sensor RENAULT KANGOO 2013 X61 / 2.G Petrol V42 Injection Owners Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 279, PDF Size: 1.29 MB

Page 244 of 279

17B-244

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$160.mif

PETROL INJECTION

Fault finding – Fault Finding Chart17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

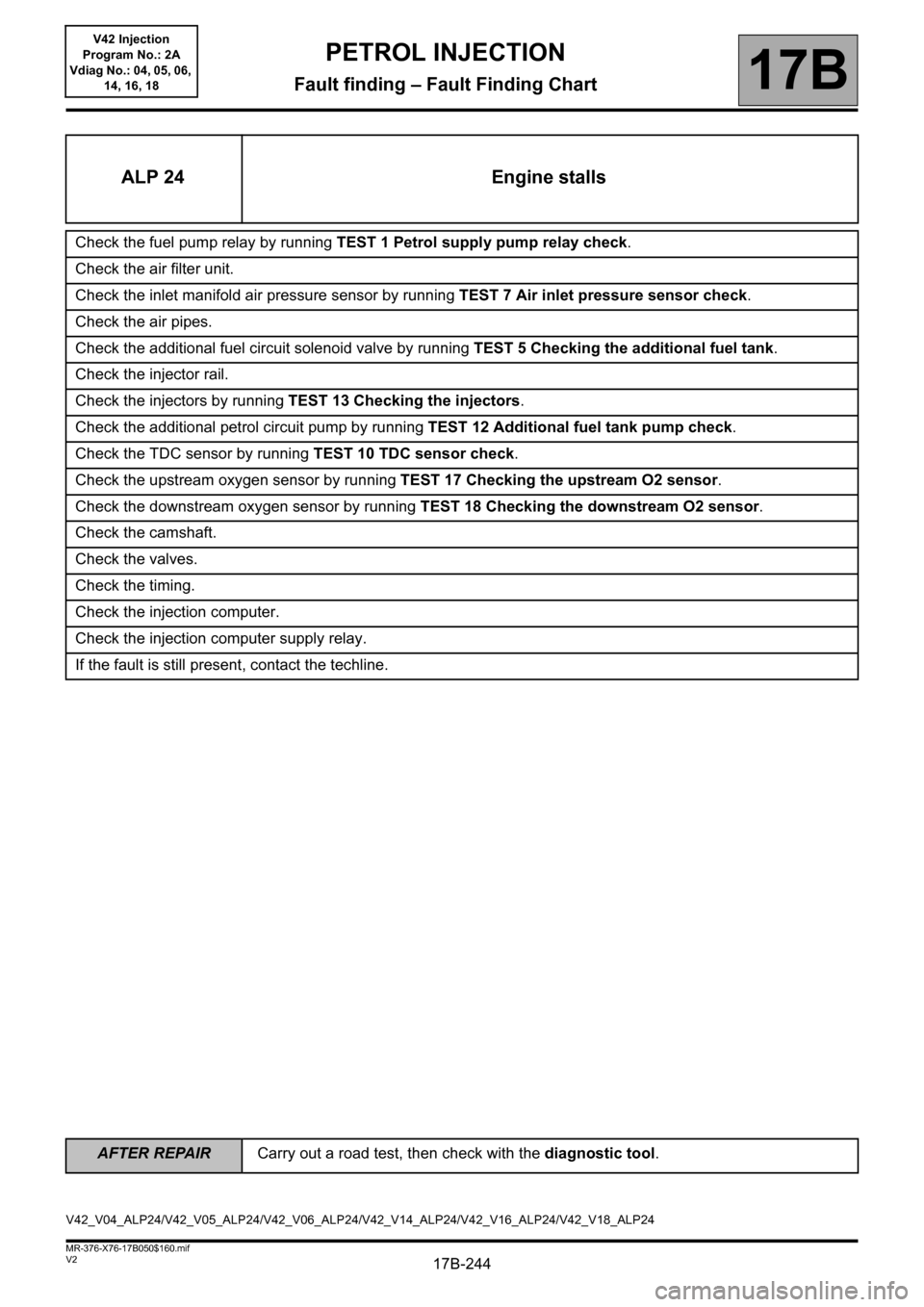

ALP 24 Engine stalls

Check the fuel pump relay by running TEST 1 Petrol supply pump relay check.

Check the air filter unit.

Check the inlet manifold air pressure sensor by running TEST 7 Air inlet pressure sensor check.

Check the air pipes.

Check the additional fuel circuit solenoid valve by running TEST 5 Checking the additional fuel tank.

Check the injector rail.

Check the injectors by running TEST 13 Checking the injectors.

Check the additional petrol circuit pump by running TEST 12 Additional fuel tank pump check.

Check the TDC sensor by running TEST 10 TDC sensor check.

Check the upstream oxygen sensor by running TEST 17 Checking the upstream O2 sensor.

Check the downstream oxygen sensor by running TEST 18 Checking the downstream O2 sensor.

Check the camshaft.

Check the valves.

Check the timing.

Check the injection computer.

Check the injection computer supply relay.

If the fault is still present, contact the techline.

V42_V04_ALP24/V42_V05_ALP24/V42_V06_ALP24/V42_V14_ALP24/V42_V16_ALP24/V42_V18_ALP24

Page 246 of 279

17B-246

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$160.mif

PETROL INJECTION

Fault finding – Fault Finding Chart17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

ALP 26 Erratic deceleration

Check the inlet manifold air pressure sensor by running TEST 7 Air inlet pressure sensor check.

Check the throttle valve by running TEST 3 Throttle valve check.

If the fault is still present, contact the techline.

V42_V04_ALP26/V42_V05_ALP26/V42_V06_ALP26/V42_V14_ALP26/V42_V16_ALP26/V42_V18_ALP26

Page 248 of 279

17B-248V2 MR-376-X76-17B050$170.mif

17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

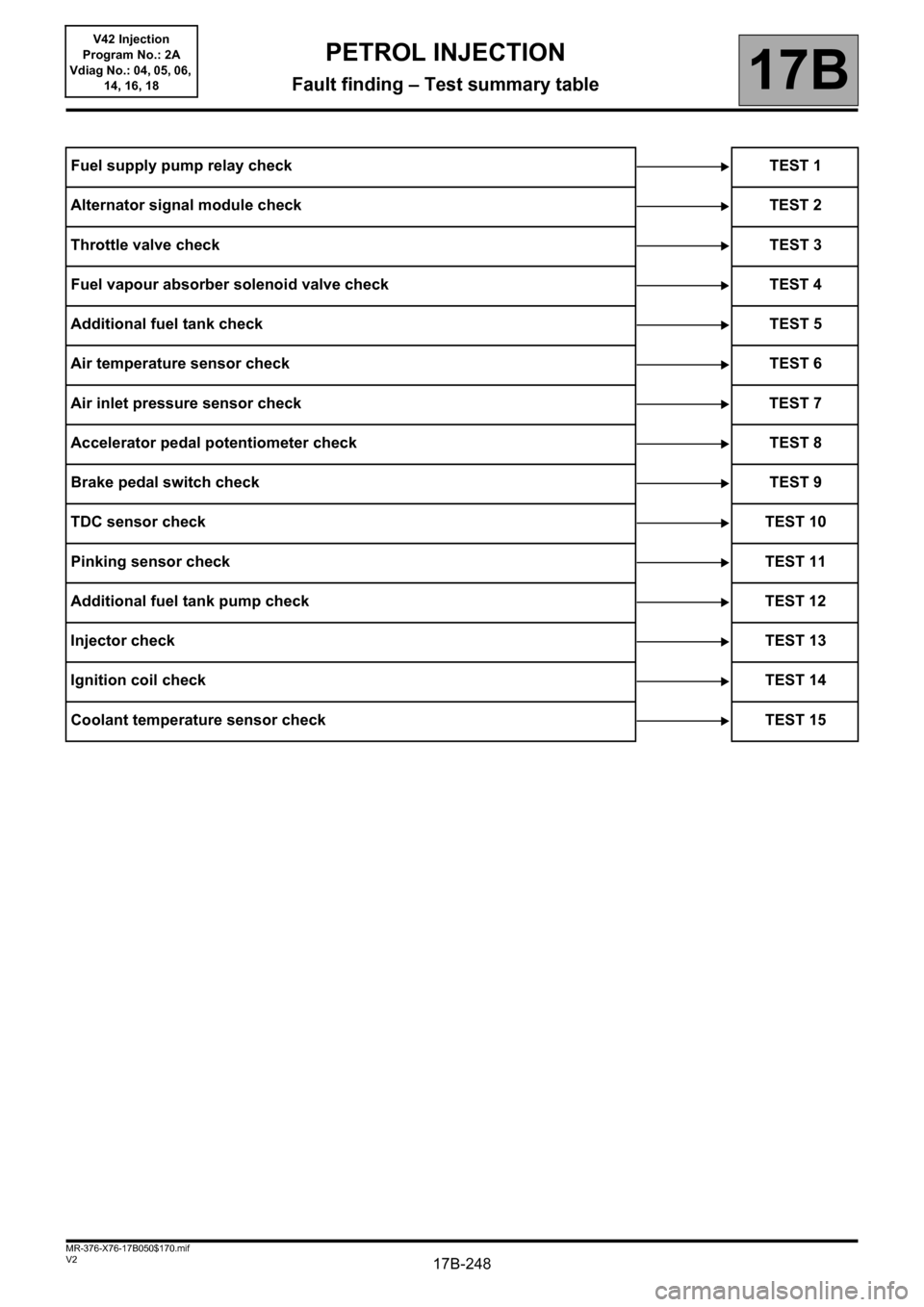

Fuel supply pump relay check TEST 1

Alternator signal module check TEST 2

Throttle valve checkTEST 3

Fuel vapour absorber solenoid valve check TEST 4

Additional fuel tank checkTEST 5

Air temperature sensor check TEST 6

Air inlet pressure sensor check TEST 7

Accelerator pedal potentiometer check TEST 8

Brake pedal switch checkTEST 9

TDC sensor checkTEST 10

Pinking sensor checkTEST 11

Additional fuel tank pump check TEST 12

Injector checkTEST 13

Ignition coil checkTEST 14

Coolant temperature sensor check TEST 15

PETROL INJECTION

Fault finding – Test summary table

Page 249 of 279

17B-249V2 MR-376-X76-17B050$170.mif

PETROL INJECTION

Fault finding – Test summary table17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

Fan relay checkTEST 16

Upstream O2 sensor check TEST 17

Downstream O2 sensor check TEST 18

Fuel conformity checkTEST 19

Camshaft sensor checkTEST 20

Page 257 of 279

17B-257

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$180.mif

PETROL INJECTION

Fault finding – Tests17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

TEST 6 Air temperature sensor check

NOTESNone.

Perform a visual inspection and look for possible sealing faults in the system.

Ensure the conformity of the system (see MR 388 (Logan and Sandero), MR 451 (Duster), MR 423 (Thalia 2/

Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL), Mechanical, 12A, Fuel mixture, Air inlet:

Description).

If the fault is still present, contact the techline.

V42_V04_TEST6/V42_V05_TEST6/V42_V06_TEST6/V42_V14_TEST6/V42_V16_TEST6/V42_V18_TEST6

Page 258 of 279

17B-258

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$180.mif

PETROL INJECTION

Fault finding – Tests17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

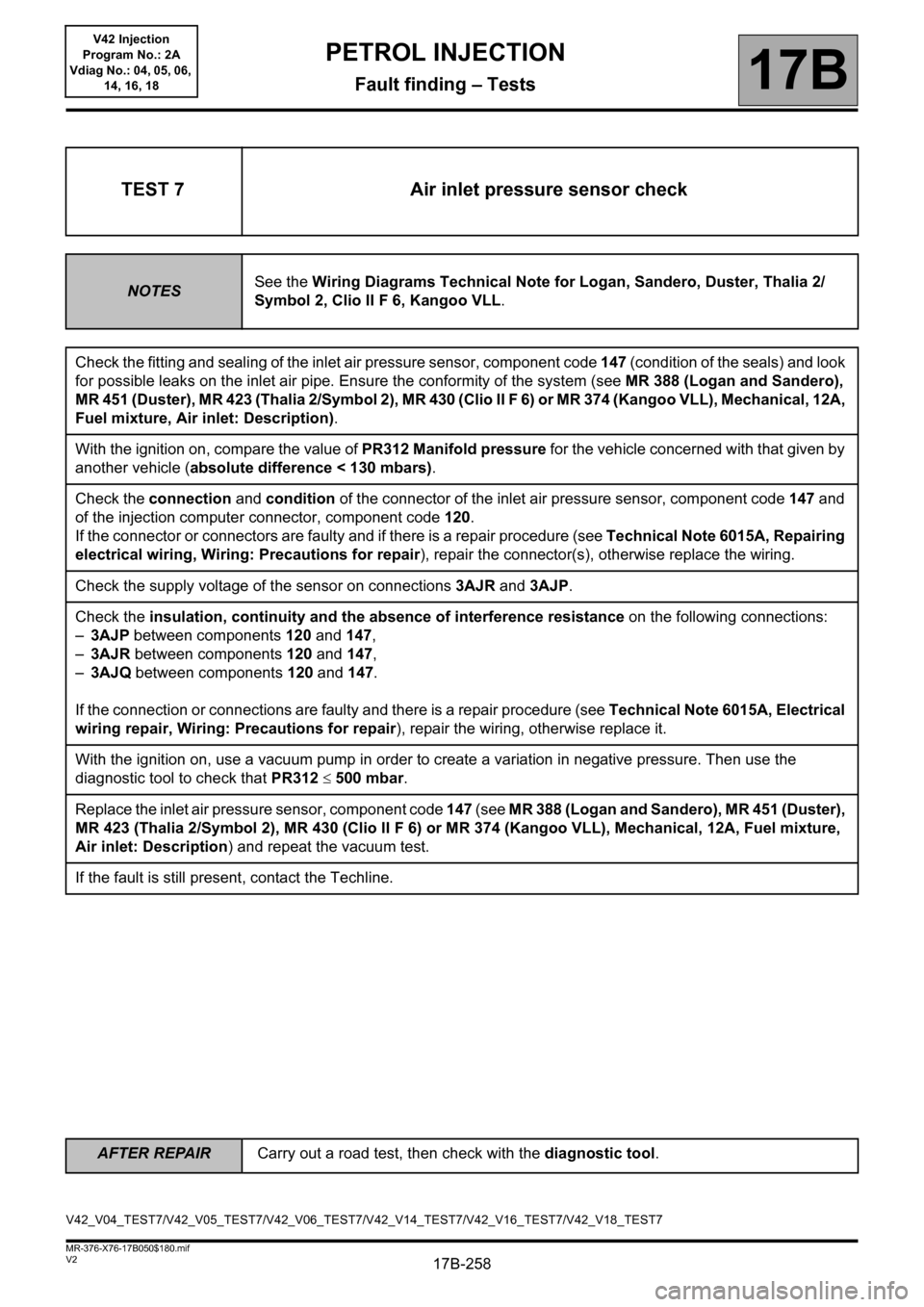

TEST 7 Air inlet pressure sensor check

NOTESSee the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

Check the fitting and sealing of the inlet air pressure sensor, component code 147 (condition of the seals) and look

for possible leaks on the inlet air pipe. Ensure the conformity of the system (see MR 388 (Logan and Sandero),

MR 451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL), Mechanical, 12A,

Fuel mixture, Air inlet: Description).

With the ignition on, compare the value of PR312 Manifold pressure for the vehicle concerned with that given by

another vehicle (absolute difference < 130 mbars).

Check the connection and condition of the connector of the inlet air pressure sensor, component code 147 and

of the injection computer connector, component code 120.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector(s), otherwise replace the wiring.

Check the supply voltage of the sensor on connections 3AJR and 3AJP.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3AJP between components 120 and 147,

–3AJR between components 120 and 147,

–3AJQ between components 120 and 147.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

With the ignition on, use a vacuum pump in order to create a variation in negative pressure. Then use the

diagnostic tool to check that PR312 500 mbar.

Replace the inlet air pressure sensor, component code 147 (see MR 388 (Logan and Sandero), MR 451 (Duster),

MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL), Mechanical, 12A, Fuel mixture,

Air inlet: Description) and repeat the vacuum test.

If the fault is still present, contact the Techline.

V42_V04_TEST7/V42_V05_TEST7/V42_V06_TEST7/V42_V14_TEST7/V42_V16_TEST7/V42_V18_TEST7

Page 260 of 279

17B-260

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$180.mif

PETROL INJECTION

Fault finding – Tests17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

TEST 8

CONTINUED 1

Remove the accelerator pedal, component code 921 (see MR 388 (Logan and Sandero), MR 451 (Duster), MR

430 (Clio II F 6), MR 374 (Kangoo VLL), Mechanical, 17B, Petrol injection, Accelerator pedal potentiometer:

Removal - Refitting or MR 423 (Thalia 2/Symbol 2), Mechanical, 37A, Mechanical component controls,

Accelerator pedal: Removal - Refitting).

Without action on the accelerator pedal, check the resistance between the following connections (between 0°C

and 40ºC):

Gang 1:

–3LT and 3LS of component 921, the resistance must be between 718 X 5263 ,

–3LT and 3LR of component 921, the resistance must be between 838X1742,

–3LR and 3LS of component 921, the resistance must be between 1312X6495.

Gang 2:

–3LV and 3LW of component 921, the resistance must be between 701 X 5242

,

–3LV and 3LU of component 921, the resistance must be between 1495X3105,

–3LU and 3LW of component 921, the resistance must be between 1978X7894.

If these checks are incorrect, replace the accelerator pedal sensor, component code 921 (see MR 388 (Logan

and Sandero), MR 388 (Logan and Sandero), MR 451 (Duster), MR 430 (Clio II F 6), MR 374 (Kangoo VLL),

Mechanical, 17B, Petrol injection, Accelerator pedal potentiometer: Removal - Refitting or MR 423 (Thalia

2/Symbol 2), Mechanical, 37A, Mechanical component controls, Accelerator pedal: Removal - Refitting).

If the fault is still present, contact the Techline.

Page 261 of 279

17B-261

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$180.mif

PETROL INJECTION

Fault finding – Tests17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

TEST 8

CONTINUED 2

With the accelerator pedal depressed as far as possible, check the resistance between the following

connections (between 0°C and 40ºC):

Gang 1:

–3LT and 3LS of component 921, the resistance must be between 1361 X 6600 ,

–3LT and 3LR of component 921, the resistance must be between 838X1742,

–3LR and 3LS of component 921, the resistance must be between 668 X 5160 .

Gang 2:

–3LV and 3LW of component 921, the resistance must be between 1276 X 6436 ,

–3LV and 3LU of component 921, the resistance must be between 1495X3105,

–3LU and 3LW of component 921, the resistance must be between 1403 X 6700 .

If these checks are incorrect, replace the accelerator pedal sensor, component code 921 (see MR 388 (Logan

and Sandero), MR 388 (Logan and Sandero), MR 451 (Duster), MR 430 (Clio II F 6), MR 374 (Kangoo VLL),

Mechanical, 17B, Petrol injection, Accelerator pedal potentiometer: Removal - Refitting or MR 423 (Thalia

2/Symbol 2), Mechanical, 37A, Mechanical component controls, Accelerator pedal: Removal - Refitting).

If the fault is still present, contact the Techline.

Page 264 of 279

17B-264

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$180.mif

PETROL INJECTION

Fault finding – Tests17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

TEST 10 TDC sensor check

NOTESSee the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

Check the sensor fitting (connectors, mountings, etc.) (see MR 388 (Logan and Sandero), MR 451 (Duster), MR

423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL), Mechanical, 17B, Petrol Injection,

Crankshaft position sensor: Removal - Refitting).

Switch on the ignition, check the change of the engine rotation speed using parameter PR055 Engine speed. The

value must be between 0 rpm and more than 120 rpm when the starter is operating.

With the engine running, accelerate to obtain different engine rotation speeds and check that the engine speed

correctly changes in relation to the accelerations.

If PR055 varies, the sensor is sound.

Check the cleanliness and condition of the TDC sensor, component code 149 and of the injection computer

connector, component code 120.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector(s), otherwise replace the wiring.

V42_V04_TEST10/V42_V05_TEST10/V42_V06_TEST10/V42_V14_TEST10/V42_V16_TEST10/V42_V18_TEST10

Page 265 of 279

17B-265

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$180.mif

PETROL INJECTION

Fault finding – Tests17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

TEST 10

CONTINUED

Check the resistance of the TDC sensor between connections 3BL and 3BG on the injection computer

connector side, component code 120 (see MR 388 (Logan and Sandero), MR 451 (Duster), MR 423 (Thalia 2/

Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL), Mechanical, 17B, Petrol injection, Petrol injection

computer: Removal - Refitting).

The resistance must be between 175 X 295 or 200 < X < 270 (F4R engine of Duster) (between 0°C

and 40°C). If the value is not correct, replace the sensor (see MR 388 (Logan and Sandero), MR 451 (Duster),

MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL), Mechanical, 17B, Petrol Injection,

Crankshaft position sensor: Removal - Refitting).

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3BL between components 120 and 149,

–3BG between components 120 and 149.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.