RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Owner's Manual

Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 21 of 329

13B-21

MR-372-J84-13B050$195.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Function13B

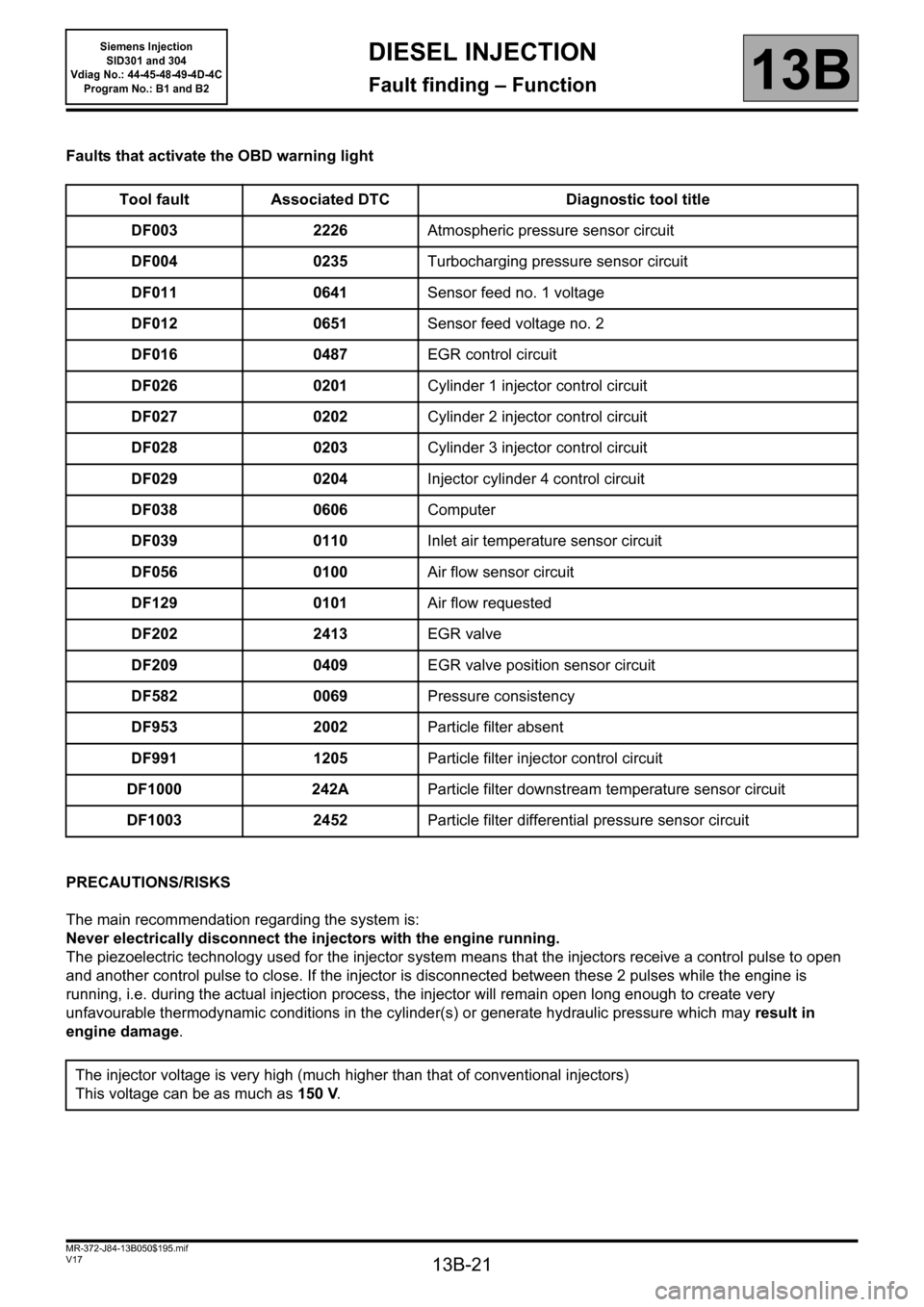

Faults that activate the OBD warning light

PRECAUTIONS/RISKS

The main recommendation regarding the system is:

Never electrically disconnect the injectors with the engine running.

The piezoelectric technology used for the injector system means that the injectors receive a control pulse to open

and another control pulse to close. If the injector is disconnected between these 2 pulses while the engine is

running, i.e. during the actual injection process, the injector will remain open long enough to create very

unfavourable thermodynamic conditions in the cylinder(s) or generate hydraulic pressure which may result in

engine damage. Tool fault Associated DTC Diagnostic tool title

DF003 2226Atmospheric pressure sensor circuit

DF004 0235Turbocharging pressure sensor circuit

DF011 0641Sensor feed no. 1 voltage

DF012 0651Sensor feed voltage no. 2

DF016 0487EGR control circuit

DF026 0201Cylinder 1 injector control circuit

DF027 0202Cylinder 2 injector control circuit

DF028 0203Cylinder 3 injector control circuit

DF029 0204Injector cylinder 4 control circuit

DF038 0606Computer

DF039 0110Inlet air temperature sensor circuit

DF056 0100Air flow sensor circuit

DF129 0101Air flow requested

DF202 2413EGR valve

DF209 0409EGR valve position sensor circuit

DF582 0069Pressure consistency

DF953 2002Particle filter absent

DF991 1205Particle filter injector control circuit

DF1000 242AParticle filter downstream temperature sensor circuit

DF1003 2452Particle filter differential pressure sensor circuit

The injector voltage is very high (much higher than that of conventional injectors)

This voltage can be as much as 150 V.

Page 22 of 329

13B-22

MR-372-J84-13B050$195.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Function13B

High pressure pump:

The pump draws in fuel from the tank, which passes through a fuel filter and supplies the fuel injectors.

Rail pressure sensor:

This sensor is fitted to the rail and shows the pressure inside the rail.

Rail pressure regulator:

This component regulates the high pressure of the fuel in the injection system.

Fuel flow regulator:

This component regulates the fuel flow of the injection system.

Fuel temperature sensor:

This sensor measures the temperature of the fuel arising from the pump and injector return.

Piezoelectric injectors:

These injectors enable rapid, precise metering of the quantity of fuel injected, with excellent injection process

repetitiveness.

Vacuum pump:

The vacuum pump is driven by the camshaft. The pump provides the vacuum required to operate the following

components: control solenoid valve, brake servo.

Control solenoid valve:

The solenoid valve connects the vacuum pump and the control diaphragm of the turbocharger blades.

Turbocharger:

The turbocharger is used to supply the engine with more air.

Intake air pressure sensor:

This sensor measures the pressure at the turbocharging air cooler output before the damper valve.

Turbocharger pressure sensor:

This sensor measures the pressure at the turbocharging air cooler output before the damper valve.

Air mass flow meter:

The flowmeter measures the amount of fresh air which goes back into the engine.

EGR valve:

The exhaust gas recirculation enables nitrogen oxide (NOx) emissions to be reduced significantly.

EGR position sensor:

The sensor gives the position of the EGR solenoid valve.

Damper valve (Vdiag 44, 45, 48, 49 and 4D only):

The damper valve is used:

– During regeneration in order to control the flow of fresh air.

– When the engine is switched off, to dampen the engine which helps stop the engine.

– When inoperative, the damper valve is by default in the fully open position.

Particle filter:

The particle filter retains the particles for destruction during regeneration, avoiding propagation of these particles in

the atmosphere (Vdiag 45, 49, 4D only).

Page 23 of 329

13B-23

MR-372-J84-13B050$195.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Function13B

TDC sensor:

The angular position is measured using a magneto-inductive sensor triggered by machined teeth on the flywheel.

This sensor gives the engine speed and the position of the crankshaft for injection.

Camshaft sensor:

This sensor gives a signal to perform the injection cycle. When the piston of cylinder 1 is at top dead centre, either at

the end of the compression stroke or at the end of the exhaust stroke, the camshaft sensor enables a distinction to

be made between these two states.

Electric coolant pump:

The electric coolant pump is activated when the coolant temperature has reached a significant temperature

threshold when the engine has stopped.

The role of the electric water pump is to cool the turbocharger when the engine stops (Vdiag 45, 49 only).

Refrigerant pressure sensor:

The role of the sensor is to measure the refrigerant fluid pressure in the air conditioning circuit.

Electric fuel pump:

The pump is controlled by a relay during each regeneration or purge phase; it is submerged in the tank and is

connected to the secondary fuel circuit only.

Coolant temperature sensor:

The engine coolant temperature sensor informs the computer about the engine coolant temperature.

Air temperature sensor:

The air temperature sensor is fitted in the inlet manifold and informs the computer about the temperature of the air

sucked up by the engine.

Turbocharging pressure sensor solenoid valve:

This solenoid valve operates the turbocharger wastegate pneumatic circuit to lower the turbocharging pressure.

Catalytic converter:

Its role is to convert pollutant gases into harmless gases.

Catalytic converter downstream temperature sensor:

This sensor gives the temperature of the exhaust gas at the catalytic converter output.

Turbine upstream temperature sensor:

This sensor gives the temperature of the exhaust gas at the turbine inlet.

Particle filter downstream temperature sensor:

This sensor gives the exhaust gas temperature at the particle filter outlet (Vdiag 45, 49, 4D only).

Particle filter upstream temperature sensor:

This sensor gives the exhaust gas temperature at the particle filter inlet (Vdiag 45, 49, 4D only).

Particle filter differential pressure sensor:

A differential pressure sensor monitors the status of the particle filter (particle weight) and triggers regeneration.

The role of the sensor is to inform the computer of the pressure difference between particle filter inlet and outlet

(Vdiag 45, 49, 4D only).

Page 24 of 329

13B-24

MR-372-J84-13B050$195.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Function13B

Cruise control/speed limiter on/off switch:

This switch turns the cruise control/speed limiter on or off.

Water in diesel fuel sensor (optional):

This sensor indicates if water is present in the diesel.

Fan unit relay:

This relay actuates the motor-driven fan assemblies when a temperature threshold has been exceeded.

Accelerator potentiometer:

The accelerator potentiometer informs the computer about the position of the accelerator pedal (engine load).

Brake pedal switch:

The brake pedal switch informs the computer about the pedal status.

Clutch pedal switch:

The clutch pedal switch informs the computer about the pedal status.

Particle filter injector:

The particle filter injector is a low pressure injector. This injector allows the temperature of the second catalytic

converter to be raised to assist with regeneration of the particle filter (Vdiag 45, 49, 4D only).

Only on Kangoo 2: an evaporator plate is present at the particle filter injector outlet, at the level of the bracket

between the exhaust pipe and the catalytic converter.

Heating elements:

The heating elements heat the engine coolant to enhance user comfort (Vdiag 45, 49, 4D only).

Heater plugs:

The heater plugs preheat the combustion chamber so that the explosion of the fuel mixture occurs under the best

conditions to start the engine.

Page 25 of 329

13B-25

MR-372-J84-13B050$234.mif

V17

13B

DIESEL INJECTION

Fault finding – Defect and safe modes

DEFECT MODES:

Accelerator pedal defect mode (Limp-home):

This defect mode prevents an immobilising fault; the vehicle can be driven well enough for it to reach the nearest

dealer.

This function provides a virtual driver demand which controls the engine speed at 1800 rpm for each gear engaged,

then limits the vehicle's speed to 48 mph (80 km/h).

The idle speed is equal to the idle speed setpoint if the brake pedal is depressed, otherwise the idle speed is

set to 1800 rpm to ensure the vehicle pulls away in all conditions.

MR-372-J84-13B050$234.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

Page 26 of 329

13B-26

MR-372-J84-13B050$273.mif

V17

13B

DIESEL INJECTION

Fault finding – Replacement of components

COMPUTER REPROGRAMMING OPERATIONS

The system can be reprogrammed via the diagnostic socket using the RENAULT CLIP diagnostic tool (see

Technical Note 3585A, Computer programming and reprogramming procedure).

Note:

Before reprogramming the injection computer, move the main Cruise control - Speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational. The procedure for resetting the function is as

follows:

– Vehicle ignition on.

– Main switch in rest position (the computer then detects the rest position).

– Switch in Cruise control position to activate the Cruise control function.

– Switch in Speed limiter position to activate the Speed limiter function.

While the computer is being reprogrammed the fan assemblies are triggered automatically.

Before reprogramming the computer:

– Save the computer data to the diagnostic tool (engine adaptives) by performing command SC003 Save

computer data.

After any computer reprogramming operation:

– Switch the ignition off and then on again,

–Use the diagnostic tool to carry out the following procedures:

– run command RZ019 Programming reinitialisation.

– run command SC001 Write saved data to restore the engine adaptives,

– run command SC013 Enter VIN,

– start the engine (warning: the start-up phase may last up to 30 seconds),

– after injection computer reprogramming, stored faults may appear in other computers. Clear the fault memory of

these computers,

– carry out a road test followed by another check with the diagnostic tool.

DO NOT CARRY OUT ANY INJECTOR CODE WRITING ON THE SIEMENS SID304 AND 301 INJECTION

SYSTEMS.IMPORTANT

Switch on the diagnostic tool (mains or cigarette lighter supply).

Connect a battery charger.

Switch off all the electrical consumers (lights, interior lighting, air conditioning, radio CD, etc.).

Wait for the engine to cool (engine coolant temperature < 60 °C and air temperature < 50 °C).

MR-372-J84-13B050$273.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4CProgram No.: B1 and B2

Page 27 of 329

13B-27

MR-372-J84-13B050$273.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Replacement of components13B

If no communication is possible with the injection computer during reprogramming or programming:

●Clear the programming using command RZ019 Reinitialise programming.

●Clear any faults using command RZ001 Fault memory.

●Enter the V.I.N. using command SC013 Enter VIN code.

●Perform a powerlatch.

●Perform a detection of the cruise control - speed limiter and the air conditioning:

– Vehicle ignition on.

– Main switch in rest position (the computer then detects the rest position).

– Switch in Cruise control position to activate the Cruise control function.

– Switch in Speed limiter position to activate the Speed limiter function.

– Air conditioning in the ON position.

●For Kangoo II, program the values for fast idle speed (if equipped) and vehicle speed restriction (if equipped)

using commands SC041 Modification of commercial vehicle idle speed and SC040 Speed limiter.

●For Vdiag 45, 49 and 4D, carry out a particle filter regeneration using command SC017 Particle filter

regeneration (see Interpretation of commands).

●For Clio III, Modus, Megane II and Scenic II vehicles:

– If the configuration reading LC106 O.C.S. is" WITH" (check in the instrument panel computer), perform

an engine oil change and initialise the value of the oil service interval using the instrument panel.

●For Kangoo II:

– Change the engine oil and initialise the value of the oil change interval using the instrument panel.

IMPORTANT

The injection computer retains the immobiliser code for life.

The system has no security code.

It is forbidden to perform tests with computers borrowed from the Parts Department or from another vehicle

which must then be returned.

These computers are hard-coded.

If the injection computer is faulty, contact the Techline (and refer to the fault finding log).

Page 28 of 329

13B-28

MR-372-J84-13B050$273.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Replacement of components13B

COMPUTER REPLACEMENT AND PROGRAMMING OPERATIONS

The system can be programmed via the diagnostic socket using the RENAULT CLIP diagnostic tool (see

Technical Note 3585A, Computer programming and reprogramming procedure).

While the computer is being programmed the fan assemblies are triggered automatically.

Before any replacement and programming of the computer:

– When possible, back up the old computer data (engine adaptives) in the diagnostic tool, by performing

command SC003 "Computer data backup".

After the computer has been programmed:

– Switch the ignition off and then on again.

– Use the diagnostic tool to carry out the following procedures:

– Run command RZ019 Reinitialise programming.

– Run command SC001 Write saved data to restore the engine adaptives,

– Start the engine. Important: the starting phase can last up to 30 seconds.

– Stop the engine (to initialise the computer) and wait 30 seconds.

– Switch on the ignition again and use the diagnostic tool to carry out the following steps:

– Run command SC013 Enter VIN code.

– After the injection has been programmed, stored faults may appear on other computers.

– Clear the fault memory of these computers.

– Carry out a road test followed by a complete check with the diagnostic tool.

After the computer has been programmed:

– Switch the ignition off and then on again.

– Use the diagnostic tool to carry out the following procedures:

– Use command RZ019 Reinitialise programming.

– Use command SC001 Write saved data to restore the engine adaptives.

– Select the UCH field,

– In the repair mode, perform command SC017 Programming injection immobiliser code and follow the

indications provided by the diagnostic tool (command SC017 Programming injection immobiliser code is

accessible in the menu "Secure programming").

– Switch the ignition off and then on again.

– Select the INJECTION field and check ET006 Code programmed.

If ET006 is "YES":

– Start the engine. Important: the starting phase can last up to 30 seconds.

– Stop the engine (to initialise the computer) and wait 30 seconds.

– Switch on the ignition again and use the diagnostic tool to carry out the following steps:

– Perform command SC013 Enter VIN code.

– After the injection has been programmed, stored faults may appear on other computers.

Clear the fault memory of these computers.

If ET006 is: "NO":

– Rerun command SC017 Programming injection immobiliser code and follow the instructions provided by the

diagnostic tool.

– Repeat the method described above.IMPORTANT

– Switch on the diagnostic tool (mains or cigarette lighter supply).

– Connect a battery charger.

– Switch off all the electrical consumers (lights, interior lighting, air conditioning, radio CD, etc.).

– Wait for the engine to cool (engine coolant temperature < 60 °C and air temperature < 50 °C).

Page 29 of 329

13B-29

MR-372-J84-13B050$273.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Replacement of components13B

REPLACING THE EGR VALVE (EXHAUST GAS RECIRCULATION VALVE)

After replacing the EGR valve, the computer must store the offset of the new valve (to 0 km), as well as the offset

measured at the time of the last engine cut-off (power-latch). With these data, the computer can detect clogging or

blocking of the EGR valve.

When the valve is replaced, clear the stored offsets so that the program uses the new valve’s offset value. The data

associated with this programming is combined under the EGR programming function.

Procedure to follow after replacement of the EGR valve:

– Select the CLEAR menu.

– Run fault clearing command RZ002 EGR adaptives,

– switch off the ignition,

–wait 30 seconds (auto-supply phase of the computer),

– start the vehicle to allow programming of the EGR valve,

– view parameters PR400 New EGR valve offset and PR129 Last EGR valve offset,

– if the reinitialisation was correctly performed then 0.6 V < PR400 = PR129 < 1.9 V.

REPLACEMENT OF PUMP, INJECTORS, RAIL + RAIL PRESSURE SENSOR OR COMPONENT OF THE LOW

PRESSURE CIRCUIT (DIESEL FILTER etc.).

After replacement of one of these components, carry out clearing using RZ004 Pressure regulation adaptives.

REPLACEMENT OF THE PARTICLE FILTER (Only Vdiag 45, 49, 4D)

After replacement of the particle filter, clear the fault DF308 Clogged particle filter if it is present or stored using

command RZ001 Fault memory. IMPORTANT

It is not possible to try an injection computer coming from the Parts Department because it will no longer be

possible to use it on another vehicle.

Page 30 of 329

13B-30

MR-372-J84-13B050$312.mif

V17

13B

DIESEL INJECTION

Fault finding – Configurations and programming

SPECIAL COMMANDS

SC001: Write saved data.

Use this command after replacing or (re)programming the computer (if the data has been saved using command

SC003).

SC003: Save computer data.

This command enables the computer operating data, the engine adaptives, to be recorded.

Use this command before replacing or (re)programming a computer.

SC013: Enter VIN.

This command permits manual entry of the vehicle's VIN into the computer.

Use this command each time the computer is replaced or (re)programmed.

SC017: Particle filter regeneration.

The regeneration command is used to burn particles which have accumulated in the filter.

Run this command when the particle filter is clogged.

SC040: Speed limiter (Kangoo II only).

This command enables the vehicle's speed to be restricted to a certain speed.

Use this command at the customer's request.

SC041: Modification of the commercial vehicle idle speed (Kangoo II only).

This command enables the idle speed for vehicles such as refrigerated vehicles, ambulances etc. to be increased or

decreased.

CONFIGURATION READING

LC005: Gearbox type.

Manual gearbox or automatic transmission/sequential gearbox

LC009: Air conditioning.

With or without.

LC065: Water in diesel fuel sensor.

With or without.

LC120: Cruise control.

With or without.

LC121: Speed limiter.

With or without.

MR-372-J84-13B050$312.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2