warning RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 441 of 652

16A-2

STARTING - CHARGING

Alternator: Removal - Refitting

D4F or D7F, and STANDARD HEATING

16A

aRemove:

-the filler neck bolt (1) ,

-the filler neck in the direction of the arrow (2) ,

-the dipstick.

aDisconnect the fuel pipe (3) from the injector rail.II - REMOVAL OPERATION FOR PART

CONCERNED

aDisconnect the connector (4) from the alternator wir-

ing harness.

aRemove:

-the alternator wiring harness nut (5) ,

-the alternator bolts,

-the alternator.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aClean the alternator pulley V-grooves to remove any

deposits. D4F, and 780

122392

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear latex gloves during the operation.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

109727

Page 446 of 652

16A-7

STARTING - CHARGING

Alternator: Removal - Refitting

K4M

16A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

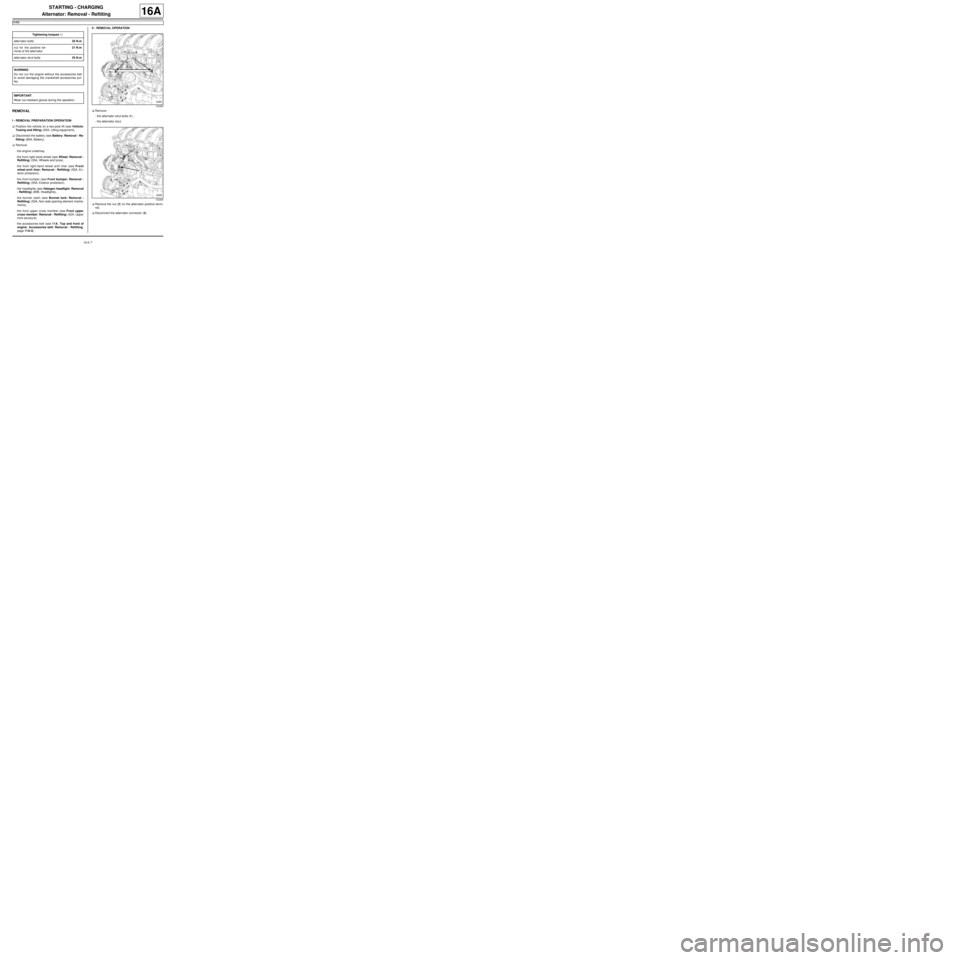

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .II - REMOVAL OPERATION

aRemove:

-the alternator strut bolts (1) ,

-the alternator strut.

aRemove the nut (2) on the alternator positive termi-

nal.

aDisconnect the alternator connector (3) . Tightening torquesm

alter nator bolts25 N.m

nut for the positive ter-

minal of the alternator21 N.m

alter nator strut bolts25 N.m

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

IMPORTANT

Wear cut-resistant gloves during the operation.

132363

132365

Page 457 of 652

17A-1

IGNITION

Coils: Removal - Refitting

D7F

17A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aConsumable (see Vehicle: Parts and consuma-

bles for the repair) :

-Fluostar 2L.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery ( (see Battery: Removal -

Refitting) ).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aDisconnect:

-the wiring (1) from the ignition coil,

-the connector (2) from the ignition coil.

aRemove the bolt from the interference suppressor.

aMove aside the air filter unit cover (3) .

aRemove:

-the bolts (4) from the ignition coil,

-the ignition coil.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the ignition coil,

-the ignition coil bolts.

aRefit the air filter unit cover.

120404

WARNING

To disconnect the spark plug leads, pull on the

extensions and not on the leads.

Page 459 of 652

17A-3

IGNITION

Coils: Removal - Refitting

D4F, and 772

17A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aConsumable (see Vehicle: Parts and consuma-

bles for the repair) :

-Fluostar 2L.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) .

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aDisconnect:

-the ignition coil high voltage wiring harness,

-the ignition coil connector.aRemove:

-the ignition coil bolts ,

-the ignition coil.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the ignition coil,

-the ignition coil bolts.

120300

WARNING

To disconnect the spark plug leads, pull on the

extensions and not on the leads.

113044

Page 468 of 652

17A-12

IGNITION

Plugs: Removal - Refitting

D7F

17A

Spark plug electrode gap

REMOVAL

OPERATION FOR REMOVAL OF PART

CONCERNED

a

aDisconnect the spark plug wiring.

aRemove the spark plugs using the (Ele. 1933)

equipped with the (Ele. 1382-01).

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck and, if necessary, correct the spark plug elec-

trode gaps using a set of feeler gauges. Special tooling required

Ele. 193323 N.m tightening wrench for

spar k plugs

Ele. 1382-0114 mm Plug spanner.

Tightening torquesm

spar k plugs23 N.m

Type of spark plug Gap (mm)

EYQUEM 0.90 ± 0.05

WARNING

To disconnect the spark plug leads, pull on the

extensions and not on the leads.

121730

Page 470 of 652

17A-14

IGNITION

Plugs: Removal - Refitting

D4F, and 780 – D4F, and 782

17A

Spark plug electrode gap

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air filter box cover bolts (1) .

aRemove the air filter box cover and the air filter box

air inlet pipe.II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

Disconnect the spark plug ignition wiring harnesses

(5) .

aRemove the spark plugs using the (Ele. 1933)

equipped with the (Ele. 1382-01).

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck and, if necessary, correct the spark plug elec-

trode gaps using a set of feeler gauges. Special tooling required

Ele. 193323 N.m tightening wrench for

spar k plugs

Ele. 1382-0114 mm Plug spanner.

Equipment required

set of feeler gauges

Tightening torquesm

spar k plugs23 N.m

Type of spark plug Gap (mm)

NGK 0.65 ± 0.05

122836

120958

WARNING

To disconnect the spark plug leads, pull on the

extensions and not on the leads.

Page 473 of 652

17A-17

IGNITION

Plugs: Removal - Refitting

D4F, and 772

17A

Spark plug electrode gap

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .a

Disconnect the spark plug wiring.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the spark plugs using the (Ele. 1933) (1)

equipped with the (Ele. 1382-01) (2) . Special tooling required

Ele. 193323 N.m tightening wrench for

spar k plugs

Ele. 1382-0114 mm Plug spanner.

Equipment required

set of feeler gauges

Tightening torquesm

spar k plugs23 N.m

Type of spark plug Gap (mm)

CHAMPION 0.90 ± 0.05

NGK 0.85 ± 0.05

132677

WARNING

To disconnect the spark plug leads, pull on the

extensions and not on the leads.

132700

Page 488 of 652

17B-13

PETROL INJECTION

Oxygen sensors: Removal - Refitting

D4F, and 772 – D7F

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).II - REMOVING THE UPSTREAM OXYGEN SENSOR

aDisconnect the upstream oxygen sensor connector

(1) .

aRemove the upstream oxygen sensor (2) using a

24mm open-ended spanner.

III - REMOVING THE DOWNSTREAM OXYGEN

SENSOR

aDisconnect the downstream oxygen sensor connec-

tor.

aRemove the downstream oxygen sensor (3) using a

24mm open-ended spanner. Equipment required

open-ended spanner

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice causes the oxygen

sensor to malfunction and results in failure to com-

ply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair)(Technical

Note 6015A, 88A, Wiring).

121732

120415

Page 490 of 652

17B-15

PETROL INJECTION

Oxygen sensors: Removal - Refitting

D4F, and 780 or 782

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

1 - Removing the upstream oxygen sensor

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .aDisconnect the upstream oxygen sensor connector

(1) .

aUnclip the upstream oxygen sensor connector from

the rocker cover.

aUnclip the upstream oxygen sensor wiring (2) .

aRemove:

-the bolts (3) from the exhaust manifold heat shield,

-the turbocharger heat shield,

-the upstream oxygen sensor (4) from the catalytic

converter using the tool (Mot. 1495-01). Special tooling required

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

Tightening torquesm

upstream oxygen sen-

sor45 N.m

turbocharger heat shield

bolts8 N.m

downstream oxygen

sensor45 N.m

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice causes the oxygen

sensor to malfunction and results in failure to com-

ply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical

Note 6015A, 88A, Wiring).

120957

120957

Page 492 of 652

17B-17

PETROL INJECTION

Oxygen sensors: Removal - Refitting

K4M

17B

REMOVING THE UPSTREAM OXYGEN

SENSOR

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the engine undertray.

II - REMOVAL OPERATION

aDisconnect the upstream oxygen sensor connector

(1) .

aUnclip the wiring from the upstream oxygen sensor

at (2) .

aRemove the upstream oxygen sensor . Special tooling required

Mot. 149522 mm socket for removal -

refitting of oxygen sensors -

1/2" square dr ive and 24 mm

hexagonal ext.

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

Tightening torquesm

upstream oxygen sen-

sor90˚

downstream oxygen

sensor45 N.m

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical

Note 6015A, 88A, Wiring).

Note:

This procedure is for removal - refitting of the

upstream oxygen sensor and the downstream oxy-

gen sensor.

132373

132539