RENAULT KANGOO 2013 X61 / 2.G ABS Bosch 8.1 Service Manual

Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 57, PDF Size: 1.44 MB

Page 41 of 57

38C-41

AFTER REPAIRClear the computer memory using command RZ001 Fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-38C000$150.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of commands38C

ABS BOSCH 8.1

Vdiag No.: 18

AC016PUMP MOTOR TEST

NOTESConditions of use of the command:

Ignition on, engine stopped and vehicle speed zero.

Before running the command, check that the battery is properly charged (see 80A,

Battery, Battery: Customer complaints).

This command is used to test the pump motor control circuit.

Select the command AC016.

The motor must run for 5 seconds.

ABS8.1X76_V18_AC016

Page 42 of 57

38C-42

AFTER REPAIRClear the computer memory using command RZ001 Fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-38C000$150.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of commands38C

ABS BOSCH 8.1

Vdiag No.: 18

SC001CHECK THE TARGET TEETH

NOTESConditions of use of the command:

Ignition on, engine stopped and vehicle speed zero.

Before running the command, check that the battery is properly charged (see 80A,

Battery, Battery: Customer complaints).

This command is used to check the number of teeth on the target.

Select the command SC001.

The test result should be equal to 48 or 44 teeth depending on the version.

ABS8.1X76_V18_SC001

Page 43 of 57

38C-43

AFTER REPAIRClear the computer memory using command RZ001 Fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-38C000$150.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of commands38C

ABS BOSCH 8.1

Vdiag No.: 18

SC006BLEEDING THE HYDRAULIC UNIT AND BRAKE CIRCUITS

NOTESConditions of use of the command:

Ignition on, engine stopped and vehicle speed zero.

Before running the command, check that the battery is properly charged (see 80A,

Battery, Battery: Customer complaints).

This command must be used only in the event of abnormal lengthening of brake pedal travel during a road test with

ABS regulation (the vehicle must have already been bled using the conventional procedure).

Select command SC006 and follow the instructions given by the diagnostic tool.

ABS8.1X76_V18_SC006

Page 44 of 57

38C-44V1 MR-376-X76-38C000$160.mif

38C

ABS BOSCH 8.1

Vdiag No.: 18

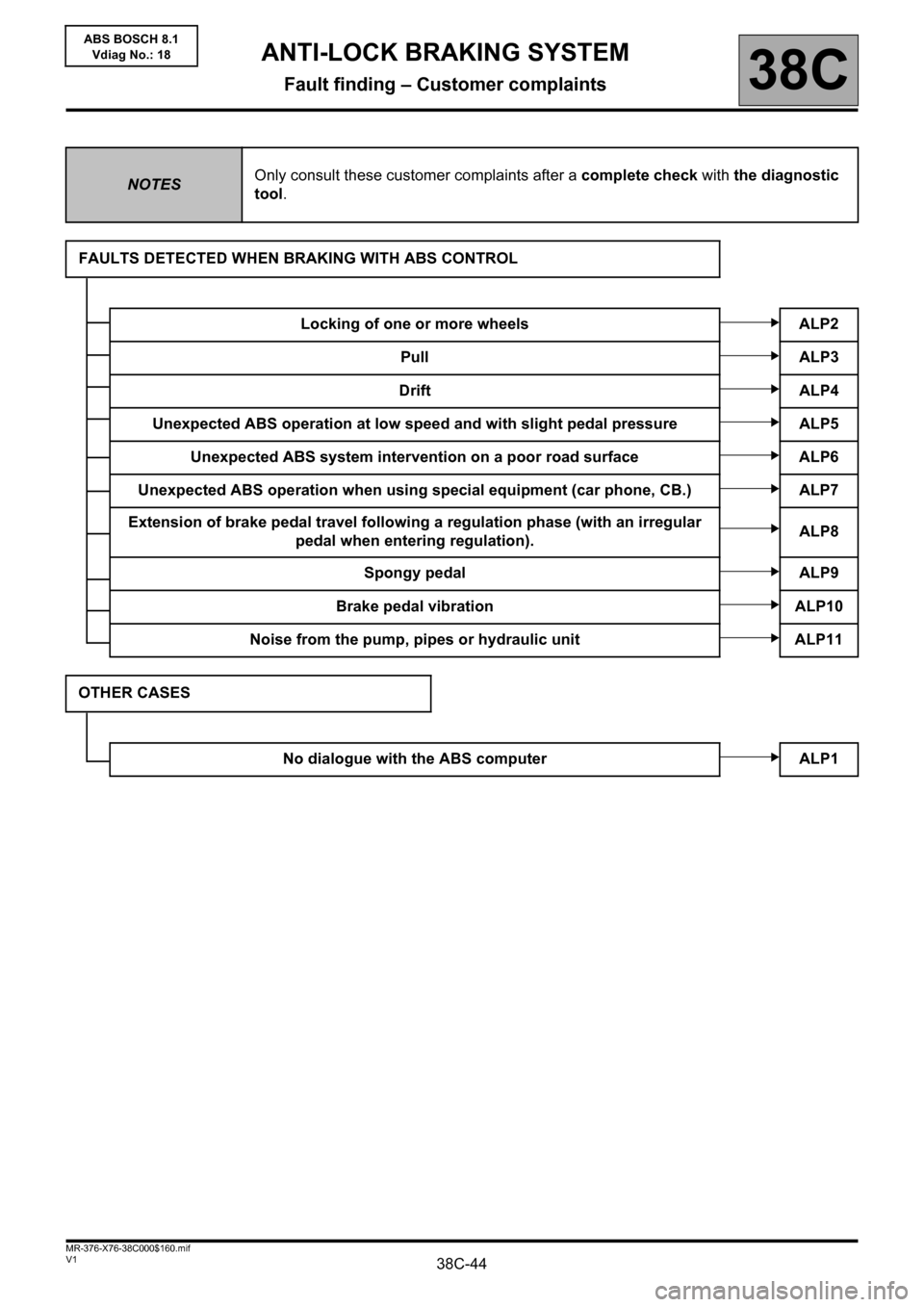

NOTESOnly consult these customer complaints after a complete check with the diagnostic

tool.

FAULTS DETECTED WHEN BRAKING WITH ABS CONTROL

Locking of one or more wheels ALP2

Pull ALP3

Drift ALP4

Unexpected ABS operation at low speed and with slight pedal pressure ALP5

Unexpected ABS system intervention on a poor road surface ALP6

Unexpected ABS operation when using special equipment (car phone, CB.) ALP7

Extension of brake pedal travel following a regulation phase (with an irregular

pedal when entering regulation).ALP8

Spongy pedal ALP9

Brake pedal vibration ALP10

Noise from the pump, pipes or hydraulic unit ALP11

OTHER CASES

No dialogue with the ABS computer ALP1

ANTI-LOCK BRAKING SYSTEM

Fault finding – Customer complaints

Page 45 of 57

38C-45

AFTER REPAIRClear the computer memory using command RZ001 Fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-38C000$170.mif

38C

ABS BOSCH 8.1

Vdiag No.: 18

ALP1 No dialogue with the ABS computer

NOTESUse the Wiring Diagrams Technical Note for KANGOO VLL.

Try to establish dialogue with a computer on another vehicle to check that the diagnostic tool is not faulty. If the

tool is not causing the fault and dialogue cannot be established with any other computer on the same vehicle, it

may be that a faulty computer is disrupting fault finding line HK.

Use a process of successive disconnections to locate this computer.

Check the battery voltage and carry out the necessary operations to obtain a correct voltage between 9.8 V < X <

16.7 V.

Check the presence and condition of the ABS fuses on the passenger compartment fuse box, component code

260, F17 and in the engine fuse box, component code 710, F01 and F10, (see MR 374 Mechanical, 81C, Fuses,

Fuses: List and location of components).

Check the connection of the ABS computer connector, component code 118 and the condition of its connections.

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the earths on the MQ connections of component 118 (good condition, not corroded, tightness of the earth

bolt on top of the ABS assembly).

Check that the supply to the computer is correct:

–Earth on the MQ connections of component 118,

–+ before ignition feed on connections BP14 and BP8 of component 118,

–+ after ignition feed on connection AP5 of component 118.

If the connection or connections are faulty and if there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the connection of the diagnostic socket connector, component code 225 and the condition of its

connections.

Check the continuity of connection HL and HK between the computer and the diagnostic socket.

If the connection is faulty and if there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

A

ABS8.1X76_V18_ALP1

ANTI-LOCK BRAKING SYSTEM

Fault finding – Fault Finding Chart

Page 46 of 57

38C-46

AFTER REPAIRClear the computer memory using command RZ001 Fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-38C000$170.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Fault Finding Chart38C

ABS BOSCH 8.1

Vdiag No.: 18

ALP1

CONTINUED

Check that the diagnostic socket, component code 225 is correctly supplied:

–+ before ignition feed on connection BP10 of component 225.

–+ after ignition feed on connection AP10 of component 225.

–Earth on connections MK and NA of component 225.

If the connection or connections are faulty and if there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If dialogue has still not been established after these checks, contact the techline.

A

Page 47 of 57

38C-47

AFTER REPAIRClear the computer memory using command RZ001 Fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-38C000$170.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Fault Finding Chart38C

ABS BOSCH 8.1

Vdiag No.: 18

ALP2 Locking of one or more wheels

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Reminder:

Locking of the wheels on a vehicle fitted with ABS or squealing of tyres, interpreted by the customer as locking,

could be related to a normal reaction of the system and should not automatically be assumed to be a fault (braking

with ABS regulation on a very bad road causes considerable squealing).

However, if the wheel(s) is/are actually locking, lift the vehicle so that you can turn the wheels and check for:

– Possible inversion when connecting the speed sensors.

Use parameters PR001 Front right-hand wheel speed, PR002 Front left-hand wheel speed, PR003 Rear

right-hand wheel speed and PR004 Rear left-hand wheel speed by turning the relevant wheels and checking

the consistency of the results obtained.

If the value measured is zero, rotate the other wheels to confirm an electrical inversion of the sensors and repair

the wiring harness.

– Possible inversion of pipes on the hydraulic unit.

Use commands AC003 Front left-hand wheel solenoid valves, AC004 Front right-hand wheel solenoid

valves, AC005 Rear left-hand wheel solenoid valves and AC006 Rear right-hand wheel solenoid valves

while depressing the brake pedal and check for the occurrence of locking/unlocking cycles on the wheel

concerned (see Command summary table). If the cycles do not occur on the wheel tested (wheel remains

locked), check whether they occur on another wheel to confirm reversed pipes.

If the cycles do not occur on one wheel and the pipes have not been inverted, contact the Techline.

ABS8.1X76_V18_ALP2

Page 48 of 57

38C-48

AFTER REPAIRClear the computer memory using command RZ001 Fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-38C000$170.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Fault Finding Chart38C

ABS BOSCH 8.1

Vdiag No.: 18

ALP2

CONTINUED

Check that the wheel speed sensor mounting is in good condition (clipping).

Visually inspect the condition of the target (clogging, metallic contamination, etc.) and clean with compressed air

if necessary.

Check the condition of the braking system (condition of linings, sealing, grating, bleed, etc.).

Check the condition of the axles and the conformity and good condition of the tyre mountings.

If the fault is still present after these checks, contact the Techline.

Page 49 of 57

38C-49

AFTER REPAIRClear the computer memory using command RZ001 Fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-38C000$170.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Fault Finding Chart38C

ABS BOSCH 8.1

Vdiag No.: 18

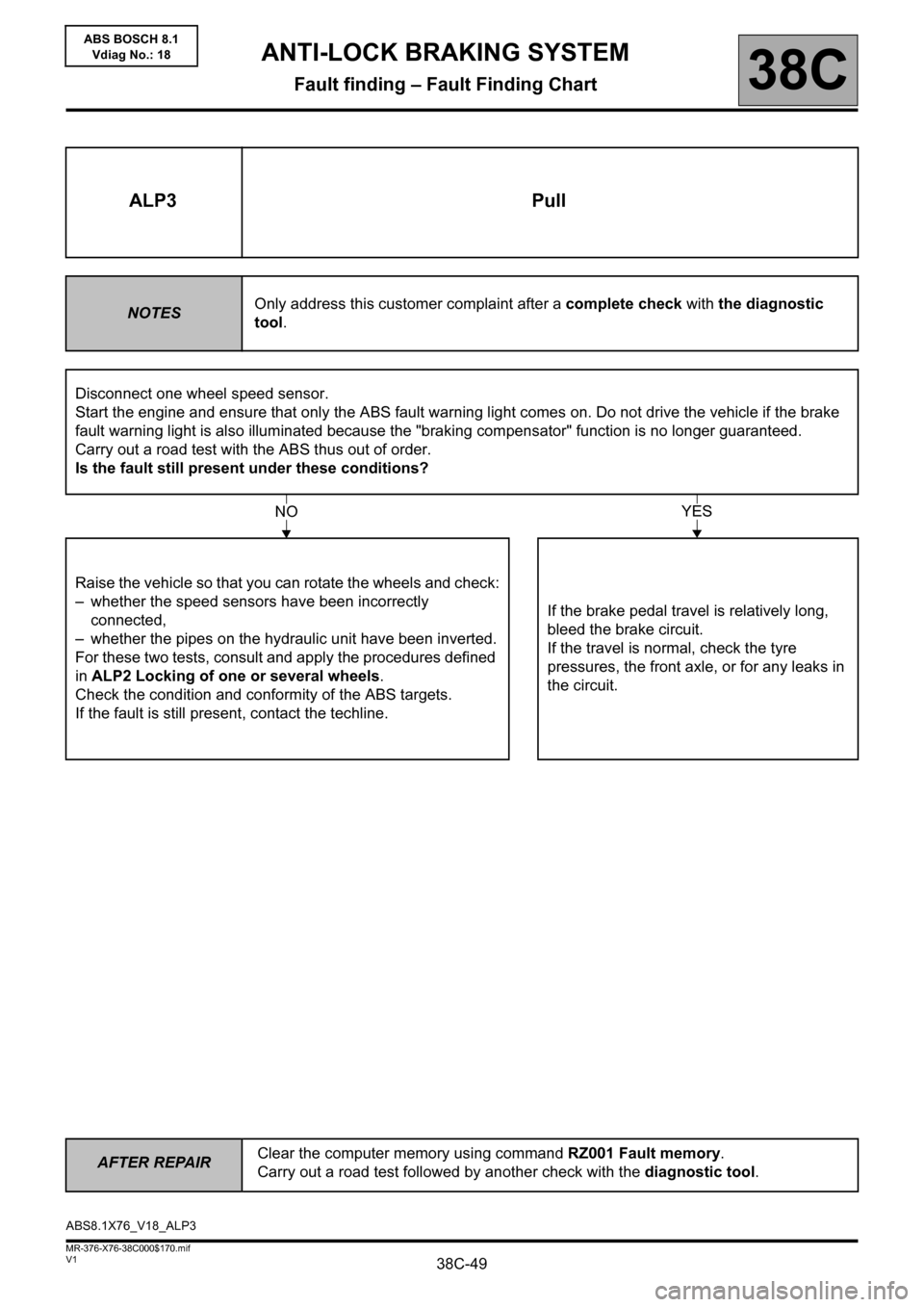

ALP3 Pull

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Disconnect one wheel speed sensor.

Start the engine and ensure that only the ABS fault warning light comes on. Do not drive the vehicle if the brake

fault warning light is also illuminated because the "braking compensator" function is no longer guaranteed.

Carry out a road test with the ABS thus out of order.

Is the fault still present under these conditions?

Raise the vehicle so that you can rotate the wheels and check:

– whether the speed sensors have been incorrectly

connected,

– whether the pipes on the hydraulic unit have been inverted.

For these two tests, consult and apply the procedures defined

in ALP2 Locking of one or several wheels.

Check the condition and conformity of the ABS targets.

If the fault is still present, contact the techline.If the brake pedal travel is relatively long,

bleed the brake circuit.

If the travel is normal, check the tyre

pressures, the front axle, or for any leaks in

the circuit.

NOYES

ABS8.1X76_V18_ALP3

Page 50 of 57

38C-50

AFTER REPAIRClear the computer memory using command RZ001 Fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-38C000$170.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Fault Finding Chart38C

ABS BOSCH 8.1

Vdiag No.: 18

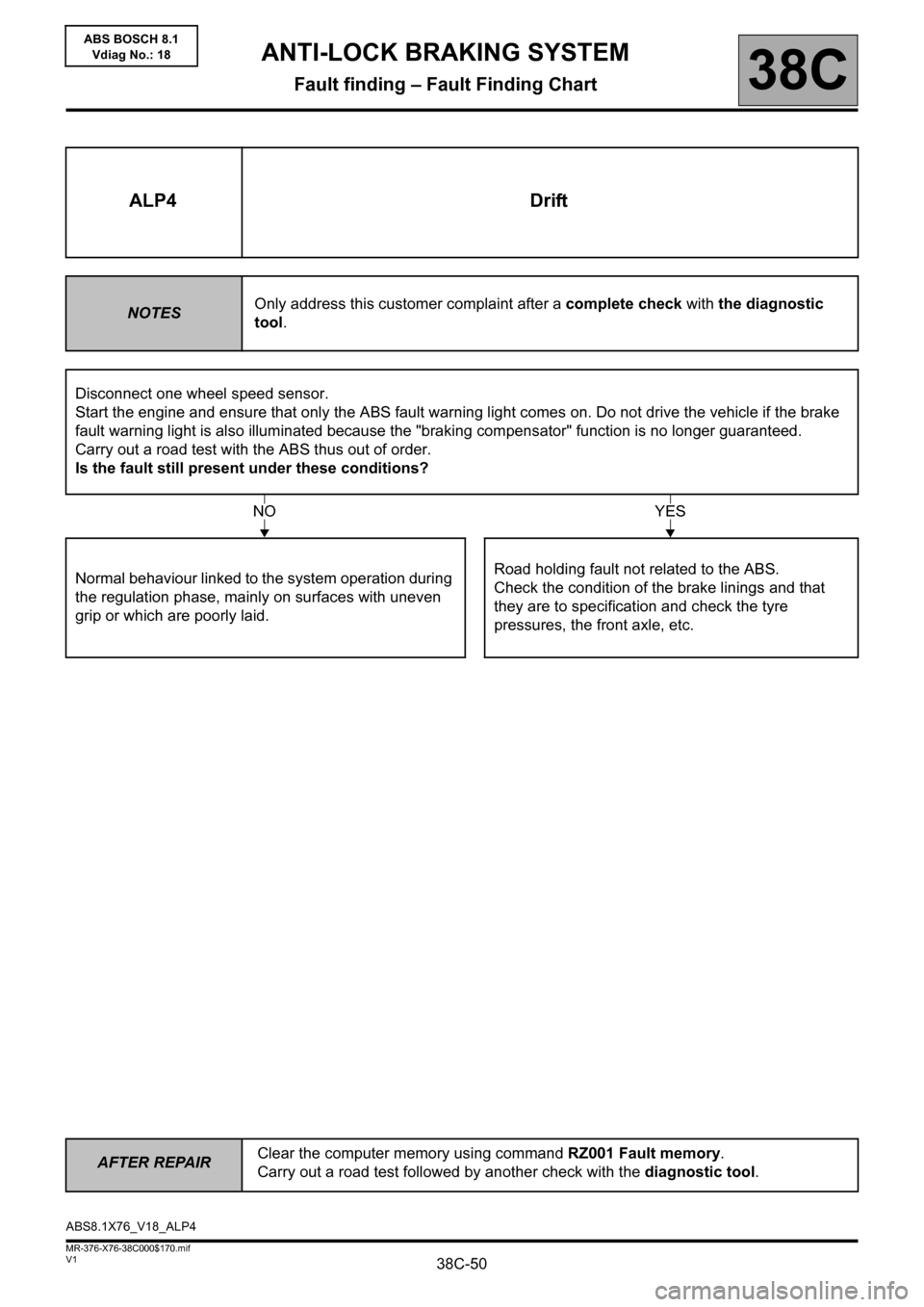

ALP4 Drift

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Disconnect one wheel speed sensor.

Start the engine and ensure that only the ABS fault warning light comes on. Do not drive the vehicle if the brake

fault warning light is also illuminated because the "braking compensator" function is no longer guaranteed.

Carry out a road test with the ABS thus out of order.

Is the fault still present under these conditions?

Normal behaviour linked to the system operation during

the regulation phase, mainly on surfaces with uneven

grip or which are poorly laid.Road holding fault not related to the ABS.

Check the condition of the brake linings and that

they are to specification and check the tyre

pressures, the front axle, etc.

NOYES

ABS8.1X76_V18_ALP4