warning RENAULT TWINGO 2009 2.G Engine And Peripherals Owners Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 388 of 652

13B-27

DIESEL INJECTION

Flow actuator: Removal - Refitting

K9K

13B

aClean the diesel pipe unions on the high pressure

pump (see 13B, Diesel injection, Diesel injection:

Precautions for the repair, page 13B-1) .

aUnclip the fuel supply pipes at (2) .

aDisconnect the high pressure pump from:

-the diesel supply pipe (3) ,

-the diesel return pipe (4) to the diesel filter.

aRemove the high pressure pump pipes.aUnclip the neck at (5) .

aRemove the neck wiring harness.

aRemove:

-the neck nut (6) ,

-the neck.

aClean the high pressure pipe unions (7) between the

rail and injector number 4 (see 13B, Diesel injec-

tion, Diesel injection: Precautions for the repair,

page 13B-1) .

121423

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

To prevent impurities from entering the circuit,

plugs must be fitted to the openings of all the fuel

circuit components exposed to the open air.121419

121418

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to r un.

Page 389 of 652

13B-28

DIESEL INJECTION

Flow actuator: Removal - Refitting

K9K

13B

aRemove:

-the clip (8) from the high pressure pipes between

the rail and injectors number 3 and 4,

-the high pressure pipe between the rail and injector

number 4 and discard it.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the bolts (9) from the fuel flow actuator on

the high pressure pump.

aRemove the fuel flow actuator (by hand with small

tugs and successive turns).

aMake sure that no impurities enter the high pressure

pump when the fuel flow actuator is removed.

102315

WARNING

To prevent impurities from entering the circuit,

plugs must be fitted to the openings of all the fuel

circuit components exposed to the open air.

102315

WARNING

Do not use the electr ical connector as a lever

ar m.

WARNING

Do not blast with compressed air once the fuel

circuit is open, otherwise impurities may enter

the system. Only use cleaning cloths.

Page 390 of 652

13B-29

DIESEL INJECTION

Flow actuator: Removal - Refitting

K9K

13B

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a

aFit the fuel flow actuator onto the high pressure

pump.

aTighten the fuel flow actuator bolts on the high pres-

sure pump until contact is made, without tightening

them.

aTorque tighten the fuel flow actuator bolts on the

high pressure pump (6 Nm).II - FINAL OPERATION.

a

aFit a new high pressure pipe between the rail and in-

jector number 4.

aFit the high pressure pipe unions between the rail

and injector number 4 until contact is made, without

tightening them.

aFit and lock a new clip between the high pressure

pipes on the rail and injectors number 3 and 4.

aUsing the (Mot. 1746), tighten to torque:

-the high pressure pipe unions between the rail

and injector number 4 (yellow) (24 Nm),

-the high pressure pipe unions between the rail

and injector number 4 (silver) (28 Nm).

aRefit:

-the channel,

-the neck nut.

aFit the neck wiring harness.

aClip the neck on. WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

Note:

Do not lubricate the seals with grease or old die-

sel fuel. Use the applicator provided in the kit for

the new part.

20960

WARNING

Before fitting a new high pressure pipe, lightly

lubricate the nut threads with the oil from the

applicator provided in the new parts kit.

Be careful not to allow oil into the high pressure

pipe.

Do not lubricate high pressure pipes supplied

without an applicator, as these high pressure

pipes are self-lubr icating.

Page 392 of 652

13B-31

DIESEL INJECTION

Venturi: Removal - Refitting

K9K

13B

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aConsumable:

-cleaning cloths (Part no. 77 11 211 707).

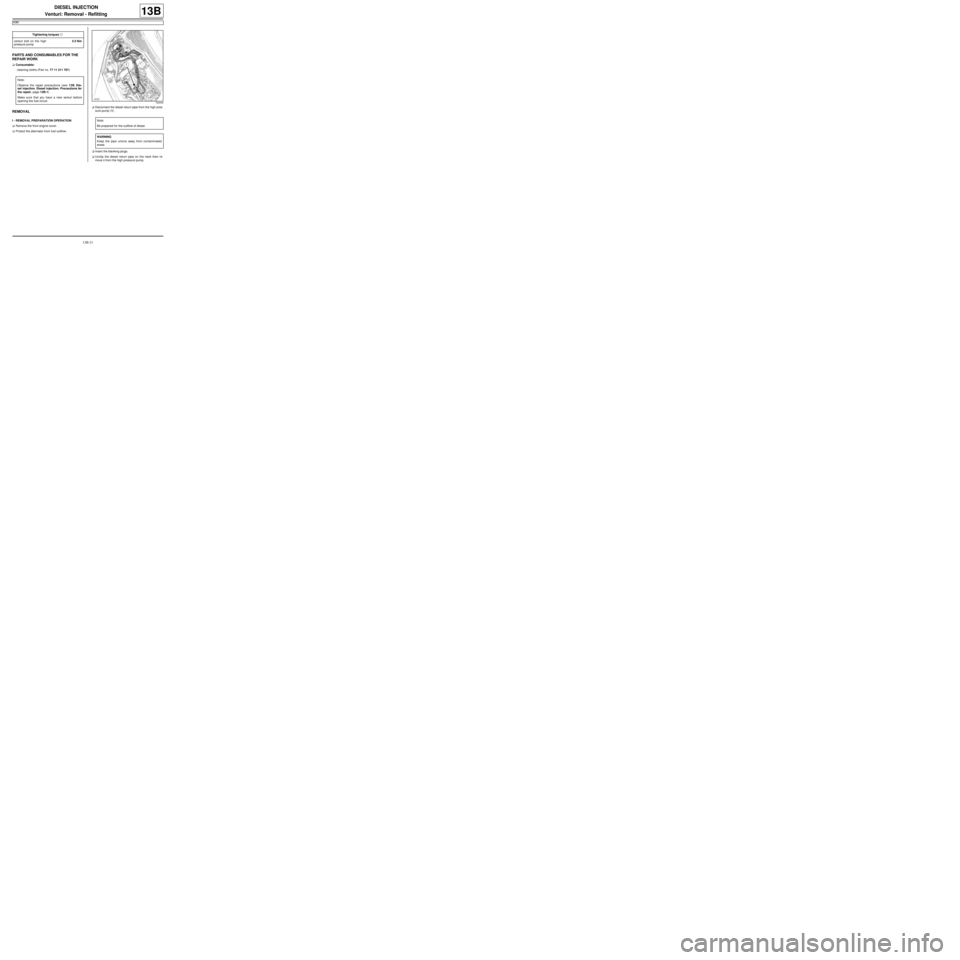

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the front engine cover.

aProtect the alternator from fuel outflow.aDisconnect the diesel return pipe from the high pres-

sure pump (1) .

aInsert the blanking plugs.

aUnclip the diesel return pipe on the neck then re-

move it from the high pressure pump. Tightening torquesm

venturi bolt on the high

pressure pump5.5 Nm

Note:

Observe the repair precautions (see 13B, Die-

sel injection, Diesel injection: Precautions for

the repair, page 13B-1) .

Make sure that you have a new venturi before

opening the fuel circuit.

120045

Note:

Be prepared for the outflow of diesel.

WARNING

Keep the pipe unions away from contaminated

areas.

Page 393 of 652

13B-32

DIESEL INJECTION

Venturi: Removal - Refitting

K9K

13B

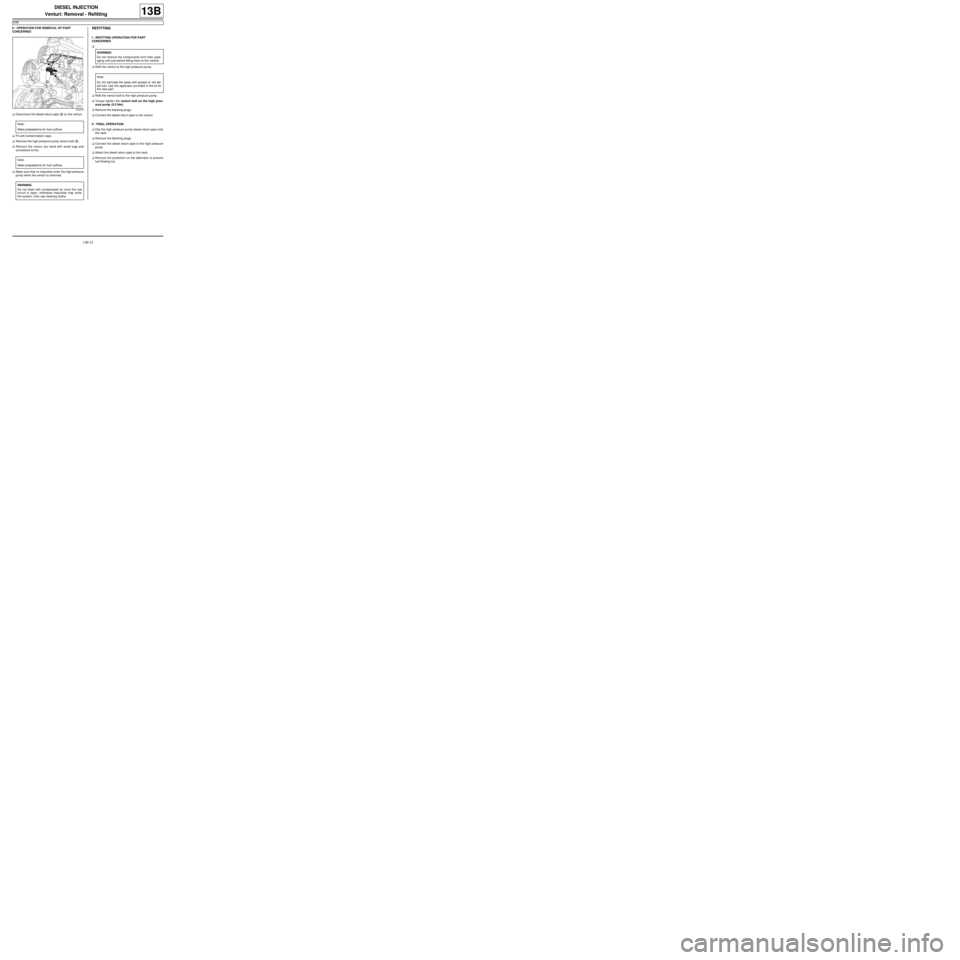

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the diesel return pipe (2) on the venturi.

aFit anti-contamination caps.

aRemove the high pressure pump venturi bolt (3) .

aRemove the venturi (by hand with small tugs and

successive turns).

aMake sure that no impurities enter the high pressure

pump when the venturi is removed.REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a

aRefit the venturi to the high pressure pump.

aRefit the venturi bolt to the high pressure pump.

aTorque tighten the venturi bolt on the high pres-

sure pump (5.5 Nm).

aRemove the blanking plugs.

aConnect the diesel return pipe to the venturi.

II - FINAL OPERATION.

aClip the high pressure pump diesel return pipe onto

the neck.

aRemove the blanking plugs.

aConnect the diesel return pipe to the high pressure

pump.

aAttach the diesel return pipe to the neck.

aRemove the protection on the alternator to prevent

fuel flowing out.

102316

Note:

Make preparations for fuel outfl ow.

Note:

Make preparations for fuel outfl ow.

WARNING

Do not blast with compressed air once the fuel

circuit is open, otherwise impurities may enter

the system. Only use cleaning cloths.

WARNING

Do not remove the components from their pack-

aging until just before fitting them to the vehicle.

Note:

Do not lubricate the seals with grease or old die-

sel fuel. Use the applicator provided in the kit for

the new par t.

Page 397 of 652

13B-36

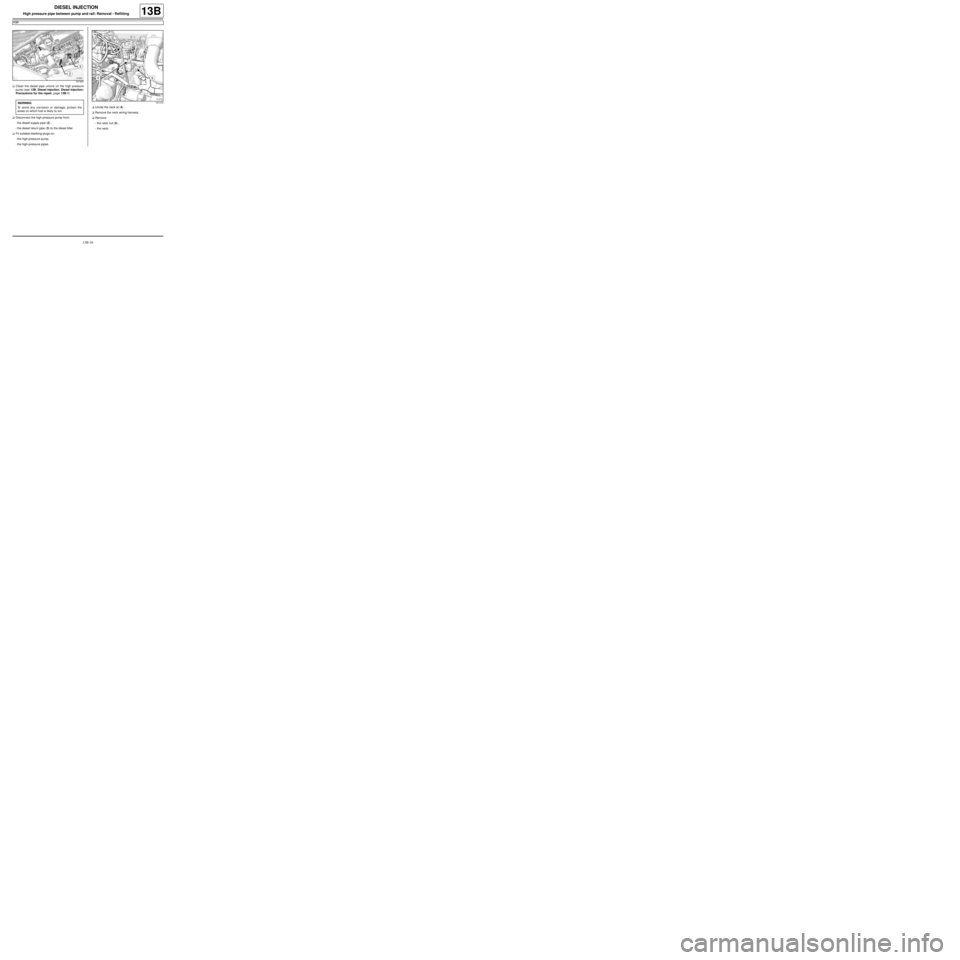

DIESEL INJECTION

High pressure pipe between pump and rail: Removal - Refitting

K9K

13B

aClean the diesel pipe unions on the high pressure

pump (see 13B, Diesel injection, Diesel injection:

Precautions for the repair, page 13B-1) .

aDisconnect the high pressure pump from:

-the diesel supply pipe (2) ,

-the diesel return pipe (3) to the diesel filter.

aFit suitable blanking plugs on:

-the high pressure pump,

-the high-pressure pipes.aUnclip the neck at (4) .

aRemove the neck wiring harness.

aRemove:

-the neck nut (5) ,

-the neck.

121423

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.121419

Page 398 of 652

13B-37

DIESEL INJECTION

High pressure pipe between pump and rail: Removal - Refitting

K9K

13B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aClean the high pressure pipe unions (6) between the

pump and the rail (see 13B, Diesel injection, Die-

sel injection: Precautions for the repair, page

13B-1) .

aRemove the high pressure pipe (6) between the

pump and the rail and discard it.

aFit suitable blanking plugs on:

-the high pressure pump,

-the injector rail.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aII - REFITTING OPERATION FOR PART

CONCERNED

a

aFit a new high pressure pipe between the pump and

the rail.

aScrew on the high pressure pipe unions between the

pump and the rail without tightening them until con-

tact is made.

aUsing the (Mot. 1746), tighten to torque:

-the high pressure pipe unions between the

pump and the yellow rail (24 Nm),

-the high pressure pipe unions between the

pump and the silver rail (28 Nm).

III - FINAL OPERATION.

aRefit:

-the channel,

-the neck nut.

aFit the neck wiring harness.

121419

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

Only remove the blanking plugs from the pro-

tected components at the last possible moment.

Also, do not remove the components from their

packaging until just before fitting them to the

vehicle.

20960

WARNING

Before fitting a new high pressure pipe, lightly

lubricate the nut threads with oil from the applica-

tor provided in the new par t.

Be careful not to allow oil into the high pressure

pipe.

Do not lubricate high pressure pipes supplied

without an applicator; these pipes are self-lubri-

cating.

Page 400 of 652

13B-39

DIESEL INJECTION

High pressure pipe between rail and injector: Removal - Refitting

K9K

13B

PARTS AND CONSUMABLES FOR THE REPAIR

Pièces à remplacer systématiquement :

-the high pressure pipes between the rail and the in-

jectors.

Ingrédients :

-cleaning cloths,

-set of K9K blanking plugs (injection DELPHI).

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove the front engine cover.aRemove:

-the dipstick,

-the dipstick guide nut (1) ,

-the oil level dipstick guide.

aBlock the dipstick guide inlet opening on the cylinder

block.

aDisconnect the connectors:

-the heater plugs,

-the injectors,

-the flow actuator,

-diesel fuel temperature sensor.

aProtect the alternator and the starter from fuel out-

flow. Special tooling required

Mot. 1746Offset wrench for tightening

High Pressure pump pipes.

Equipment required

Diagnostic tool

Tightening torquesm

high pressure pipe

unions between the

pump and the yellow rail24 Nm

high pressure pipe

unions between the

pump and the silver rail28 Nm

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 13B, Diesel injection, Diesel injec-

tion: Precautions for the repair, page 13B-1) .

WARNING

Obtain the special high pressure injection circuit

blanking plugs kit.

Always replace any high pressure pipe or high pres-

sure pipe clip removed with a new one.

114527

Page 401 of 652

13B-40

DIESEL INJECTION

High pressure pipe between rail and injector: Removal - Refitting

K9K

13B

aClean the diesel pipe unions on the high pressure

pump (see 13B, Diesel injection, Diesel injection:

Precautions for the repair, page 13B-1) .

aDisconnect from the high pressure pump:

-the diesel supply pipe (2) ,

-the diesel return pipe (3) to the diesel filter.aUnclip the neck at (4) .

aRemove the neck wiring harness.

aRemove:

-the neck nut (5) ,

-the neck.

121423

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

To prevent impurities from entering the circuit,

plugs must be fitted to the openings of all the fuel

circuit components exposed to the open air.121419

Page 402 of 652

13B-41

DIESEL INJECTION

High pressure pipe between rail and injector: Removal - Refitting

K9K

13B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aClean the high pressure pipe unions (6) between the

rail and the injectors (see 13B, Diesel injection,

Diesel injection: Precautions for the repair, page

13B-1) .

aRemove then dispose of:

-the clips between the high pressure pipes,

-the high pressure pipes (6) between the rail and the

injectors.REFITTING

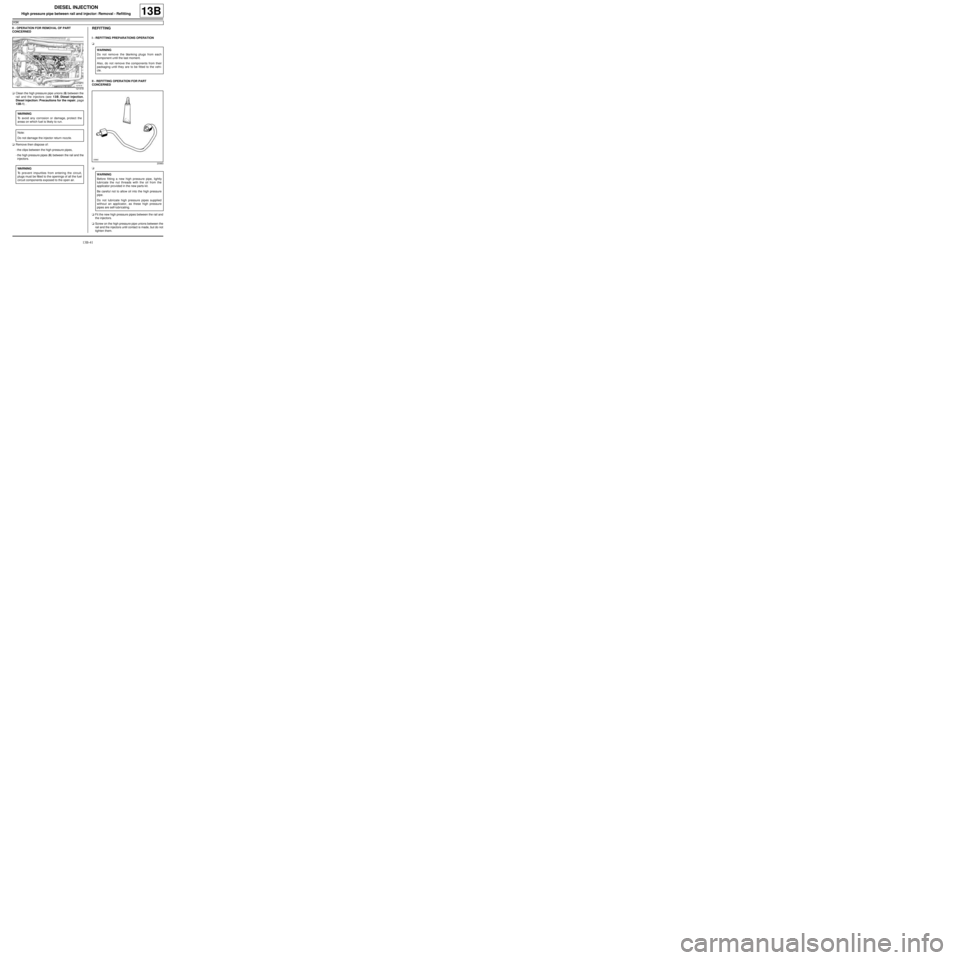

I - REFITTING PREPARATIONS OPERATION

a

II - REFITTING OPERATION FOR PART

CONCERNED

a

aFit the new high pressure pipes between the rail and

the injectors.

aScrew on the high pressure pipe unions between the

rail and the injectors until contact is made, but do not

tighten them.

121418

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

Note:

Do not damage the injector return nozzle.

WARNING

To prevent impurities from entering the circuit,

plugs must be fitted to the openings of all the fuel

circuit components exposed to the open air.

WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

20960

WARNING

Before fitting a new high pressure pipe, lightly

lubricate the nut threads with the oil from the

applicator provided in the new parts kit.

Be careful not to allow oil into the high pressure

pipe.

Do not lubricate high pressure pipes supplied

without an applicator, as these high pressure

pipes are self-lubr icating.