sensor RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 163 of 363

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 10

Fiche n° 27

RICHNESS REGULATION

XR25 aid:Richness regulation faulty

No fault bargraphs should be illuminated.

Ignition correct (a check may be made using the OPTIMA 5800 station).

No other status bargraph should show a fault.

NOTES

Check the sealing of the canister bleed valve (a leak can disrupt the richness considerably).

Check the sealing of the exhaust pipe upstream from the oxygen sensor.

Check the sealing of the inlet manifold.

If the vehicle has only been driven in town, the sensor is contaminated (try driving under load).

Check the fuel pressure.

If the idle speed is unstable, check the valve clearances.

Check the injectors (flow and shape of the jet).

If necessary, replace the oxygen sensor.

17-118

Page 166 of 363

if the value read is incoherent:

- Check that the sensor is correctly mounted and supplied:

•+12 V on A1

• Earth on B2

- Check the insulation, continuity and that there is no interference resistance on the line:

Computer 8 B1 vehicle speed sensor

Repair.

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

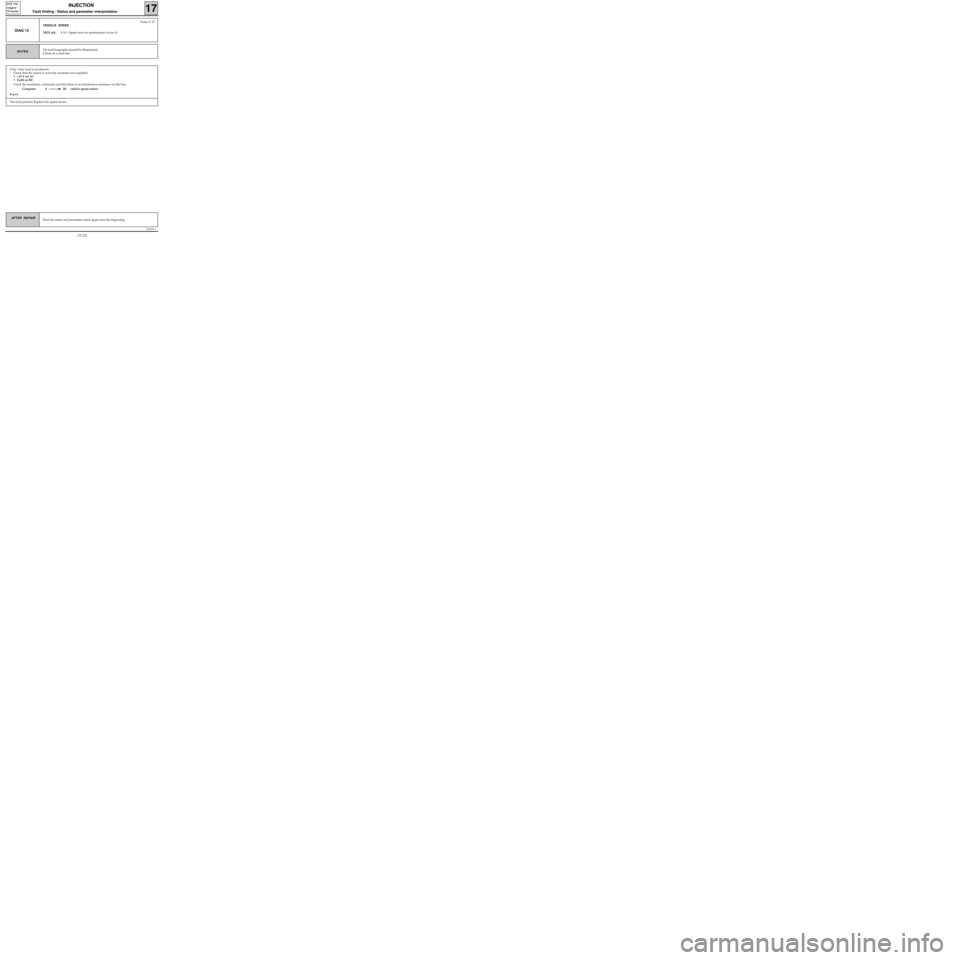

DIAG 13

Fiche n° 27

VEHICLE SPEED

XR25 aid:# 18 = Speed read on speedometer in km/h

No fault bargraphs should be illuminated.

Check on a road test.NOTES

The fault persists! Replace the speed sensor.

17-121

Page 168 of 363

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

NOTES

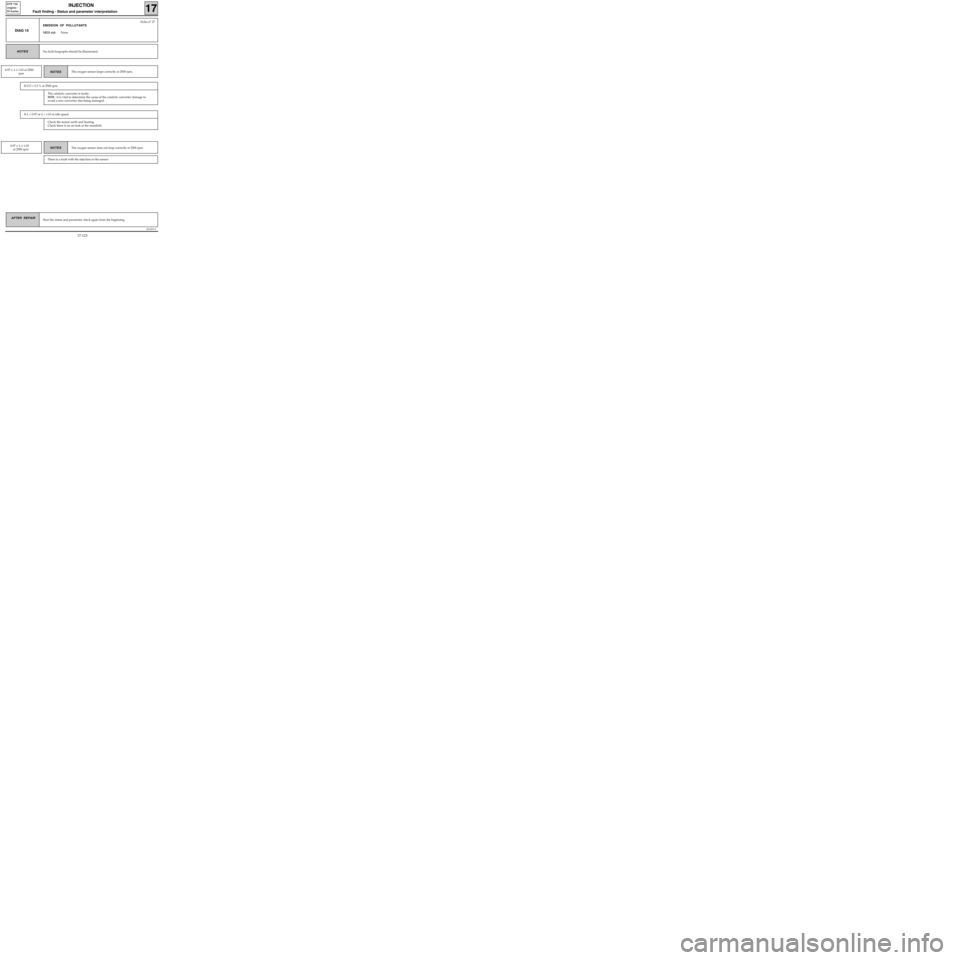

DIAG 15

Fiche n° 27

EMISSION OF POLLUTANTS

XR25 aid:None

No fault bargraphs should be illuminated.NOTES

0.97 ≤ λ ≤ 1.03 at 2500

rpmThe oxygen sensor loops correctly at 2500 rpm.

If CO > 0.3 % at 2500 rpm

NOTES 0.97 ≤ λ ≤ 1.03

at 2500 rpmThe oxygen sensor does not loop correctly at 2500 rpm.

There is a fault with the injection or the sensor.

The catalytic converter is faulty.

NOTE : it is vital to determine the cause of the catalytic converter damage to

avoid a new converter also being damaged.

If λ < 0.97 or λ > 1.03 at idle speed

Check the sensor earth and heating.

Check there is no air leak at the manifold.

17-123

Page 169 of 363

JSA051.0

INJECTION

Fault finding - Status and parameter interpretation17

D7F 710

engine -

35 tracks

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 15

CONT

Fiche n° 27

No fault bargraphs should be illuminated.NOTES

NOTES λ > 1.03

at 2500 rpmNone

The oxygen sensor loops correctly at 2500 rpm.

NOTES λ < 0.97

at 2500 rpm.The oxygen sensor does not loop correctly at 2500 rpm., CO >

0.3 % at 2500 rpm.

Check the pressure sensor.

Check the sensor.

Check that an injector is not faulty.

Check there is no leak at the exhaust.

Check that an injector has not seized.

Check the fuel pressure is not too low.

The oxygen sensor does not loop correctly at 2500 rpm.

Check there is not an injection fault.

Check there is not an ignition fault.

Check the sensor is not faulty.

Check the fuel pressure.

17-124

Page 179 of 363

JSA051.0

INJECTION

Fault finding -Aid

17

D7F 710

engine -

35 tracks

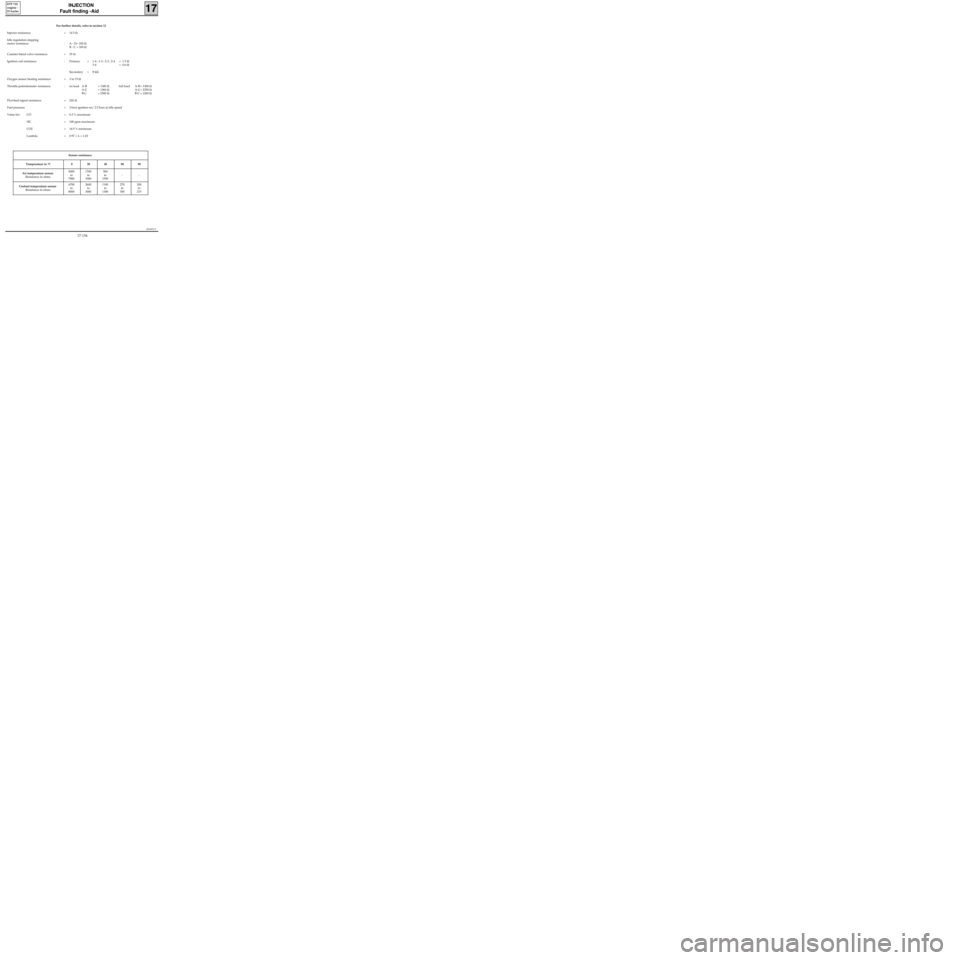

For further details, refer to section 12

Injector resistance = 14.5 Ω

Idle regulation stepping

motor resistance : A - D= 100 Ω

B - C = 100 Ω

Canister bleed valve resistance = 35 Ω

Ignition coil resistance : Primary = 1-4 ; 1-3 ; 2-3 ; 2-4 = 1.5 Ω

3-4 = 0.6 Ω

Secondary = 8 kΩ

Oxygen sensor heating resistance = 3 to 15 Ω

Throttle potentiometer resistance : no load A-B = 1300 Ωfull load A-B = 1300 Ω

A-C = 1360 ΩA-C= 2350 Ω

B-C = 2300 ΩB-C = 1260 Ω

Flywheel signal resistance = 220 Ω

Fuel pressure = 3 bars ignition on/ 2.5 bars at idle speed

Value for: CO = 0.3 % maximum

HC = 100 ppm maximum

CO2 = 14.5 % minimum

Lambda = 0.97 < λ < 1.03

Sensor resistance

Temperature in °C 0 20 40 80 90

Air temperature sensor

Resistance in ohms5000

to

70001700

to

3300500

to

1550--

Coolant temperature sensor

Resistance in ohms6700

to

80002600

to

30001100

to

1300270

to

300200

to

215

17-134

Page 182 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

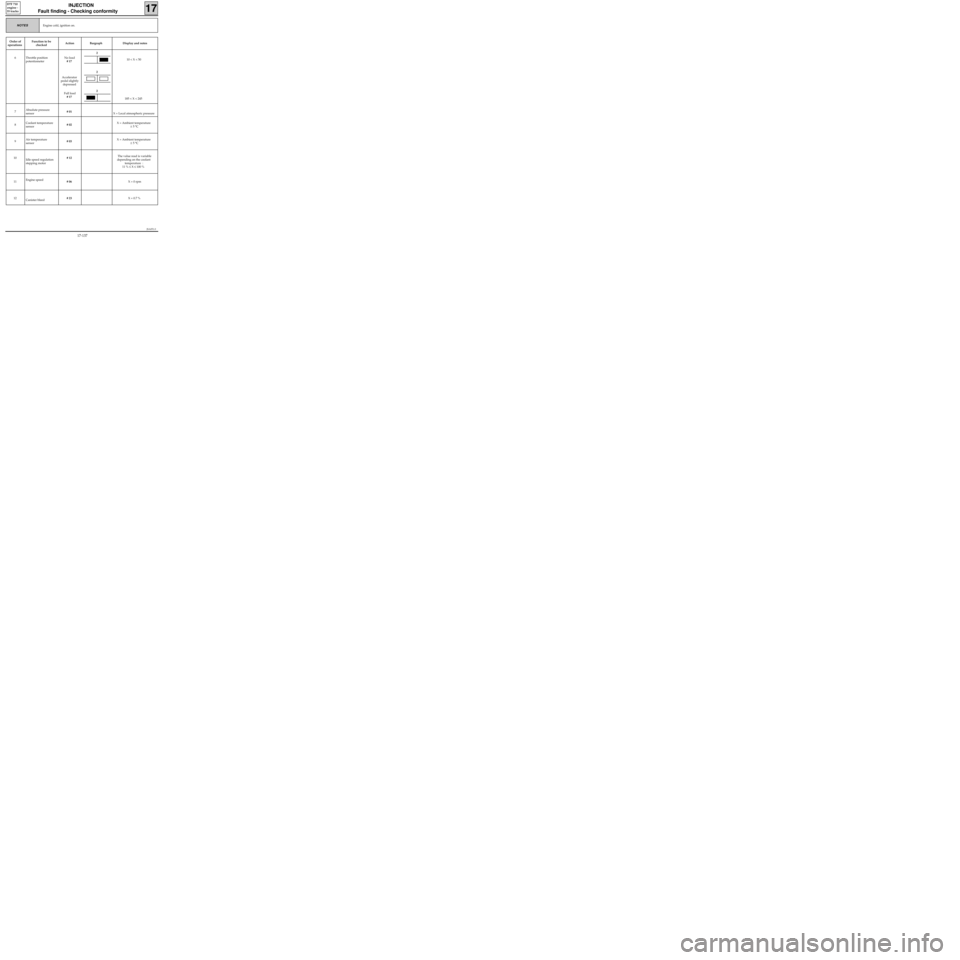

Engine cold, ignition on.NOTES

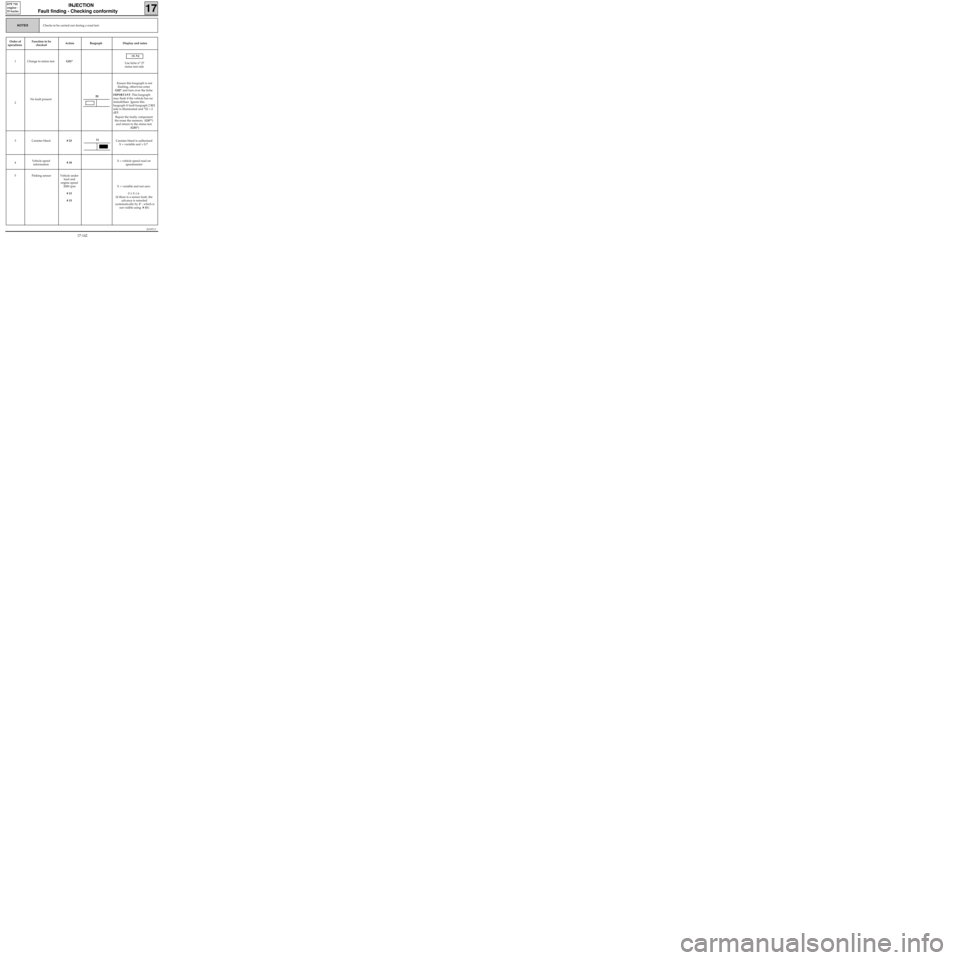

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

6 Throttle position

potentiometerNo load

# 17

Accelerator

pedal slightly

depressed

Full load

# 17 10 < X < 50

185 < X < 245

7Absolute pressure

sensor# 01

X = Local atmospheric pressure

8Coolant temperature

sensor# 02 X = Ambient temperature

± 5 °C

9Air temperature

sensor# 03 X = Ambient temperature

± 5 °C

10

Idle speed regulation

stepping motor# 12The value read is variable

depending on the coolant

temperature :

11 % ≤ X ≤ 100 %

11Engine speed

# 06 X = 0 rpm

12

Canister bleed# 23 X = 0.7 %

2

2

2

17-137

Page 187 of 363

JSA051.0

INJECTION

Fault finding - Checking conformity

17

D7F 710

engine -

35 tracks

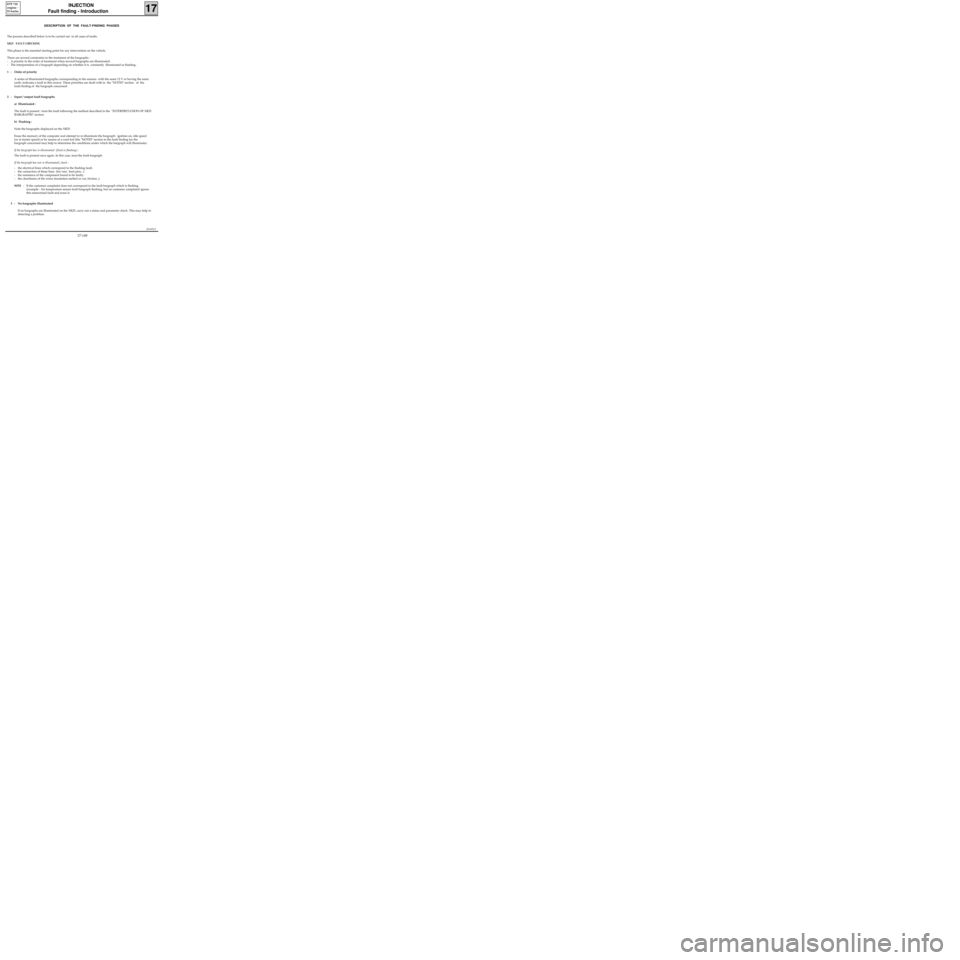

Checks to be carried out during a road test.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

1 Change to status testG01*

10.NJ

Use fiche n° 27

status test side

2No fault presentEnsure this bargraph is not

flashing, otherwise enter

G02* and turn over the fiche.

IMPORTANT: This bargraph

may flash if the vehicle has no

immobiliser. Ignore this

bargraph if fault bargraph 2 RH

side is illuminated and *22 = 2

dEF.

Repair the faulty component

the erase the memory (G0**)

and return to the status test

(G01*)

3 Canister bleed# 23Canister bleed is authorised

X = variable and > 0.7

4Vehicle speed

information# 18X = vehicle speed read on

speedometer

5 Pinking sensor Vehicle under

load and

engine speed

2000 rpm

# 13

# 15X = variable and not zero

0 ≤ X ≤ 6

(if there is a sensor fault, the

advance is retarded

systematically by 4° , which is

not visible using # 15)

11

20

17-142

Page 192 of 363

JSA052.0

INJECTION

Fault finding - Introduction

17

D7F 710

engine -

55 tracks

DESCRIPTION OF THE FAULT-FINDING PHASES

The process described below is to be carried out in all cases of faults.

XR25 FAULT-CHECKING

This phase is the essential starting point for any intervention on the vehicle.

There are several constraints to the treatment of the bargraphs :

- A priority in the order of treatment when several bargraphs are illuminated.

- The interpretation of a bargraph depending on whether it is constantly illuminated or flashing .

1 - Order of priority

A series of illuminated bargraphs corresponding to the sensors with the same 12 V or having the same

earth, indicates a fault in this source. These priorities are dealt with in the "NOTES" section of the

fault-finding of the bargraph concerned.

2 - Input / output fault bargraphs

a) Illuminated :

The fault is present : treat the fault following the method described in the "INTERPRETATION OF XR25

BARGRAPHS" section.

b) Flashing :

Note the bargraphs displayed on the XR25.

Erase the memory of the computer and attempt to re-illuminate the bargraph: ignition on, idle speed

(or at starter speed) or by means of a road test (the "NOTES" section in the fault finding for the

bargraph concerned may help to determine the conditions under which the bargraph will illuminate).

If the bargraph has re-illuminated (fixed or flashing) :

The fault is present once again. In this case, treat the fault bargraph.

If the bargraph has not re-illuminated, check :

- the electrical lines which correspond to the flashing fault,

- the connectors of these lines (for rust, bent pins...).

- the resistance of the component found to be faulty.

- the cleanliness of the wires (insulation melted or cut, friction..).

NOTE : If the customer complaint does not correspond to the fault bargraph which is flashing

(example : Air temperature sensor fault bargraph flashing, but no customer complaint) ignore

this memorised fault and erase it.

3 - No bargraphs illuminated

If no bargraphs are illuminated on the XR25, carry out a status and parameter check. This may help in

detecting a problem.

17-149

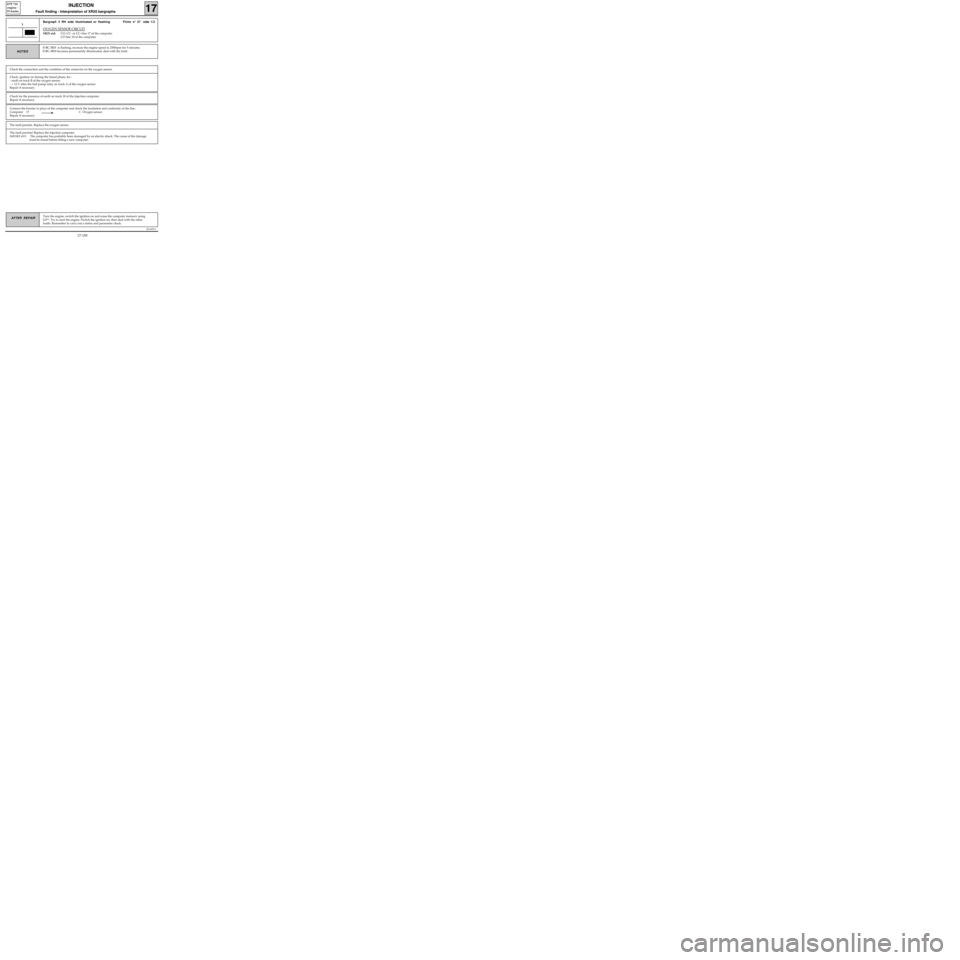

Page 201 of 363

Connect the bornier in place of the computer and check the insulation and continuity of the line.

Computer 20 2 Air temperature sensor

Computer 46 1 Air temperature sensor

Repair if necessary.

JSA052.0

INJECTION

Fault finding - Interpretation of XR25 bargraphs17

D7F 710

engine -

55 tracks

Erase the computer memory using G0**.

Try to start the engine. Switch the ignition on, then deal with the other faults.

Remember to carry out a status and parameter check.AFTER REPAIR

Bargraph 3 LH side illuminatedFiche n° 27 side 1/2

AIR TEMPERATURE SENSOR CIRCUIT

XR25 aid:CO, CC- or CC+line 20 or 46 of the computer

3

If BG 6RH is also illuminated, check line 46 of the computer.NOTES

Check the resistance of the sensor. Replace if necessary.

The fault persists! Replace the injection computer.

IMPORTANT: The computer has probably been damaged by an electric shock. The cause of the damage

must be found before fitting a new computer.

17-158

Page 202 of 363

Connect the bornier in place of the computer and check the insulation and continuity of the line:

Computer 17 C Oxygen sensor

Repair if necessary.

JSA052.0

INJECTION

Fault finding - Interpretation of XR25 bargraphs17

D7F 710

engine -

55 tracks

Turn the engine, switch the ignition on and erase the computer memory using

G0**. Try to start the engine. Switch the ignition on, then deal with the other

faults. Remember to carry out a status and parameter check.AFTER REPAIR

Bargraph 3 RH side illuminated or flashing Fiche n° 27 side 1/2

OXYGEN SENSOR CIRCUIT

XR25 aid:CO, CC- or CC+line 17 of the computer

CO line 18 of the computer

3

If BG 3RH is flashing, increase the engine speed to 2500rpm for 5 minutes.

If BG 3RH becomes permanently illuminated, deal with the fault.

NOTES

Check the connection and the condition of the connector on the oxygen sensor.

Check, ignition on during the timed phase, for :

- earth on track B of the oxygen sensor,

- + 12 V after the fuel pump relay on track A of the oxygen sensor.

Repair if necessary.

Check for the presence of earth on track 18 of the injection computer.

Repair if necessary.

The fault persists. Replace the oxygen sensor.

The fault persists! Replace the injection computer.

IMPORTANT: The computer has probably been damaged by an electric shock. The cause of the damage

must be found before fitting a new computer.

17-159