check engine RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Manual PDF

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 108 of 431

13B-108V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF065

CONTINUED

DF065 appears on the diagnostic tool when the engine management computer has detected a fault during the

combustion phase several times in succession.

Several components may be responsible:

– the piston rings,

– the piston,

– the valves,

– the injector,

– the heater plug sealing.

Check that the stored injector codes are consistent with those engraved on each injector. If not, run command

SC002 Enter injector codes, and follow the procedure.

When dealing with a number of misfiring faults, check the fuel conformity by running test 11 Diesel fuel

conformity check.

Check the engine compressions.

Carry out the necessary repairs.

If the fault is still present, apply test 10: Incorrect injector operation.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 109 of 431

13B-109V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF069

PRESENT

OR

STOREDIMPACT DETECTED SIGNAL

1.DEF: Impact stored by the injection computer

NOTESConditions for applying the fault finding procedure to stored faults:

Only apply the interpretation of this fault if the fault is present and the vehicle will not

start.

Special notes:

The fault appears when the injection computer receives a frontal impact signal from the

Airbag computer via the multiplex network.

As soon as the injection computer receives this signal:

– engine operation is prohibited,

–the level 2 warning light is lit.

Use bornier Elé. 1681 or Elé. 1590 for any operation on the injection computer

connectors.

If the vehicle has been involved in an accident:

Carry out any necessary repairs,

– clear the fault,

– switch off the ignition,

–wait for 1 minute,

– switch on the ignition.

If the fault does not reappear, end of fault finding procedure.

If the fault recurs, run fault finding on the AIRBAG computer.

If the vehicle has not been involved in an accident:

Run fault finding on the AIRBAG computer (see 88C, Airbag and pretensioner).

EDC16C36_V44_DF069/EDC16C36_V4C_DF069/EDC16C36_V48_DF069/EDC16C36_V50_DF069/EDC16C36_V54_DF069/

EDC16C36_V58_DF069

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 110 of 431

13B-110V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF086

PRESENT

OR

STOREDCOOLANT PUMP RELAY CONTROL CIRCUITCC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

CO: Open circuit

1.DEF: Internal electronic fault

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition has been switched off and after waiting

for 1 minute,

Or after an actuator control AC195 Electric coolant pump.

Special notes:

The control relay is located in the engine connection unit.

If the fault is present:

– turbocharger reliability compromised,

– coolant reliability compromised,

–the level 1 warning light is lit.

Use bornier Elé. 1681 or Elé. 1590 for any operation on the

injection computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V44_DF086/EDC16C36_V4C_DF086/EDC16C36_V48_DF086/EDC16C36_V50_DF086/EDC16C36_V54_DF086/

EDC16C36_V58_DF086

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 111 of 431

1 3 B - 111V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF086

CONTINUED

CO.0NOTESNone.

Check the condition of the electric coolant pump relay connector (A 20A) (see Wiring Diagram Technical Note

for Mégane II ph2, Scénic II ph2, component code 573) and check that it operates correctly.

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

– connection codes 32A and 32B between components 688 and 1337,

– connection codes 47Q and 115A between components 688 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check for connection code M earth on the turbocharger bearing coolant pump component code 369.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 112 of 431

13B-112V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF091

PRESENT

OR

STOREDVEHICLE SPEED SIGNAL

1.DEF: Vehicle speed too high.

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after a road test.

Special notes:

– engine torque limited,

– the cruise control/speed limiter function is inhibited,

The vehicle speed signal sent by the ABS computer to the injection computer is greater

than the threshold defined in the calibration.

Use bornier Elé.1681 for any operations on the injection computer connectors.

Check the condition of the ABS computer connector (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, component Code 118 or 1094).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run full fault finding on the ABS (see 38C Anti-lock braking system).

Repair if necessary.

Run complete fault finding on the multiplex network (see 88B, Multiplexing).

Repair if necessary.

If the fault is still present, contact the Techline.

EDC16C36_V44_DF091/EDC16C36_V4C_DF091/EDC16C36_V48_DF091/EDC16C36_V50_DF091/EDC16C36_V54_DF091/

EDC16C36_V58_DF091

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 113 of 431

13B-113V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF098

PRESENT

OR

STOREDFUEL TEMPERATURE SENSOR CIRCUIT

CC.0: Short circuit to earth

CO.1: Open circuit or short circuit to +12 V

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on.

– Engine running

Special notes:

If the fault is present:

– the fuel temperature safe value PR063 Fuel temperature = 100°C.

Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

CC.0

NOTESNone.

Check the condition of the fuel temperature sensor connector (see Wiring Diagram Technical Note, Mégane II

ph2, Scénic II ph2, component code 1066).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Measure the resistance of the fuel temperature sensor between the following connections:

– Connection code 3FAB of component 1066.

– Connection code 3LD of component 1066.

Replace the sensor if resistance is less than 85Ω or greater than 50 kΩ.

EDC16C36_V44_DF098/EDC16C36_V4C_DF098/EDC16C36_V48_DF098/EDC16C36_V50_DF098/EDC16C36_V54_DF098/

EDC16C36_V58_DF098

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 114 of 431

13B-114V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF098

CONTINUED

Check the insulation to earth of the following connection:

– Connection code 3FAB between components 1066 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

•3XU between components 120 and 1288,

•3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

CO.1

NOTESNone.

Check the condition of the fuel temperature sensor connector (see Wiring Diagram Technical Note, Mégane II

ph2, Scénic II ph2, component code 1066).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair) repair the wiring, otherwise replace it.

Measure the resistance of the fuel temperature sensor between the following connections:

– Connection code 3FAB of component 1066.

– Connection code 3LD of component 1066.

Replace the sensor if resistance is less than 85Ω or greater than 50 kΩ.

Check the continuity and insulation to + 12 V on the following connections:

– Connection code 3FAB between components 1066 and 120.

– Connection code 3LD between components 1066 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 115 of 431

13B-115V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF107

PRESENT

OR

STOREDCOMPUTER MEMORY

1.DEF: Internal electronic fault

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the ignition has been switched on

Special notes:

The level 1 and European On Board Diagnostic warning lights are lit.

Use bornier Elé.1681 for any operations on the injection computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

If the fault is stored, clear the fault from the computer memory.

– Switch off the ignition and wait for the diagnostic tool message (maximum time 8minutes) Communication

lost with computer: EDC16 C36, check the tool connection and computer power supply before switching

the ignition back on.

Start the engine and re-establish dialogue.

This fault may be linked to a write error following disconnection of the battery when the computer was in the

process of writing to the EEPROM phase (computer memory).

If this is the case, loading a new calibration will remove the fault.

If a more recent calibration is available, load this calibration on to the computer.

If the fault is still present:

– use the command RZ034 Computer memory,

– Switch off the ignition and wait for the computer dialogue lost message,

– switch on the ignition again,

– define the injector codes using the control SC002 Enter injector codes.

– Run the programming commands (See configuration and programming),

– switch off the ignition and wait for the message loss of communication with the computer.

Perform a road test to reinitialise the vehicle parameters.

EDC16C36_V44_DF107/EDC16C36_V4C_DF107/EDC16C36_V48_DF107/EDC16C36_V50_DF107/EDC16C36_V54_DF107/

EDC16C36_V58_DF107

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 116 of 431

13B-116V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF107

CONTINUED

Only for F9Q816:

If the vehicle is not new (mileage greater than 10 km):

Check that there are no leaks or blockages in the exhaust pipe,

Repair if necessary

– Do an after-sales regeneration using the control SC017 Particle filter regeneration.

– Perform an oil change (see MR 364 (Mégane II) or MR 370 (Scénic II), Mechanical, 10A Engine and

peripherals, Engine oil: Draining – Filling).

If the fault is still present, contact the Techline.

Page 117 of 431

13B-117V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

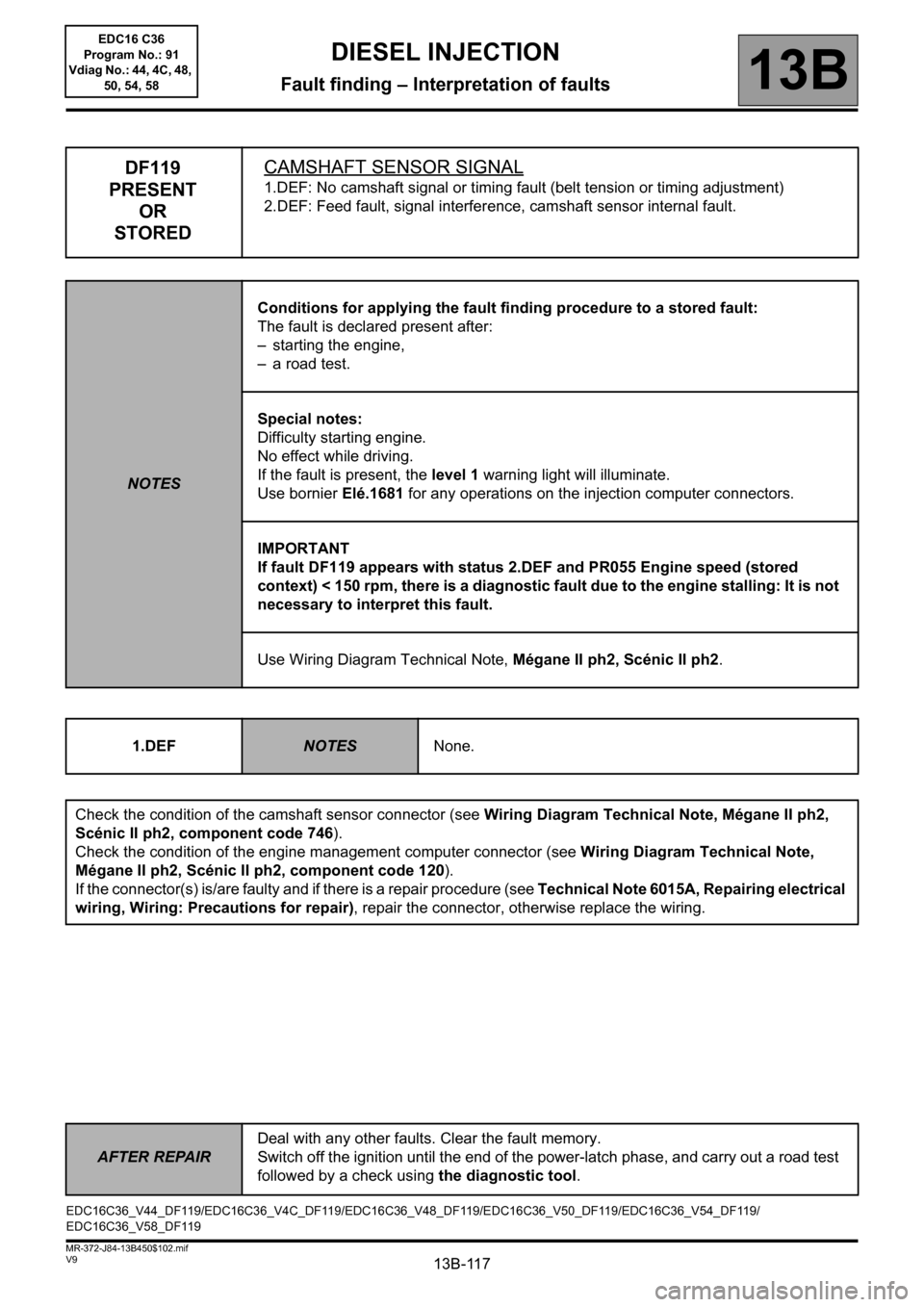

DF119

PRESENT

OR

STOREDCAMSHAFT SENSOR SIGNAL

1.DEF: No camshaft signal or timing fault (belt tension or timing adjustment)

2.DEF: Feed fault, signal interference, camshaft sensor internal fault.

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– starting the engine,

– a road test.

Special notes:

Difficulty starting engine.

No effect while driving.

If the fault is present, the level 1 warning light will illuminate.

Use bornier Elé.1681 for any operations on the injection computer connectors.

IMPORTANT

If fault DF119 appears with status 2.DEF and PR055 Engine speed (stored

context) < 150 rpm, there is a diagnostic fault due to the engine stalling: It is not

necessary to interpret this fault.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

1.DEF

NOTESNone.

Check the condition of the camshaft sensor connector (see Wiring Diagram Technical Note, Mégane II ph2,

Scénic II ph2, component code 746).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector(s) is/are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

EDC16C36_V44_DF119/EDC16C36_V4C_DF119/EDC16C36_V48_DF119/EDC16C36_V50_DF119/EDC16C36_V54_DF119/

EDC16C36_V58_DF119

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58