ESP Seat Toledo 2012 Workshop Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Toledo, Model: Seat Toledo 2012Pages: 249, PDF Size: 3.6 MB

Page 192 of 249

191

Wheels and tyres

Follow the instructions below when driving with this wheel fitted.

● After fitting the wheel, the warning sign must not be covered.

● Do not drive faster than 80 km/h (50 mph) with a spare wheel and take

great care during the trip. Avoid heavy acceleration, hard braking and fast

cornering.

● The tyre pressure is the same as that of the standard tyres.

● Only use this spare wheel to reach the nearest Official Service, as it is

not designed for permanent use.

WARNING

● Under no circumstances must damaged spare wheels be used.

● If the spare wheel is different in size or design to the tyres currently

fitted, never drive faster than 80 km/h (50 mph). Avoid heavy accelera-

tion, hard braking and fast cornering.

CAUTION

Follow the instructions given on the temporary spare wheel label.

Note

The tyre pressure of the spare wheel must always correspond to the highest

pressure prescribed for the model of vehicle in question.

Wheel trim

Removing

– Place the hook from the vehicle tool kit on the reinforced edge

of the wheel trim. –

Insert the box spanner through the hook, supporting it on the

tyre and remove the wheel trim.

Fitting

– First press the wheel trim onto the wheel at the cut out de-

signed for the valve. Then press the wheel trim on both sides in

the direction of the valve so that it fits correctly in place around

all the perimeter.

CAUTION

● Press down by hand, do not hit the wheel trim! Knocking it sharply, par-

ticularly at points where the wheel trim has not yet been inserted, could re-

sult in damage to the wheel trim guiding and centring elements.

● Before fitting the trim on a steel alloy wheel attached with an anti-theft

wheel bolt, make sure the bolt is in the hole in the valve area ⇒ page 202,

Anti-theft wheel bolts.

● Where trim is fitted at a later date, ensure enough air inflow is guaran-

teed in order to cool the brake system.

Wheel bolt caps

Fig. 127 Pull off the

wheel bolt cap

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 194 of 249

193

Wheels and tyres

WARNING

● If the warning lamp lights up, slow down immediately and avoid

any severe braking or steering manoeuvres. Stop and check the tyres and

their pressure as soon as possible.

● Under certain conditions (e.g. sporty driving style, driving on loose

surfaces or in the winter) the warning lamp may take a while to light

up or may remain switched off.

● Despite the tyre pressure monitoring system, the driver remains re-

sponsible for maintaining the correct tyre pressure. You must therefore

check the tyre pressure often.

Note

● The tyre pressure monitoring system is not a replacement for regularly

checking the tyre pressure, as it is unable to recognise an even drop in pres-

sure.

● The tyre pressure monitoring system is unable to warn of a sudden drop

in tyre pressure, e.g. a puncture. In this case, try to stop the vehicle carefully

with no severe braking or steering manoeuvres.

● To ensure the tyre pressure monitoring system works correctly, the basic

setting must be performed every 10 000 km (6000 miles) or once a year.

Wheel bolts

The wheel bolts are matched to the rims. When installing different wheels,

e.g. to fit light alloy wheels or wheels with winter tyres, it is important to use

the correct wheel bolts with the right length and correctly shaped bolt

heads. The is essential for the secure fit of the wheels and for the proper

function of the brake system. Winter tyres

Winter tyres will significantly improve handling of the vehicle in winter road

conditions. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip at temperatures below 7 °C (45 °F), on ice and snow.

This applies particularly to vehicles equipped with

wide section tyres or

high speed tyres (code letters H or V on the sidewall).

In order to preserve the performance of the vehicle as much as possible,

winter tyres must be fitted on all four wheels, the minimum depth of the

tread must be 4 mm and the maximum age must be 4 years.

You can use winter tyres of a lower speed rating if the maximum speed limit

of these tyres will not be exceeded, even if the maximum speed limit for the

vehicle is higher.

For the sake of the environment

Summer tyres should be fitted again in time, as they give better handling on

roads free of snow and ice and at temperatures over 7 °C (45 °F). Summer

tyres have a shorter braking distance, produce less rolling noise and do not

wear down as quickly. They also reduce fuel consumption.

Snow chains

Snow chains must only be used on the front wheels.

In winter road conditions, snow chains not only help to improve grip but al-

so improve the braking capacity.

For technical reasons snow chains may only be used on tyres with the fol-

lowing wheel rim/tyre combinations.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 196 of 249

195

Accessories, modifications and spare parts

Accessories, modifications and spare parts

General notes

If you wish to retrofit accessories in the vehicle, or if a part of the vehicle

has been replaced by a new part or technical modifications are required, the

following instructions must be taken into account.

● Before purchasing accessories or spare parts and before making techni-

cal modifications, always request advice from an Authorised SEAT dealer

⇒

.

● In the event that technical modifications are carried out on the vehicle,

the instructions and regulations specified by the company, SEAT, must be

observed.

No damage will be caused to the vehicle if the established procedures are

respected, which guarantees safe driving and operation. After the modifica-

tions are carried out, the vehicle will comply with the restrictions and regu-

lations of the highway code. More information can be obtained at an Au-

thorised SEAT dealer, where all jobs required can be carried out appropriate-

ly.

Vehicle improvements and refurbishment

The owner must store the technical documents regarding the modifications

carried out on the vehicle to be handed over to those responsible for the

processing of the end-of-life vehicle. This ensures end-of-life processing of

the vehicle, while protecting the environment.

Work done on the electrical components and software can cause disruption

in operations. Due to the interconnection of electronic components, this

disruption can also negatively influence systems that are not directly affec-

ted. This can adversely affect reliability of the vehicle, and can produce ex-

cessive wear of the parts.

Damage caused by technical modifications that are not made with the con-

sent of SEAT will be excluded from the warranty – see warranty certificate.

WARNING

● Jobs or modifications unduly carried out on your vehicle can cause

disruption to operations - Risk of accident!

● We recommend that you use only expressly authorised SEAT Original

Accessories and ® SEAT Original Spare Parts for your vehicle. The relia-

bility, safety and compatibility with your vehicle of SEAT Original Acces-

sories and ® SEAT Original Spare Parts has been checked.

● Despite the continuous observation of the market, we cannot judge

nor guarantee the suitability of other products for your vehicle, be they

authorised products or products approved by a state testing facility.

Note

SEAT Original Accessories and ® SEAT Original Spare Parts can be pur-

chased at authorised SEAT dealers where the purchased parts can also be

fitted.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 197 of 249

196Accessories, modifications and spare parts

Modifications and effects of the airbag

system

In the adjustment and modification, respect the SEAT directive.

Modifications and corrections of the front bumper, doors, front seats, roof

or bodywork must be carried out at authorised SEAT workshops. Compo-

nents of the airbag system can be found in these parts of the vehicle.

WARNING

● Airbag modules must never be repaired. They must be replaced.

● Never fit components of the airbag system removed from old vehicles

or those originating from a recycling process in the vehicle.

● The modification of the suspension of the vehicle wheels, including

the use of non-permitted combinations of tyres and rims can alter the op-

eration of the airbag system and increase the risk of serious or fatal inju-

ries in an accident.

● During all jobs on the airbag system, in addition to the removal and

fitting of parts of the system in the course of other repair jobs, parts of

the airbag system can be damaged. Therefore in the event of an accident,

this may cause the airbags to activate incorrectly or not activate al all.

Page 201 of 249

200Self-help

–Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the

box spanner and then the anti-theft wheel bolt ⇒ page 200.

– Replace the hub cap and/or the bolt covers.

Note

● All bolts must be clean and turn easily.

● Never grease or oil the wheel bolts!

● Note the direction of rotation when putting on a tyre with directional

tread pattern ⇒ page 187.

After changing a wheel

Tasks that must be carried out after changing a wheel.

– Place the wheel with the defective tyre in the spare wheel well

and secure it using a special bolt ⇒ page 190.

– Put the vehicle tools back in their storage location.

– Check the tyre pressure of the newly fitted spare wheel as soon

as possible.

– Have the tightening torque of the wheel bolts checked as soon

as possible with a torque wrench.

– Have the flat tyre replaced or ask an Official Service about the

possibility of repair.

Note

● If you notice that the wheel bolts are rusty and difficult to turn when

changing a wheel, they must be replaced before having the tightening tor-

que checked.

● Drive carefully and at moderate speeds until the tightening torque of the

wheel bolts has been checked.

Loosening and tightening wheel bolts

Fig. 131 Changing a

wheel: Loosening wheel

bolts

Loosening wheel bolts

– Fit the box spanner as far as it will go over the wheel bolt 1)

.

– Grip the end of the box spanner and turn the wheel bolt about

one turn anti-clockwise ⇒ Fig. 131.

Tightening wheel bolts

– Fit the box spanner as far as it will go over the wheel bolt 1)

.

1)

The corresponding adapter is required to unscrew or tighten the anti-theft wheel bolts

⇒ page 202.

Page 211 of 249

210Fuses and bulbs

Fuses and bulbs

Fuses

Introduction

All the electrical circuits are protected by fuses.

● Switch off the ignition and the electrical component concerned before

changing a fuse.

● Identify the fuse corresponding to the failed electrical component

⇒ page 211, Fuses in the dash panel, or ⇒ page 214, Changing fuses in

the engine compartment.

● Take the plastic clip from inside the fuse cover, fit it onto the blown fuse

and pull the fuse out.

● Replace the blown fuse (which will have a melted metal strip) with a new

fuse of the same amp rating.

Fuse colour code

ColourMaximum amp rating

light brown5dark brown7,5red10blue15yellow20white25green30

WARNING

Read and follow the warnings ⇒ page 173, Engine compartment before

starting work in the engine compartment.

CAUTION

● Never “repair” a fuse or replace it by fitting a fuse with a higher amp rat-

ing. Risk of fire! This could also cause damage to other parts of the electri-

cal system.

● If a newly replaced fuse blow again when the electrical component con-

cerned is switched on, the electrical system must be checked by an Official

Service as soon as possible.

Note

● It is advisable to always keep spare fuses in the vehicle. The spare fuse

box is available in the range of original SEAT parts.

● One single electrical component could have more than one fuse.

● Several electrical components may be protected by the same fuse.

Page 216 of 249

215

Fuses and bulbs

WARNING

● Take particular care when working on components in the engine com-

partment if the engine is warm. Risk of burns.

● Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

● The high voltage element of gas discharge bulbs* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.

CAUTION

● Remove the ignition key before working on the electric system. Other-

wise, a short circuit could occur.

● Switch off the lights and the parking light before changing a bulb.

For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the prop-

er manner.

Note

● Depending on weather conditions (cold or wet), the front lights, the fog

lights, the rear lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may remain misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also in that of all other road users. ●

Before changing a bulb, make sure you have the correct new bulb.

● Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will va-

porise as a result of the heat generated by the bulb, they will be deposited

on the reflector and will impair its surface.

Double headlight bulbs

Fig. 146 Main headlight

bulbs

Installation position of double headlight bulbs side light

main beam headlight

dipped beam headlight

turn signal light

daytime driving light

A

BCDE

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 225 of 249

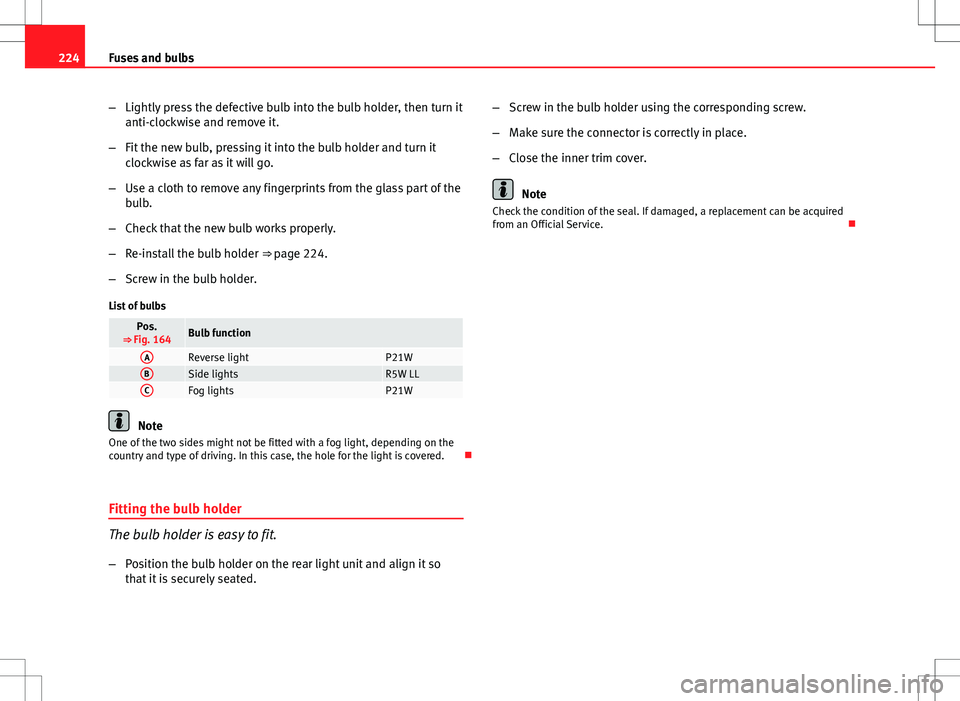

224Fuses and bulbs

–Lightly press the defective bulb into the bulb holder, then turn it

anti-clockwise and remove it.

– Fit the new bulb, pressing it into the bulb holder and turn it

clockwise as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check that the new bulb works properly.

– Re-install the bulb holder ⇒ page 224.

– Screw in the bulb holder.

List of bulbs

Pos.

⇒ Fig. 164Bulb function

AReverse lightP21WBSide lightsR5W LLCFog lightsP21W

Note

One of the two sides might not be fitted with a fog light, depending on the

country and type of driving. In this case, the hole for the light is covered.

Fitting the bulb holder

The bulb holder is easy to fit. – Position the bulb holder on the rear light unit and align it so

that it is securely seated. –

Screw in the bulb holder using the corresponding screw.

– Make sure the connector is correctly in place.

– Close the inner trim cover.

Note

Check the condition of the seal. If damaged, a replacement can be acquired

from an Official Service.

Page 228 of 249

227

Description of the data

Vehicle identification data on the data sticker

Fig. 167 Data sticker

Fig. 168 Type plate

Vehicle data sticker

The vehicle data sticker ⇒ Fig. 167 is located on the luggage compartment

floor and is also attached to the Service Plan.

The following information is provided on the vehicle data sticker:

Vehicle identification number (VIN)

Vehicle model

Identifying letters of the gearbox/number of the original paint finish/In-

terior equipment number/engine power/engine identifying letter

1

23

Partial description of the vehicle

Weight in running order

Fuel consumption (in litres per/100 km (miles)) – urban/on the motor-

way/combined

Combined CO

2 emissions (g/km (miles))

Type plate

The type plate ⇒ Fig. 168 is located at the bottom of the front driver side

door pillar between the front and rear door.

The type plate indicates the following weights:

Total permitted weight of the vehicle when loaded

Maximum authorised weight of the vehicle with a trailer, when the vehi-

cle operates as a tractor

Maximum permitted load of the front axle

Maximum permitted load of the rear axle

Weight in running order

The weight in running order only has one approximate value. This value cor-

responds to the minimum operative weight of the vehicle without additional

equipment that increases its weight, i.e. air conditioning, spare wheel, tow-

ing bracket.

The weight in running order also includes 75 kg of the weight of the driver

and the service liquids, in addition to a fuel tank at 90 % capacity.

From the difference between the total permitted weight in running order the

approximate carrying capacity can be calculated ⇒

.

The carrying capacity must include:

● occupants

● all pieces of equipment and other weights

● roof loads incl. roof rack

4

56

7

89

1011

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 230 of 249

229

Description of the data

Weights

Kerb weight refers to the basic model with a fuel tank filled to 90% capacity

and without optional extras. The figure quoted includes 75 kg to allow for

the weight of the driver.

For special versions and optional equipment fittings or for the addition of

accessories, the weight of the vehicle will increase ⇒

.

WARNING

● Please note that the centre of gravity may shift when transporting

heavy objects; this may affect the vehicle's handling and lead to an acci-

dent. Always adjust your speed and driving style to suit road conditions

and requirements.

● Never exceed the gross axle weight rating or the gross vehicle weight

rating. If the allowed axle load or the allowed total weight is exceeded,

the driving characteristics of the vehicle may change, leading to acci-

dents, injuries and damage to the vehicle.

Towing a trailer Trailer weights

Trailer weight

The trailer weights and drawbar loads approved are selected in intensive tri-

als according to precisely defined criteria. The approved trailer weights are

valid for vehicles in the EU for maximum speeds of 80 km/h (50 mph) (in

certain circumstances up to 100 km/h, 62 mph). The figures may be differ-

ent in other countries. All data in the official vehicle documentation takes

precedence over these data at all times ⇒

.Drawbar load

The maximum permitted drawbar load on the ball joint of the towing bracket

must not exceed

75 kg.

In the interest of road safety, we recommend that you always tow approach-

ing the maximum drawbar load. The response of the trailer on the road will

be poor if the drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers or tandem axle trailers with a

wheelbase of less than 1 metre), a minimum of 4% of the actual trailer

weight is legally required for the drawbar load.

WARNING

● For safety reasons, do not exceed the 80 km/h (50 mph) limit. This is

also valid in countries where higher speeds are permitted.

● Never exceed the maximum trailer weights or the drawbar load. If the

permissible axle load or the permissible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

Wheels

Tyre pressure, snow chains, wheel bolts

Tyre pressures

The sticker with the tyre pressure values can be found on the inside of the

fuel tank flap. The tyre pressure values given there are for cold tyres. Do not

reduce the slightly raised pressures of warm tyres ⇒

.

Snow chains

Snow chains may be fitted only to the front wheels.

Safety FirstOperating instructionsPractical TipsTechnical specifications