Seat Alhambra 2015 Owner's Manual

Manufacturer: SEAT, Model Year: 2015, Model line: Alhambra, Model: Seat Alhambra 2015Pages: 305, PDF Size: 5.46 MB

Page 251 of 305

Emergencies

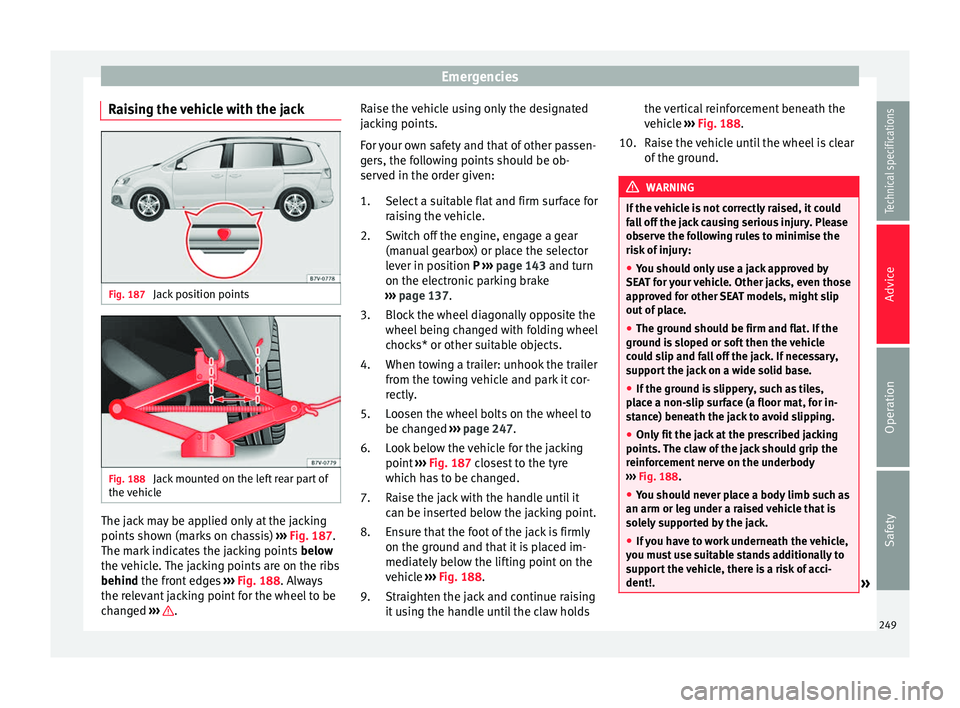

Raising the vehicle with the jack Fig. 187

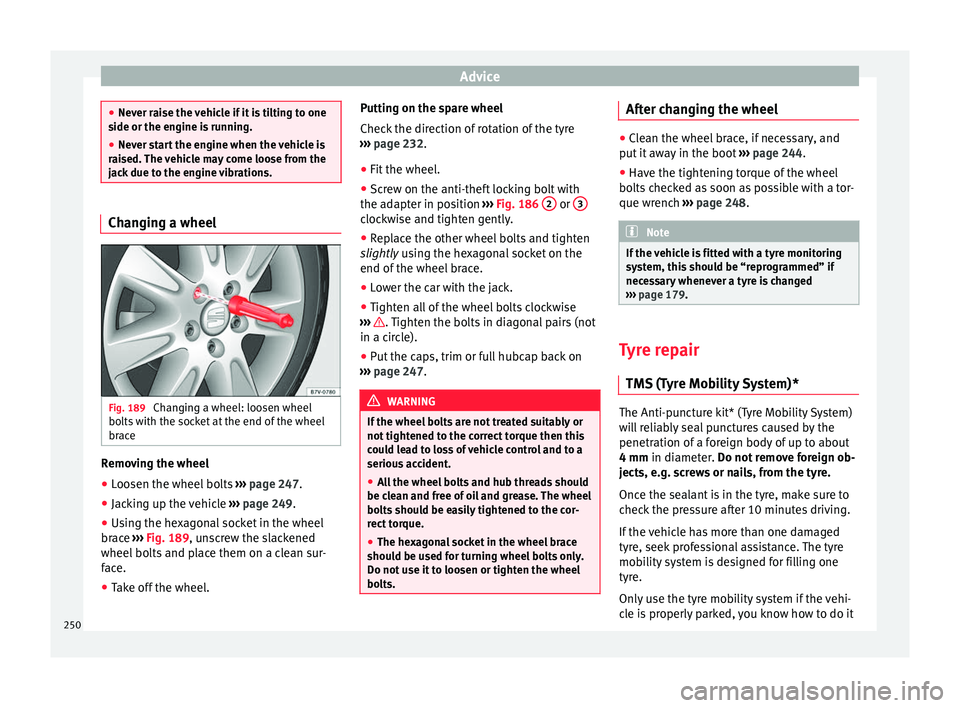

Jack position points Fig. 188

Jack mounted on the left rear part of

the vehicle The jack may be applied only at the jacking

points shown (marks on chassis)

››› Fig. 187 .

The m ark

indicates the jacking points below

the vehicle. The jacking points are on the ribs

behind

the front edges ››› Fig. 188. Always

the rel

evant jacking point for the wheel to be

changed ››› . Raise the vehicle using only the designated

jacking points.

For your own safety and that of other passen-

gers, the following points should be ob-

served in the order given:

Select a suitable flat and firm surface for

raising the vehicle.

Switch off the engine, engage a gear

(manual gearbox) or place the selector

lever in position P

›

›› p

age 143 and turn

on the electronic parking brake

››› page 137.

Block

the wheel diagonally opposite the

wheel being changed with folding wheel

chocks* or other suitable objects.

When towing a trailer: unhook the trailer

from the towing vehicle and park it cor-

rectly.

Loosen the wheel bolts on the wheel to

be changed ››› page 247.

Look below the vehicle for the jacking

point ››› Fig. 187 closest to the tyre

which h

as to be changed.

Raise the jack with the handle until it

can be inserted below the jacking point.

Ensure that the foot of the jack is firmly

on the ground and that it is placed im-

mediately below the lifting point on the

vehicle ››› Fig. 188

.

Straighten the jack and continue raising

it using the handle until the claw holds

1.

2.

3.

4.

5.

6.

7.

8.

9. the vertical reinforcement beneath the

vehicle

››› Fig. 188

.

Raise the vehicle until the wheel is clear

of the ground. WARNING

If the vehicle is not correctly raised, it could

fall off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT for your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground is sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

place a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The claw of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 188.

● You shou

ld never place a body limb such as

an arm or leg under a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you must use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!. » 10.

249

Technical specifications

Advice

Operation

Safety

Page 252 of 305

Advice

●

Never raise the vehicle if it is tilting to one

side or the engine is running.

● Never start the engine when the vehicle is

raised. The vehicle may come loose from the

jack due to the engine vibrations. Changing a wheel

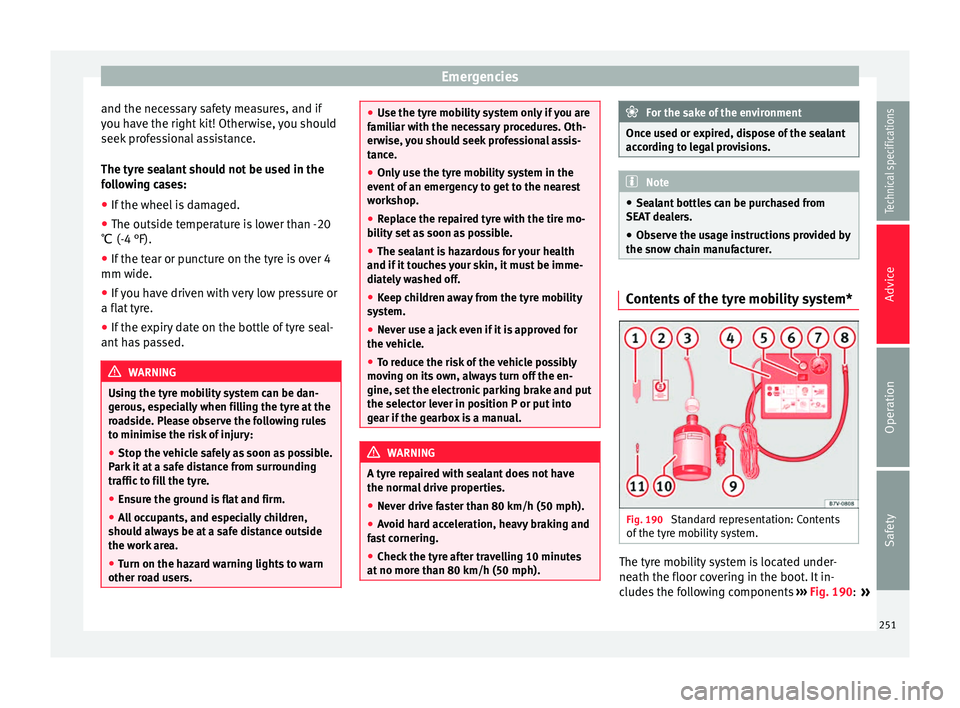

Fig. 189

Changing a wheel: loosen wheel

bolts with the socket at the end of the wheel

brace Removing the wheel

● Loosen the wheel bolts ››› page 247 .

● Jacking up the vehicle ››› page 249.

● Using the hexagonal socket in the wheel

brace ››› Fig. 189 , unscrew the slackened

wheel bo

lts and place them on a clean sur-

face.

● Take off the wheel. Putting on the spare wheel

Check the direction of rotation of the tyre

››› page 232.

● Fit the wheel

.

● Screw on the anti-theft locking bolt with

the adapter in position ››› Fig. 186 2 or

3 clockwise and tighten gently.

●

Replace the other wheel bolts and tighten

slightly using the hexagonal socket on the

end of the wheel

brace.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

››› . Tighten the bolts in diagonal pairs (not

in a circle).

● Put the caps, trim or full hubcap back on

››› page 247 . WARNING

If the wheel bolts are not treated suitably or

not tightened to the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be clean and free of oil and grease. The wheel

bolts should be easily tightened to the cor-

rect torque.

● The hexagonal socket in the wheel brace

should be used for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. After changing the wheel

●

Clean the wheel brace, if necessary, and

put it away in the boot ››› page 244.

● Have the tightening torque of the wheel

bolts checked as soon as possible with a tor-

que wrench ››› page 248. Note

If the vehicle is fitted with a tyre monitoring

system, this should be “reprogrammed” if

necessary whenever a tyre is changed

››› page 179. Tyre repair

TMS (Tyre Mobility System)* The Anti-puncture kit* (Tyre Mobility System)

will reliably seal punctures caused by the

penetration of a foreign body of up to about

4 mm

in diameter.

Do not remove foreign ob-

j

ects, e.g. screws or nails, from the tyre.

Once the sealant is in the tyre, make sure to

check the pressure after 10 minutes driving.

If the vehicle has more than one damaged

tyre, seek professional assistance. The tyre

mobility system is designed for filling one

tyre.

Only use the tyre mobility system if the vehi-

cle is properly parked, you know how to do it

250

Page 253 of 305

Emergencies

and the necessary safety measures, and if

you have the right kit! Otherwise, you should

seek professional assistance.

The tyre sealant should not be used in the

following cases:

● If the wheel is damaged.

● The outside temperature is lower than -20

℃ (-4 °F).

● If the tear or puncture on the tyre is over 4

mm wide.

● If you have driven with very low pressure or

a flat tyre.

● If the expiry date on the bottle of tyre seal-

ant has passed. WARNING

Using the tyre mobility system can be dan-

gerous, especially when filling the tyre at the

roadside. Please observe the following rules

to minimise the risk of injury:

● Stop the vehicle safely as soon as possible.

Park it at a safe distance from surrounding

traffic to fill the tyre.

● Ensure the ground is flat and firm.

● All occupants, and especially children,

should always be at a safe distance outside

the work area.

● Turn on the hazard warning lights to warn

other road users. ●

Use the tyre mobility system only if you are

familiar with the necessary procedures. Oth-

erwise, you should seek professional assis-

tance.

● Only use the tyre mobility system in the

event of an emergency to get to the nearest

workshop.

● Replace the repaired tyre with the tire mo-

bility set as soon as possible.

● The sealant is hazardous for your health

and if it touches your skin, it must be imme-

diately washed off.

● Keep children away from the tyre mobility

system.

● Never use a jack even if it is approved for

the vehicle.

● To reduce the risk of the vehicle possibly

moving on its own, always turn off the en-

gine, set the electronic parking brake and put

the selector lever in position P or put into

gear if the gearbox is a manual. WARNING

A tyre repaired with sealant does not have

the normal drive properties.

● Never drive faster than 80 km/h (50 mph).

● Avoid hard acceleration, heavy braking and

fast cornering.

● Check the tyre after travelling 10 minutes

at no more than 80 km/h (50 mph). For the sake of the environment

Once used or expired, dispose of the sealant

according to legal provisions. Note

● Sealant bottles can be purchased from

SEAT dealers.

● Observe the usage instructions provided by

the snow chain manufacturer. Contents of the tyre mobility system*

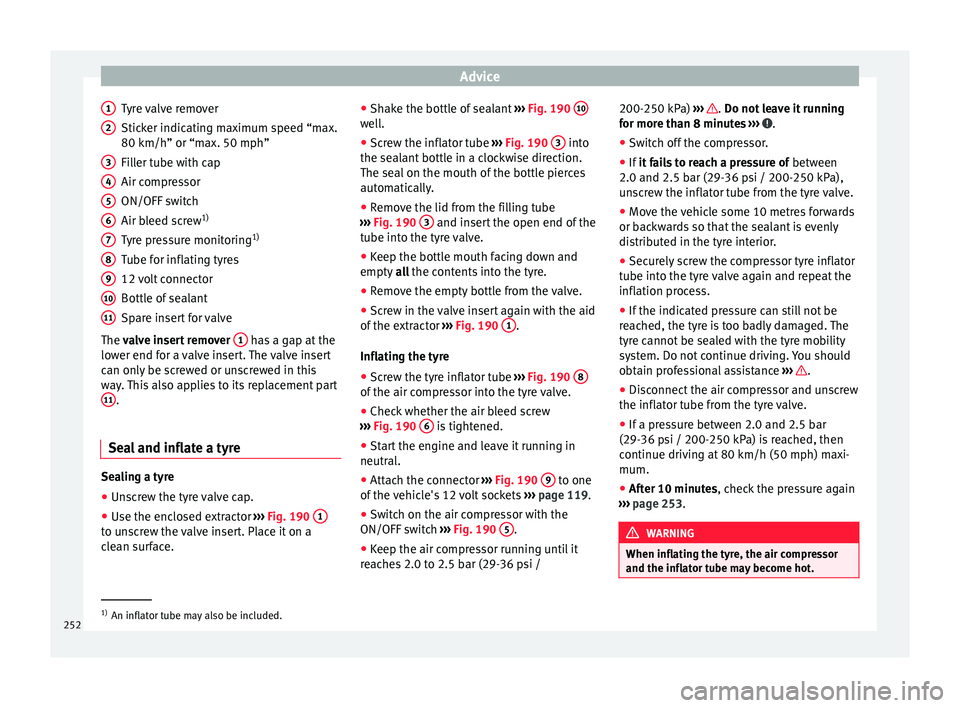

Fig. 190

Standard representation: Contents

of the tyre mobility system. The tyre mobility system is located under-

neath the floor covering in the boot. It in-

cludes the following components

››› Fig. 190 :

»

251Technical specifications

Advice

Operation

Safety

Page 254 of 305

Advice

Tyre valve remover

Sticker indicating maximum speed “max.

80 km/h” or “max. 50 mph”

Filler tube with cap

Air compressor

ON/OFF switch

Air bleed screw 1)

Tyre pressure monitoring 1)

Tube for inflating tyres

12 volt connector

Bottle of sealant

Spare insert for valve

The valve insert remover

1 has a gap at the

lower end for a valve insert. The valve insert

can only be screwed or unscrewed in this

way. This also applies to its replacement part 11 .

Seal and inflate a tyre Sealing a tyre

● Unscrew the tyre valve cap.

● Use the enclosed extractor ›››

Fig. 190 1 to unscrew the valve insert. Place it on a

clean surface.1 2

3

4

5

6

7

8

9

10

11 ●

Shake the bottle of sealant ››› Fig. 190 10 well.

●

Screw the inflator tube ››› Fig. 190 3 into

the sealant bottle in a clockwise direction.

The seal on the mouth of the bottle pierces

automatically.

● Remove the lid from the filling tube

››› Fig. 190 3 and insert the open end of the

tube into the tyre valve.

● Keep the bottle mouth facing down and

empty all the contents into the tyre.

● Remo

ve the empty bottle from the valve.

● Screw in the valve insert again with the aid

of the extractor ››› Fig. 190

1 .

Inflating the tyre

● Screw the tyre inflator tube ››› Fig. 190 8 of the air compressor into the tyre valve.

●

Check whether the air bleed screw

››› Fig. 190 6 is tightened.

● Start the engine and leave it running in

neutral.

● Attach the connector ››› Fig. 190 9 to one

of the vehicle's 12 volt sockets ››› page 119.

● Switch on the air compressor with the

ON/OFF switch ››› Fig. 190 5 .

● Keep the air compressor running until it

reaches 2.0 to 2.5 bar (29-36 psi / 200-250 kPa)

››› .

Do not leave it running

f or mor

e than 8 minutes ››› .

● Switch off the compressor.

● If it fails to reach a pressure of between

2.0 and 2.5 bar (29-36 psi / 200-250 kPa),

unscrew the inflator tube from the tyre valve.

● Move the vehicle some 10 metres forwards

or backwards so that the sealant is evenly

distributed in the tyre interior.

● Securely screw the compressor tyre inflator

tube into the tyre valve again and repeat the

inflation process.

● If the indicated pressure can still not be

reached, the tyre is too badly damaged. The

tyre cannot be sealed with the tyre mobility

system. Do not continue driving. You should

obtain professional assistance ››› .

● Disconnect the air compressor and unscrew

the inflator tube from the tyre valve.

● If a pressure between 2.0 and 2.5 bar

(29-36 psi / 200-250 kPa) is reached, then

continue driving at 80 km/h (50 mph) maxi-

mum.

● After 10 minutes , check the pressure again

› ›

› page 253. WARNING

When inflating the tyre, the air compressor

and the inflator tube may become hot. 1)

An inflator tube may also be included.

252

Page 255 of 305

Emergencies

●

Protect hands and skin from hot parts.

● Do not place the air compressor or inflator

tube onto flammable materials while they are

hot.

● Before storing the equipment, let it cool.

● If a minimum pressure of 2.0 bar

(29 psi / 200 kPa) cannot be reached, the tyre

is badly damaged. In this instance, the seal-

ant will not be able to seal the tyre. Do not

continue driving. Seek specialist assistance. CAUTION

The air compressor should be turned off after

a maximum of 8 minutes since otherwise it

will overheat. Before switching it on again, let

it cool for a few minutes. Check after 10 minutes of driving

Screw the inflator tube

››› Fig. 190 8 again

and check the tyre pressure on the gauge 7 .

Equal to or below 1.3 bar (19 psi/130 kPa):

● Stop driving! The tyre could not be suffi-

c iently

sealed with the tyre mobility system.

● You should obtain professional assistance

››› .

Equal to or above 1.4 bar (20 psi/140 kPa):

● Correct the tyre pressure until the correct

level is reached ››› page 231 . ●

Car

efully head to the nearest specialised

workshop at a maximum speed of 80 km/h

(50 mph).

● Ask the workshop to change the damaged

tyre. WARNING

Driving with a tyre that cannot be sealed is

dangerous and may lead to accidents and se-

rious injury.

● Do not continue driving if the tyre pressure

is 1.3 bar (19 psi / 130 kPa) or lower.

● Seek specialist assistance. Starting assistance

Introduction If the engine fails to start because of a dis-

charged battery, the battery of another vehi-

cle can be used to start the engine. Before

starting, check the magic eye on the battery

››› page 227 .

F or s

tarting assistance, jump lead cables con-

forming to the standard DIN 72553 are re-

quired (see the cable manufacturer instruc-

tions). The jump lead cable must be at least

25 mm 2

in section (0.038 inches 2

) for petrol

engines, and 35 mm 2

(0.054 inches 2

) for die-

sel engines. For vehicles whose battery is not in the en-

gine compartment, the jump leads should

only be connected to the starting assistance

connection points in the engine compart-

ment.

WARNING

Incorrect use of jump leads and incorrectly

jump starting could cause the battery to ex-

plode resulting in serious injury. Please ob-

serve the following rules to minimise the risk

of a battery explosion:

● The battery providing current must have

the same voltage (12V) and approximately

the same capacity (see markings on battery)

as the flat battery.

● Never charge a frozen or recently thawed

battery. A flat battery can also freeze at tem-

peratures close to 0 °C (+32 °F).

● If a battery is frozen and/or has been frozen

then it must be replaced.

● A highly explosive mixture of gases is re-

leased when the battery is being charged. Al-

ways keep lit cigarettes, flames, sparks and

fire far from the battery. Never use a mobile

telephone when connecting and removing the

jump leads.

● Charge the battery only in well ventilated

areas given that when the battery is charged

by outside assistance, it creates a mix of

highly explosive gases.

● Jump leads should never enter into contact

with moving parts in the engine compart-

ment. » 253

Technical specifications

Advice

Operation

Safety

Page 256 of 305

Advice

●

Never switch the positive and negative

poles or connect the jump leads incorrectly.

● Note the instruction manual provided by

the manufacturer of the jump leads. CAUTION

To avoid considerable damage to the vehicle

electrical system, note the following careful-

ly: ● If the jump leads are incorrectly connected,

this could result in a short circuit.

● The vehicles must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected. Positive pole on the starting

assistance points

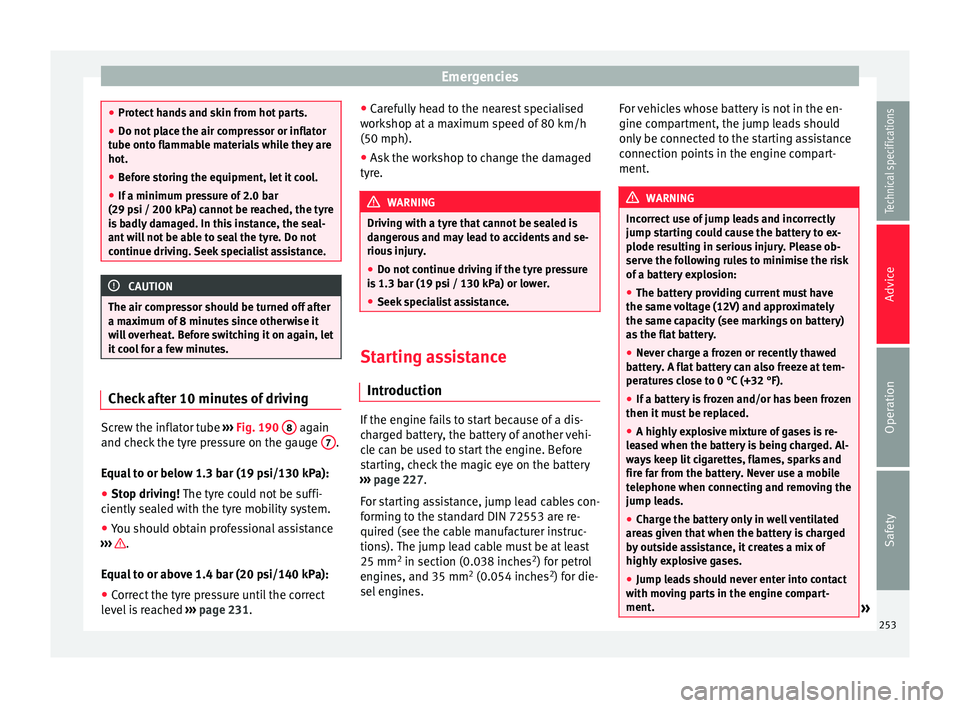

Fig. 191

In the engine compartment: positive

pole for starting assistance + On some vehicles, there is a starting assis-

tance terminal in the engine compartment,

under a labelled cover.

How to jump start: description Fig. 192

Diagram of connections for vehicles

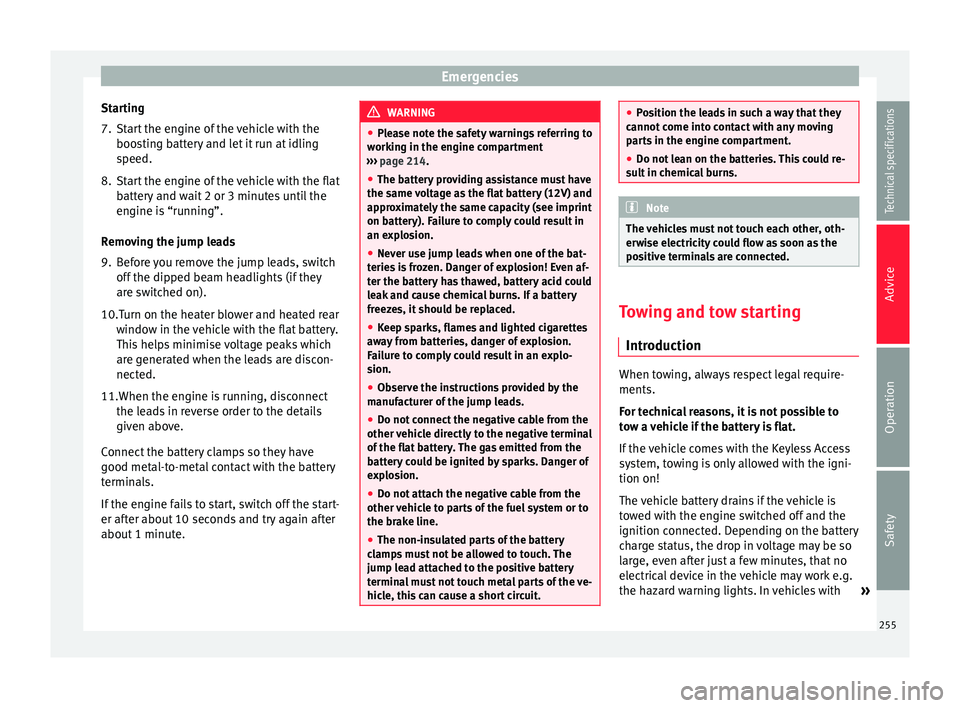

without Start-Stop system. Fig. 193

Diagram of connections for vehicles

with Start-Stop system. Jump lead terminal connections

1. Switch off the ignition of both vehicles

››› .

2. Connect one end of the red jump lead to

the po s

itive + terminal of the vehicle

with the flat battery A

››› Fig. 192 .

3. C

onnect the other end of the red

jump

lead to the positive terminal + in the ve-

hicle providing assistance B .

4. For vehicles without Start-Stop system:

connect one end of the black jump lead to

the negative terminal – of the vehicle

providing the current B

››› Fig. 192 .

– For

vehicles with Start-Stop system: con-

nect one end of the black jump lead X to a

suitable ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 193 .

5. C

onnect the other end of the black jump

lead X to a solid metal component bolted

to the engine block or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot come into contact with any moving

parts in the engine compartment.

254

Page 257 of 305

Emergencies

Starting

7. Start the engine of the vehicle with the boosting battery and let it run at idling

speed.

8. Start the engine of the vehicle with the flat battery and wait 2 or 3 minutes until the

engine is “running”.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped beam headlights (if they

are switched on).

10. Turn on the heater blower and heated rear

w indo

w in the vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11.When the engine is running, disconnect the leads in reverse order to the details

given above.

Connect the battery clamps so they have

good metal-to-metal contact with the battery

terminals.

If the engine fails to start, switch off the start-

er after about 10 seconds and try again after

about 1 minute. WARNING

● Please note the safety warnings referring to

working in the engine compartment

››› page 214.

● The b att

ery providing assistance must have

the same voltage as the flat battery (12V) and

approximately the same capacity (see imprint

on battery). Failure to comply could result in

an explosion.

● Never use jump leads when one of the bat-

teries is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

away from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufacturer of the jump leads.

● Do not connect the negative cable from the

other vehicle directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehicle to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamps must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit. ●

Position the leads in such a way that they

cannot come into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult in chemical burns. Note

The vehicles must not touch each other, oth-

erwise electricity could flow as soon as the

positive terminals are connected. Towing and tow starting

Introduction When towing, always respect legal require-

ments.

For technical reasons, it is not possible to

tow a vehicle if the battery is flat.

If the vehicle comes with the Keyless Access

system, towing is only allowed with the igni-

tion on!

The vehicle battery drains if the vehicle is

towed with the engine switched off and the

ignition connected. Depending on the battery

charge status, the drop in voltage may be so

large, even after just a few minutes, that no

electrical device in the vehicle may work e.g.

the hazard warning lights. In vehicles with

»

255

Technical specifications

Advice

Operation

Safety

Page 258 of 305

Advice

the Keyless Access system, the steering

wheel could lock ››› .

WARNING

A vehicle with a flat battery should never be

towed.

● Never remove the key from the ignition

lock. Otherwise, the steering wheel lock

could suddenly lock. The vehicle would not

be controlled and a serious accident could

ensue. WARNING

When towing the vehicle, the handling and

braking efficiency change considerably.

Please observe the following instructions to

minimise the risk of serious accidents and in-

jury:

● As the driver of the vehicle being towed:

– The brake must be depressed must hard-

er as the brake servo does not operate.

Always remain aware to avoid collision

with the towing vehicle.

– More strength is required at the steering

wheel as the power steering does not op-

erate when the engine is switched off.

● As the driver of the towing vehicle:

– Accelerate gently and carefully.

– Avoid sudden braking and manoeuvres.

– Brake well in advance than usual and

brake gently. CAUTION

● Carefully fit and remove the towline anchor-

age and its cover to avoid damage to the ve-

hicle (e.g. paintwork).

● When towing, fuel could enter the catalytic

converter and cause damage! Instructions for tow starting

In general, the vehicle should not be started

by towing. Jump-starting is much more pref-

erable

› › ›

page 253.

For technical reasons, the following vehicles

can

not be tow started:

● Vehicles with an automatic gearbox.

● Vehicles with the Keyless Access locking

and ignition system, since the electronic

steering lock may not unlock.

● Vehicles with an electronic parking brake,

given that it is possible that the brake will

not be disengaged.

● If the vehicle battery is flat, it is possible

that the engine control units do not operate

correctly.

However, if your vehicle must absolutely be

tow-started (manual gearbox):

● Put it into second or third gear.

● Keep the clutch pressed down. ●

Switch on the ignition and the hazard warn-

ing lights.

● Release the clutch when both vehicles are

moving.

● As soon as the engine starts, press the

clutch and move the gear lever into neutral.

This helps to prevent a collision with the tow-

ing vehicle. CAUTION

When tow-starting, fuel could enter the cata-

lytic converter and damage it. Towing instructions

Tow rope or tow bar

When towing, the tow bar is the safest and

vehicle friendly way. You should only use a

tow rope if you do not have a tow bar.

A tow rope should be slightly elastic to avoid

damage to both vehicles. It is advisable to

use a tow rope made of synthetic fibre or sim-

ilarly elastic material.

Only secure the tow rope or tow bar to the

towline anchorage or specially designed fit-

ting.

Vehicles with a

factory fitted towing device ,

can only

be used for towing with a tow bar,

s

pecially designed to fit on a tow hitch ball

››› page 179.

256

Page 259 of 305

Emergencies

Towing vehicles with an automatic gearbox

Note the following for a towed vehicle:

● Make sure the gear selector lever is in the N

position.

● Do not drive faster than 50 km/h (30 mph).

● Do not tow further than 50 km (30 miles).

● If a breakdown truck is used, the vehicle

must be towed with the front wheels raised.

Note the following instructions for towing

four all-wheel drive vehicles.

Instructions for towing all-wheel drive

vehicles

All-wheel drive vehicles can be towed using a

toolbar or tow rope. If the vehicle is towed

with the front or rear axle raised, the engine

must be turned off to avoid transmission

damage.

For vehicles with a double clutched DSG ®

(di-

rect shift gearbox) the instructions for towing

vehicles with an automatic gearbox apply

››› page 257 .

Sit uation

s in which the vehicle should not be

towed

In the following cases, the vehicle should not

be towed but transported on a trailer or spe-

cial vehicle:

● If the vehicle gearbox does not contain lu-

bricant due to a fault. ●

If the vehicle battery is flat and, as a result,

the electronic steering lock and electronic

parking brake cannot be disengaged if ap-

plied.

● If the vehicle to be towed has an automatic

gearbox and the distance to be covered is

greater than 50 km (30 miles). Note

● The vehicle can only be towed if the elec-

tronic parking brake and steering lock are de-

activated. If the vehicle has no power supply

or there is an electric system fault, the en-

gine must be started using jump leads to de-

activate the electronic parking brake and

electronic steering lock.

● Vehicles with the Keyless Access locking

and ignition system should only be towed

with the ignition connected since, otherwise,

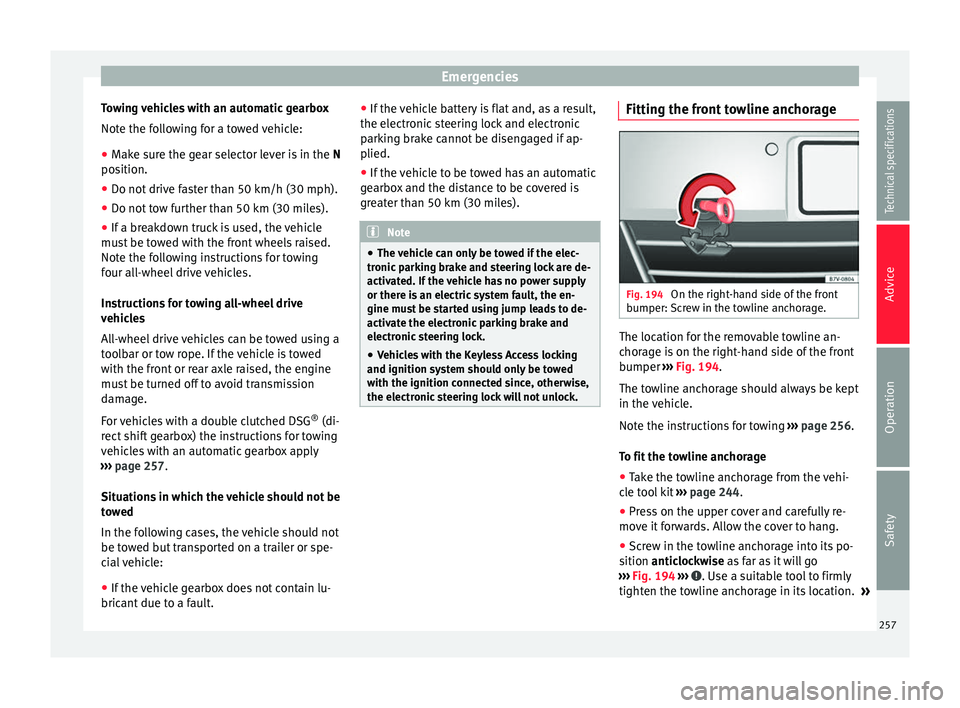

the electronic steering lock will not unlock. Fitting the front towline anchorage

Fig. 194

On the right-hand side of the front

bumper: Screw in the towline anchorage. The location for the removable towline an-

chorage is on the right-hand side of the front

bumper

››› Fig. 194 .

The t o

wline anchorage should always be kept

in the vehicle.

Note the instructions for towing ››› page 256.

To fit the towline anchorage

● Take the towline anchorage from the vehi-

cle tool kit ››› page 244.

● Pre

ss on the upper cover and carefully re-

move it forwards. Allow the cover to hang.

● Screw in the towline anchorage into its po-

sition anticlockwise as far as it will go

›

›› Fig. 194 ››› . Use a suitable tool to firmly

tighten the towline anchorage in its location. »

257

Technical specifications

Advice

Operation

Safety

Page 260 of 305

Advice

● After towing, remove the towline anchorage

by turning it clockwise and put the cover

b ac

k in place. CAUTION

The towline anchorage must always be com-

pletely and firmly tightened. Otherwise, it

could be released while towing and tow-start-

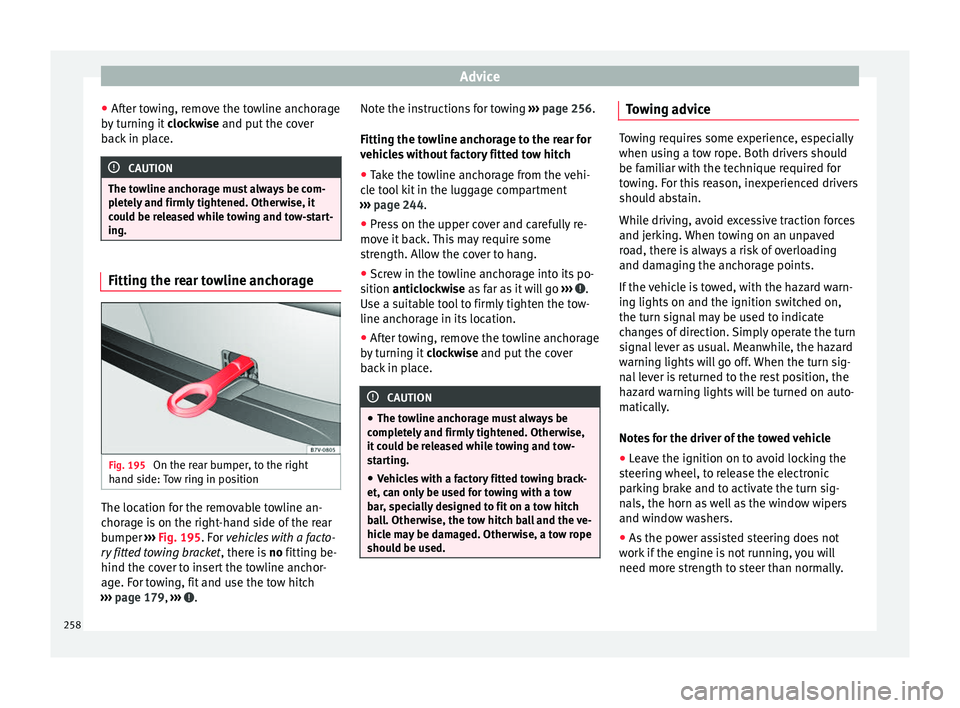

ing. Fitting the rear towline anchorage

Fig. 195

On the rear bumper, to the right

hand side: Tow ring in position The location for the removable towline an-

chorage is on the right-hand side of the rear

bumper

››› Fig. 195 . For

vehicles with a facto-

ry

fitted towing bracket , there is no fitting be-

hind the cover to insert the towline anchor-

age. For towing, fit and use the tow hitch

››› page 179, ››› . Note the instructions for towing

››› page 256.

Fitting the towline anchorage to the rear for

vehicles without factory fitted tow hitch ● Take the towline anchorage from the vehi-

cle tool kit in the luggage compartment

››› page 244 .

● Pr e

ss on the upper cover and carefully re-

move it back. This may require some

strength. Allow the cover to hang.

● Screw in the towline anchorage into its po-

sition anticlockwise as far as it will go ›

›› .

Use a suitable tool to firmly tighten the tow-

line anchorage in its location.

● After towing, remove the towline anchorage

by turning it clockwise and put the cover

b ac

k in place. CAUTION

● The towline anchorage must always be

completely and firmly tightened. Otherwise,

it could be released while towing and tow-

starting.

● Vehicles with a factory fitted towing brack-

et, can only be used for towing with a tow

bar, specially designed to fit on a tow hitch

ball. Otherwise, the tow hitch ball and the ve-

hicle may be damaged. Otherwise, a tow rope

should be used. Towing advice

Towing requires some experience, especially

when using a tow rope. Both drivers should

be familiar with the technique required for

towing. For this reason, inexperienced drivers

should abstain.

While driving, avoid excessive traction forces

and jerking. When towing on an unpaved

road, there is always a risk of overloading

and damaging the anchorage points.

If the vehicle is towed, with the hazard warn-

ing lights on and the ignition switched on,

the turn signal may be used to indicate

changes of direction. Simply operate the turn

signal lever as usual. Meanwhile, the hazard

warning lights will go off. When the turn sig-

nal lever is returned to the rest position, the

hazard warning lights will be turned on auto-

matically.

Notes for the driver of the towed vehicle

●

Leave the ignition on to avoid locking the

steering wheel, to release the electronic

parking brake and to activate the turn sig-

nals, the horn as well as the window wipers

and window washers.

● As the power assisted steering does not

work if the engine is not running, you will

need more strength to steer than normally.

258