sensor RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 137 of 363

Connect the bornier in place of the computer and check the insulation, continuity and that there is no

interference resistance on the line:

Computer 1 2 Pinking sensor

Computer 15 1 Pinking sensor

Computer 16 Pinking sensor screening

Repair if necessary.

JSA051.0

INJECTION

Fault finding - Interpretation of XR25 bargraphs17

D7F 710

engine -

35 tracks

Erase the computer memory using G0**.

Try to start the engine. Switch the ignition on, then deal with the other faults.

Remember to carry out a status and parameter check.AFTER REPAIR

Bargraph 6 LH side illuminatedFiche n° 27 side 1/2

PINKING SENSOR CIRCUIT

XR25 aid:CO, CC- or CC+ line 1 or 15

6

For certain faults BG 6LH will only illuminate permanently at 3000 rpm. for 1

minute. If BG 4LH or BG 5LH or BG 3LH or BG 6RH is also illuminated, check line 15

on the computer.

NOTES

The fault persists! Replace the injection computer.

IMPORTANT: The computer has probably been damaged by an electric shock. The cause of the damage

must be found before fitting a new computer.

The fault persists! Replace the pinking sensor.

17-92

Page 149 of 363

JSA051.0

INJECTION

Fault finding - Status and parameter checks

17

D7F 710

engine -

35 tracks

Engine cold, ignition on.NOTES

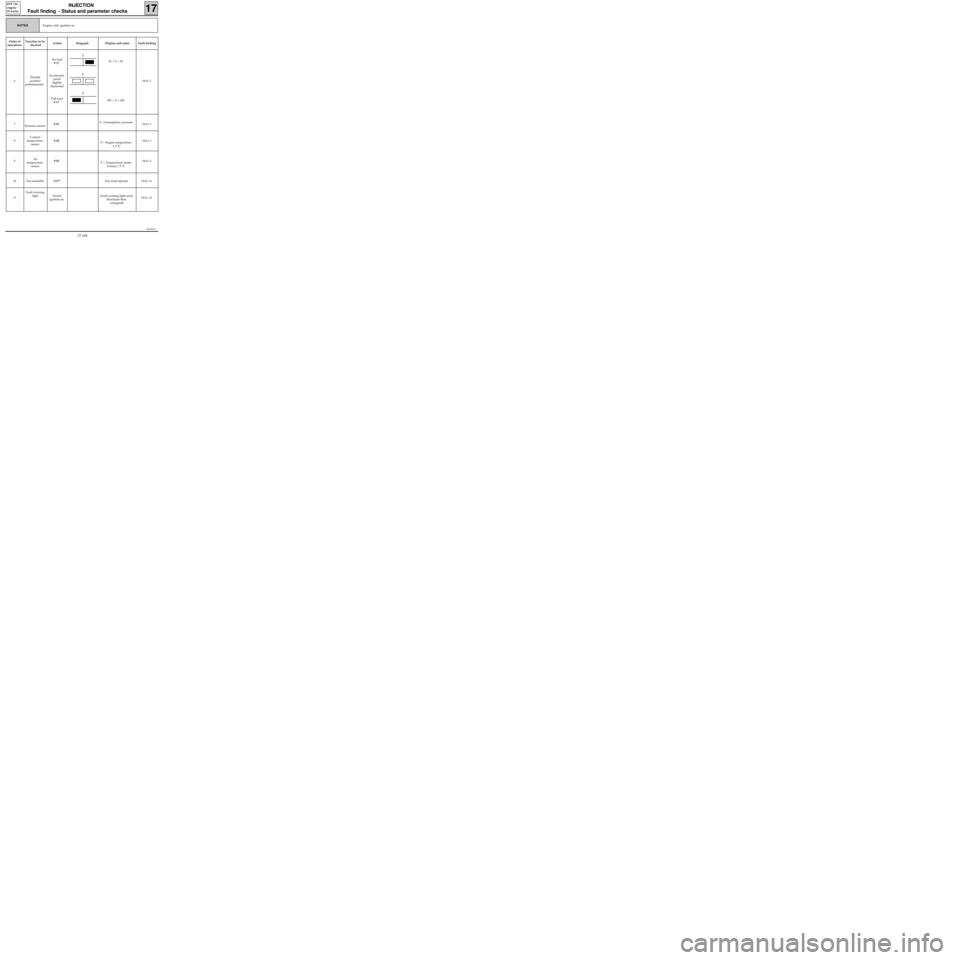

Order of

operationsFunction to be

checkedAction Bargraph Display and notes Fault finding

6Throttle

position

potentiometer

.No load

# 17

Accelerator

pedal

slightly

depressed

Full load

# 1710 < X < 50

185 < X < 245

DIAG 2

7

Pressure sensor# 01X =Atmospheric pressureDIAG 9

8Coolant

temperature

sensor# 02

X = Engine temperature

± 5 °CDIAG 3

9Air

temperature

sensor# 03

X = Temperature under

bonnet ± 5 °CDIAG 4

10 Fan assemblyG17*Fan must operateDIAG 16

11Fault warning

light Switch

ignition onFault warning light must

illuminate then

extinguishDIAG 18

2

2

2

17-104

Page 150 of 363

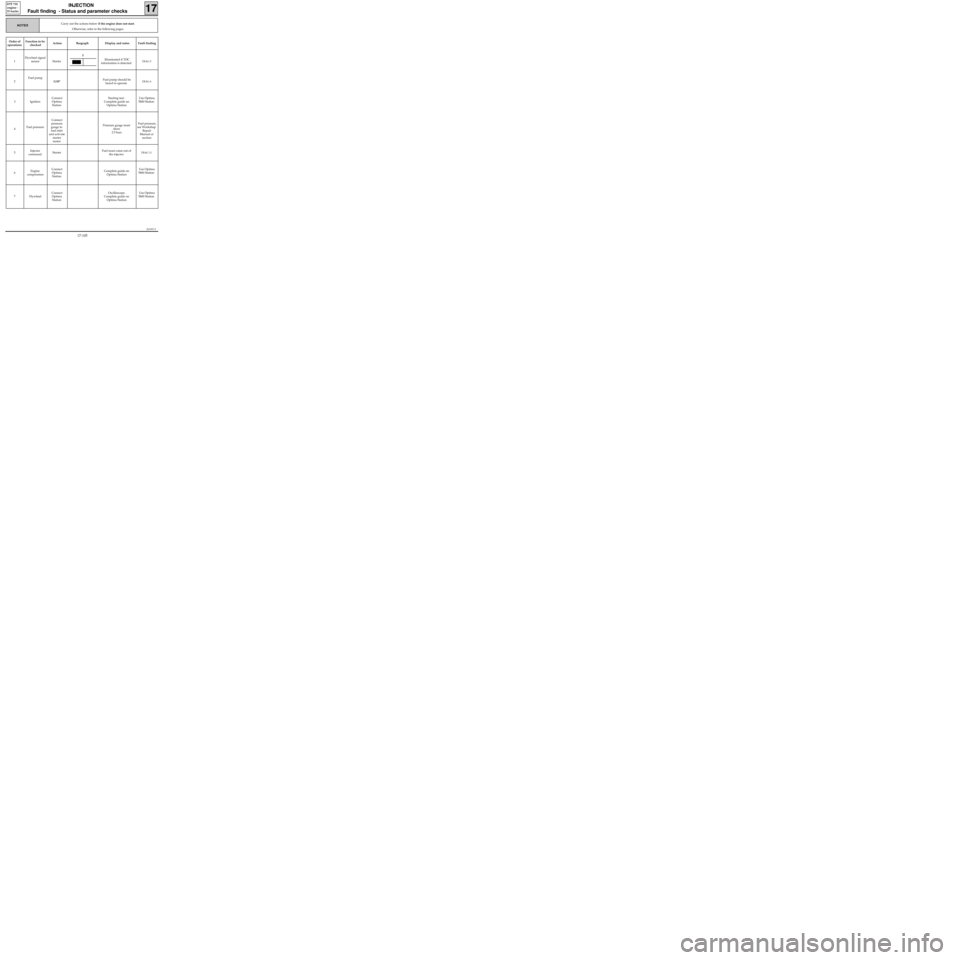

Order of

operationsFunction to be

checkedAction Bargraph Display and notes Fault finding

1Flywheel signal

sensor StarterIlluminated if TDC

information is detected

DIAG 5

2Fuel pump

G10*Fuel pump should be

heard to operateDIAG 6

3 IgnitionConnect

Optima

StationStarting test.

Complete guide on

Optima StationUse Optima

5800 Station

4Fuel pressureConnect

pressure

gauge to

fuel inlet

and activate

starter

motorPressure gauge must

show

2.5 bars Fuel pressure,

see Workshop

Repair

Manual or

section

5Injector

commandStarterFuel must come out of

the injector

DIAG 11

6Engine

compressionConnect

Optima

StationComplete guide on

Optima StationUse Optima

5800 Station

7 FlywheelConnect

Optima

StationOscilloscope.

Complete guide on

Optima StationUse Optima

5800 Station

JSA051.0

INJECTION

Fault finding - Status and parameter checks

17

D7F 710

engine -

35 tracks

Carry out the actions below if the engine does not start.

Otherwise, refer to the following pages.NOTES

3

17-105

Page 155 of 363

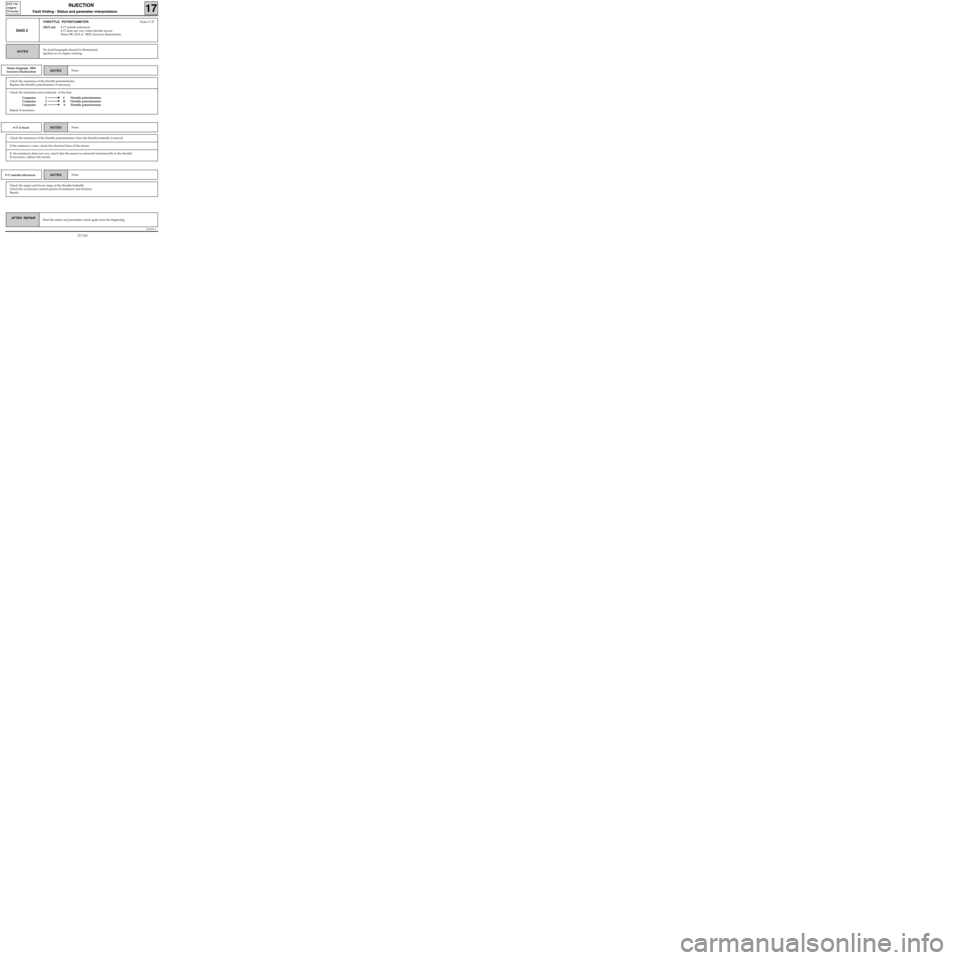

Check the insulation and continuity of the line:

Computer 3 C Throttle potentiometer

Computer 5 B Throttle potentiometer

Computer 15 A Throttle potentiometer

Repair if necessary.

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 2

THROTTLE POTENTIOMETERFiche n° 27

XR25 aid:# 17 outside tolerances

# 17 does not vary when throttle moves

Status BG 2LH or 2RH, incorrect illumination

No fault bargraphs should be illuminated.

Ignition on or engine running.NOTES

Status bargraph 2RH

incorrect illuminationNoneNOTES

Check the resistance of the throttle potentiometer.

Replace the throttle potentiometer if necessary.

# 17 is fixedNoneNOTES

Check the resistance of the throttle potentiometer when the throttle butterfly is moved.

If the resistance varies, check the electrical lines of the sensor.

If the resistance does not vary, check that the sensor is connected mechanically to the throttle.

If necessary, replace the sensor.

# 17 outside tolerancesNoneNOTES

Check the upper and lower stops of the throttle butterfly.

Check the accelerator control (points of resistance and friction).

Repair.

17-110

Page 156 of 363

Check the insulation, continuity and that there is no interference resistance on the electrical line :

Computer 6 2 Coolant temperature sensor

Computer 15 1 Coolant temperature sensor

Repair.

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 3

Fiche n° 27

COOLANT TEMPERATURE

XR25 aid: # 02 = Engine temperature ± 5 °C

No fault bargraphs should be illuminated.NOTES

If the value read is incoherent, check the sensor is correctly following the standard table of values for

"resistance as a function of temperature".

Replace the sensor if the values are incorrect (

NOTE : If a sensor is incorrect, this is often due to an electric

shock).

17-111

Page 157 of 363

Check the insulation, continuity and that there is no interference resistance on the electrical line :

Computer 2 2 Air temperature sensor

Computer 15 1 Air temperature sensor

Repair.

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 4

Fiche n° 27

AIR TEMPERATURE

XR25 aid:# 03 = Temperature under the bonnet ± 5 °C

No fault bargraphs should be illuminated.NOTES

If the value read is incoherent, check the sensor is correctly following the standard table of values for

"resistance as a function of temperature".

Replace the sensor if the values are incorrect (

NOTE : If a sensor is incorrect, this is often due to an electric

shock).

17-112

Page 158 of 363

Check the insulation, continuity and that there is no interference resistance on the electrical line :

Computer 13 B Flywheel signal sensor

Computer 31 A Flywheel signal sensor

Repair.

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 5

Fiche n° 27

TDC DETECTION

XR25 aid:Status BG 3LH, incorrect illumination

No fault bargraphs should be illuminated.

When the starter motor is activated.NOTES

Check the resistance of the TDC sensor.

Replace the sensor if necessary.

Check the sensor is correctly mounted.

Repair if necessary.

Check the condition of the target (if it has been removed).

Repair if necessary.

17-113

Page 159 of 363

Check the insulation and continuity of the wiring:

Fuel pump relay 5 Impact sensor

Impact sensor C1 Fuel pump

Repair if necessary.

Check the 25A fuel pump fuse.

Check the insulation and continuity of the wiring:

Fuel pump fuse 3 Fuel pump relay

Repair if necessary.

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 6

Fiche n° 27

FUEL PUMP

XR25 aid:The command mode should cause the fuel pump to operate

No fault bargraphs should be illuminated.NOTES

Check the hygiene and presence of earth on track C2 of the fuel pump.

If + 12 V is not reaching the fuel pump, replace the fuel pump relay.

If + 12 V is reaching the fuel pump, replace the fuel pump.

17-114

Page 161 of 363

The pinking sensor should give a signal which is variable and not zero, to prove that it is recording the

mechanical vibrations of the engine.

If the signal is zero:

- Check the sensor is correctly screwed in.

- Check the insulation and continuity of the wiring:

Computer 1 2 Pinking sensor

Computer 15 1 Pinking sensor

Computer 16 Pinking sensor screening

If necessary, replace the sensor.

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 8

Fiche n° 27

ANTI-PINKING CIRCUIT

XR25 aid:# 13 is not zero and variable for fast idle or under load

No fault bargraphs should be illuminated.NOTES

17-116

Page 162 of 363

Check the insulation, continuity and that there is no interference resistance

on the line:

Computer 5 C Pressure sensor

Computer 15 A Pressure sensor

Computer 23 B Pressure sensor

Repair if necessary.

JSA052.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 9

Fiche n° 27

PRESSURE CIRCUIT

XR25 aid:Ignition on # 01 not coherent

At idle speed # 01 < Minimum or # 01 > Maximum

# 16 not coherent

No fault bargraphs should be illuminated.NOTES

# 01 not coherent

ignition on

# 01 < Minimum at idle

speed

# 16 not coherent

If all these points are correct, replace the sensor.

A vacuum pump with a pressure gauge may be used to check coherence with

# 01 and to show a faulty sensor.

# 01 > Maximum at idle

speedThe manifold pressure is often a sign of incorrect engine operation. Check

- the sealing of the pipe between the manifold and the sensor,

- the valve clearances,

- the canister bleed valve which should be closed at idle speed,

- cylinder compression using the OPTIMA 5800 station.

If all these points are correct, replace the sensor.

A vacuum pump with a pressure gauge may be used to check coherence with

# 01 and to show a faulty sensor.

17-117