warning RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 495 of 652

17B-20

PETROL INJECTION

Petrol injection computer: Removal - Refitting

D4F or D7F

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the injection computer connectors (1) .

aRemove:

-the injection computer nuts (2) ,

-the injection computer.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the injection computer,

-the injection computer nuts.

aTorque tighten the injection computer nuts (8

N.m).

aConnect the injection computer connectors.

II - FINAL OPERATION

aConnect the battery (see ) (MR 411, 80A, Battery).

aCarry out the necessary configurations and/or pro-

gramming, using the Diagnostic tool (see Fault

finding - Replacement of components) (MR 413,

17B, Petrol injection). Equipment required

Diagnostic tool

Tightening torquesm

injection computer nuts8 N.m

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical

Note 6015A, 88A, Wiring).

120779

Page 496 of 652

17B-21

PETROL INJECTION

Petrol injection computer: Removal - Refitting

K4M

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the battery (see Battery: Removal - Refit-

ting) (80A, Battery).aRemove:

-the tamperproof bolts (1) using the tool (Mot. 1844)

(2) and a drill,

-the petrol injection computer protector. Special tooling required

Mot. 1844Drill bush for removing the

tamper-proof bolts from the

injection computer protective

cover

Equipment required

drill

Diagnostic tool

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical Note

6015A, 88A, Wiring).

RIGHT-HAND DRIVE

132448

Page 506 of 652

17B-31

PETROL INJECTION

Injector rail - Injectors: Removal - Refitting

D4F, and 780 or 782

17B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the dipstick.

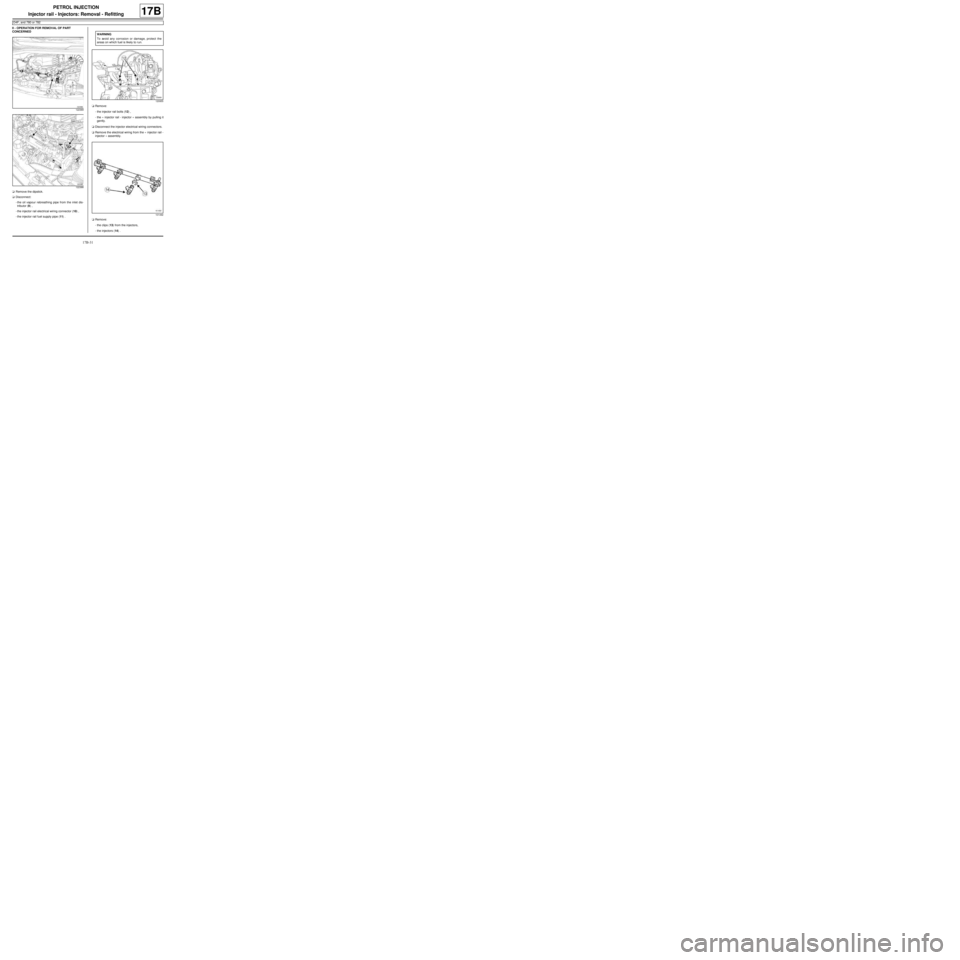

aDisconnect:

-the oil vapour rebreathing pipe from the inlet dis-

tributor (9) ,

-the injector rail electrical wiring connector (10) ,

-the injector rail fuel supply pipe (11) .aRemove:

-the injector rail bolts (12) ,

-the « injector rail - injector » assembly by pulling it

gently.

aDisconnect the injector electrical wiring connectors.

aRemove the electrical wiring from the « injector rail -

injector » assembly.

aRemove:

-the clips (13) from the injectors,

-the injectors (14) .

122389

122388

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to r un.

120955

101492

Page 508 of 652

17B-33

PETROL INJECTION

Injector rail - Injectors: Removal - Refitting

K4M

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).a

aDisconnect the fuel supply pipe (1) from the injector

rail.

aInsert the blanking plugs.

aRemove the inlet distributor (see 12A, Fuel mixture,

Inlet distributor: Removal - Refitting, page 12A-

29) . Tightening torquesm

injector rail bolts10 N.m

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

131767

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to r un.

Page 512 of 652

19A-2

COOLING

Engine cooling system: Check

19A

Expansion bottle cap valve rating:

I - CHECKING THE COOLING SYSTEM USING THE

TOOL (MOT. 1700)

a1 - Checking the expansion bottle cap valve

aUse the cooling system filling and diagnostic tool

(Mot. 1700). Consult the user's manual for this tool

(see Cooling system filling and diagnostic tool:

Use) (Technical Note 3857A, 19A, Cooling).

2 - Checking the sealing of the cooling circuit

aUse the cooling system filling and diagnostic tool

(Mot. 1700). Consult the user's manual for this tool

(see Cooling system filling and diagnostic tool:

Use) (Technical Note 3857A, 19A, Cooling).

II - CHECKING THE COOLING SYSTEM USING THE

TOOL (MS. 554-07)

a Special tooling required

Mot. 1700Fault finding and filling -

bleeding the cooling circuit.

Ms. 554-07Instr ument for testing the

cooling circuit and the expan-

sion bottle valve. Contains

caps 554-01, 554-04, 554-06

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

Note:

There are two procedures for checking the cooling

system:

-the procedure using the (Mot. 1700)

-the procedure using the (Ms. 554-07)

Expansion bottle cap with

...Valve rating

... a brown circle1.2 bar

... a yellow marking1.4 bar

... a white marking1.6 bar

... a grey marking1.8 bar

WARNING

If the coolant is leaking from the expansion bottle

cap, replace the valve.

107138

WARNING

If the coolant is leaking from the expansion bottle

cap, replace the valve.

Page 519 of 652

19A-9

COOLING

Cooling system: Draining - Refilling

D4F or D7F or K4M or K9K

19A

a

I - DRAINING

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the expansion bottle cap.aRemove the engine undertray.

aPosition the coolant recovery tray under the vehi-

cle.

aRemove the cooling radiator bottom hose clip using

the tool (Mot. 1202-01) or (Mot. 1202-02) or (Mot.

1448).

aOpen the cooling system by removing the cooling ra-

diator bottom hose using the tool (Car. 1363).

aUse a compressed air nozzle to blow air into the

system through the expansion bottle opening to re-

move as much coolant as possible.

II - CLEANING

aFill the cooling system with water through the expan-

sion bottle.

aLet the water run until the water collected by the

cooling radiator bottom hose becomes clear.

aUse a compressed air nozzle to blow air into the

circuit through the expansion bottle opening to re-

move as much water as possible.

aRefit the hose which was removed.

III - FILLING

a

1 - Filling procedure with the tool (Mot. 1700)

aFill the cooling system with engine coolant recom-

mended by the manufacturer (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) using the tool (Mot. 1700).

For the use of this tool (see Cooling system filling

and diagnostic tool: Use) (NT 3857A, 19A, Cool-

ing). Special tooling required

Mot. 1202-01Clip pliers for hose clips

(large size).

Mot. 1202-02Clip pliers for hose clips

(small size)

Mot. 1448Remote operation pliers for

hose clips .

Car. 1363Set of tr im removal levers.

Mot. 1700Fault finding and filling -

bleeding the cooling circuit.

Ms. 554-07Instr ument for testing the

cooling circuit and the expan-

sion bottle valve. Contains

caps 554-01, 554-04, 554-06

Equipment required

coolant recovery tray

compressed air nozzle

pedal press

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unex-

pectedly (risk of being cut).

To avoid any risk of serious burns when the

engine is hot:

-do not open the expansion bottle cap,

-do not dr ain the cooling system,

-do not open the bleed screw(s).

WARNING

Before the operation, protect the electrical acces-

sories to prevent any risk of short circuiting and

protect the belts to avoid damaging them.

K4M

Note:

There are two procedures for filling the cooling

system:

-the method using the (Mot. 1700) tool is recom-

mended by Renault. It saves a considerable

amount of time because it does not require the

cooling system bleed screws to be opened,

-the procedure without a special tool.

Page 520 of 652

19A-10

COOLING

Cooling system: Draining - Refilling

D4F or D7F or K4M or K9K

19A

2 - Filling method without special tools

a

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aRemove the front engine cover.

aOpen the bleed screws (1) and (2) .

aFill the cooling system with engine coolant recom-

mended by the manufacturer (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) via the expansion bottle until it

overflows.

aClose all the bleed screws as soon as the coolant

starts to flow in a continuous stream.aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aRefit the engine cover.

aPressurise the system using the (Ms. 554-07) to

check that there are no leaks (see 19A, Cooling,

Engine cooling system: Check, page 19A-2) .

aRefit the expansion bottle cap.

aClean any surfaces soiled by the coolant.

IV - BLEEDING

a

aStart the engine.

aMaintain the engine speed at 2500 rpm using the

pedal press for 5 min.

aStabilise the engine speed at 2000 rpm until the fan

assembly has been activated twice.

aMaintain the engine speed at 2500 rpm, using the

pedal press for 5 minutes.

aStabilise the engine speed at 2000 rpm until the fan

assembly is activated.

aNote the coolant level in the expansion bottle after

this first activation.

aAccelerate at a minimum of 4000 rpm for several

seconds, until the level of coolant fluid in the expan-

sion bottle drops. WARNING

It is essential to open all of the bleed screws to

remove as much as air as possible in the cooling

system. Failure to perform this procedure may

prevent the cooling system from filling properly

and may damage the engine.

D4F, and 772 – K4M

K9K

120526

D4F, and 772 – K4M

K9K

WARNING

Do not open the bleed screw whilst the engine is

running; this would damage the engine.

D4F, and 772 – D7F, and 800

D4F, and 780 or 782

Page 524 of 652

19A-14

COOLING

Cooling radiator: Removal - Refitting

K9K

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDisconnect the pressostat connector (1) .

aRemove the plastic cover (2) from the condenser.

aUnscrew the condenser connecting pipe unions (3) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

refrigerant charging station

safety strap(s)

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.AIR CONDITIONING

K9K, and 718, and AIR CONDITIONING

141214

Page 525 of 652

19A-15

COOLING

Cooling radiator: Removal - Refitting

K9K

19A

aDisconnect the pressostat connector (4) .

aRemove the plastic cover (5) from the condenser.

aUnscrew the condenser connecting pipe unions (6) .aUncouple the connecting pipes from the condenser.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aUse the (Mot. 1448) to disconnect:

-the top hose (7) on the radiator,

-the degassing hose (8) on the radiator. K9K, and 740, and AIR CONDITIONING

121174

121312

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which

are open to the air.

121431

Page 527 of 652

19A-17

COOLING

Cooling radiator: Removal - Refitting

K9K

19A

-the top hose on the radiator,

-the bottom hose on the radiator.

a

aLubricate the seals with the recommended air condi-

tioning oil to facilitate fitting.

aFit the condenser connecting pipes.

aFit the connecting pipe unions to the condenser.

aRefit the plastic cover on the condenser.

aConnect the pressostat connector.

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

aConnect the battery (see ) (80A, Battery).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .aCheck that the system is operating correctly (see Air

conditioning: Check) (62A, Air conditioning).

aFill the refrigerant circuit using a refrigerant charg-

ing station (see Refrigerant circuit: Draining -

Filling) (62A, Air conditioning).

aCheck the refrigerant circuit (see Refrigerant cir-

cuit: Check) (62A, Air conditioning). AIR CONDITIONING

WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

WARNING

To avoid any leaks, check that the seal and the

pipe surface are in good condition. The seal and

the surface must be clean and scratch free.

AIR CONDITIONING