Seat Alhambra 2015 Owner's Manual

Manufacturer: SEAT, Model Year: 2015, Model line: Alhambra, Model: Seat Alhambra 2015Pages: 305, PDF Size: 5.46 MB

Page 241 of 305

Wheels and tyresTyre code (example)Meaning

P215 / 55 R 16Size:

PPassenger vehicle code.

215Nominal width between walls, in mm.

55Height/width ratio in %

RTyre type (R indicates "radial").

16Rim diameter in inches

91 VLoad index

››› page 240 and speed rating ››› page 240.

XLReinforced tyres (“Reinforced”).

M+S or M/SWinter tyres (mud and snow tyres) ››› page 241.

SSR or DSST, Eufonia, RFT, ROF, RSC, ZP,

Conti-SealSpecific manufacturer codes for run-flat tyres.

RADIAL TUBELESSRadial tyre without inner tube.

E4 ...E-mark certifying tyre complies with international legislation followed by a number denoting the country granting the

authorisation. The authorisation number ( several digits) is shown below.

DOT BT RA TY5 1709Tyre identification number (TIN a)

, may be only on interior wall of wheel) and date of manufacture:

DOTThe tyre complies with the legal requirements of the US Department of Transport, responsible for tyre

safety regulations.

BTPlace of manufacture code.

RAInformation about manufacturer and tyre size.

TY5Manufacturer's tyre specifications.

1709Date of manufacture: Week 17 of 2009.

TWIThis identifies the position of the Tread Wear Indicator ››› page 236.» 239

Technical specifications

Advice

Operation

Safety

Page 242 of 305

AdviceTyre code (example)Meaning

MAX LOAD 615 KG (1356 LBS)US load rating, indicating maximum permitted load per tyre.

MAX INFLATION 350 KPA (51 PSI)US limit, indicating maximum permitted tyre pressure.

SIDEWALL 1 PLY RAYONInformation about tyre wall components:

1 layer of rayon (artificial silk).

TREAD 4 PLIES

1 RAYON + 2 STEEL + 1 NYLONInformation about tread components:

In the example, there are 4 layers below the tread: 1 layer of rayon (artificial silk), 2 layers of steel reinforcement and 1

layer of nylon.

Information for the end consumer concerning the comparative values of the established base tyres (standardised test procedures)

:

TREADWEAR 280Relative service life of the tyre, with respect to specific US standard test.

TRACTION AABraking capacity of tyre on wet surface (AA, A, B or C).

TEMPERATURE ATyre temperature resistance at higher test speeds (A, B or C).

If there are different letters, they are specific codes of the tyre manufacturer or specific national codes.

a)

The letters TIN refer to the tyre serial number.

Tyres with directional tread pattern

Tyres with directional tread pattern have

been designed to operate best when rotating

in only one direction. An arrow on the tyre

sidewall indicates the direction of rotation on

tyres with directional tread. Always observe

the direction of rotation indicated when

mounting the wheel. This guarantees opti-

mum grip and helps to avoid aquaplaning,

grip, noise and wear. Tyre load rating

The load rating code indicates the maximum

load in kilogrammes each wheel can carry

(load capacity).

615 kg (1,356 pounds)

650 kg (1,433 pounds)

690 kg (1,521 pounds)

730 kg (1,609 pounds)

775 kg (1,709 pounds)

91

93

95

97

99 Speed rating

The speed rating indicates the maximum

speed permitted for the tyres.

max. 150 km/h (93 mph)

max. 160 km/h (99 mph)

max. 170 km/h (106 mph)

max. 180 km/h (112 mph)

max. 190 km/h (118 mph)

max. 200 km/h (124 mph)

max. 210 km/h (130 mph)

max. 240 km/h (149 mph)

P

Q

R

S

T

U

H

V

240

Page 243 of 305

Wheels and tyres

max. 240 km/h (149 mph)

max. 270 km/h (168 mph)

max. 300 km/h (186 mph)

Some manufacturers use the letters “ZR” for

tyres with a maximum authorised speed

above 240 km/h (149 mph).

Winter service

Winter tyres* In winter conditions winter tyres will consid-

erably improve the vehicle's handling. The

design of summer tyres (width, rubber com-

pound, tread pattern) gives less grip on ice

and snow. Winter tyres also improve the vehi-

cle braking performance, reducing the brak-

ing distance in winter weather. SEAT recom-

mend that winter tyres be fitted to the vehicle

at temperatures below +7 °C (+45 °F).

The performance of winter tyres is much re-

duced if the

tyre tread is worn below 4 mm

(1/16 inc h).

The age of the tyre is another

factor affecting performance, regardless of

the depth of the tyre tread.

Please observe the following when using

winter tyres:

● Observe legal requirements in each coun-

try. Z

W

Y ●

Winter tyres must be fitted on all four

wheels.

● Only use winter tyres in wintery weather

conditions.

● Only use winter tyres of the size authorised

for the vehicle.

● Only use radial winter tyres of the same

type, size (rolling circumference) and tread

pattern.

● Adjust speeds to within the limits indicated

(code letter on tyre) ››› .

Speed limit

A code letter indicating the speed limit is

stamped on all winter tyres ››› page 240.

In some vehicles, it is possible to set a speed

warning in the MFA (multifunction display)

menu on the instrument panel ››› page 47.

If you use V-rated tyres the speed limits and

ty r

e pressure will be determined by engine

size. Please ask your technical service centre

for further information on the maximum per-

mitted speed and the required pressures for

the tyres.

All-wheel drive*

Thanks to its all-wheel drive, your car will

have plenty of traction in winter conditions,

even with the standard tyres. Nevertheless,

SEAT still recommend that winter tyres or all-

season tyres should be fitted on all fourwheels when winter road conditions are ex-

pected, mainly because this will give a better

braking response

.

Please observe all instructions and warnings

when using

snow chains ››› page 242. WARNING

Although winter tyres help to make driving

safer in the winter, you should not take un-

necessary risks.

● Adjust your speed and driving style to visi-

bility, road, traffic and weather conditions.

● Never exceed the maximum permitted

speed or loads specified for the type of winter

tyre fitted on your vehicle. For the sake of the environment

When winter is over, change back to summer

tyres. In temperatures above +7 °C (+45 °F),

performance will be improved if summer tyres

are used. Fuel consumption, wear and noises

while driving will all be reduced. Note

● If the vehicle is fitted with a tyre control

system, this should be “reprogrammed”

whenever a tyre is changed ››› page 179.

● Please ask at a technical service centre for

information about the permitted sizes for

winter tyres. 241

Technical specifications

Advice

Operation

Safety

Page 244 of 305

Advice

Snow chains When using snow chains, applicable local

legislation and maximum permitted speed

limits must be observed.

In winter weather, snow chains not only help

to improve grip but also improve the braking

capacity.

Snow chains must only be mounted

on the

front wheels , even on all-wheel drive vehi-

cles, and only with the tyre and rim combina-

tions listed below:Tyre sizeWheel rim

205/60 R166 1/2 J x 16 ET 33 SEAT recommends you ask a technical serv-

ice for further information on wheel, tyre and

chain sizes.

Wherever possible use fine-link chains meas-

uring less than 15 mm (37/64 inch) includ-

ing the lock.

Remove wheel hub covers and trim rings be-

fore fitting snow chains

››› . The wheel bolts

should be covered with caps for safety rea-

sons. These are available from technical serv-

ices. WARNING

The use of unsuitable or incorrectly fitted

chains could lead to serious accidents and

damage.

● Always the appropriate snow chains.

● Observe the fitting instructions provided by

the snow chain manufacturer.

● Never exceed the maximum permitted

speeds when driving with snow chains. CAUTION

● Remove the snow chains to drive on roads

without snow. Otherwise they will impair

handling, damage the tyres and wear out very

quickly.

● Wheel rims may be damaged or scratched if

the chains come into direct contact with

them. SEAT recommends the use of covered

snow chains. Note

Snow chains are available in different sizes

according to the vehicle type. Emergencies

In case of emergency First aid kit, warning triangle,

reflective vests and fire

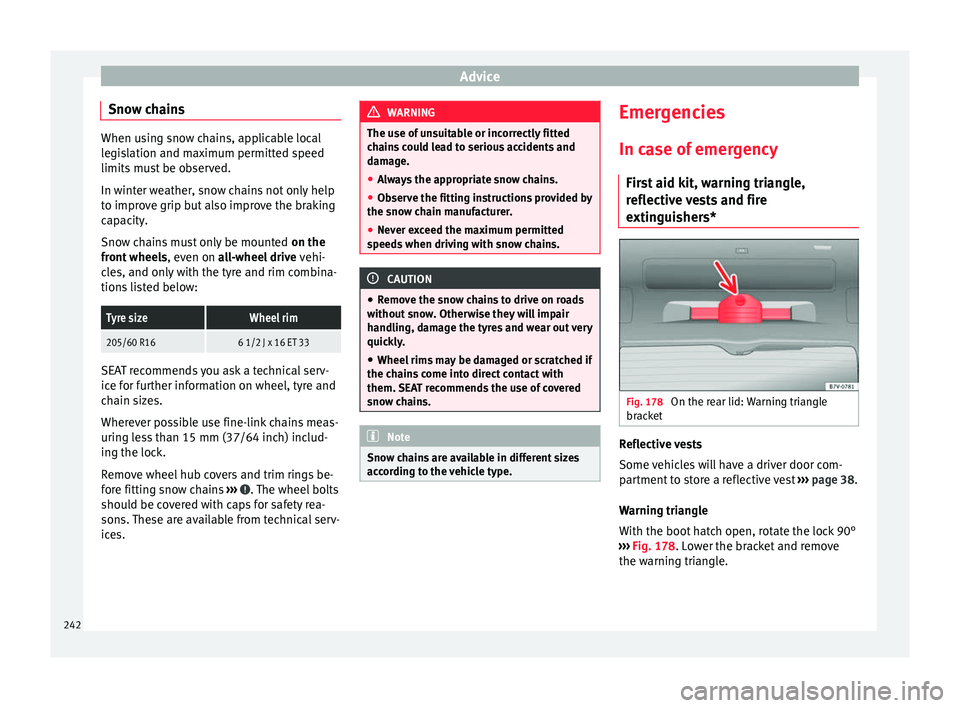

extinguishers* Fig. 178

On the rear lid: Warning triangle

bracket Reflective vests

Some vehicles will have a driver door com-

partment to store a reflective vest

››› page 38 .

W arnin

g triangle

With the boot hatch open, rotate the lock 90°

››› Fig. 178. Lower the bracket and remove

the warnin

g triangle.

242

Page 245 of 305

Emergencies

First-aid kit

There is a first aid kit ››› page 112 in the rear

left-hand side storage compartment of the

luggage compartment.

The first aid kit must comply with legal re-

quirements. Check the expiry date of the con-

tents of the first aid kit.

Fire extinguisher

There is a Fire extinguisher underneath the

fr ont

passenger seat.

The fire extinguisher must conform to legal

requirements, be ready for use and be

checked regularly. Check the certification

seal on the extinguisher. WARNING

Loose objects in the vehicle interior can be vi-

olently thrown in case of a sudden manoeu-

vre or braking and especially in accidents

causing serious injury.

● Secure fire extinguishers, first aid kit, re-

flective vests and warning triangle securely

to their respective supports. Protecting yourself and securing the

vehicle

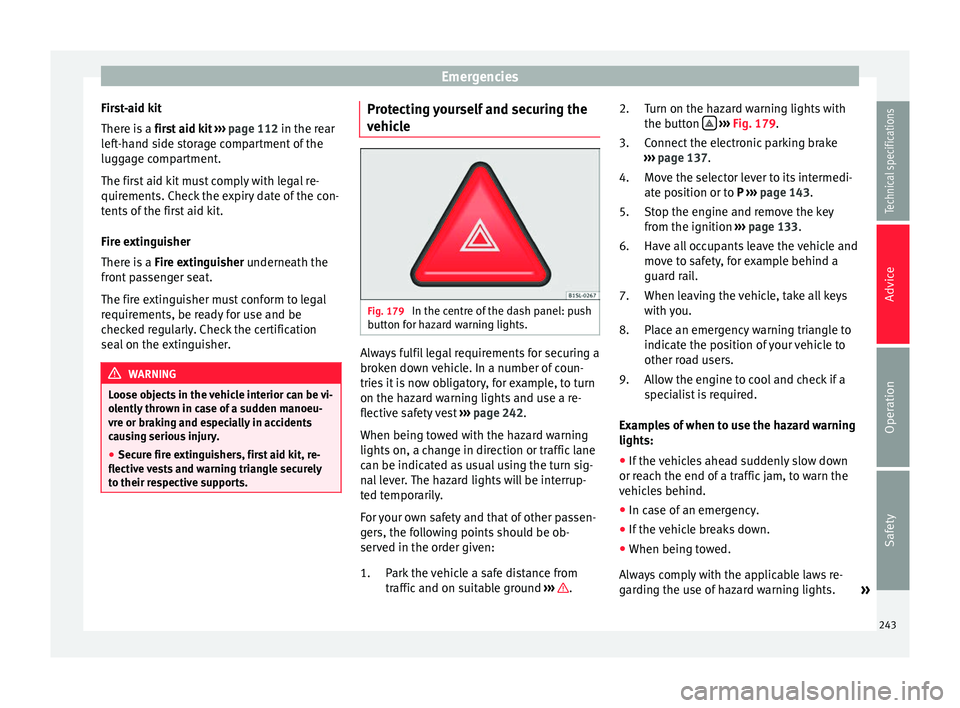

Fig. 179

In the centre of the dash panel: push

button for hazard warning lights. Always fulfil legal requirements for securing a

broken down vehicle. In a number of coun-

tries it is now obligatory, for example, to turn

on the hazard warning lights and use a re-

flective safety vest

››› page 242.

When being towed with the hazard warning

lights on, a change in direction or traffic lane

can be indicated as usual using the turn sig-

nal lever. The hazard lights will be interrup-

ted temporarily.

For your own safety and that of other passen-

gers, the following points should be ob-

served in the order given:

Park the vehicle a safe distance from

traffic and on suitable ground ››› .

1. Turn on the hazard warning lights with

the button

››› Fig. 179.

Connect the electronic parking brake

››› page 137 .

Mo v

e the selector lever to its intermedi-

ate position or to

P ››› page 143.

Stop the engine and remove the key

from the ignition ››› page 133.

Have all occupants leave the vehicle and

move to safety, for example behind a

guard rail.

When leaving the vehicle, take all keys

with you.

Place an emergency warning triangle to

indicate the position of your vehicle to

other road users.

Allow the engine to cool and check if a

specialist is required.

Examples of when to use the hazard warning

lights:

● If the vehicles ahead suddenly slow down

or reach the end of a traffic jam, to warn the

vehicles behind.

● In case of an emergency.

● If the vehicle breaks down.

● When being towed.

Always comply with the applicable laws re-

garding the use of hazard warning lights. »

2.

3.

4.

5.

6.

7.

8.

9.

243Technical specifications

Advice

Operation

Safety

Page 246 of 305

Advice

If the hazard warning lights are not working,

you must use an alternative method of draw-

ing attention to your vehicle. This method

must comply with traffic legislation. WARNING

A faulty vehicle in traffic represents a risk of

accident for the driver and for other road

users.

● Stop the vehicle safely as soon as possible.

Park the vehicle a safe distance from sur-

rounding traffic to lock all the doors in case of

an emergency. Turn on the hazard warning

lights to warn other road users.

● Never leave children or disabled people

alone in the vehicle if the doors are to be

locked. In case of an emergency, passengers

will be trapped inside the vehicle. Individuals

locked in the vehicle can be exposed to very

high or very low temperatures. WARNING

The components of the exhaust system reach

very high temperatures. This could cause a

fire and considerable damage.

● Always park your vehicle so that no part of

the exhaust system can come in contact with

flammable materials (such as dried grass or

fuel). Note

● The vehicle battery will discharge and run

down if the hazard warning lights remain on for too long (even with the ignition turned

off).

● For some vehicles, the brake lights will

blink when braking suddenly at speeds of ap-

proximately 80 km/h (50 mph) to alert vehi-

cles to the rear. If braking continues, the haz-

ard warning lights system will automatically be turned on at a speed of less than approxi-

mately 10 km/h (6 mph). The brake lights re-

main lit. Upon accelerating, the hazard warn-

ing lights will be automatically turned off. Vehicle tool kit*

Introduction When securing the vehicle in case of a break-

down, please note the legal requirements for

each country.

WARNING

Loose objects in the vehicle interior can be vi-

olently fired through the compartment in

case of a sudden manoeuvre or braking and

especially in accidents causing serious in-

jury.

● Make sure that the vehicle tools are stored

safely in the luggage compartment. WARNING

Unsuitable or damaged vehicle tools can

cause injury or accidents.

● Never work with inappropriate or damaged

tools. Location

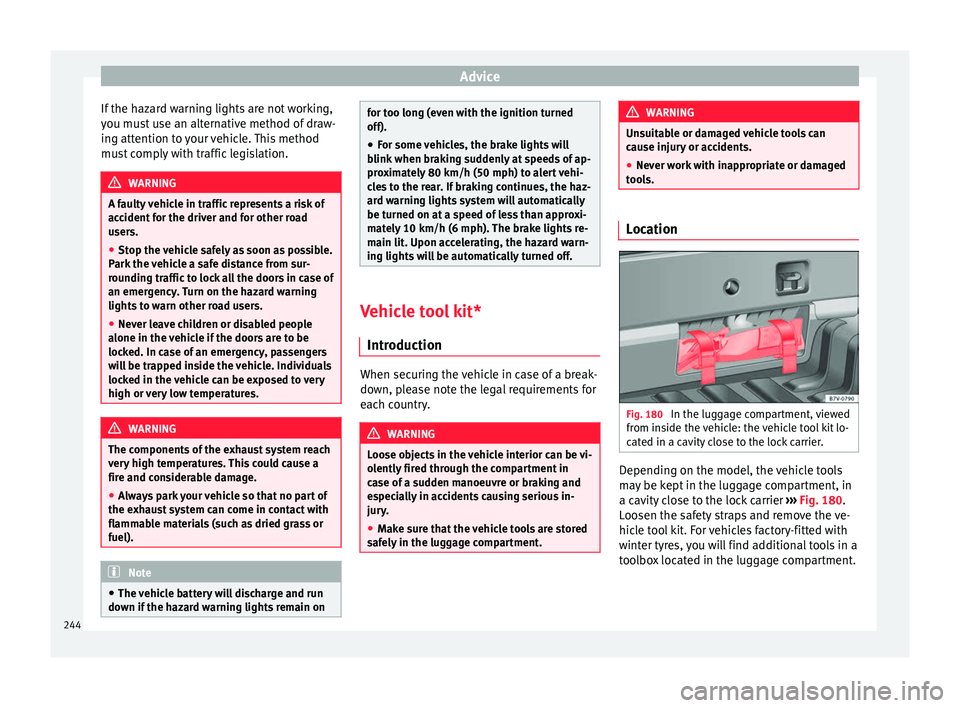

Fig. 180

In the luggage compartment, viewed

from inside the vehicle: the vehicle tool kit lo-

cated in a cavity close to the lock carrier. Depending on the model, the vehicle tools

may be kept in the luggage compartment, in

a cavity close to the lock carrier

››› Fig. 180 .

L oo

sen the safety straps and remove the ve-

hicle tool kit. For vehicles factory-fitted with

winter tyres, you will find additional tools in a

toolbox located in the luggage compartment.

244

Page 247 of 305

Emergencies

Note

After use, return the jack to its initial position

using the handle in order to securely store it

in the vehicle. Components

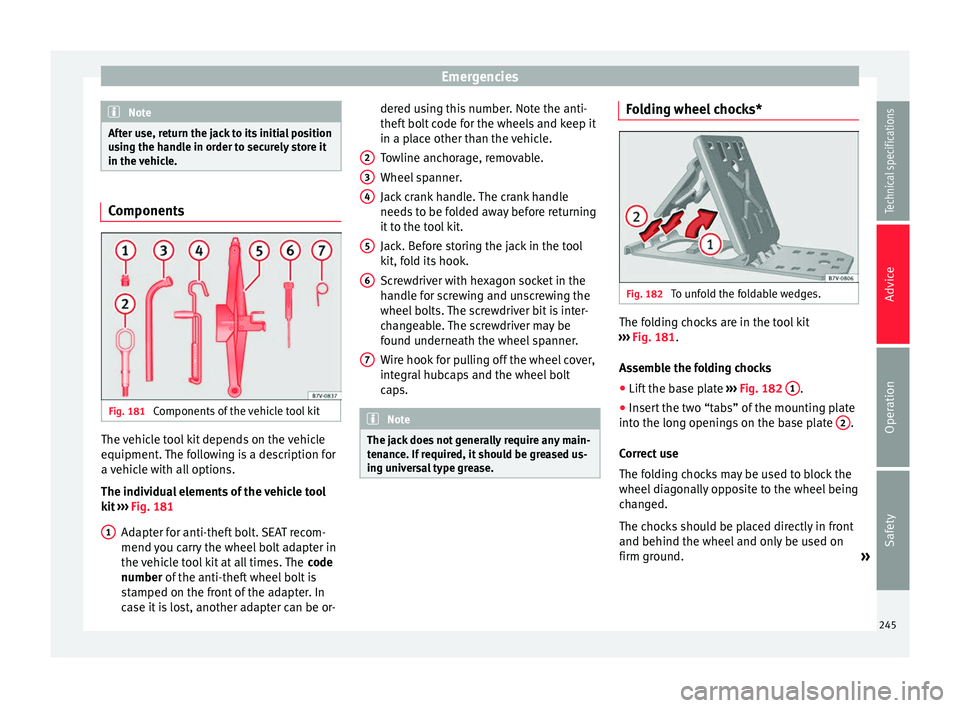

Fig. 181

Components of the vehicle tool kit The vehicle tool kit depends on the vehicle

equipment. The following is a description for

a vehicle with all options.

The individual elements of the vehicle tool

kit

›

›› Fig. 181

Ad apter for anti-theft bolt. SEAT recom-

mend you carry the wheel bolt adapter in

the vehicle tool kit at all times. The code

number

of the anti-theft wheel bolt is

stamped on the front of the adapter. In

case it is lost, another adapter can be or-

1 dered using this number. Note the anti-

theft bolt code for the wheels and keep it

in a place other than the vehicle.

Towline anchorage, removable.

Wheel spanner.

Jack crank handle. The crank handle

needs to be folded away before returning

it to the tool kit.

Jack. Before storing the jack in the tool

kit, fold its hook.

Screwdriver with hexagon socket in the

handle for screwing and unscrewing the

wheel bolts. The screwdriver bit is inter-

changeable. The screwdriver may be

found underneath the wheel spanner.

Wire hook for pulling off the wheel cover,

integral hubcaps and the wheel bolt

caps.

Note

The jack does not generally require any main-

tenance. If required, it should be greased us-

ing universal type grease. 2

3

4

5

6

7 Folding wheel chocks*

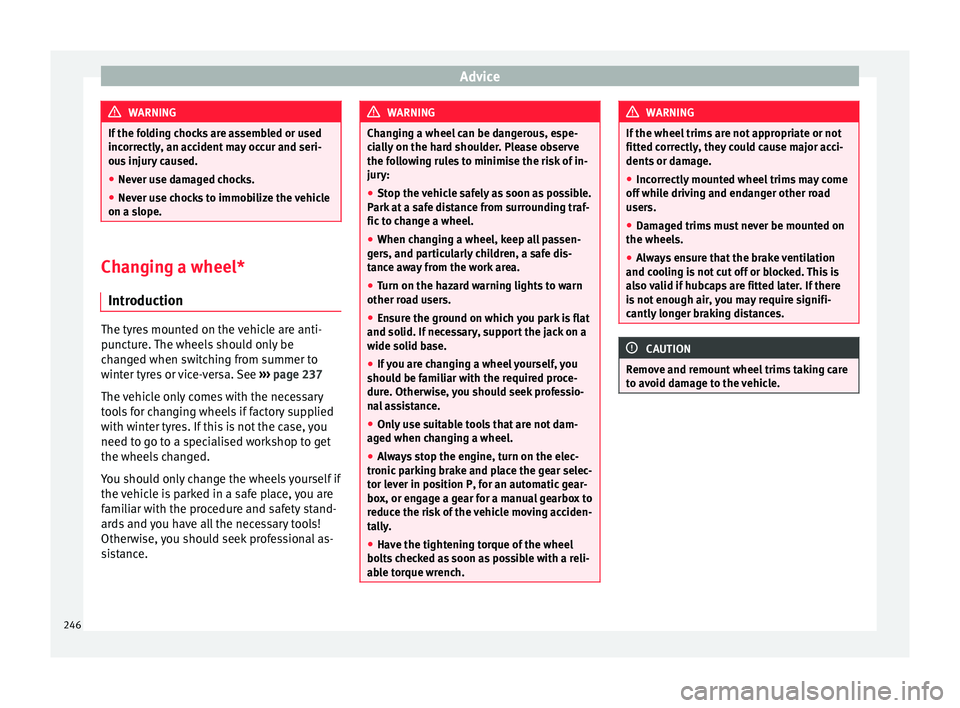

Fig. 182

To unfold the foldable wedges. The folding chocks are in the tool kit

››› Fig. 181 .

As semb

le the folding chocks

● Lift the base plate ››› Fig. 182 1 .

● Insert the two “tabs” of the mounting plate

into the long openings on the base plate 2 .

Correct use

The folding chocks may be used to block the

wheel diagonally opposite to the wheel being

changed.

The chocks should be placed directly in front

and behind the wheel and only be used on

firm ground. »

245

Technical specifications

Advice

Operation

Safety

Page 248 of 305

Advice

WARNING

If the folding chocks are assembled or used

incorrectly, an accident may occur and seri-

ous injury caused.

● Never use damaged chocks.

● Never use chocks to immobilize the vehicle

on a slope. Changing a wheel*

Introduction The tyres mounted on the vehicle are anti-

puncture. The wheels should only be

changed when switching from summer to

winter tyres or vice-versa. See

›››

page 237

The vehicle only comes with the necessary

tools for changing wheels if factory supplied

with winter tyres. If this is not the case, you

need to go to a specialised workshop to get

the wheels changed.

You should only change the wheels yourself if

the vehicle is parked in a safe place, you are

familiar with the procedure and safety stand-

ards and you have all the necessary tools!

Otherwise, you should seek professional as-

sistance. WARNING

Changing a wheel can be dangerous, espe-

cially on the hard shoulder. Please observe

the following rules to minimise the risk of in-

jury:

● Stop the vehicle safely as soon as possible.

Park at a safe distance from surrounding traf-

fic to change a wheel.

● When changing a wheel, keep all passen-

gers, and particularly children, a safe dis-

tance away from the work area.

● Turn on the hazard warning lights to warn

other road users.

● Ensure the ground on which you park is flat

and solid. If necessary, support the jack on a

wide solid base.

● If you are changing a wheel yourself, you

should be familiar with the required proce-

dure. Otherwise, you should seek professio-

nal assistance.

● Only use suitable tools that are not dam-

aged when changing a wheel.

● Always stop the engine, turn on the elec-

tronic parking brake and place the gear selec-

tor lever in position P, for an automatic gear-

box, or engage a gear for a manual gearbox to

reduce the risk of the vehicle moving acciden-

tally.

● Have the tightening torque of the wheel

bolts checked as soon as possible with a reli-

able torque wrench. WARNING

If the wheel trims are not appropriate or not

fitted correctly, they could cause major acci-

dents or damage.

● Incorrectly mounted wheel trims may come

off while driving and endanger other road

users.

● Damaged trims must never be mounted on

the wheels.

● Always ensure that the brake ventilation

and cooling is not cut off or blocked. This is

also valid if hubcaps are fitted later. If there

is not enough air, you may require signifi-

cantly longer braking distances. CAUTION

Remove and remount wheel trims taking care

to avoid damage to the vehicle. 246

Page 249 of 305

Emergencies

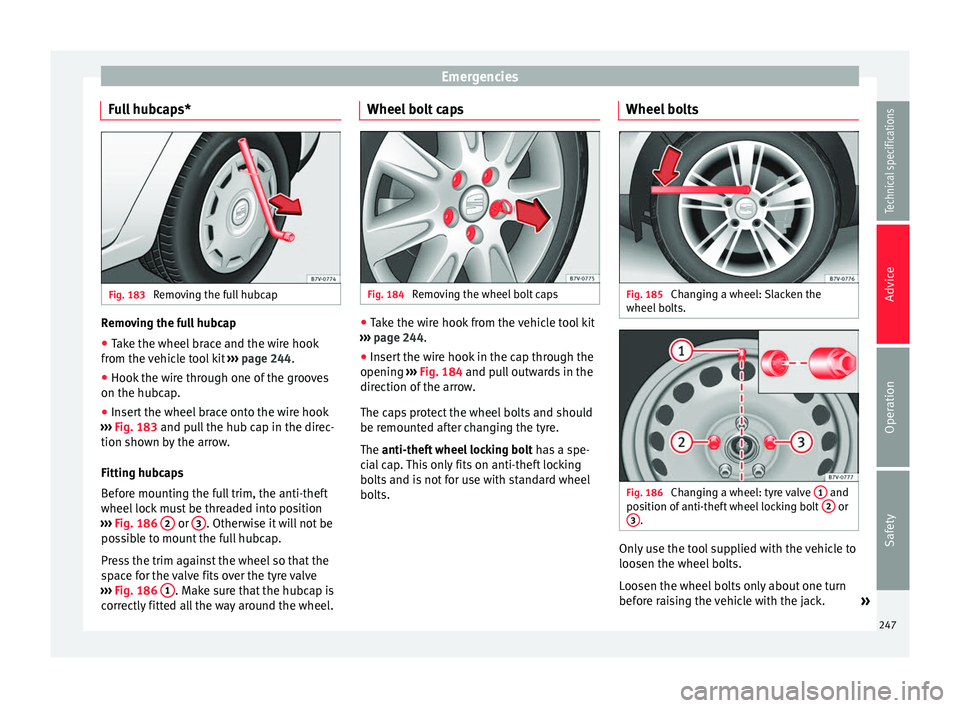

Full hubcaps* Fig. 183

Removing the full hubcap Removing the full hubcap

● Take the wheel brace and the wire hook

from the vehicle tool kit ››› page 244.

● Hook the wire through one of the grooves

on the hubcap.

● Insert the wheel brace onto the wire hook

››› Fig. 183 and pull the hub cap in the direc-

tion sho wn b

y the arrow.

Fitting hubcaps

Before mounting the full trim, the anti-theft

wheel lock must be threaded into position

››› Fig. 186 2 or

3 . Otherwise it will not be

possible to mount the full hubcap.

Press the trim against the wheel so that the

space for the valve fits over the tyre valve

››› Fig. 186 1 . Make sure that the hubcap is

correctly fitted all the way around the wheel. Wheel bolt caps

Fig. 184

Removing the wheel bolt caps ●

Take the wire hook from the vehicle tool kit

››› page 244 .

● Inser

t the wire hook in the cap through the

opening ››› Fig. 184 and pull outwards in the

direction of

the arrow.

The caps protect the wheel bolts and should

be remounted after changing the tyre.

The

anti-theft wheel locking bolt has a spe-

cial cap. This only fits on anti-theft locking

bolts and is not for use with standard wheel

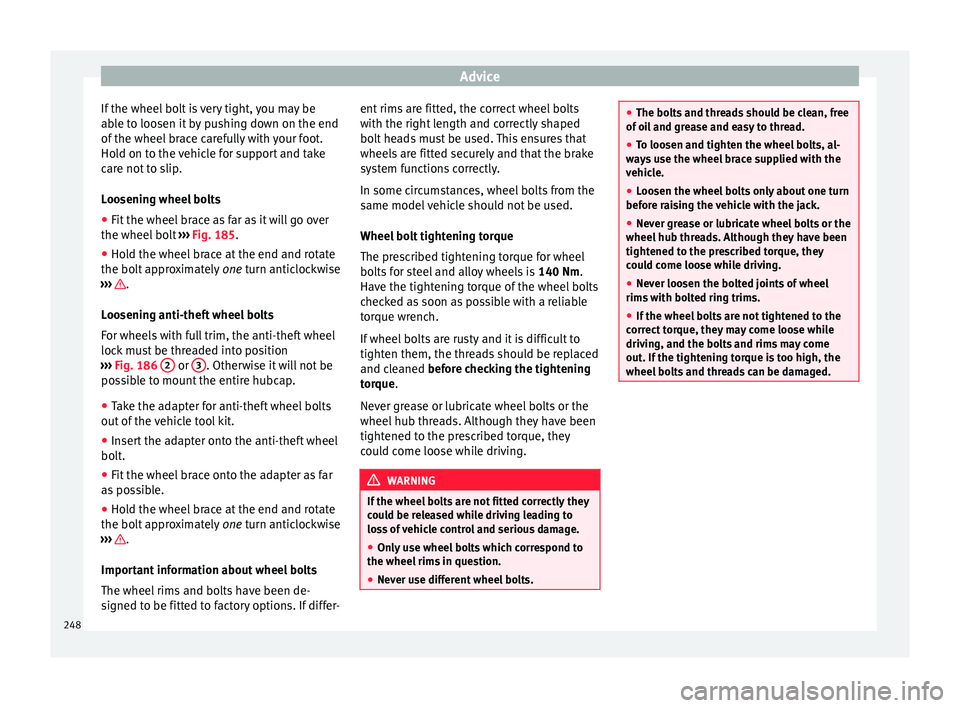

bolts. Wheel bolts

Fig. 185

Changing a wheel: Slacken the

wheel bolts. Fig. 186

Changing a wheel: tyre valve 1 and

position of anti-theft wheel locking bolt 2 or

3 .

Only use the tool supplied with the vehicle to

loosen the wheel bolts.

Loosen the wheel bolts only about one turn

before raising the vehicle with the jack.

»

247

Technical specifications

Advice

Operation

Safety

Page 250 of 305

Advice

If the wheel bolt is very tight, you may be

able to loosen it by pushing down on the end

of the wheel brace carefully with your foot.

Hold on to the vehicle for support and take

care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over

the wheel bolt ››› Fig. 185 .

● Ho l

d the wheel brace at the end and rotate

the bolt approximately one turn anticlockwise

››

› .

Loosening anti-theft wheel bolts

For wheels with full trim, the anti-theft wheel

lock must be threaded into position

››› Fig. 186 2 or

3 . Otherwise it will not be

possible to mount the entire hubcap.

● Take the adapter for anti-theft wheel bolts

out of the vehicle tool kit.

● Insert the adapter onto the anti-theft wheel

bolt.

● Fit the wheel brace onto the adapter as far

as possible.

● Hold the wheel brace at the end and rotate

the bolt approximately one turn anticlockwise

› ›

› .

Important information about wheel bolts

The wheel rims and bolts have been de-

signed to be fitted to factory options. If differ- ent rims are fitted, the correct wheel bolts

with the right length and correctly shaped

bolt heads must be used. This ensures that

wheels are fitted securely and that the brake

system functions correctly.

In some circumstances, wheel bolts from the

same model vehicle should not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is

140 Nm.

Hav e the tight

ening torque of the wheel bolts

checked as soon as possible with a reliable

torque wrench.

If wheel bolts are rusty and it is difficult to

tighten them, the threads should be replaced

and cleaned before checking the tightening

tor

que.

Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving. WARNING

If the wheel bolts are not fitted correctly they

could be released while driving leading to

loss of vehicle control and serious damage.

● Only use wheel bolts which correspond to

the wheel rims in question.

● Never use different wheel bolts. ●

The bolts and threads should be clean, free

of oil and grease and easy to thread.

● To loosen and tighten the wheel bolts, al-

ways use the wheel brace supplied with the

vehicle.

● Loosen the wheel bolts only about one turn

before raising the vehicle with the jack.

● Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving.

● Never loosen the bolted joints of wheel

rims with bolted ring trims.

● If the wheel bolts are not tightened to the

correct torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

wheel bolts and threads can be damaged. 248