ignition RENAULT KANGOO 1997 KC / 1.G Foult Finding - Injection Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 363

Page 93 of 363

Connect the bornier in place of the computer and check the insulation and continuity of the line:

Computer 17 C Oxygen sensor

Repair if necessary.

JF5111.0

INJECTION

Fault finding - Status and parameter interpretation17

E7J 780

engine

AFTER REPAIRStart the status and parameter check again from the beginning.

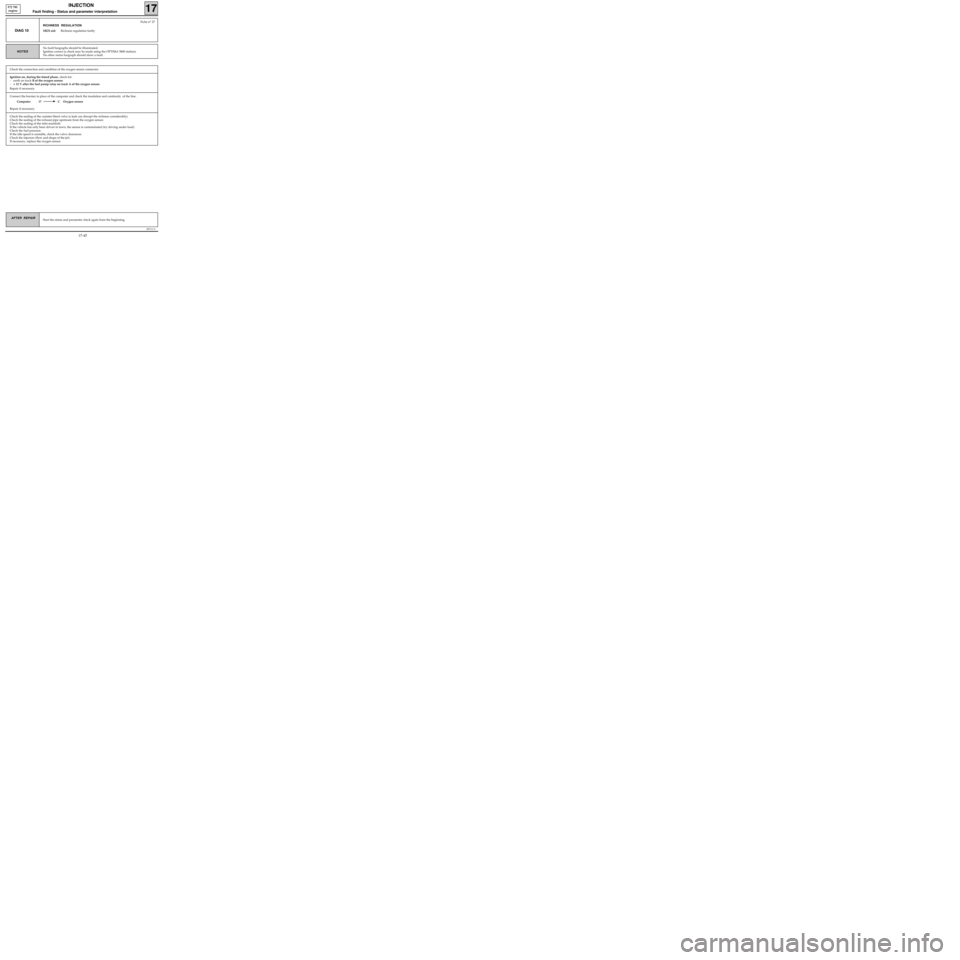

DIAG 10

Fiche n° 27

RICHNESS REGULATION

XR25 aid:Richness regulation faulty

No fault bargraphs should be illuminated.

Ignition correct (a check may be made using the OPTIMA 5800 station).

No other status bargraph should show a fault.

NOTES

Check the sealing of the canister bleed valve (a leak can disrupt the richness considerably).

Check the sealing of the exhaust pipe upstream from the oxygen sensor.

Check the sealing of the inlet manifold.

If the vehicle has only been driven in town, the sensor is contaminated (try driving under load).

Check the fuel pressure.

If the idle speed is unstable, check the valve clearances.

Check the injectors (flow and shape of the jet).

If necessary, replace the oxygen sensor.

Check the connection and condition of the oxygen sensor connector.

Ignition on, during the timed phase, check for:

- earth on track B of the oxygen sensor.

-+ 12 V after the fuel pump relay on track A of the oxygen sensor.

Repair if necessary.

17-45

Page 95 of 363

JF5111.0

INJECTION

Fault finding - Status and parameter interpretation17

E7J 780

engine

AFTER REPAIRStart the status and parameter check again from the beginning.

DIAG 12

Fiche n° 27

IMMOBILISER

XR25 aid:Status BG 3RH illuminated, ignition on

No fault bargraphs should be illuminated.NOTES

Check the insulation and continuity of the wiring for track 37 on the injection computer.

If the fault persists, refer to the immobiliser fault finding.

17-47

Page 99 of 363

JF5111.0

INJECTION

Fault finding - Status and parameter interpretation17

E7J 780

engine

AFTER REPAIRStart the status and parameter check again from the beginning.

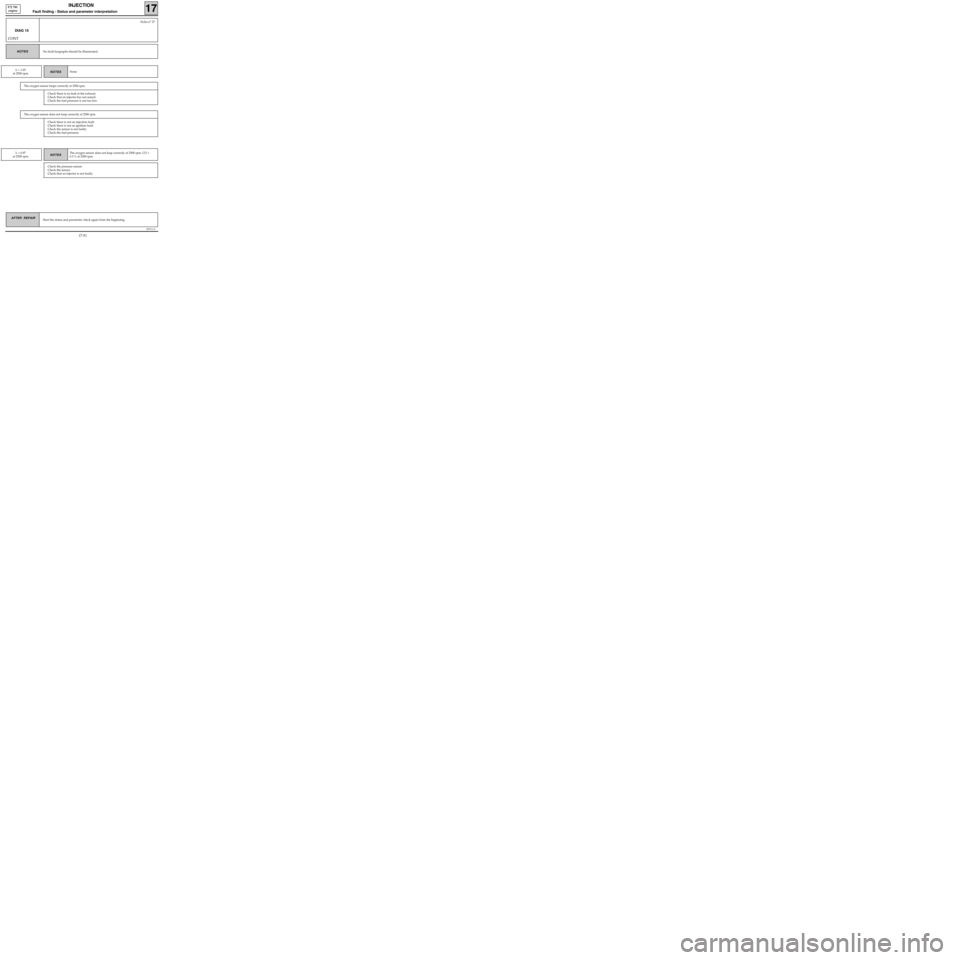

DIAG 15

CONT

Fiche n° 27

No fault bargraphs should be illuminated.NOTES

NOTES λ > 1.03

at 2500 rpm.None

The oxygen sensor loops correctly at 2500 rpm.

NOTES λ < 0.97

at 2500 rpm.The oxygen sensor does not loop correctly at 2500 rpm. CO >

0.3 % at 2500 rpm.

Check the pressure sensor.

Check the sensor.

Check that an injector is not faulty.

Check there is no leak at the exhaust.

Check that an injector has not seized.

Check the fuel pressure is not too low.

The oxygen sensor does not loop correctly at 2500 rpm.

Check there is not an injection fault.

Check there is not an ignition fault.

Check the sensor is not faulty.

Check the fuel pressure.

17-51

Page 101 of 363

Check the insulation and continuity of the line:

Relay 5 2 Fan assembly

Fan assembly 1 Earth

Repair.

Connect the bornier in place of the computer and

check the insulation and continuity of the line:

Bornier 14 2 Relay

Repair.

JF5111.0

INJECTION

Fault finding - Status and parameter interpretation17

E7J 780

engine

AFTER REPAIRStart the status and parameter check again from the beginning.

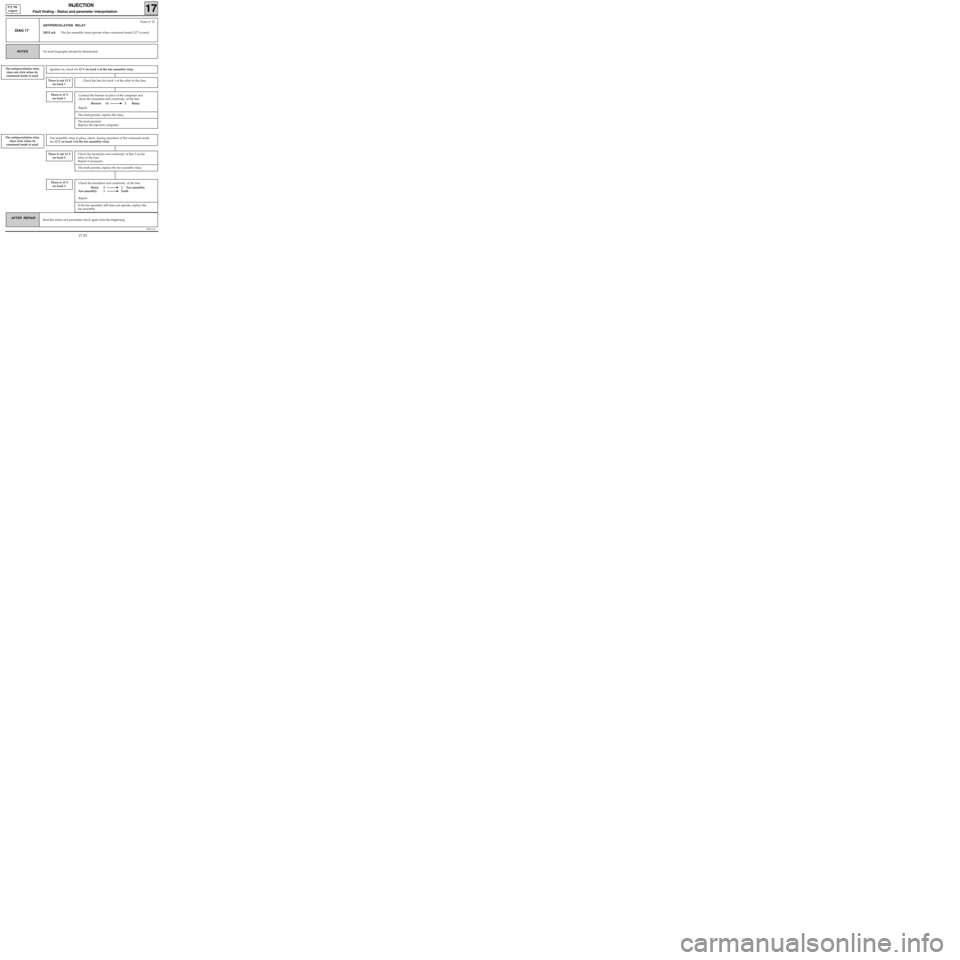

DIAG 17

Fiche n° 27

ANTIPERCOLATION RELAY

XR25 aid:The fan assembly must operate when command mode G17* is used.

No fault bargraphs should be illuminated.NOTES

The antipercolation relay

does not click when its

command mode is used

There is 12 V

on track 1

Ignition on, check for 12 V on track 1 of the fan assembly relay.

There is not 12 V

on track 1Check the line for track 1 of the relay to the fuse.

The antipercolation relay

does click when its

command mode is usedFan assembly relay in place, check, during operation of the command mode,

for 12 V on track 5 of the fan assembly relay.

There is not 12 V

on track 5Check the insulation and continuity of line 3 on the

relay to the fuse.

Repair if necessary.

The fault persists, replace the fan assembly relay.

There is 12 V

on track 5

If the fan assembly still does not operate, replace the

fan assembly.

The fault persists, replace the relay.

The fault persists!

Replace the injection computer.

17-53

Page 110 of 363

JF5111.0

INJECTION

Fault finding -Aid

17

E7J 780

engine

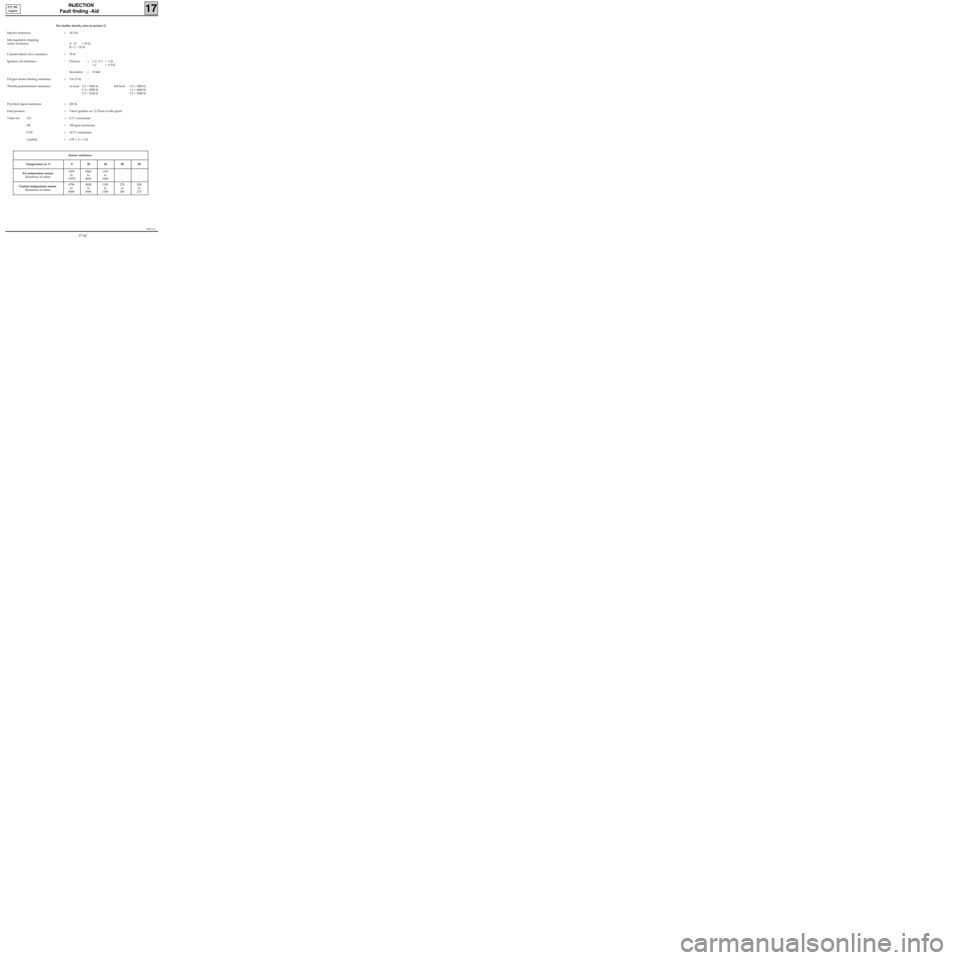

For further details, refer to section 12

Injector resistance = 14.5 Ω

Idle regulation stepping

motor resistance : A - D = 52 Ω

B - C = 52 Ω

Canister bleed valve resistance = 35 Ω

Ignition coil resistance : Primary = 1-3 ; 2-3 = 1 Ω

1-2 = 0.5 Ω

Secondary = 10 kΩ

Oxygen sensor heating resistance = 3 to 15 Ω

Throttle potentiometer resistance : no load 1-2 = 5440 Ωfull load 1-2 = 2200 Ω

1-3 = 4500 Ω1-3 = 4460 Ω

2-3 = 2160 Ω2-3 = 5340 Ω

Flywheel signal resistance = 220 Ω

Fuel pressure = 3 bars ignition on/ 2.5 bars at idle speed

Value for: CO = 0.3 % maximum

HC = 100 ppm maximum

CO2 = 14.5 % minimum

Lambda = 0.97 < λ < 1.03

Sensor resistance

Temperature in °C 0 20 40 80 90

Air temperature sensor

Resistance in ohms7470

to

119703060

to

40451315

to

1600--

Coolant temperature sensor

Resistance in ohms6700

to

80002600

to

30001100

to

1300270

to

300200

to

215

17-62

Page 111 of 363

JF5111.0

INJECTION

Fault finding - Checking conformity

17

E7J 780

engine

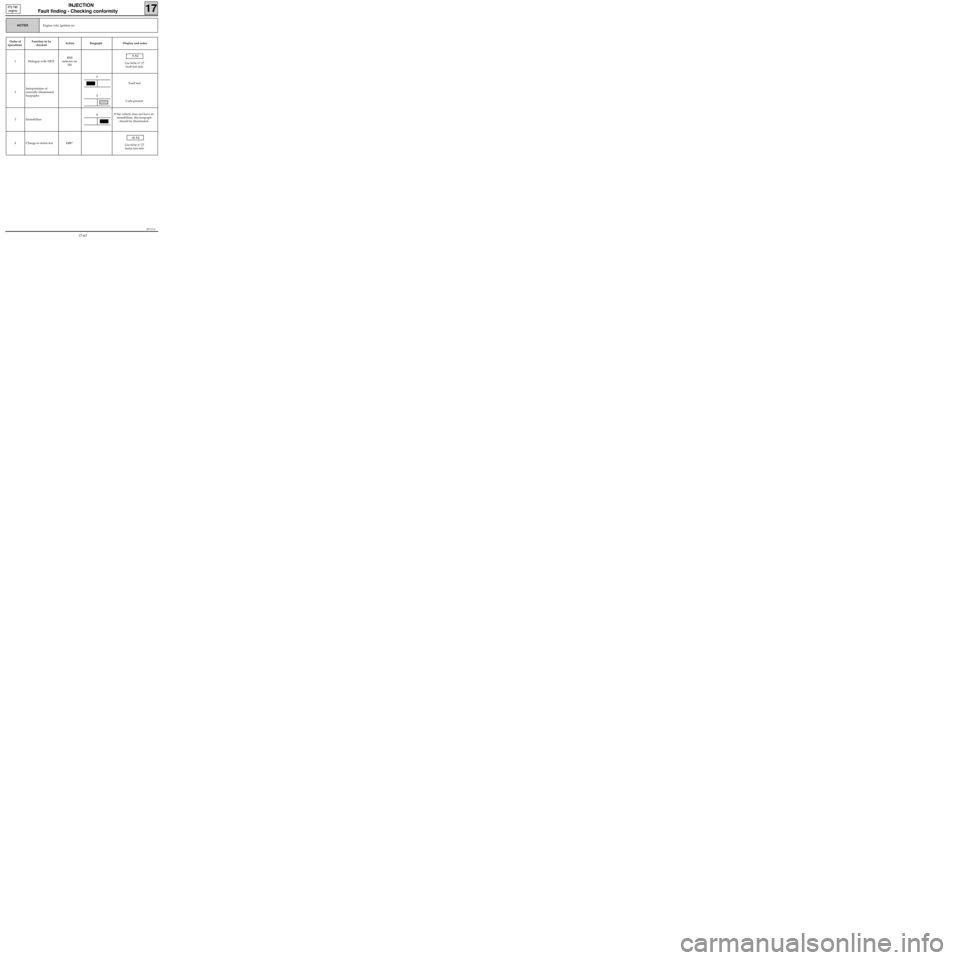

Engine cold, ignition on.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

1 Dialogue with XR25D13

(selector on

S8)

9.NJ

Use fiche n° 27

fault test side

2Interpretation of

normally illuminated

bargraphsFault test

Code present

3 ImmobiliserIf the vehicle does not have an

immobiliser, this bargraph

should be illuminated.

4 Change to status testG01*

10.NJ

Use fiche n° 27

status test side

1

1

2

17-63

Page 112 of 363

JF5111.0

INJECTION

Fault finding - Checking conformity

17

E7J 780

engine

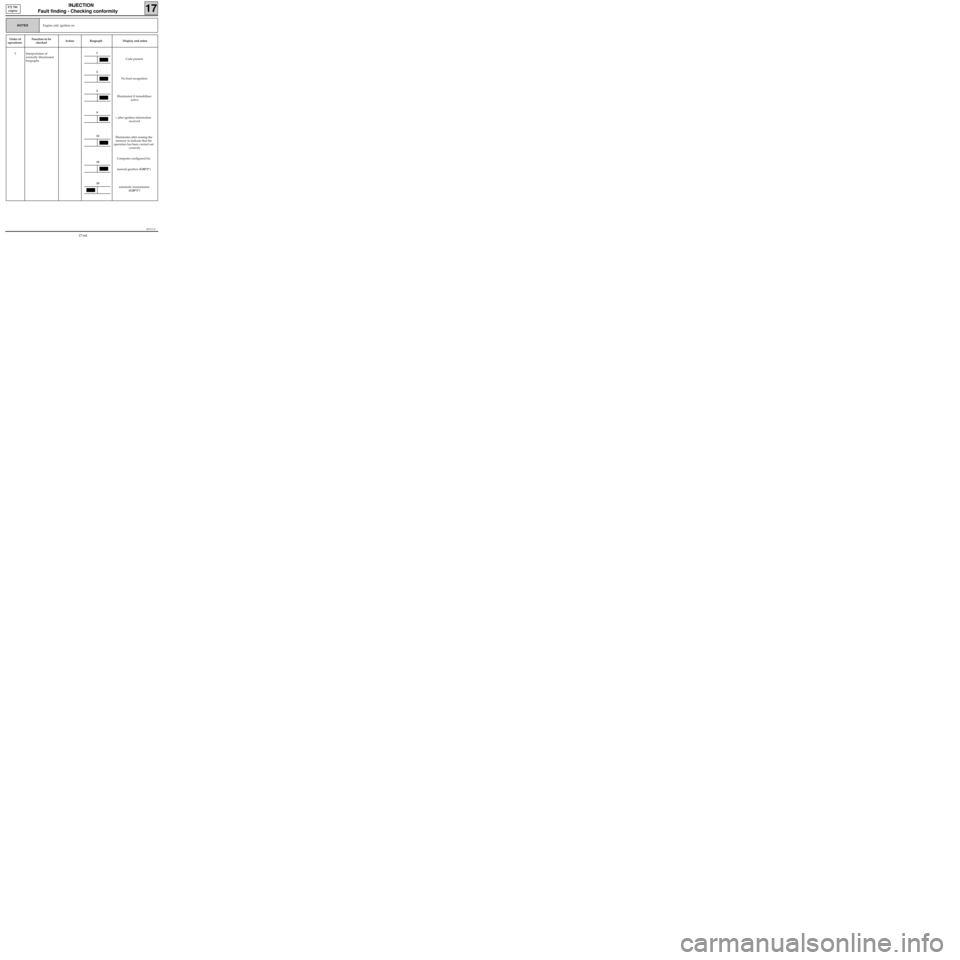

Engine cold, ignition on.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

5 Interpretation of

normally illuminated

bargraphs

Code present

No load recognition

Illuminated if immobiliser

active

+ after ignition information

received

Illuminates after erasing the

memory to indicate that the

operation has been carried out

correctly

Computer configured for:

manual gearbox (G50*2*)

automatic transmission

(G50*1*)

1

2

3

4

12

19

19

17-64

Page 113 of 363

JF5111.0

INJECTION

Fault finding - Checking conformity

17

E7J 780

engine

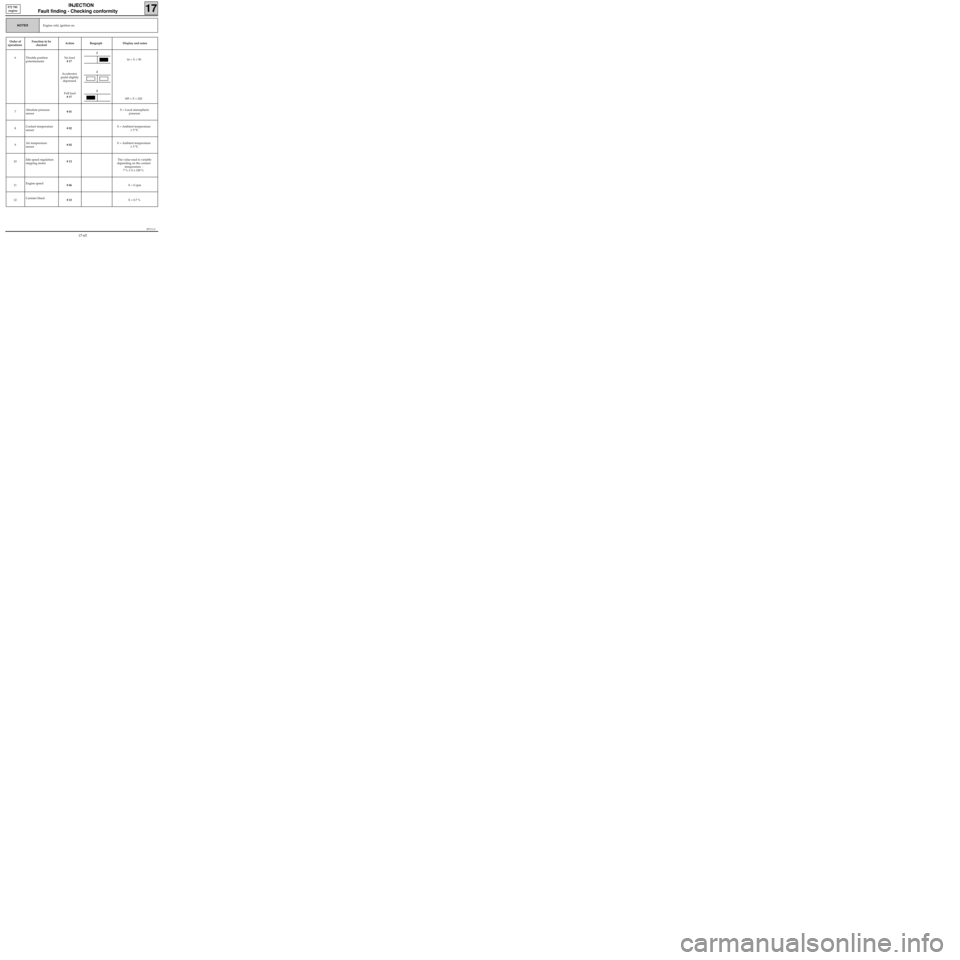

Engine cold, ignition on.NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

6 Throttle position

potentiometerNo load

# 17

Accelerator

pedal slightly

depressed

Full load

# 17 16 < X < 50

185 < X < 243

7Absolute pressure

sensor# 01 X = Local atmospheric

pressure

8Coolant temperature

sensor# 02 X = Ambient temperature

± 5 °C

9Air temperature

sensor# 03 X = Ambient temperature

± 5 °C

10Idle speed regulation

stepping motor# 12The value read is variable

depending on the coolant

temperature :

7 % ≤ X ≤ 100 %

11Engine speed

# 06 X = 0 rpm

12Canister bleed

# 23 X = 0.7 %

2

2

2

17-65

Page 115 of 363

JF5111.0

INJECTION

Fault finding - Checking conformity

17

E7J 780

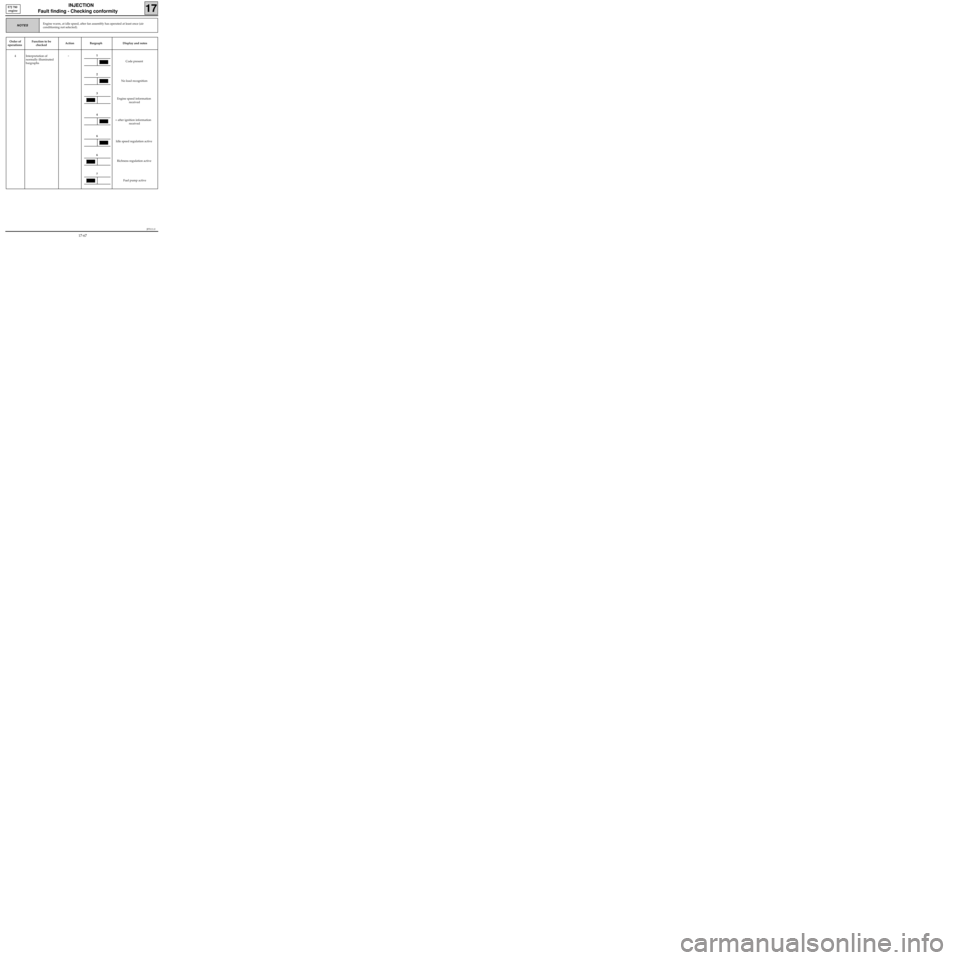

engine

Engine warm, at idle speed, after fan assembly has operated at least once (air

conditioning not selected).NOTES

Order of

operationsFunction to be

checkedAction Bargraph Display and notes

4 Interpretation of

normally illuminated

bargraphs

-

Code present

No load recognition

Engine speed information

received

+ after ignition information

received

Idle speed regulation active

Richness regulation active

Fuel pump active1

2

4

6

6

3

7

17-67

Page 120 of 363

JSA051.0

INJECTION

Fault finding- Introduction

17

D7F 710

engine -

35 tracks

SETTING UP DIALOGUE BETWEEN THE XR25 AND THE COMPUTER

- Connect the test kit to the diagnostic socket.

- Put the selector on S8

- Switch on the ignition.

- Enter D13 9.NJ

COMPUTER IDENTIFICATION

The computer is not identified by reading a fault code but by reading the Part Number directly from the

computer. After having set up a dialogue with the computer:

ENTER G70*7700

XXX

XXX

The Part Number will then appear on the central display in three sequences.

Each sequence is displayed for approximately two seconds. The display is repeated twice .

ERASING THE MEMORY (ignition on)

After an operation on the injection system the computer’s memory can be erased by using the code G0** .

17-75