check engine RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 149 of 431

13B-149

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF228

CONTINUED 2

Check the brake pedal switch connections and the engine management computer connections.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the condition and adjustment of the brake-pedal switch. Repair if necessary.

Check for + 12 V after ignition feed on the connections of the brake pedal switch connector and the condition of

the fuse.

– Connection code AP10 of component 160.

– Connection code SP13 of component 160.

Check the continuity and insulation against + 12 V and against earth of the following connection:

– Connection code 5A between components 160 and 120/645/119.

Check that the brake pedal switch is working correctly:

in rest position: infinite resistance continuity between the following connections:

– Connection code 5A of component 160.

– Connection code SP13 of component 160.

depressed: continuity between the following connections:

– Connection code 5A of component 160.

– Connection code SP13 of component 160.

Replace the switch if necessary.

A

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 150 of 431

13B-150

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF232

PRESENT

OR

STOREDREFRIGERANT PRESSURE SENSOR CIRCUIT

CC.0: Short circuit to earth

CO.1: Open circuit or short circuit to +12 V

NOTESPriority when dealing with a number of faults:

If DF012 Sensor feed voltage no. 2 is present or stored:

– deal with it first,

– fan assembly GMV1 activated (low-speed),

– heating and air conditioning system inhibited.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Check the condition of the refrigerant pressure sensor connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 1202) and ensure that it is operating correctly.

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

– connection codes 38U, 38X, 38Y between components 1202 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

•3XU between components 120 and 1288,

•3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

EDC16C36_V44_DF232/EDC16C36_V4C_DF232/EDC16C36_V48_DF232/EDC16C36_V50_DF232/EDC16C36_V54_DF232/

EDC16C36_V58_DF232EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 151 of 431

13B-151

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF249

PRESENT

OR

STOREDINJECTOR CONTROL

1.DEF: Internal electronic fault

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on,

– the engine is started.

Priority when dealing with a number of faults:

Deal with faults DF046 Battery voltage, DF026 Injector cylinder 1 control circuit,

DF027 Injector cylinder 2 control circuit, DF028 Injector cylinder 3 control circuit

and DF029 Injector cylinder 4 control circuit first if they are present or stored.

Special notes:

In some cases if the fault is present, the level 2 warning light illuminates and the engine

stops.

Use bornier Elé.1681 for all operations on the engine management computer.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF249/EDC16C36_V4C_DF249/EDC16C36_V48_DF249/EDC16C36_V50_DF249/EDC16C36_V54_DF249/

EDC16C36_V58_DF249EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 152 of 431

13B-152

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF249

CONTINUED

This fault appears when the computer detects a fault on the injector control section

Check the condition of the injector connectors (see Wiring Diagram Technical Note, Mégane II ph2, Scénic II

ph2, Component codes 193, 194, 195, 196).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and insulation of the following connections:

– Connection code 3KW between components 193 and 120.

– Connection code 3CR between components 193 and 120.

– Connection code 3KX between components 194 and 120.

– Connection code 3CS between components 194 and 120.

– Connection code 3KY between components 195 and 120.

– Connection code 3CT between components 195 and 120.

– Connection code 3KZ between components 196 and 120.

– Connection code 3CU between components 196 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 153 of 431

13B-153

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF272

PRESENT

OR

STOREDEGR VALVE CONTROL CIRCUITCO: Open circuit

CC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

CC: Short circuit

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on.

– the engine is started,

– a road test.

Special notes:

If the fault is present:

–the European On Board Diagnostic warning light is lit,

– there is smoke from the exhaust.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

For EGR valves with a flat connector, it is not possible to check the sensor resistance.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF272/EDC16C36_V4C_DF272/EDC16C36_V48_DF272/EDC16C36_V50_DF272/EDC16C36_V54_DF272/

EDC16C36_V58_DF272EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 154 of 431

13B-154

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF272

CONTINUED 1

CONOTESNone.

Check the condition of the connector of the EGR valve (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, Component code 1460).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity of the following connections:

– Connection code 3VP between components 1460 and 120.

– Connection code 3VQ between components 1460 and 120.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

EGR valve with a square connector:

Measure the resistance of the EGR valve between the following connections:

– Connection code 3VP of component 1460.

– Connection code 3VQ of component 1460.

EGR valve with a flat connector:

Replace the EGR valve.

Replace the valve if the resistance is not between 1 Ω

reinitialise the EGR valve offsets (see Replacement of components).

If the fault is still present, contact the Techline.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 155 of 431

13B-155

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF272

CONTINUED 2

CC.0

CC.1NOTESNone.

Check the condition of the connector of the EGR valve (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, Code organe1460).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation from + 12 V of the following connections:

– Connection code 3VP between components 1460 and 120.

– Connection code 3VQ between components 1460 and 120.

Check the insulation against +5 V (computer supplies) of the following connections:

– Connection code 3VP between components 1460 and 120.

– Connection code 3VQ between components 1460 and 120.

Check the insulation against earth of the following connections:

– Connection code 3VP between components 1460 and 120.

– Connection code 3VQ between components 1460 and 120.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

EGR valve with a square connector:

Measure the resistance of the EGR valve between the following connections:

– Connection code 3VP of component 1460.

– Connection code 3VQ of component 1460.

EGR valve with a flat connector:

– Replace the EGR valve.

Replace the valve if the resistance is not between 1 Ω

and select EGR valve to

reinitialise the EGR valve offsets (see Replacement of components).

If the fault is still present, contact the Techline.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 156 of 431

13B-156

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF272

CONTINUED 3

CCNOTESNone.

Check the condition of the connector of the EGR valve (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, Component code 1460).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation between the following connections:

– Connection code 3VP between components 1460 and 120.

– Connection code 3VQ between components 1460 and 120.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

EGR valve with a square connector:

Measure the resistance of the EGR valve between the following connections:

– Connection code 3VP of component 1460.

– Connection code 3VQ of component 1460.

EGR valve with a flat connector:

– Replace the EGR valve.

Replace the valve if the resistance is not between 1 Ω

reinitialise the EGR valve offsets (see Replacement of components).

If the fault is still present, contact the Techline.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 157 of 431

13B-157

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF276

PRESENT

OR

STOREDINJECTOR CODE PROGRAMMING

1.DEF: No code stored

2.DEF: Internal electronic fault during programming

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the ignition has been switched on.

Special notes:

If the fault is present,

– torque limited, engine speed limited to 1500 rpm,

– engine torque limited,

–the level 1 warning light is illuminated.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

1.DEF

2.DEF

NOTESThis fault appears:

– when an incorrect injector code has been entered using

command SC002 Enter injector codes,

– after replacing the injection computer,

– after (re)programming.

EDC16C36_V44_DF276/EDC16C36_V4C_DF276/EDC16C36_V48_DF276/EDC16C36_V50_DF276/EDC16C36_V54_DF276/

EDC16C36_V58_DF276EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 159 of 431

13B-159

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

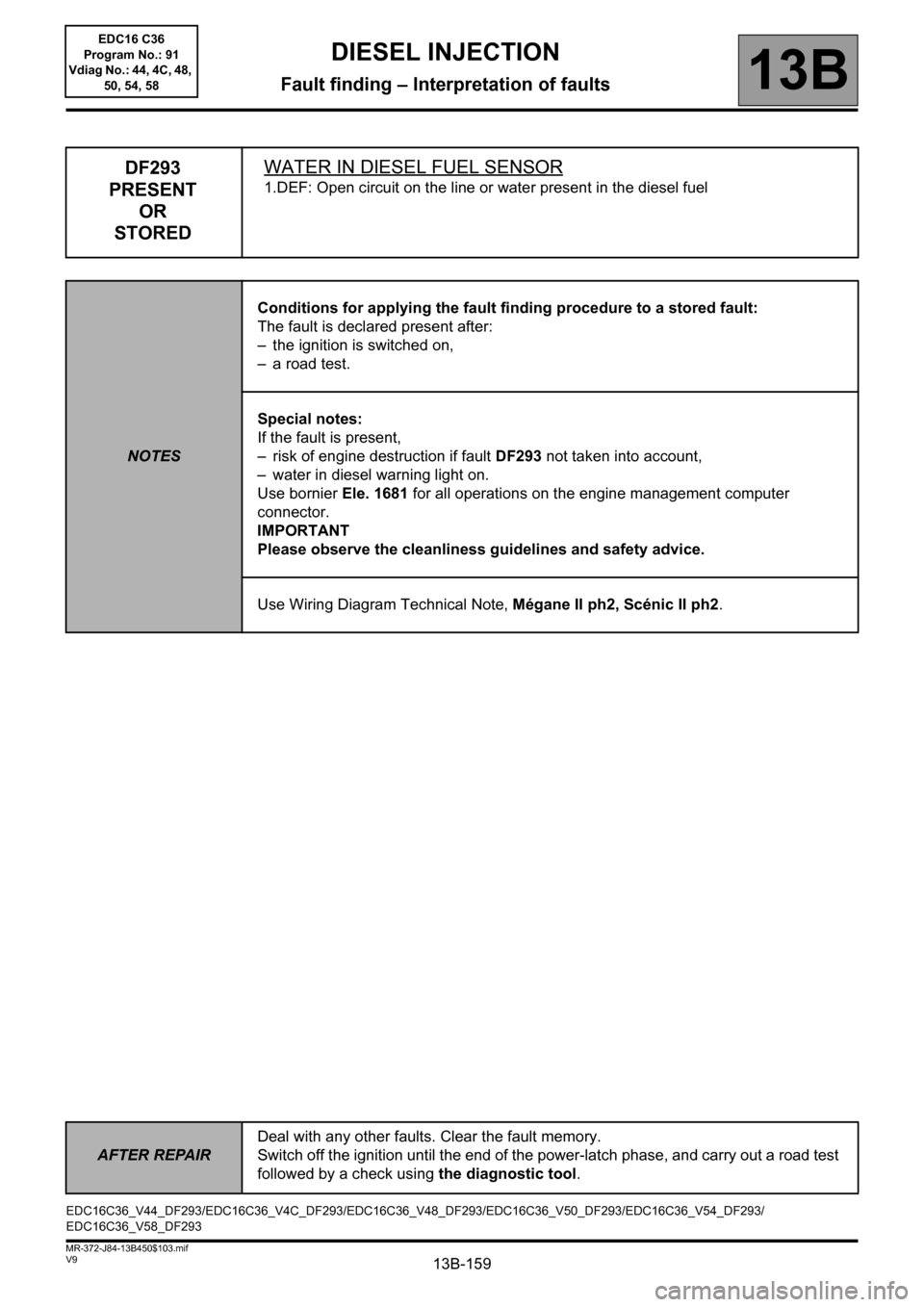

DF293

PRESENT

OR

STOREDWATER IN DIESEL FUEL SENSOR

1.DEF: Open circuit on the line or water present in the diesel fuel

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on,

– a road test.

Special notes:

If the fault is present,

– risk of engine destruction if fault DF293 not taken into account,

– water in diesel warning light on.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

IMPORTANT

Please observe the cleanliness guidelines and safety advice.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF293/EDC16C36_V4C_DF293/EDC16C36_V48_DF293/EDC16C36_V50_DF293/EDC16C36_V54_DF293/

EDC16C36_V58_DF293EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58