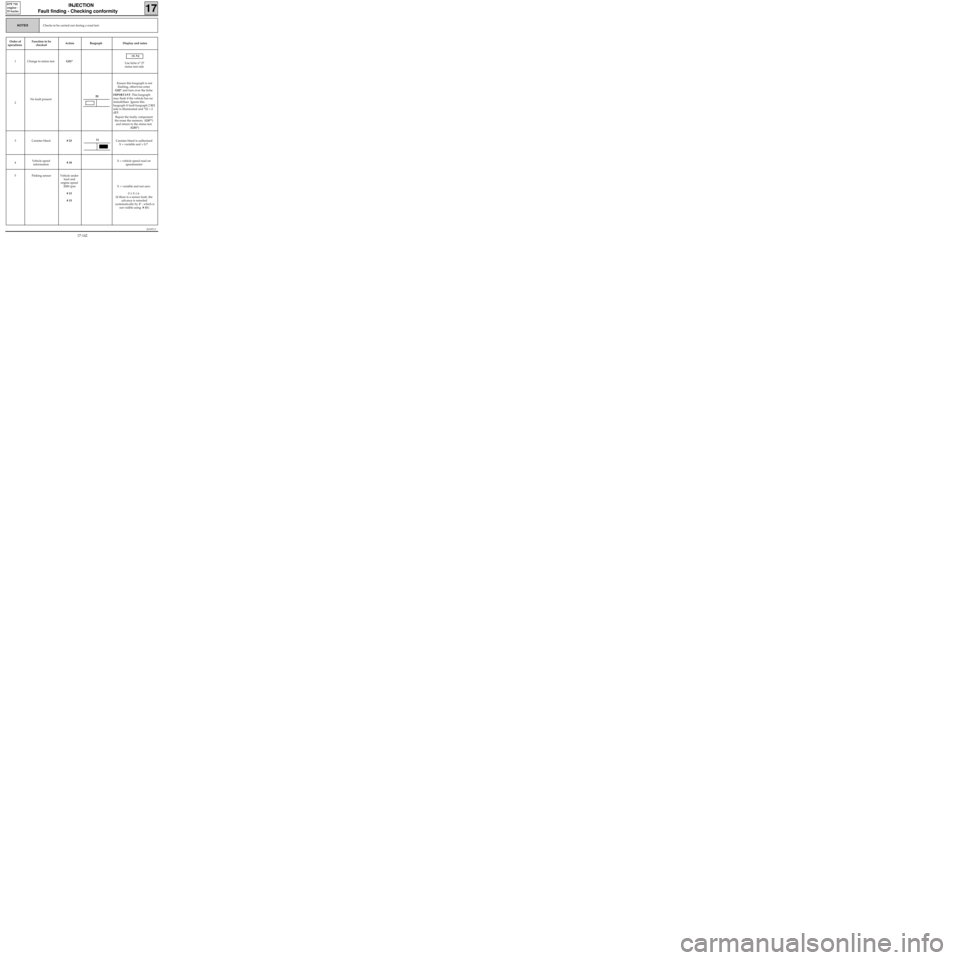

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

1 Change to status test

modeG01*

10.NJ

Use fiche n° 27

status test side

2 No fault presentEnsure this bargraph is not

flashing, otherwise enter

G02* and turn over the fiche.

IMPORTANT: This bargraph

may flash if the vehicle has no

immobiliser. Ignore this

bargraph if fault bargraph 2 RH

side is illuminated and *22 = 2

dEF.

Repair the faulty component

the erase the memory (G0**)

and return to the status test

(G01*)

3 Battery voltage# 04

if in # 04

then # 06 13 volts < X < 14.5 volts

X < 12.7 volts

Engine speed < X < 880

rpm nominal

Engine warm, at idle speed, after fan assembly has operated at least onceNOTES

20

17-138

Page 184 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

Engine warm, at idle speed, after fan assembly has operated at least once NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

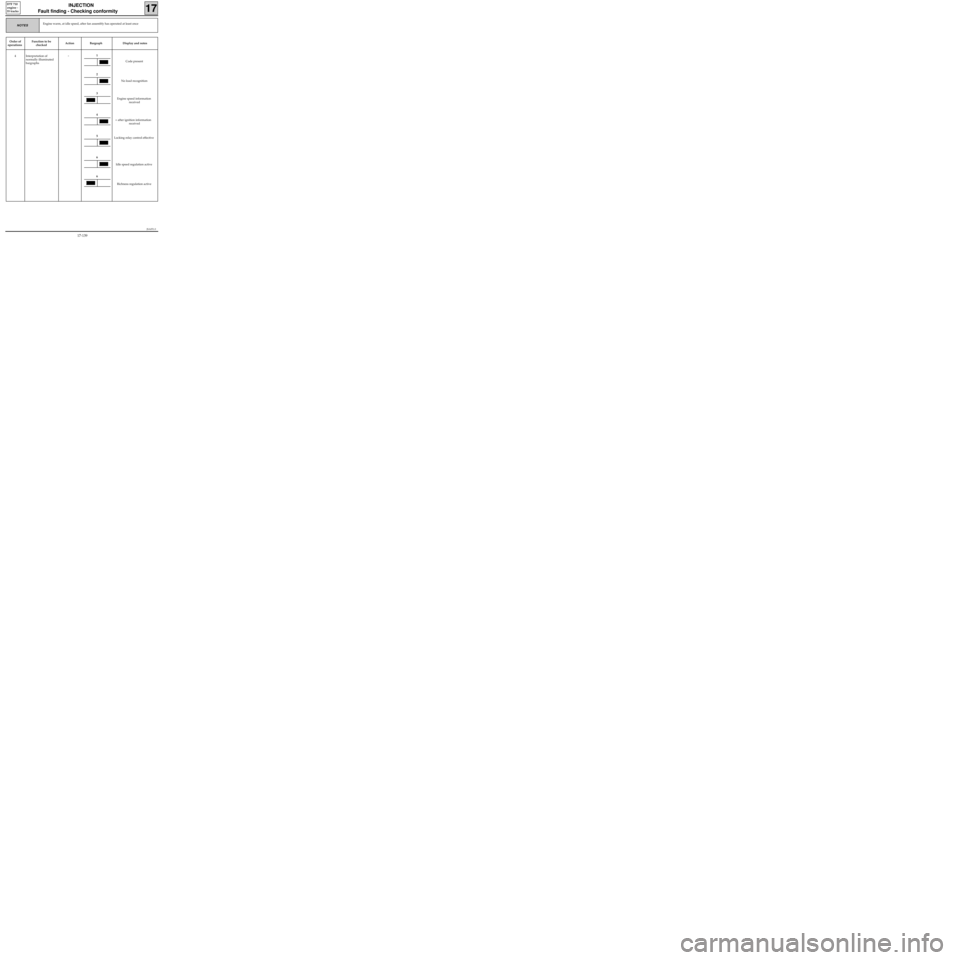

4 Interpretation of

normally illuminated

bargraphs

-

Code present

No load recognition

Engine speed information

received

+ after ignition information

received

Locking relay control effective

Idle speed regulation active

Richness regulation active1

2

5

4

6

6

3

17-139

Page 185 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

Engine warm, at idle speed, after fan assembly has operated at least once NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

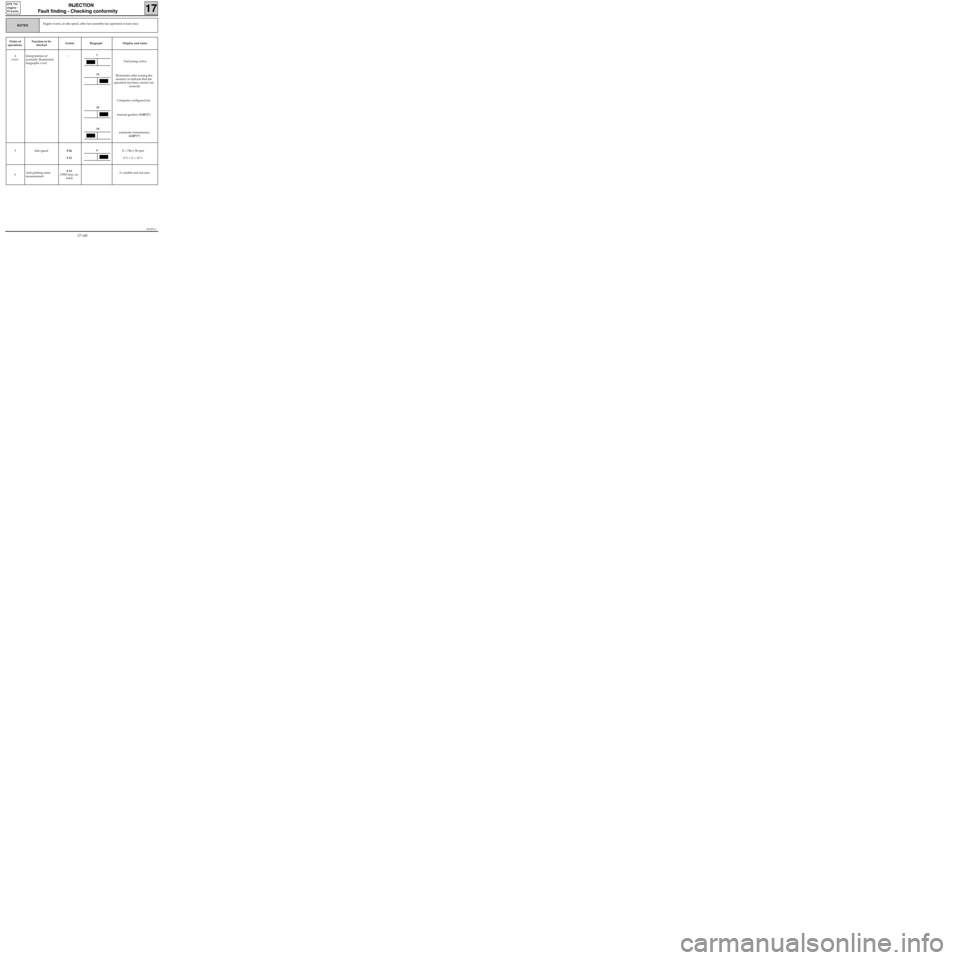

4

(cont)Interpretation of

normally illuminated

bargraphs (cont)

-

Fuel pump active

Illuminates after erasing the

memory to indicate that the

operation has been carried out

correctly

Computer configured for:

manual gearbox (G50*2*)

automatic transmission

(G50*1*)

5 Idle speed# 06

# 12X = 740 ± 50 rpm

4 % < X < 14 %

6Anti-pinking noise

measurement# 13

(3500 rpm, no

load) X variable and not zero

7

19

12

19

6

17-140

Page 186 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

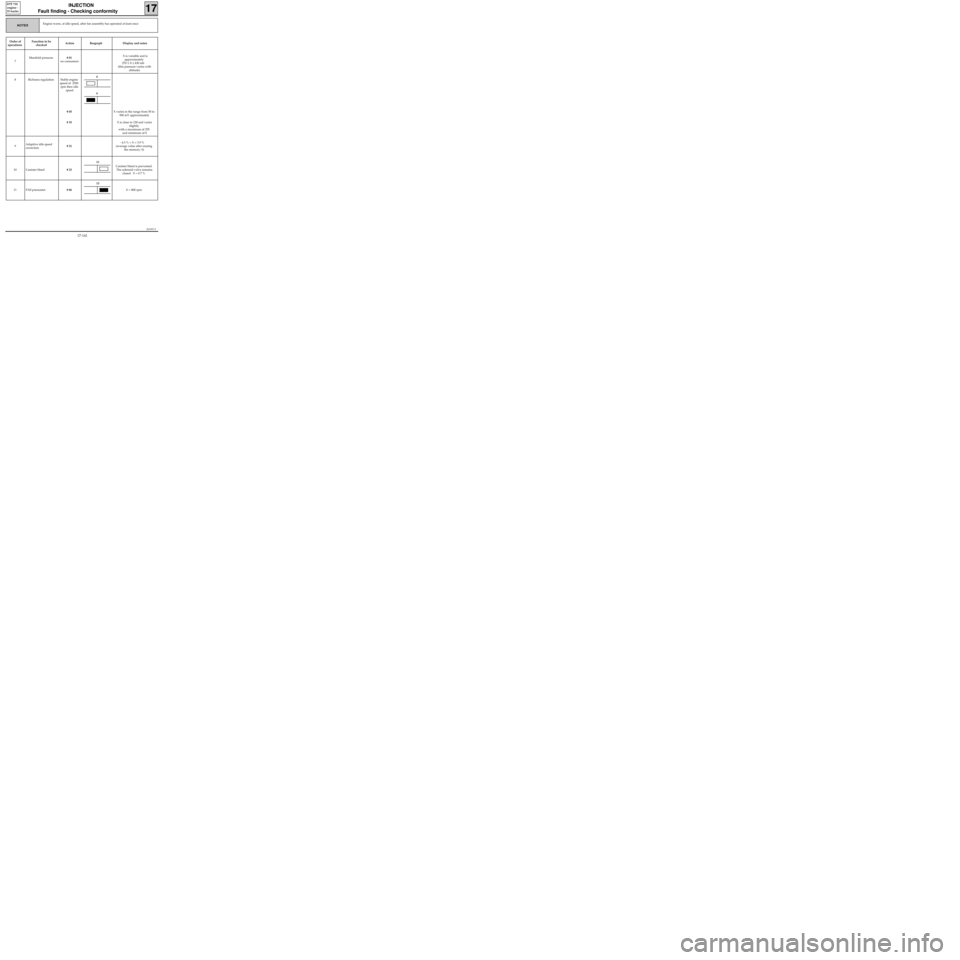

7Manifold pressure# 01

no consumers X is variable and is

approximately

270 ≤ X ≤ 430 mb

(this pressure varies with

altitude)

8 Richness regulation Stable engine

speed of 2500

rpm then idle

speed

# 05

# 35X varies in the range from 50 to

900 mV approximately

X is close to 128 and varies

slightly

with a maximum of 255

and minimum of 0

9Adaptive idle speed

correction# 21- 4.3 % < X < 3.9 %

(average value after erasing

the memory: 0)

10 Canister bleed# 23Canister bleed is prevented.

The solenoid valve remains

closed. X = 0.7 %

11 PAS pressostat# 06X = 800 rpm

Engine warm, at idle speed, after fan assembly has operated at least once

6

6

11

13

17-141

Page 187 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

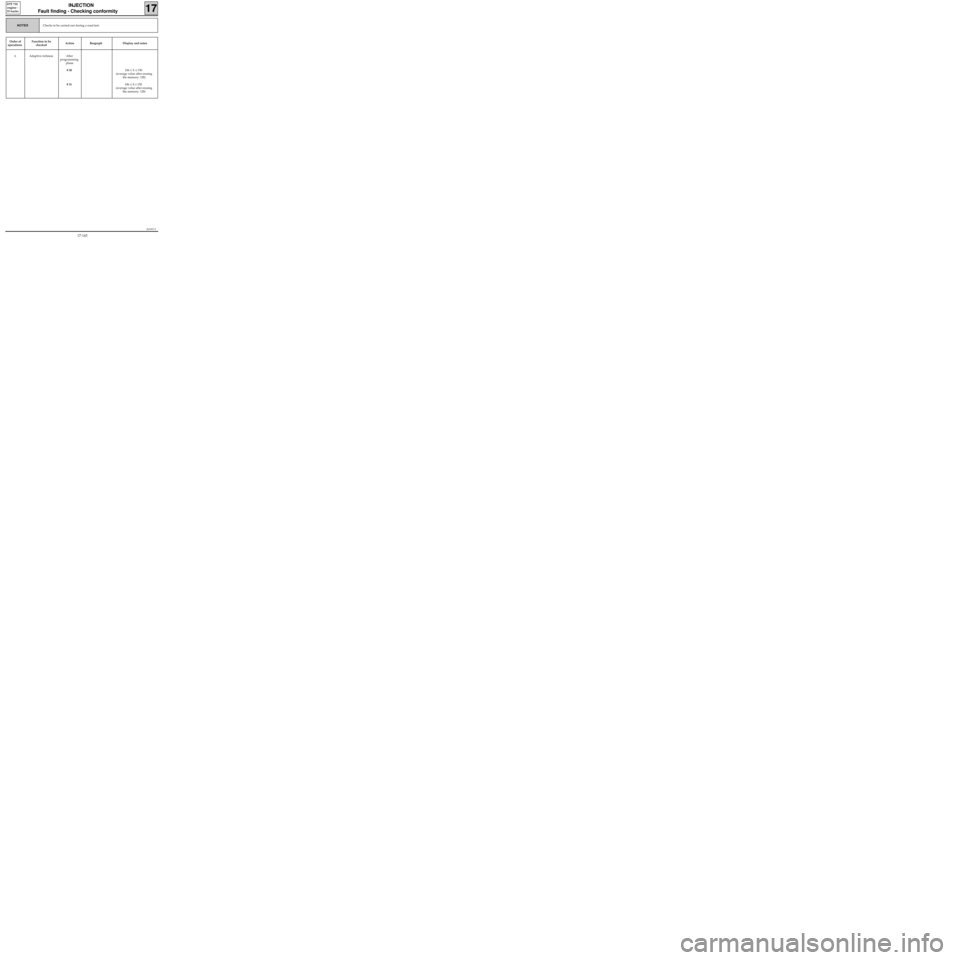

Checks to be carried out during a road test.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

1 Change to status testG01*

10.NJ

Use fiche n° 27

status test side

2No fault presentEnsure this bargraph is not

flashing, otherwise enter

G02* and turn over the fiche.

IMPORTANT: This bargraph

may flash if the vehicle has no

immobiliser. Ignore this

bargraph if fault bargraph 2 RH

side is illuminated and *22 = 2

dEF.

Repair the faulty component

the erase the memory (G0**)

and return to the status test

(G01*)

3 Canister bleed# 23Canister bleed is authorised

X = variable and > 0.7

4Vehicle speed

information# 18X = vehicle speed read on

speedometer

5 Pinking sensor Vehicle under

load and

engine speed

2000 rpm

# 13

# 15X = variable and not zero

0 ≤ X ≤ 6

(if there is a sensor fault, the

advance is retarded

systematically by 4° , which is

not visible using # 15)

11

20

17-142

Page 188 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

Checks to be carried out during a road test.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

6 Adaptive richness After

programming

phase

# 30

# 31 106 ≤ X ≤ 150

(average value after erasing

the memory: 128)

106 ≤ X ≤ 150

(average value after erasing

the memory: 128)

17-143

Page 189 of 363

D7F 710 ENGINE - 55 tracks

MULTIPOINT INJECTION

FAULT FINDING

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

XR25 fiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Interpretation of XR25 bargraphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Status and parameter checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Status and parameter interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Customer complaints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Fault charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Checking conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208Page

Page 190 of 363

JSA052.0

INJECTION

Fault finding- Introduction

17

D7F 710

engine -

55 tracks

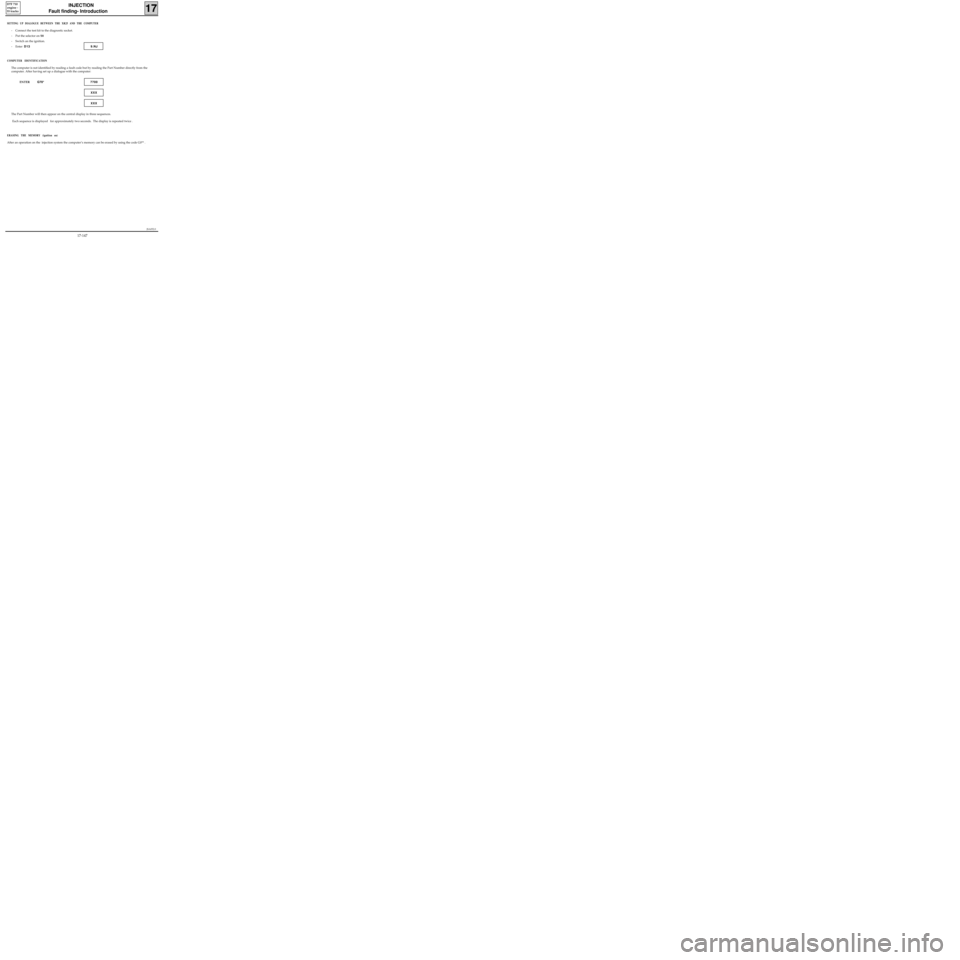

SETTING UP DIALOGUE BETWEEN THE XR25 AND THE COMPUTER

- Connect the test kit to the diagnostic socket.

- Put the selector on S8

- Switch on the ignition.

- Enter D13 9.NJ

COMPUTER IDENTIFICATION

The computer is not identified by reading a fault code but by reading the Part Number directly from the

computer. After having set up a dialogue with the computer:

ENTER G70*7700

XXX

XXX

The Part Number will then appear on the central display in three sequences.

Each sequence is displayed for approximately two seconds. The display is repeated twice .

ERASING THE MEMORY (ignition on)

After an operation on the injection system the computer’s memory can be erased by using the code G0** .

17-147

Page 191 of 363

JSA052.0

INJECTION

Fault finding - Introduction

17

D7F 710

engine -

55 tracks

If the information obtained by the XR25 requires electrical continuities to be checked, connect bornier Sus

1228.

Bornier Sus 1228 is a 55 track base with a printed circuit on which are 55 copper coated surfaces, numbered

from 1 to 55.

Using the wiring diagrams, the tracks connecting the components to be tested can be easily identified.

IMPORTANT :

• All tests using bornier Sus 1228 must be carried out with the battery disconnected.

• The bornier is only designed to operate with an ohmmeter. Under no circumstances should 12 Volts be

applied to the test points.

97434S

17-148

Page 192 of 363

JSA052.0

INJECTION

Fault finding - Introduction

17

D7F 710

engine -

55 tracks

DESCRIPTION OF THE FAULT-FINDING PHASES

The process described below is to be carried out in all cases of faults.

XR25 FAULT-CHECKING

This phase is the essential starting point for any intervention on the vehicle.

There are several constraints to the treatment of the bargraphs :

- A priority in the order of treatment when several bargraphs are illuminated.

- The interpretation of a bargraph depending on whether it is constantly illuminated or flashing .

1 - Order of priority

A series of illuminated bargraphs corresponding to the sensors with the same 12 V or having the same

earth, indicates a fault in this source. These priorities are dealt with in the "NOTES" section of the

fault-finding of the bargraph concerned.

2 - Input / output fault bargraphs

a) Illuminated :

The fault is present : treat the fault following the method described in the "INTERPRETATION OF XR25

BARGRAPHS" section.

b) Flashing :

Note the bargraphs displayed on the XR25.

Erase the memory of the computer and attempt to re-illuminate the bargraph: ignition on, idle speed

(or at starter speed) or by means of a road test (the "NOTES" section in the fault finding for the

bargraph concerned may help to determine the conditions under which the bargraph will illuminate).

If the bargraph has re-illuminated (fixed or flashing) :

The fault is present once again. In this case, treat the fault bargraph.

If the bargraph has not re-illuminated, check :

- the electrical lines which correspond to the flashing fault,

- the connectors of these lines (for rust, bent pins...).

- the resistance of the component found to be faulty.

- the cleanliness of the wires (insulation melted or cut, friction..).

NOTE : If the customer complaint does not correspond to the fault bargraph which is flashing

(example : Air temperature sensor fault bargraph flashing, but no customer complaint) ignore

this memorised fault and erase it.

3 - No bargraphs illuminated

If no bargraphs are illuminated on the XR25, carry out a status and parameter check. This may help in

detecting a problem.

17-149