sensor RENAULT SCENIC 2008 J84 / 2.G Gas Injection LPG 3000 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2008, Model line: SCENIC, Model: RENAULT SCENIC 2008 J84 / 2.GPages: 107, PDF Size: 0.31 MB

Page 46 of 107

17C-46

MR-372-J84-17C000$354.mif

V2

GAS INJECTION

Fault finding - Interpretation of faults

LPG 3000

Program No: AB

Vdiag No: 08/10

17C

DF092

CONTINUED

Replace the sensor if the pressure is no more than 0.8 bar greater than the manifold pressure PR001 Manifold

pressure.

Check the manifold pressure sensor sealing.

Check the pressure value using parameters PR001 Manifold pressure, PR003 Pressure difference:

LPG/manifold and PR112 LPG pressure downstream of expansion valve and ensure that

PR003 = PR112 - PR001.

If the fault is still present, deal with the other faults, then proceed to the conformity check.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 47 of 107

17C-47

MR-372-J84-17C000$413.mif

V2

17C

GAS INJECTION

Fault finding - Interpretation of faults

DF095

PRESENT

OR

STOREDLPG TEMPERATURE SENSOR CIRCUIT

1.DEF : Signal outside lower limit

2.DEF : Signal outside upper limit

3.DEF : Non-compliance with emission control standards

IMPORTANT

Before working on an LPG supply circuit component, always refer to the appropriate section of the

Workshop Repair Manual (see 17D, LPG Injection, Introduction, Safety advice for all operations).

NOTESConditions for applying the fault finding procedure to stored faults:

–The fault is declared present after the engine has been started and switched to LPG

mode.

Manipulate the wiring harness between the LPG computer and the LPG temperature/pressure sensor in order to

produce a change in status (present to stored).

Look for any damage to the harness, and check the connection and condition of the LPG pressure/temperature

sensor and its connectors.

If necessary, repair or replace the connector.

Check for + 5 V on track 3 of the LPG pressure/temperature sensor in LPG mode.

Check the following connections for insulation from earth, continuity and absence of extraneous resistance:

LPG computer track A3 track 3 of the LPG pressure/temperature sensor

Repair if necessary.

Check for earth on track 1 of the LPG pressure/temperature sensor in LPG mode.

Check the following connections for insulation from +5 V, continuity and absence of extraneous resistance:

LPG computer track B3 track 1 of the LPG pressure/temperature sensor

Repair if necessary.

Check the insulation, the continuity and absence of unwanted resistance on the connection between:

LPG computer track E2 track 2 of the LPG pressure/temperature sensor

Repair if necessary.

Measure the resistance of the temperature sensor.

Replace the sensor if the resistance is not: 2.5 kΩ ± 0.1 kΩ at 20 ˚C

1.2 kΩ ± 0.1 Ω at 40 ˚C

If the fault is still present, deal with the other faults, then proceed to the conformity check.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

GAZ3000_V08_DF095 / GAZ3000_V10_DF095

LPG 3000

Program No: AB

Vdiag No: 08/10

MR-372-J84-17C000$413.mif

Page 48 of 107

17C-48

MR-372-J84-17C000$413.mif

V2

GAS INJECTION

Fault finding - Interpretation of faults

LPG 3000

Program No: AB

Vdiag No: 08/10

17C

DF096

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE

1.DEF : Voltage outside permitted range of values

2.DEF : Non-compliance with emission control standards

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after the engine has been running for 10 seconds in

LPG mode.

Manipulate the wiring harness between the LPG computer and the LPG temperature/ pressure sensor in order to

produce a change in status (present ↔ stored).

Look for any damage to the harness, and check the connection and condition of the LPG pressure/temperature

sensor and its connectors.

If necessary, repair or replace the connector.

Check for + 5 V on track A4 and A3 (for Mégane 2) and on track B2 and A3 (for Logan) and for earth on

track B3 and D3 (for Mégane 2) or tracks G1 and H1 (for Logan) of the LPG computer.

Repair if necessary.

If incorrect, contact the Techline.

Check for a supply on tracks A3 and A4 of the LPG computer.

The voltage value must be between:

4.8 < V < 5.2

Check the insulation and continuity of the following connections:

For Mégane 2:

LPG computer track A4

LPG computer track A3

For Logan:

LPG computer track B2

LPG computer track A3track B of the LPG tank sender

track 1 of the LPG pressure sensor

track A2 of the LPG tank sender

track 3 of the LPG pressure sensor

Repair if necessary.

If the fault is still present, deal with the other faults, then proceed to the conformity check.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

GAZ3000_V08_DF096 / GAZ3000_V10_DF096

Page 54 of 107

17C-54

MR-372-J84-17C000$472.mif

V2

17C

GAS INJECTION

Fault finding - Conformity check

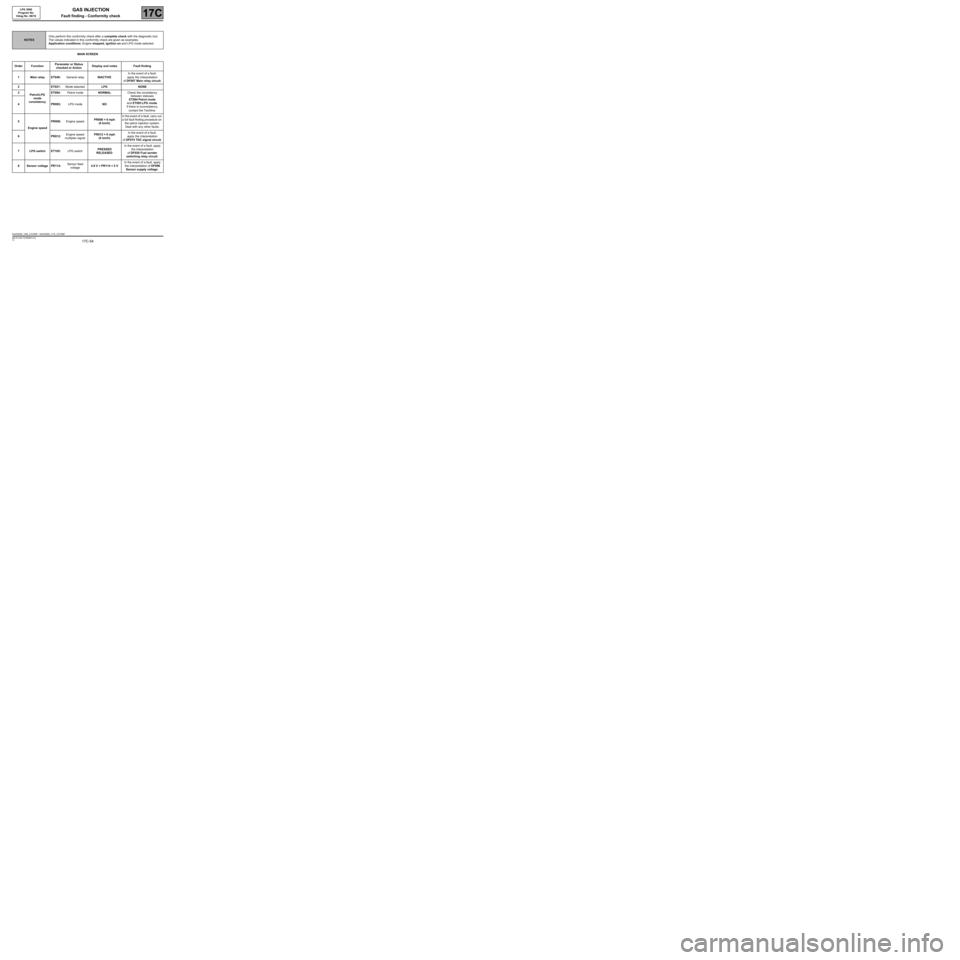

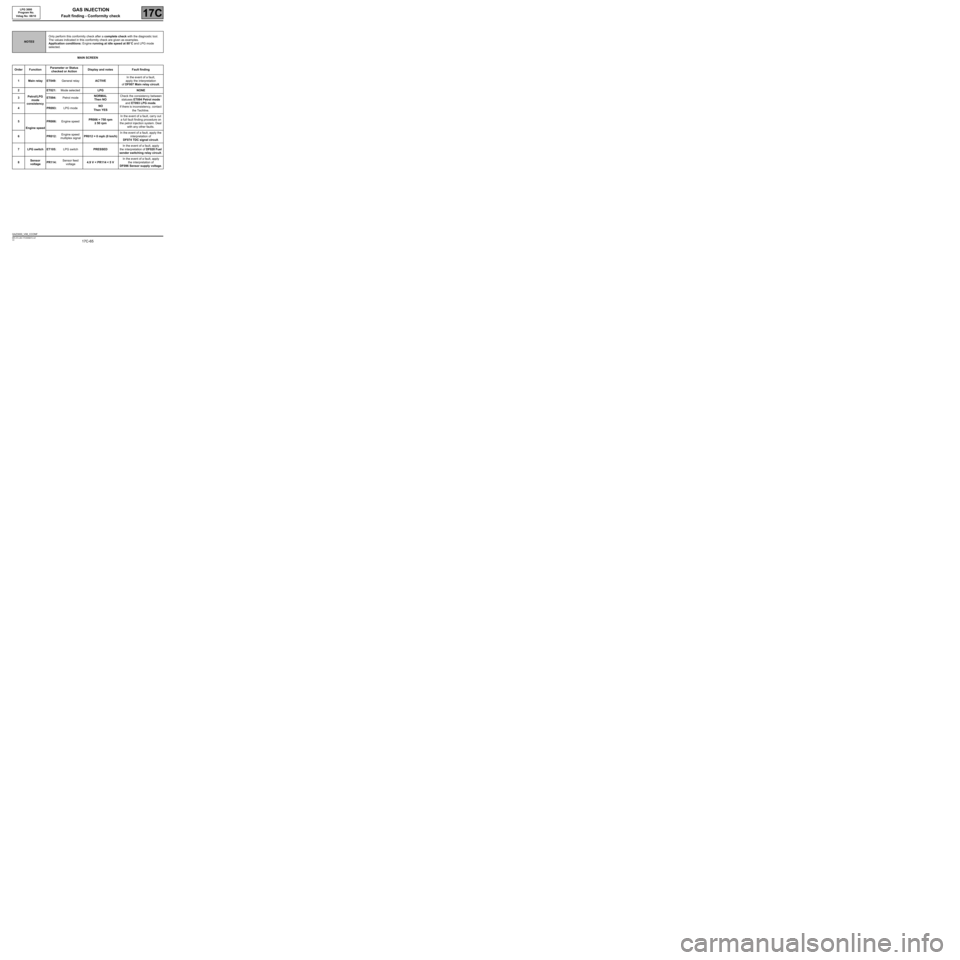

MAIN SCREEN

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values indicated in this conformity check are given as examples.

Application conditions: Engine stopped, ignition on and LPG mode selected.

Order FunctionParameter or Status

checked or ActionDisplay and notes Fault finding

1Main relay ET049:General relayINACTIVEIn the event of a fault,

apply the interpretation

of DF007 Main relay circuit.

2

Petrol/LPG

mode

consistencyET021:Mode selectedLPG NONE

3ET094:Petrol modeNORMALCheck the consistency

between statuses

ET094 Petrol mode

and ET093 LPG mode.

If there is inconsistency,

contact the Techline. 4PR093:LPG modeNO

5

Engine speedPR006:Engine speedPR006 = 0 mph

(0 km/h)In the event of a fault, carry out

a full fault finding procedure on

the petrol injection system.

Deal with any other faults.

6PR012:Engine speed

multiplex signalPR012 = 0 mph

(0 km/h)In the event of a fault,

apply the interpretation

of DF074 TDC signal circuit.

7LPG switch ET105:LPG switchPRESSED

RELEASEDIn the event of a fault, apply

the interpretation

of DF020 Fuel sender

switching relay circuit.

8Sensor voltage PR114:Sensor feed

voltage4.9 V < PR114 < 5 VIn the event of a fault, apply

the interpretation of DF096

Sensor supply voltage.

GAZ3000_V08_CCONF / GAZ3000_V10_CCONF

LPG 3000

Program No.

Vdiag No: 08/10

MR-372-J84-17C000$472.mif

Page 61 of 107

17C-61

MR-372-J84-17C000$472.mif

V2

LPG 3000

Program No.

Vdiag No: 08/10GAS INJECTION

Fault finding - Conformity check17C

SUB-FUNCTION: OPERATION IN LPG MODE (CONTINUED 1)

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values indicated in this conformity check are given as examples.

Application condition: Engine stopped, ignition on and LPG mode selected.

Order FunctionParameter or Status

checked or ActionDisplay and notes Fault finding

5Manifold

pressurePR001:Manifold

pressureIndicates the inlet manifold

vacuum pressure in mb.

PR001 = atmospheric

pressureIn the event of a fault, carry

out a full fault finding

procedure on the petrol

injection system. Deal with

any other faults.

6

LPG pressurePR003:Pressure

difference: LPG/

manifoldCalculation of the

difference between LPG

pressure and manifold

pressure in mb.

PR003 ≈ 800 mbarCheck that:

PR112 - PR001 = PR003

7PR112:LPG pressure

downstream of

expansion valveIndicates the LPG pressure

downstream of the

expansion valve in mb.

PR112 = PR001 + 800 mbarIn the event of a fault, apply

the interpretation of

DF092 Expansion valve

downstream LPG

pressure sensor circuit

and DF017 LPG leak

detection downstream

of expansion valve.

Page 65 of 107

17C-65

MR-372-J84-17C000$472.mif

V2

LPG 3000

Program No.

Vdiag No: 08/10GAS INJECTION

Fault finding - Conformity check17C

MAIN SCREEN

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values indicated in this conformity check are given as examples.

Application conditions: Engine running at idle speed at 80°C and LPG mode

selected.

Order FunctionParameter or Status

checked or ActionDisplay and notes Fault finding

1Main relay ET049:General relayACTIVEIn the event of a fault,

apply the interpretation

of DF007 Main relay circuit.

2

Petrol/LPG

mode

consistencyET021:Mode selectedLPG NONE

3ET094:Petrol modeNORMAL

Then NOCheck the consistency between

statuses ET094 Petrol mode

and ET093 LPG mode.

If there is inconsistency, contact

the Techline. 4PR093:LPG modeNO

Then YES

5

Engine speedPR006:Engine speedPR006 = 750 rpm

± 50 rpmIn the event of a fault, carry out

a full fault finding procedure on

the petrol injection system. Deal

with any other faults.

6PR012:Engine speed

multiplex signalPR012 = 0 mph (0 km/h)In the event of a fault, apply the

interpretation of

DF074 TDC signal circuit.

7LPG switch ET105:LPG switchPRESSED In the event of a fault, apply

the interpretation of DF020 Fuel

sender switching relay circuit.

8Sensor

voltagePR114:Sensor feed

voltage4.9 V < PR114 < 5 VIn the event of a fault, apply

the interpretation of

DF096 Sensor supply voltage.

GAZ3000_V08_CCONF

Page 71 of 107

17C-71

MR-372-J84-17C000$472.mif

V2

LPG 3000

Program No.

Vdiag No: 08/10GAS INJECTION

Fault finding - Conformity check17C

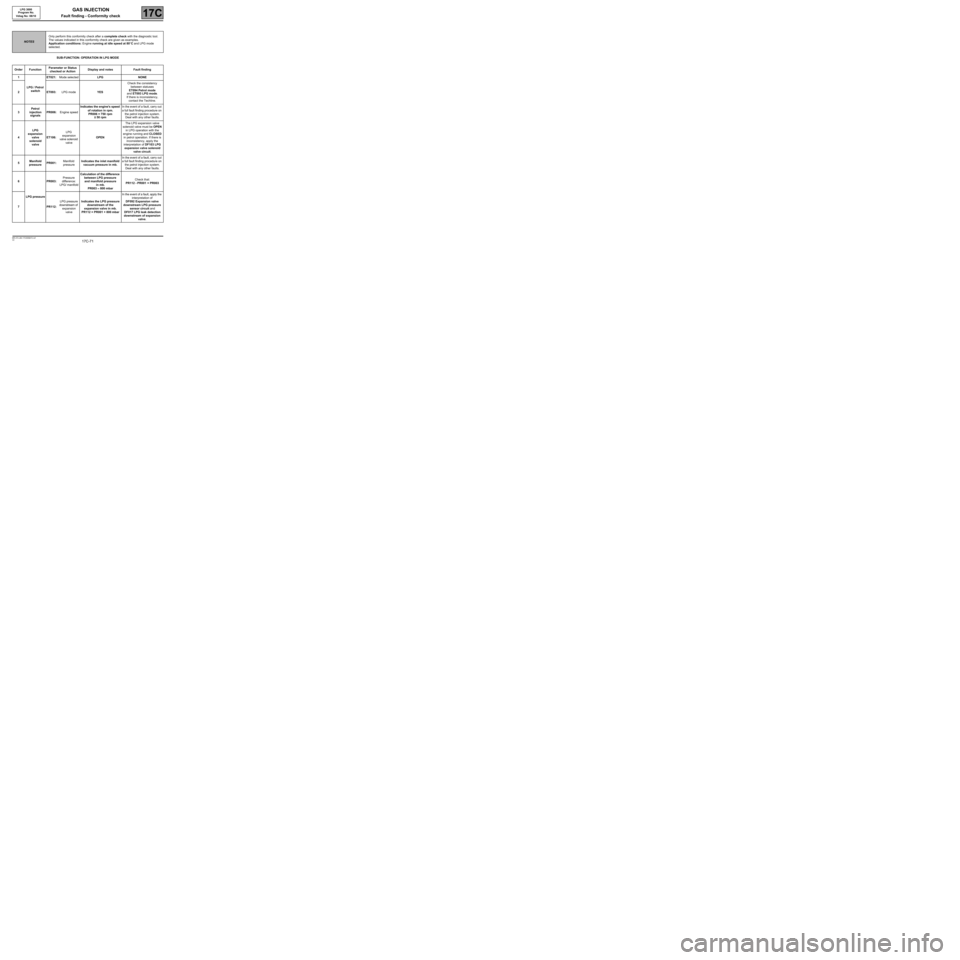

SUB-FUNCTION: OPERATION IN LPG MODE

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values indicated in this conformity check are given as examples.

Application conditions: Engine running at idle speed at 80°C and LPG mode

selected.

Order FunctionParameter or Status

checked or ActionDisplay and notes Fault finding

1

LPG / Petrol

switchET021:Mode selectedLPG NONE

2ET093:LPG modeYESCheck the consistency

between statuses

ET094 Petrol mode

and ET093 LPG mode.

If there is inconsistency,

contact the Techline.

3Petrol

injection

signalsPR006:Engine speedIndicates the engine's speed

of rotation in rpm.

PR006 = 750 rpm

± 50 rpmIn the event of a fault, carry out

a full fault finding procedure on

the petrol injection system.

Deal with any other faults.

4LPG

expansion

valve

solenoid

valveET106:LPG

expansion

valve solenoid

valveOPENThe LPG expansion valve

solenoid valve must be OPEN

in LPG operation with the

engine running and CLOSED

in petrol operation. If there is

inconsistency, apply the

interpretation of DF103 LPG

expansion valve solenoid

valve circuit.

5Manifold

pressurePR001:Manifold

pressureIndicates the inlet manifold

vacuum pressure in mb.In the event of a fault, carry out

a full fault finding procedure on

the petrol injection system.

Deal with any other faults.

6

LPG pressurePR003:Pressure

difference:

LPG/ manifoldCalculation of the difference

between LPG pressure

and manifold pressure

in mb.

PR003 ≈ 800 mbarCheck that:

PR112 - PR001 = PR003

7PR112:LPG pressure

downstream of

expansion

valveIndicates the LPG pressure

downstream of the

expansion valve in mb.

PR112 = PR001 + 800 mbarIn the event of a fault, apply the

interpretation of

DF092 Expansion valve

downstream LPG pressure

sensor circuit and

DF017 LPG leak detection

downstream of expansion

valve.

Page 82 of 107

17C-82

MR-372-J84-17C000$590.mif

V2

GAS INJECTION

Fault finding - Interpretation of statuses

LPG 3000

Program No.

Vdiag No: 08/10

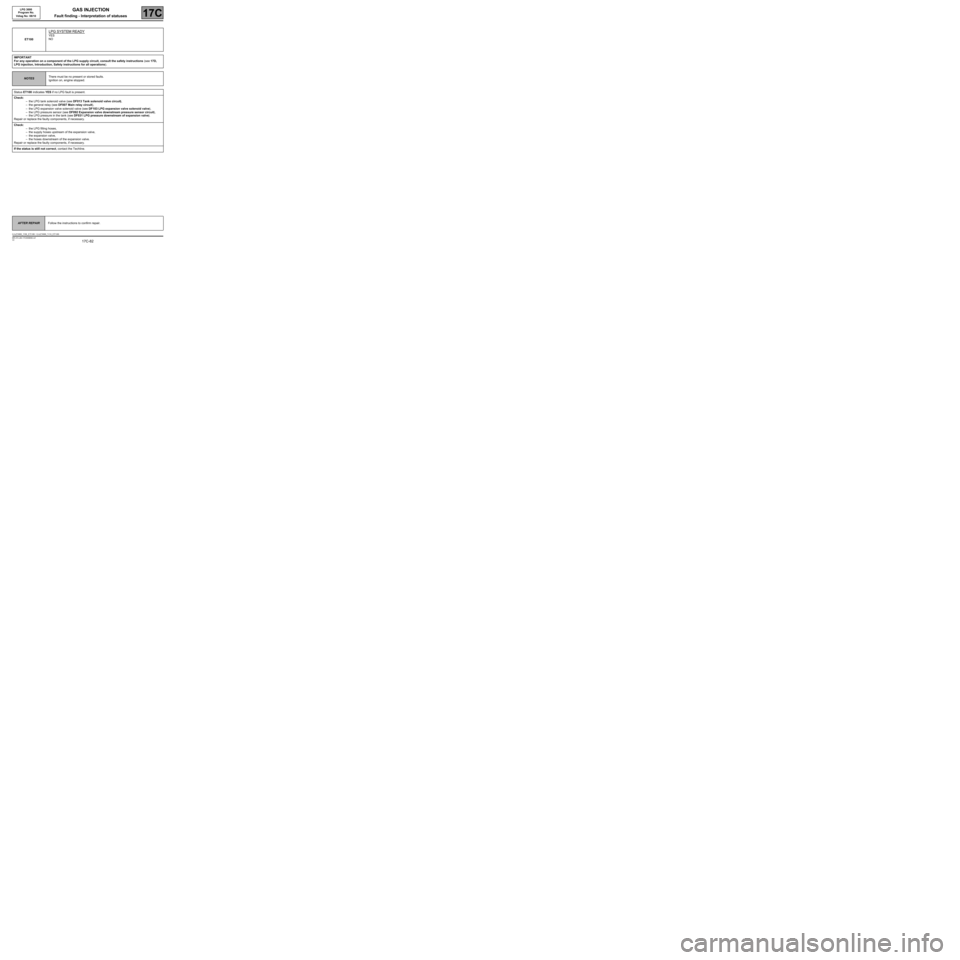

17C

ET100

LPG SYSTEM READY

YES

NO

IMPORTANT

For any operation on a component of the LPG supply circuit, consult the safety instructions (see 17D,

LPG injection, Introduction, Safety instructions for all operations).

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Status ET100 indicates YES if no LPG fault is present.

Check:

–the LPG tank solenoid valve (see DF013 Tank solenoid valve circuit),

–the general relay (see DF007 Main relay circuit),

–the LPG expansion valve solenoid valve (see DF103 LPG expansion valve solenoid valve),

–the LPG pressure sensor (see DF092 Expansion valve downstream pressure sensor circuit),

–the LPG pressure in the tank (see DF031 LPG pressure downstream of expansion valve).

Repair or replace the faulty components, if necessary.

Check:

–the LPG filling hoses,

–the supply hoses upstream of the expansion valve,

–the expansion valve,

–the hoses downstream of the expansion valve.

Repair or replace the faulty components, if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

GAZ3000_V08_ET100 / GAZ3000_V10_ET100

Page 83 of 107

17C-83

MR-372-J84-17C000$649.mif

V2

17C

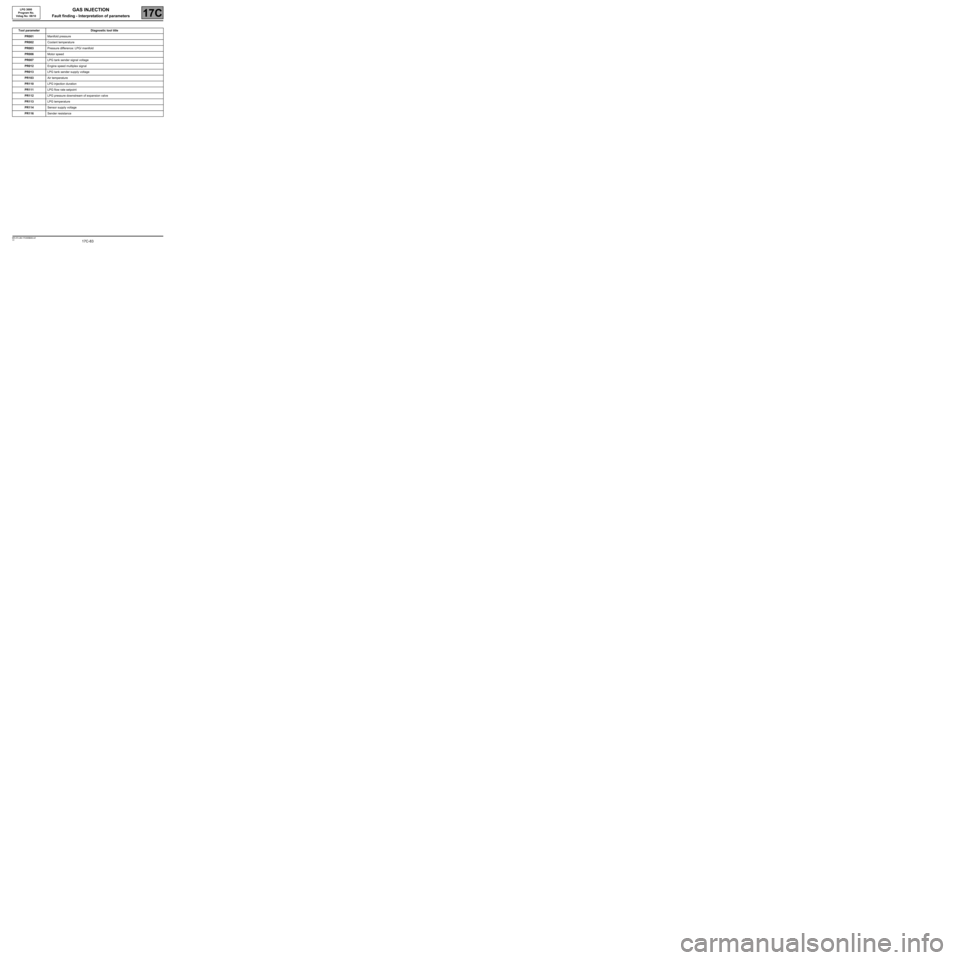

GAS INJECTION

Fault finding - Interpretation of parameters

Tool parameter Diagnostic tool title

PR001Manifold pressure

PR002Coolant temperature

PR003Pressure difference: LPG/ manifold

PR006Motor speed

PR007LPG tank sender signal voltage

PR012Engine speed multiplex signal

PR013LPG tank sender supply voltage

PR103Air temperature

PR110LPG injection duration

PR111LPG flow rate setpoint

PR112LPG pressure downstream of expansion valve

PR113LPG temperature

PR114Sensor supply voltage

PR116Sender resistance

LPG 3000

Program No.

Vdiag No: 08/10

MR-372-J84-17C000$649.mif

Page 84 of 107

17C-84

MR-372-J84-17C000$708.mif

V2

17C

GAS INJECTION

Fault finding - Interpretation of parameters

PR003

PRESSURE DIFFERENCE: LPG/ MANIFOLD

IMPORTANT

For an operation on a component of the LPG supply circuit, consult the safety instructions (see 17D,

Gas injection, Introduction, Safety instructions for all operations).

NOTESThere must be no present or stored faults.

Engine running in LPG mode.

Check that the pressure difference is 800 mbar.

Check the consistency in pressure difference using parameters PR001 Manifold pressure, PR003 Pressure

difference: LPG/manifold and PR112 LPG pressure downstream of expansion valve and ensure that

PR003 = PR112 - PR001.

If the fault is still present, manipulate the wiring harness between the manifold pressure sensor and the LPG

pressure/temperature sensor in order to produce a change in status.

Check the connection and condition of the manifold pressure sensor and the LPG pressure / temperature

sensor, and its connections.

If necessary, repair or replace the connector.

If the pressure difference is still inconsistent, apply the interpretation of fault DF031 LPG pressure downstream

of expansion valve.

If the fault is still present, replace the LPG pressure/temperature sensor (see MR 364 Mechanical, 17D,

LPG injection).

If the fault is still present, check the manifold pressure sensor by testing the Petrol computer (see 17B,

Petrol injection, Interpretation of faults).

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

GAZ3000_V08_PR003 / GAZ3000_V10_PR003

LPG 3000

Program No.

Vdiag No: 08/10

MR-372-J84-17C000$708.mif